文章编号:1004-0609(2014)03-0593-07

冷却速率对AZ91D镁合金非平衡凝固组织的影响

杨 伟,陈寿辉,张守银,余 欢,严青松,蔡长春

(南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063)

摘 要:采用铜模喷铸和单辊甩带分别制备AZ91D镁合金非平衡凝固试样,利用ProCAST数值模拟软件及理论公式分别估算相应冷却速率。综合采用光学显微镜、扫描电镜、能谱分析仪、X射线衍射仪及差热分析仪对比研究冷却速率对镁合金非平衡凝固组织的影响规律。结果表明:随冷却速率提高,AZ91D合金的初生相形貌从粗大枝晶向细小等轴晶发生转变,晶粒发生明显细化,平均尺寸从铸态条件下的800 μm降低到单辊甩带条件下的5 μm以内。共晶相从连续网状向不连续弥散状分布转变,体积分数不断减小,单辊甩带条件下可制备出单相固溶体组织。快速凝固条件下合金基体中Mg和Al元素成分分布均匀,溶质偏析得到有效控制。

关键词:镁合金;非平衡凝固;晶粒细化;溶质偏析

中图分类号:TG146.2 文献标志码:A

Effect of cooling rate on non-equilibrium solidified microstructure of AZ91D magnesium alloy

YANG Wei, CHEN Shou-hui, ZHANG Shou-yin, YU Huan, YAN Qing-song, CAI Chang-chun

(National Defence Key Discipline Laboratory of Light Alloy Processing Science and Technology,

Nanchang Hangkong University, Nanchang 330063, China)

Abstract: Non-equilibrium solidified specimens of AZ91D magnesium alloy were fabricated by copper mould casting and melt-spinning techniques, separately. The corresponding cooling rates were calculated by numerical simulation ProCAST software and theoretical equation. Using optical microscopy, scanning electron microscopy, energy dispersive spectrum, X-ray diffractometry and differential thermal analyzer, the effects of the cooling rate on the non-equilibrium solidified microstructures were investigated. The results show that the morphology of primary phase changes from coarse dendrite to fine equiaxed grain with increasing cooling rate, as indicated by the significant reduction of grain size from 800 μm under as-cast condition to within 5 μm for rapid solidification. Moreover, the distribution of eutectic phase varies from continuous network to discontinuous dispersion and its volume fraction decreases gradually. Single-phase solid solution structure can be fabricated by melt-spinning method. Both the distribution of Mg and Al elements in rapid solidified alloy are homogeneous without the occurrence of solute segregation.

Key words: magnesium alloy; non-equilibrium solidification; grain refinement; solute segregation

镁合金作为最轻的金属结构材料,具有密度低、比强度高、铸造性能好、减震性和抗磁性好以及尺寸稳定等一系列综合优点,被誉为21世纪的绿色工程材料,在汽车和电子等领域具有广泛的应用前景[1-3]。然而,由于大多数镁合金属于密排六方结构,滑移系少,室温塑性能力差,加之其电负性弱,三分之二的溶质元素在镁中最大固溶度均小于1%(摩尔分数),难以通过合金化来提高材料强度[4]。目前,工程中常见的AZ系列镁合金在凝固过程中易形成网状低熔点Mg17Al12共晶相,耐热及抗高温蠕变性能较差,无法满足发动机等关键零部件的高温使用要求,严重制约了其在航空航天等国防领域的大规模应用[5]。

快速凝固作为研发高性能新结构材料的重要手段,不仅可以提高传统金属材料性能,挖掘现存材料使用潜力,而且可以找到新的强化相或消除一些有害相,得到微晶、非晶和纳米晶材料[6-10]。KAWAMARA等[11]采用单辊熔体旋铸技术制备的新型快速凝固镁合金是目前世界已报道的屈服强度高于600 MPa的最高强镁合金,其性能不但大大超过常规镁合金的性能,比强度甚至超过Ti6Al4V及7075铝合金的比强度,成为先进镁合金材料的典型代表。快速凝固镁合金已发展成为与非晶镁合金和镁基复合材料并存的超高强度镁合金代表。

