DOI: 10.11817/j.issn.1672-7207.2019.12.006

料筒温度对超声塑化微制件充填质量的影响

蒋炳炎,张英平,齐鹏程,邹洋,魏国猛,吴旺青

(中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:为研究料筒温度对超声塑化微制件充填质量的影响,采用瞬态热分析法研究不同料筒温度下超声塑化过程聚甲基丙烯酸甲酯(PMMA)温度场升温特性,并结合单因素实验法研究料筒温度对超声塑化微拉伸试验件充填率、充填长度、溢料现象的影响规律。研究结果表明:提高料筒温度可明显缩短聚合物达到黏流温度所需的时间,提高聚合物熔体的最高温度,从而提高超声塑化微制件充填质量;当料筒温度为100 ℃时,聚合物颗粒完全熔融,制件充填率提高12.20%,制件长度提高16.00%,无明显烧焦及溢料现象;当料筒温度提高至180 ℃时,充填质量出现小幅度下降,制件出现烧黑与溢料现象。

关键词:超声塑化;料筒温度;微注射成型;充填质量

中图分类号:TQ320.66 文献标志码:A 文章编号:1672-7207(2019)12-2969-09

Effect of barrel temperature on filling quality of ultrasonic plasticized micro-parts

JIANG Bingyan, ZHANG Yingping, QI Pengcheng, ZOU Yang, WEI Guomeng, WU Wangqing

(State Key Laboratory of High Performance Complex Manufacturing, Central South University,

Changsha 410083, China)

Abstract: To study the effect of barrel temperature on the filling quality of ultrasonic plasticized micro-parts, the transient thermal analysis method was used to study the heating characteristics of the temperature field of polymethyl methacrylate(PMMA) in ultrasonic plasticizing process at different barrel temperatures. The single-factor experiment was conducted to research the influence of barrel temperature on ultrasonic plasticized micro-parts. The results show that time required for the polymer to reach the viscous flow temperature is shortened, and the maximum temperature of the polymer melt increases with the increase of barrel temperature, thereby the filling quality of the ultrasonic plasticized micro-parts is improved. When the barrel temperature is 100 ℃, the polymer particles are completely melted, the filling rate of the micro-part is increased by 12.20%, the length of the part is increased by 16.00%, and no charring and flashing phenomenon is observed. When the temperature of the barrel reaches 180 ℃, the filling quality has a slight decline with the appearance of blackening and flashing.

Key words: ultrasonic plasticization; barrel temperature; micro injection molding; filling quality

超声塑化微注射成型技术解决了常规螺杆塑化微注射成型在最小塑化量限制的问题,具有节能高效、减少材料降解和浪费、提高聚合物熔体流动性能等优点[1]。近年来,超声塑化微注塑成型技术研究在高性能工程塑料[2-3]、生物可降解聚合物[4-5]、聚合物纳米材料微注射成型[6-7]等领域取得快速发展,使之成为微注射成型技术发展的一个重要方向。但超声塑化单次塑化量小,频率高,能量集中,微制件质量对振幅等工艺参数非常敏感,超声塑化微制件经常出现塑化不完全、溢料严重、充填不足、材料降解烧焦等问题[8],因此,有必要针对上述问题进行研究。JIANG等[9-10]建立了超声塑化聚合物黏弹性生热和摩擦生热的计算模型,发现超声振动聚合物摩擦生热过程仅0.078 s,黏弹性生热效应是聚合物超声塑化热量的主要来源。DORF等[11]通过检测超声塑化PEEK微制件降解程度,发现过大的超声振幅和过低的注射速率都是导致PEEK降解的重要因素。GRABALOSA等[12-13]研究了超声振幅对聚酰胺(PA)、聚苯砜(PPSU)微制件塑化质量的影响,发现聚合物塑化质量对超声振幅非常敏感,较大的超声振幅容易导致聚合物颗粒烧黑与降解。过大或过小的塑化压力都会导致塑化不完全与材料降解从而导致制件性能降低。MASOTO等[14]研究了微型腔中聚合物流动和温度特性,发现浇口附近的熔体温度最高,型腔末端附近的熔体温度最低,容易导致型腔末端充填不足。张胜等[15]通过实验证明了料筒中聚合物超声场不均匀且沿料筒中心轴线方向衰减的特性。LIANG等[16]发现未经加热的UHMWPE超声模塑微阵列的相结构存在初生态和熔化再结晶态两相,而加热到85 ℃时UHMWPE模塑微阵列相结构只包含熔化再结晶态,温度外场有助于提高塑化程度,但未对其影响机理进行研究。JIANG等[17]发现超声塑化聚合物与金属壁面的热交换导致超声波能量损失20%,但实验研究对象不是微量聚合物。综上所述,由于功率超声的振幅与频率工艺参数可以选择的范围小且不好精准控制,超声工具头压力对聚合物黏弹性生热速率影响不显著,因此,考虑采用外部加热的方式改善超声塑化微制件的充填质量。但现有研究并未就温度外场对超声塑化微制件充填质量的影响开展研究,为此,本文作者采用瞬态热分析方法仿真研究不同料筒温度下聚甲基丙烯酸甲酯(PMMA)温度场升温特性,并结合单因素实验研究料筒温度对微拉伸试验件充填质量的影响规律。