针对镁合金快速凝固,人们先后开展了多方面的基础研究,并在快速凝固薄带组织、凝固特征和相结构分析方面取得了丰富的研究成果[12-15]。TENG等[12]采用真空吸铸方式实现了AZ61镁合金亚快速凝固,并对晶粒细化进行了系统研究。徐春杰等[13]采用单辊甩带结合往复挤压技术制备出纳米强化相增强高性能镁合金,深入分析了材料组织及力学性能的变化规律。周涛等[14]采用双辊急冷法,全面分析了稀土Ce对快速凝固Mg-Zn合金薄带微观组织、物相种类和时效硬化的影响。盛绍顶等[15]采用雾化法制备出快速凝固镁合金颗粒,并结合粉末冶金技术,通过控制烧结过程中沉淀相的析出,研究了镁合金性能的变化规律。然而,如果采用单一快速凝固方式,冷却速度变化范围有限,不利于全面系统地揭示镁合金非平衡凝固组织演变规律。

本文作者综合采用铜模喷铸和单辊甩带技术制备出不同冷却条件下的AZ91D镁合金非平衡凝固试样,并通过ProCAST数值模拟软件及理论公式对其冷却速率分别进行了定量估算。在此基础上,采用多种分析测试手段对比研究了不同冷却速度作用下镁合金晶粒尺寸、物相结构及溶质分布等非平衡凝固组织的演变规律,从而为高性能镁合金的研制提供科学依据。

1 实验

选用工程中广泛应用的AZ91D镁合金,其成分如下(质量分数,下同):Al 8.5%~9.5%,Zn 0.45%~ 0.9%,w(Mn)≤0.17%,w(Si)≤0.05%,w(Fe)≤0.004%,w(Cu)≤0.015%,w(Ni)≤0.001%,杂质≤0.01%,其余为Mg。首先将经过机械打磨后的AZ91D镁合金装入石英玻璃管内,并通过特定卡具固定在真空感应熔炼炉中。采用机械泵和分子泵二级泵抽气系统实现6.67×10-4 Pa的极限真空。为避免镁合金在熔炼过程中挥发烧损,炉舱内返充99.999%的高纯氩气至0.03 MPa,并将最高熔炼温度控制在650 ℃。合金熔化并保温5 min确保均匀混合后,在石英坩埚上方通入0.02 MPa的氩气,金属液被垂直喷射入紫铜模具或高速旋转的铜辊上(工艺参数见表1),从而制备出非平衡凝固镁合金试棒或条带。

通过镶嵌、打磨、抛光及腐蚀等标准金相制备步骤后,在 VHX-600E三维超景深显微镜上进行光学显微组织分析。采用Nova Nano SEM450 场发射扫描电子显微镜进行高倍数下微观组织分析,并利用 INCA 250 X-Max 50 型能谱仪对微区成分进行测定。采用 D8 X射线衍射仪进行物相结构分析。采用德国Netzsch公司生产的 STA449F3 差热分析仪对试样进行差热分析。

2 结果与讨论

2.1 冷却速率计算

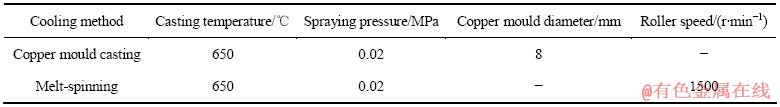

表1 非平衡凝固镁合金制备工艺参数

Table 1 Technological parameters for non-equilibrium solidified magnesium alloys via copper mould casting and melt-spinning method