1 超声塑化系统温度场仿真分析

1.1 聚合物超声塑化黏弹性生热计算

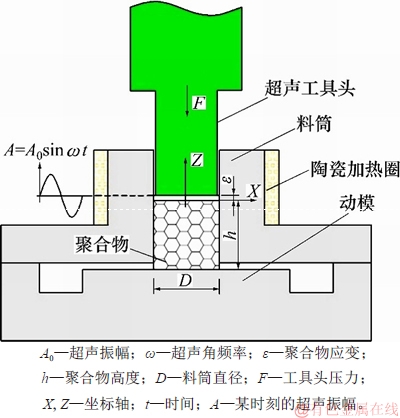

超声塑化过程中摩擦生热阶段只持续0.078 s[10],提供聚合物超声塑化过程的启动能量。聚合物颗粒界面消融后黏弹性生热效应提供了超声塑化主要热量。超声工具头施加正弦交变压力载荷,超声振动产生的机械能通过做功转换为聚合物内部黏弹性生热。聚合物超声塑化黏弹性生热物理模型如图1所示。

图1 聚合物超声塑化黏弹性生热示意图

Fig. 1 Schematic diagram of viscoelastic heating during ultrasonic plasticization

假设工具头端面产生的超声波垂直于工具头端面且均匀分布。黏弹性生热率计算方法为[18]

(1)

(1)

式中:Q为聚合物黏弹性生热率;T为聚合物温度;f为超声振动频率;ω为超声振动角频率;Z为距离工具头端面的距离; 为储能模量;

为储能模量; 为损耗模量;C为超声波在聚合物中的传播速度;

为损耗模量;C为超声波在聚合物中的传播速度; 为超声工具头端面振幅。BENATAR等[19-20]基于广义Maxwell力学模型与时温等效原理表征了聚合物模量与温度、频率和松弛时间的关系:

为超声工具头端面振幅。BENATAR等[19-20]基于广义Maxwell力学模型与时温等效原理表征了聚合物模量与温度、频率和松弛时间的关系:

(2)

(2)

式中:j为广义Maxwell模型阶数;τj(T)为各阶松弛时间关于温度的函数;Ej(T)为各阶松弛模量关于温度的函数。根据式(1)~(2)可得到聚合物在超声振动载荷下黏弹性生热率Q的计算公式:

(3)

(3)

式中:ρ为聚合物密度;H为聚合物松弛转变活化能,取335 kJ/mol;T0为参考温度;Tg为PMMA玻璃化转变温度,为105 ℃;R为气体摩尔常量。

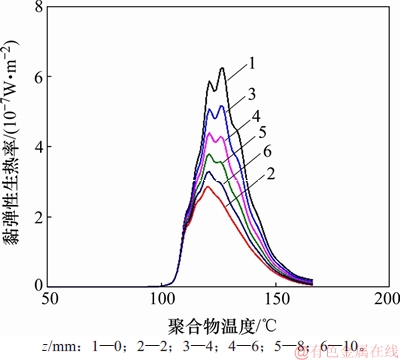

选择典型无定形聚合物PMMA为研究对象,利用Matlab对超声塑化黏弹性生热率进行计算。取超声频率为20 kHz,超声振幅为20 μm,常数C1=17.6,C2=65.5,距离超声波端面的高度z小于10 mm,计算结果如图2所示(其中,z为聚合物与超声工具头端面的距离)。

图2 聚合物与超声工具头端面距离不同时PMMA的黏弹性生热速率

Fig. 2 Viscoelastic heating rate of PMMA at different distances

当超声频率与振幅确定时,聚合物PMMA黏弹性生热率依赖于温度,这本质上是聚合物分子结构受温度影响的体现,反映了聚合物分子在承受交变载荷时单位时间内的能量消耗。聚合物黏弹性生热率在105~165 ℃范围内呈现先急剧增加后下降的趋势,并在超声波传播方向上存在显著衰减。

1.2 超声塑化系统温度场仿真

根据式(3)采用ANSYS非线性瞬态热分析模块对超声塑化系统温度场仿真,非线性瞬态热分析的平衡方程为

(4)

(4)

式中:[K(T)]为传导矩阵;[C(T)]为比热矩阵;{T}为节点温度向量; 为温度对时间的导数向量;{Q}为节点热流率向量;t为时间。

为温度对时间的导数向量;{Q}为节点热流率向量;t为时间。

超声塑化系统温度场仿真求解过程如下:首先,采用ANSYS瞬态热分析求解料筒初始温度场;然后,将温度场作为初始条件加载到塑化系统黏弹性生热瞬态中,采用牛顿-拉夫森迭代法进行计算。在瞬态分析中,每一迭代子步完成后可提取其单元节点温度,从而根据式(3)获得下一个子步的温度场分布,最终获得超声塑化聚合物的温度场。

1.2.1 基本假设

超声塑化是聚合物在超声振动下摩擦生热、黏弹性生热、料筒温度场综合作用下的复杂温度变化过程。为简化研究,假设摩擦生热和黏弹性生热为相对独立的过程。以聚合物玻璃化转变温度105 ℃作为聚合物温度场仿真的起始温度,此时,聚合物界面完全消融,介质分布均匀,摩擦生热阶段结束,黏弹性占主导作用。忽略不同介质间的接触热阻。

1.2.2 有限元模型的建立及边界条件

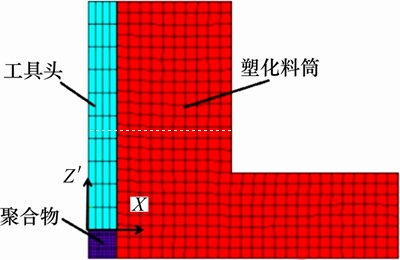

聚合物黏弹性生热率Q沿中心轴线Z 轴对称,故聚合物塑化系统内部的温度场分布沿其中心轴线对称,仍以典型无定形聚合物PMMA为研究对象,采用ANSYS 15.0前处理模块建立塑化系统热分析的 1/2二维有限元仿真网格模型,如图3所示。

轴对称,故聚合物塑化系统内部的温度场分布沿其中心轴线对称,仍以典型无定形聚合物PMMA为研究对象,采用ANSYS 15.0前处理模块建立塑化系统热分析的 1/2二维有限元仿真网格模型,如图3所示。