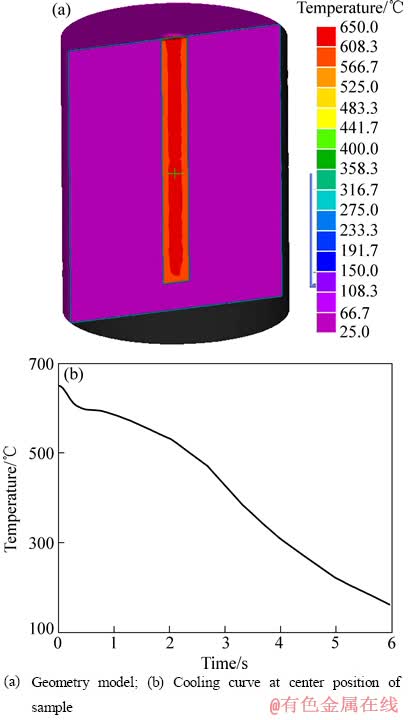

首先利用ProCAST软件对铜模喷铸过程中AZ91D合金冷却阶段温度场进行数值模拟,其中假设熔体温度均匀、充型瞬间完成,并忽略充型时熔体的流动。图1(a)所示为所建几何模型。通过网格划分及有限元模拟后,图1(b)给出了试棒中心位置处的冷却曲线。可以看出,金属液从初始浇铸温度650 ℃冷却到液相线温度594 ℃阶段内,由于属于纯液相冷却,受铜模激冷影响,熔体温度下降迅速。随后由于凝固过程的发生,相变潜热被释放出来,这在一定程度上减弱了铜模对合金试样的外部冷却效果,导致冷却速度变化趋于平缓,温度曲线上出现“再辉”平台。当温度下降到430 ℃时,凝固过程结束,合金冷却速率继续增加。综合考虑上述各阶段,铜模喷铸过程中平均冷却速率R可估算为1×102 ℃/s。

图1 AZ91D镁合金铜模喷铸过程中的温度场模拟

Fig. 1 Numerical simulation of temperature field for copper mould casting process of AZ91D magnesium alloy

根据文献[16],单辊甩带条件下合金冷却速率(R)的计算式如下:

(1)

(1)

式中:h为热传导系数;T和T0分别为熔液温度及铜辊温度;c和ρ分别为镁合金比热容及密度;z为条带厚度。根据表2中各参量值,由式(1)可估算出单辊甩带条件下AZ91D合金的冷却速率为5.43×106 ℃/s。