图3 超声塑化系统有限元模型

Fig. 3 Finite element model of ultrasonic plasticizing system

取单次塑化量为0.35 g,料筒半径为5 mm,聚合物高度为6 mm。假设料筒初始温度为室温 20 ℃,料筒外表面与加热圈接触处设置陶瓷加热圈的热流密度q为

(5)

(5)

式中:q为热流密度;P为陶瓷加热圈功率;h 为料筒高度;R为料筒半径。

为料筒高度;R为料筒半径。

由图2可知PMMA黏弹性生热率在105~165 ℃之间受温度影响明显,故将料筒仿真温度参数设为20,100,120,140,160和180 ℃。将ANSYS瞬态热分析求解的料筒温度场作为料筒温度初始条件。环境温度设定为20 ℃。对料筒外壁与空气接触处施加与环境空气间的热对流,对流换热系数为12.5 W/(m2·℃)。料筒上端设置有纤维隔热板,设置导热系数为0.03 W/(m·℃),动模温度设置为PMMA注塑成型的模具温度60 ℃。取工具头振幅为20 μm,超声频率为20 kHz,利用ANSYS中的Function Editor功能将式(3)所示的超声塑化聚合物黏弹性生热模型导入载荷公式中,然后,选择该黏弹性生热载荷公式计算聚合物热生成率的体载荷,计算步长为1×10-5 s。

1.2.3 材料参数的确定

超声工具头材料为钛合金TC4,料筒、动模板材料为7075铝合金,聚合物材料为PMMA。各材料主要性能参数如表1~3所示。

表1 仿真实验中的材料属性

Table 1 Performance parameters of simulation materials

表2 不同温度时PMMA的导热系数

Table 2 Thermal conductivity of PMMA at different temperatures

表3 不同温度时PMMA的比热容

Table 3 Specific heat capacity of PMMA at different temperatures

1.3 超声塑化系统温度场仿真结果与分析

1.3.1 超声塑化PMMA温度场特性

在料筒温度140 ℃下,PMMA温度场的仿真结果如图4所示。由于超声波能量在聚合物中传播方向上有显著衰减,聚合物上端面温度最高,距离超声工具头端面越远,其黏弹性生热率越低,同时,料筒内壁与聚合物接触产生热传导,PMMA料筒温度在聚合物半径方向上由聚合物中心轴线向外衰减。