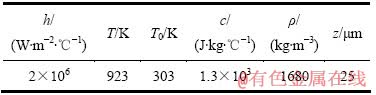

表2 单辊甩带过程中冷却速度计算所需各参量值

Table 2 Parameters for calculation of cooling rate in melt-spinning experiment

2.2 不同冷却速度下AZ91D合金组织形貌及成分分析

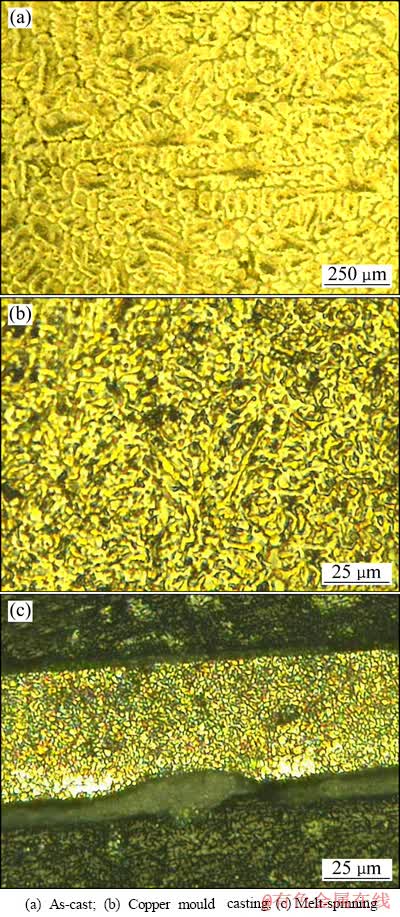

常规铸造条件下,AZ91D合金在凝固过程中首先析出α-Mg初生相,随后由于固相扩散不均匀,发生共晶反应,形成β-Mg17Al12相。图2(a)所示为合金近平衡凝固条件下的光学显微组织。其中,铸态组织以粗大枝晶为主,平均尺寸可达800 μm,共晶相以网状分布于晶界周围。随冷却速率提高,铜模喷铸条件下晶粒发生明显细化,枝晶尺寸得到急剧减小(见图2(b))。单辊甩带时由于冷却速率最高,晶粒形貌更加细小,并且呈现出粒状等轴晶组织(见图2(c))。根据凝固理论[17]可知,铸件的最终晶粒尺寸大小主要取决于结晶过程中形核的发生。快速凝固条件下,形核初始过冷度得到大幅度提高,同时较高的冷却速率又有利于凝固潜热的释放,促进后续形核的发生,因此提高了单位体积内的有效形核数目,导致晶粒尺寸的急剧减小。

图2 不同冷却条件下AZ91D镁合金的光学显微组织

Fig. 2 Optical micrographs of AZ91D magnesium alloy under different cooling conditions

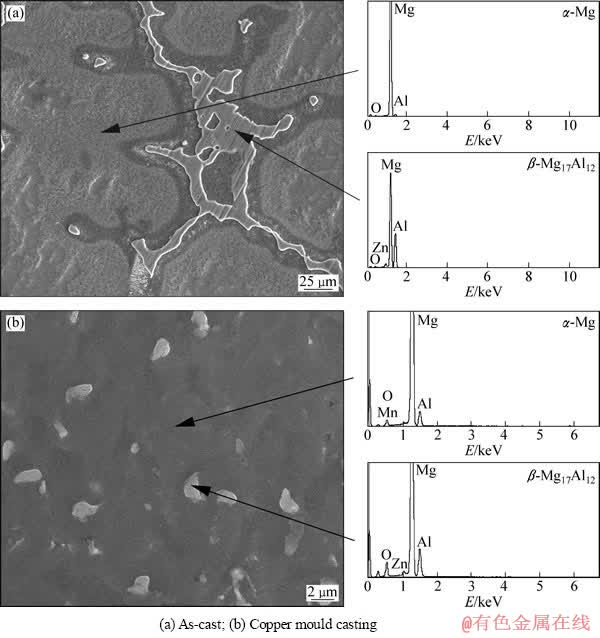

图3给出了铸态及铜模喷铸条件下AZ91D合金扫描电镜显微组织及其能谱测试结果。对比分析可看出,铸态条件下,共晶β相所占体积分数较大,并且以连续无规则网状分布在初生α相晶界区域(见图3(a))。铜模喷铸条件下,β相体积分数明显降低,以不连续弥散状分布于α相周围(见图3(b))。能谱分析结果进一步表明,相比于常规铸态组织,喷铸条件下α基体中Al元素含量相对较高。

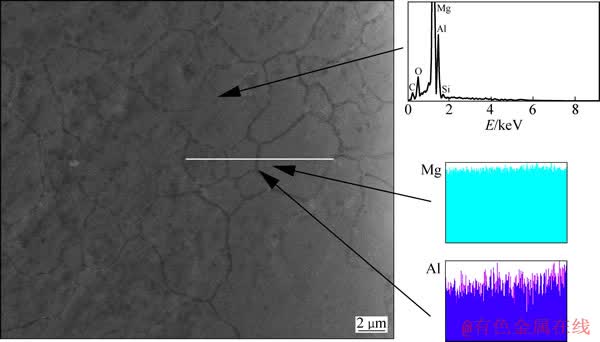

当冷却速率进一步增加时,单辊甩带条件下所制备的AZ91D镁合金非平衡凝固组织转变为单相固溶体,晶间第二相完全消失,由此也说明快速凝固条件下共晶反应得到充分抑制(见图4)。从晶粒形貌上看,此时的α相以大小不均匀的等轴晶形貌呈现,其中晶粒尺寸普遍在5 μm以内。这是由于在快速凝固过程中,液固界面推移速度过快,结晶固相中容易形成更多的位错及空穴等缺陷,从而导致再结晶的发生。能谱分析结果表明,单辊甩带条件下基体中所固溶的Al元素含量最高。通过对晶粒内部线扫描可知,基体中Mg和Al元素成分稳定,基本不存在偏析现象。