图4 料筒温度为140 ℃时PMMA温度场分布

Fig. 4 Temperature field distribution of PMMA at barrel temperature of 140 ℃

1.3.2 料筒温度对超声塑化PMMA升温速率的影响

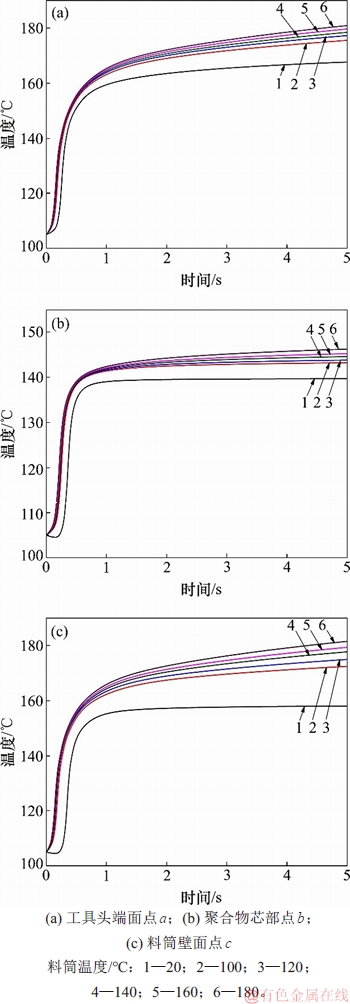

提取聚合物3个特征点a,b和c处升温曲线,分析料筒温度对料筒内各点超声塑化升温速率的影响。不同料筒温度下各点聚合物升温曲线如图5所示。

图5 不同料筒温度下各点聚合物升温曲线

Fig. 5 Temperature curves of PMMA at different barrel temperatures

从图5可见:当料筒温度为100 ℃时,聚合物温度场各点温度明显提高,温度增幅从大到小的点依次为点c,a和b;点a处于超声工具头端面中心位置,超声能量衰减最少,能量最集中;点b处于聚合物芯部,超声能量衰减大,故温度增幅最小;点c在料筒温度100 ℃下聚合物温度升至黏流温度的时间为0.80 s,聚合物熔体温度达到172 ℃,与料筒不加热条件相比,升至黏流温度上的时间缩短了0.88 s,熔体温度提高了14 ℃,有效减少了料筒壁面处传导产生的热损失,从而提高了聚合物熔体流动性能;当料筒温度升至180 ℃后,聚合物温度场温度均无明显提高。这是由于料筒温度为100 ℃时,大部分聚合物已进入高弹态,高弹态聚合物的分子链之间的摩擦力较大,损耗模量大,黏弹性生热效应更剧烈;当料筒温度升至180 ℃时,聚合物快速升高至黏流温度,分子链之间的运动相对自由,黏弹性生热效应减弱。仿真结果符合图2所示的黏弹性生热速率数值计算规律。

2 实验

2.1 实验平台与材料

实验研究基于超声塑化微注射成型实验平台[21],平台参数如表4所示。自行设计料筒温度控制系统采用PLC和K型热电偶、陶瓷加热圈组成的闭环控制方式。PLC通过PID功能改变输出脉冲信号的占空比,控制陶瓷加热圈的加热功率。K型热电偶测温点固定于料筒底部,通过热电偶模块将信号返回至PLC以执行PID计算。温度控制精度为±1 ℃。

表4 超声塑化实验平台参数

Table 4 Experimental parameters of ultrasonic plastic platform

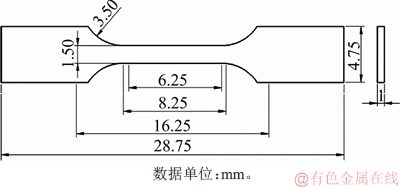

为满足研究与检测需求,选择微拉伸试验件作为微制件实验对象,参考ASTM_D638-2010塑料拉伸实验标准进行设计。实验材料选择无定形聚合物PMMA,牌号为Evonik PMMA Plexiglas 8N。微拉伸试验件基本尺寸如图6所示。

图6 微拉伸试验件基本尺寸

Fig. 6 Basic dimensions of micro tensile test piece

2.2 实验方案

为研究料筒温度对微拉伸试验件充填质量的影响,根据仿真研究结果设计单因素实验,实验参数如表5所示。

表5 PMMA微拉伸试验件成型实验参数

Table 5 Ultrasonic plasticization parameters of PMMA micro-parts

为保证实验结果的准确性,首先对PMMA材料进行干燥处理,干燥温度为80 ℃,干燥时间为6 h。实验前,开启料筒与模具的预热,打模至设备稳定状态后进行取样。每组实验对相应工艺参数下5组微拉伸试验件充填质量进行检测,除去最大与最小值后取平均值作为统计结果。

实验结果分析中,聚合物塑化程度通过可视化评估为未塑化、部分黏结、完全熔融、烧焦降解共4个等级,分别用0,1,2和3表示。以微拉伸试验件的制件质量与完全充填的理论质量的百分比作为充填率评价指标,称质量仪器为德国赛多利斯公司的BSA124S型精密电子天平。微拉伸试验件的长度与窄部厚度分别由数显游标卡尺和数显千分尺测量。

3 结果与讨论

3.1 料筒温度对聚合物塑化程度的影响

不同料筒温度下聚合物塑化程度如图7所示,其中,塑化程度1表示聚合物末塑化,塑化程度2表示聚合物部分塑化,塑化程度3表示聚合物完全塑化。从图7可见:当料筒温度为20 ℃时,料筒壁面的聚合物颗粒界面仍未完全消融;当料筒温度提高至100 ℃后,与料筒壁面接触的聚合物能完全塑化,与图5(c)所示结果一致;当料筒温度达到180 ℃时,超声振动瞬间产生的高温使其超过PMMA热分解温度,导致聚合物发生降解并出现烧黑现象。