由Mg-Al二元合金相图可知[18],β-Mg17Al12共晶相的形成关键取决于凝固后期残余液相中溶质Al的含量。根据质量守恒,残余液相成分cl可表示为[19]

(2)

(2)

式中:c0为合金原始含量;cs和f分别为已结晶固相含量和体积分数。根据Aziz溶质截留模型[20],已结晶固相成分可表示为

(3)

(3)

式中:k为非平衡溶质分配系数;ke为平衡溶质分配系数;v和vD分别为液-固界面迁移速度和液相溶质原子扩散速度。随冷却速率增加,液-固界面迁移速度v较大,界面前方所富集的Al原子由于扩散不及时而固溶于结晶固相中,非平衡溶质分配系数不断增大,导致固相成分cs提高,这与图3和4中能谱分析结果一致。结合式(2),还可推断出残余液相中Al元素含量降低,从而有效地抑制了凝固后期共晶反应的发生。

图3 AZ91D镁合金的SEM像及其EDS能谱

Fig. 3 SEM images and EDS spectra of AZ91D magnesium alloy

图4 单辊甩带条件下制备AZ91D镁合金的SEM像及其EDS能谱

Fig. 4 SEM image and EDS spectra of AZ91D magnesium alloy fabricated by melt-spinning method

2.3 不同冷却速度下AZ91D镁合金物相结构及差热分析

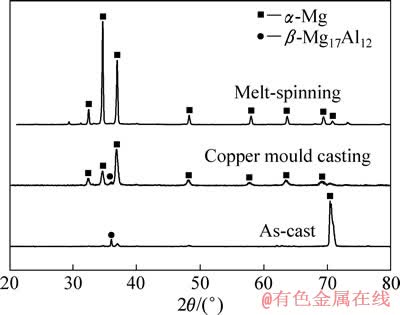

为进一步确定不同冷却速度作用下AZ91D镁合金的相组成,图5给出了铸态、铜模喷铸及单辊甩带条件下合金的XRD谱。可以看出,常规铸态条件下,AZ91D合金的XRD谱中以α-Mg相为主,但也存在一定量的β-Mg17Al12相。随着冷却速率的增加,α-Mg相的衍射峰出现增多、增强的趋势,其中喷铸条件下还存在较弱的β-Mg17Al12相衍射峰,而对于冷却速率最高的单辊甩带试样,β-Mg17Al12相衍射峰完全消失。

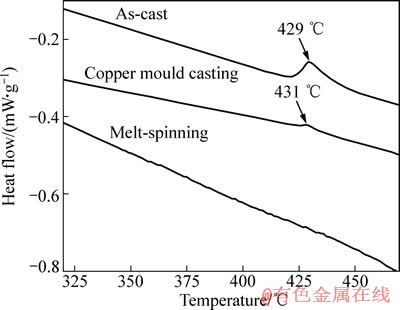

图6所示为铸态、铜模喷铸及单辊甩带条件下所制备试样升温过程中的差热分析曲线。可以看出,铸态AZ91D镁合金在加热到429 ℃时存在一个非常明显的吸热峰值变化。根据Mg-Al合金相图可知[18],该峰所对应的是升温过程中共晶相的溶解。相比之下,喷铸铜模试样的DTA曲线的共晶反应峰向右偏移,最大值出现在431 ℃,而且峰的强度较铸态的明显减弱。由上述分析可知,这是由于冷却速度增加导致共晶相β-Mg17Al12体积分数减少,从而降低了整体吸热强度。在单辊甩带法所制得的试样DTA曲线中,峰值完全消失,此时AZ91D镁合金中没有共晶相,完全以α-Mg形式存在。这进一步说明利用快速凝固技术,可以大幅度增加AZ91D镁合金基体中的溶质极限固溶度,消除共晶β-Mg17Al12相,有利于提高合金高温力学性能。

图5 不同冷却条件下AZ91D镁合金的XRD谱

Fig. 5 XRD patterns of AZ91D magnesium alloy under different cooling conditions

图6 不同冷却条件下AZ91D镁合金的DTA曲线

Fig. 6 DTA curves of AZ91D magnesium alloy under different cooling conditions

3 结论

1) 利用ProCAST数值模拟及理论公式,计算出铜模喷铸和单辊甩带条件下AZ91D镁合金非平衡凝固过程中的冷却速率分别为1×102和5.43×106 ℃/s。

2) 冷却速率的增加导致AZ91D镁合金初生α-Mg相形貌从粗大枝晶向细小等轴晶转变,尺寸发生明显下降,从铸态条件下的800 μm降低到单辊甩带条件下的5 μm以内。

3) 非平衡凝固条件下,溶质截留的发生导致基体中Al元素含量升高,β-Mg17Al12相体积分数降低,共晶反应得到抑制。XRD及差热分析结果表明,快速凝固条件下可获得成分均匀的单相α-Mg固溶体组织。

REFERENCES

[1] MORDIKE B L, EBERT T. Magnesium properties- applications-potential[J]. Materials Science and Engineering A, 2001, 302(1): 37-45.

[2] ELIEZER D, AGHION E, FROES F H. Magnesium science, technology and applications[J]. Advanced Performance Materials, 1998, 5(3): 201-212.

[3] FRIEDRICH H, SCHUMANN S. Research for a “new age of magnesium” in the automotive industry[J]. Journal of Materials Processing Technology, 2001, 117(3): 276-281.

[4] YAMASHIA A, HORITA I, LANGDON T G. Improving the mechanical properties of magnesium and magnesium alloy through severe plastic deformation[J]. Materials Science and Engineering A, 2001, 300(1): 142-147.

[5] KUBOTA K, MABBUCH M, HIGASHI K. Review processing and mechanical properties of fine-grained magnesium alloys[J]. Journal of Materials Science, 1999, 34(10): 2255-2262.

[6] CHEN J H, WEI J Y, YAN H G, PAN X Q. Effects of cooling rate and pressure on microstructure and mechanical properties of sub-rapidly solidified Mg-Zn-Sn-Al-Ca alloy[J]. Materials and Design, 2013, 45(3): 300-307.

[7] JONES H. A perspective on the development of rapidly solidification and nonequilibrium processing and its future[J]. Materials Science and Engineering A, 2001, 304: 11-19.

[8] 肖冬飞, 谭敦强, 欧阳高勋, 陈 伟. 镁合金快速凝固技术的研究现状及进展[J]. 铸造, 2007, 69(5): 909-914.

XIAO Dong-fei, TAN Dun-qiang, OUYANG Gao-xun, CHEN Wei. Current status and development of rapidly solidified magnesium alloys[J]. Foundry, 2007, 69(5): 909-914.

[9] 徐锦锋, 翟秋亚, 袁 森. AZ91D镁合金的快速凝固特征[J]. 中国有色金属学报, 2004, 14(6): 939-944.

XU Jing-feng, QU Qiu-ya, YUAN Sen. Rapidly solidification characteristics of melt-spun AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(6): 939-944.

[10] 盛绍顶, 严红革, 陈振华. 快速凝固粉末冶金AZ91镁合金的组织性能[J]. 矿冶工程, 2010, 30(1): 69-74.