图7 料筒温度对聚合物塑化程度的影响

Fig. 7 Influence of barrel temperature on plasticized degree of polymer

图8 料筒温度对聚合物溢料现象的影响

Fig. 8 Influence of barrel temperature on flash phenomenon of polymer

3.2 料筒温度对聚合物溢料现象的影响

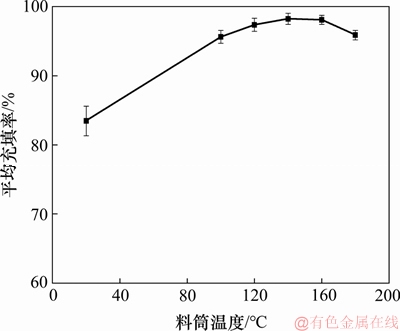

图9 料筒温度对微拉伸试验件充填率的影响

Fig. 9 Influence of barrel temperature on filling rate of micro tensile test pieces

由图5(c)可知:当料筒温度升高时,聚合物与料筒接触面上的温度提高最显著,黏度降低,流动性能增强。可以推断料筒温度提高可以减小聚合物与料筒之间的溢料间隙。不同料筒温度下PMMA制件的溢料现象如图8所示。从图8可见:当料筒温度为100 ℃时,溢料现象不明显;当料筒温度提高至180 ℃时,出现严重溢料现象。这是由于当料筒上升至180 ℃时,与料筒壁面接触的聚合物温度显著增加,溢料间隙减小,同时,料筒的温度大于PMMA黏流温度(160 ℃),使保压阶段中制件与料筒壁面接触的聚合物保持流动。

3.3 料筒温度对制件充填率的影响

由图5(b)可知:料筒不加热时,料筒底部聚合物最高温度仅为139 ℃,未达到黏流温度,导致底部聚合物流动性能相对工具头端面聚合物较差,抑制了聚合物熔体的充填;当料筒温度提高至140 ℃后,料筒底部聚合物最高温度为160 ℃,达到黏流温度,流动性能提高,可以促进聚合物熔体的充填。不同料筒温度下PMMA微拉伸试验件的充填率如图9所示。从图9可见:制件充填率随着料筒温度增加呈现先增加后下降的趋势;当料筒温度为20 ℃时,制件的充填率只有83.40%;当料筒温度升高至100 ℃时,拉伸试验件的充填率随料筒温度提高而增加;当料筒温度为140 ℃时,充填率达到最大值98.26%;当料筒温度升高到180 ℃时,微拉伸试验件充填率有所下降,这可能是聚合物温度过高时发生降解释放出气体所致。

3.4 料筒温度对制件尺寸的影响

料筒温度对拉伸试验件尺寸的影响如图10所示。从图10可见:随着料筒温度增大,拉伸试验件的充填长度先增大,达到稳定后呈小幅下降的趋势;当料筒不加热时,拉伸试验件的充填长度只有23.84 mm,小于拉伸试验件的理论长度28.75 mm;随着料筒温度增大到140 ℃,充填长度增大到28.70 mm,接近拉伸试验件的理论长度;当料筒温度上升到180 ℃时,充填长度有小幅度下降,这与聚合物发生降解有关;当料筒温度增加时,拉伸试验件厚度保持稳定;当料筒温度由20 ℃增加到180 ℃时,拉伸试验件厚度的变化幅度只有0.008 mm,表明料筒温度对拉伸试验件厚度无显著影响效果。

图10 料筒温度对微拉伸试验件尺寸的影响

Fig. 10 Influence of barrel temperature on dimensions of micro tensile test pieces