SHENG Shao-ding, YAN Hong-ge, CHEN Zhen-hua. Microstructures and mechanical properties of AZ91 Mg alloy processed by rapid solidification and power metallurgy technology[J]. Mining and Metallurgical Engineering, 2010, 30(1): 69-74.

[11] KAWAMARA Y, HAYASHI K, INOUE A. Rapidly solidified power metallurgy Mg97Zn1Y2 alloys with excellent tensile yield strength above 600 MPa[J]. Materials Transactions JIM, 1999, 42(7): 1172-1176.

[12] TENG H T, ZHANG X L, ZHANG Z T, LI T J. Research on microstructures of sub-rapidly solidified AZ61 magnesium alloy[J]. Materials Characterization, 2009, 60: 482-486.

[13] 徐春杰, 郭学锋, 刘 礼, 张忠明. 往复挤压准晶增强快速凝固Mg92.5Zn6.4Y1.1合金[J]. 中国稀土学报, 2007, 25(2): 224-228.

XU Chun-jie, GUO Xue-feng, LIU Li, ZHANG Zhong-ming. Quasicrystal strengthened rapid solidification Mg92.5Zn6.4Y1.1 alloys by reciprocating extrusion[J]. Journal of the Chinese Rare Earth Society, 2007, 25(2): 224-228.

[14] 周 涛, 夏 华, 周志明, 彭成允, 陈 康, 库美芳, 陈振华. 快速凝固Mg-6Zn-5Ce合金的微观组织研究[J]. 材料导报, 2011, 25(2): 97-100.

ZHOU Tao, XIA Hua, ZHOU Zhi-ming, PENG Cheng-yun, CHEN Kang, KU Mei-fang, CHEN Zhen-hua. Investigation on microstructure of rapidly solidified Mg-6Zn-5Ce alloy[J]. Materials Review, 2011, 25(2): 97-100.

[15] 盛绍顶, 陈 鼎, 陈振华, 陈 刚, 严红革. 快速凝固/粉末冶金AZ91/SiCp镁基复合材料的相组成及界面[J]. 中国有色金属学报, 2008, 18(7): 1185-1190.

SHENG Shao-ding, CHEN Ding, CHEN Zhen-hua, CHEN Gang, YAN Hong-ge. Phase composition and interface of rapidly solidified/power metallurgy AZ91/SiCp Mg-based composite material[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(7): 1185-1190.

[16] WATERLOO G, JONES H. Microstructure and thermal stability of melt-spun Al-Nd and Al-Ce alloy ribbons[J]. Journal of Materials Science, 1996, 31: 2301-2310.

[17] KURZ W, FISHER D J. Fundamentals of solidification [M]. Switzerland: Trans Tech Publications Ltd, 1998: 125-127.

[18] 刘楚明, 朱秀荣, 周海涛. 镁合金相图集[M]. 长沙: 中南大学出版社, 2006: 4.

LIU Chu-ming, ZHU Xiu-rong, ZHOU Hai-tao. Magnesium alloy phase diagram[M]. Changsha: Central South University Press, 2006: 4.

[19] YANG W, LIU F, WANG H F, LU B P, YANG G C. Non-equilibrium transformation kinetics and primary grain size distribution in the rapid solidification of Fe-B hypereutectic alloy[J]. Journal of Alloys and Compounds, 2011, 509: 2903-2908.

[20] AZIZ M J. Model for solute redistribution during rapid solidification[J]. Journal of Applied Physics, 1982, 53: 1158-1168.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(51164028,51261025);江西省自然科学基金资助项目(CA201203054);江西省教育厅青年基金资助项目(GJJ12446);轻合金加工科学与技术国防重点学科实验室开放课题(GF201201003)

收稿日期:2013-04-28;修订日期:2013-09-23

通信作者:杨 伟,博士;电话:0791-86453167;传真:0791-86453167;E-mail:weiyang@mail.nwpu.edu.cn