4 结论

1) 通过仿真与实验研究解释了料筒温度对聚合物超声塑化升温特性与微制件充填质量的影响规律。合理的料筒温度能显著提高聚合物超声塑化温度,从而改善微制件的充填质量。研究结果解释了温度外场对聚合物超声塑化的影响机理,为提高超声塑化微制件充填质量提供了实验基础。

2) PMMA黏弹性生热速率随着料筒温度的升高呈先增加后降低的趋势。当料筒温度为140 ℃时,聚合物达到黏流温度的时间缩短0.88 s,聚合物熔体温度提高14 ℃。在相同条件下,料筒壁面处聚合物温度提高效果最大,改善了熔体温度的均匀性。

3) 合理设置料筒温度可显著改善微拉伸试验件塑化与充填质量。微拉伸试验件充填率和充填尺寸随料筒温度升高呈先增加后降低的趋势。当料筒温度设置为100,120,140,160和180 ℃时,PMMA微拉伸试验件充填率分别提高12.18%,13.92%,14.79%,14.64%和12.43%,长度分别提高3.840,4.160,4.870,4.760和3.294 mm;当料筒温度提高至160 ℃时,充填质量均有小幅度下降,提高至180 ℃时则出现聚合物烧焦与溢料现象。超声塑化成型PMMA微制件的最佳料筒温度为140 ℃。

参考文献:

[1] MICHAELI W, SPENNEMANN A, GARTNER R. New plastification concepts for micro injection moulding[J]. Microsystem Technologies, 2002, 8(1): 55-57.

[2] SANCHEZ-SANCHEZ X, HERNANDEZ-AVILA M, ELIZALDE L E, et al. Micro injection molding processing of UHMWPE using ultrasonic vibration energy[J]. Materials & Design, 2017, 132: 1-12.

[3] SANCHEZ-SANCHEZ X, ELIAS-ZUNIGA A, HERNANDEZ-AVILA M. Processing of ultra-high molecular weight polyethylene/graphite composites by ultrasonic injection moulding: Taguchi optimization[J]. Ultrasonics Sonochemistry, 2018, 44: 350-358.

[4] HEREDIA U, VAZQUEZ E, FERRER I, et al. Feasibility of manufacturing low aspect ratio parts of PLA by ultrasonic moulding technology[J]. Procedia Manufacturing, 2017, 13: 251-258.

[5] SACRISTAN M, PLANTA X, MORELL M, et al. Effects of ultrasonic vibration on the micro-molding processing of polylactide[J]. Ultrasonics Sonochemistry, 2014, 21(1): 376-386.

[6] DIAZ A,CASAS M,PUIGGALI J.Dispersion of functionalized silica micro- and nanoparticles into poly(nonamethylene azelate) by ultrasonic micro-molding[J]. Applied Sciences, 2015, 5(4): 1252-1271.

[7] PLANELLAS M, SACRISTAN M, REY L, et al. Micro-molding with ultrasonic vibration energy: New method to disperse nanoclays in polymer matrices[J]. Ultrasonics Sonochemistry, 2014, 21(4): 1557-1569.

[8] MICHAELI W, KAMPS T, HOPMANN C. Manufacturing of polymer micro parts by ultrasonic plasticization and direct injection[J]. Microsystem Technologies, 2011, 17(2): 243-249.

[9] JIANG Bingyan, PENG Huajian, WU Wangqing, et al. Numerical simulation and experimental investigation of the viscoelastic heating mechanism in ultrasonic plasticizing of amorphous polymers for micro injection molding[J]. Polymers, 2016, 8(5): 199.

[10] WU Wangqing, PENG Huajian, JIA Yunlong, et al. Characteristics and mechanisms of polymer interfacial friction heating in ultrasonic plasticization for micro injection molding[J]. Microsystem Technologies, 2017, 23(5): 1385-1392.

[11] DORF T, FERRER I, CIURANA J. Characterizing ultrasonic micro-molding process of polyetheretherketone (PEEK)[J]. International Polymer Processing, 2018, 33(4): 442-452.

[12] GRABALOSA J, FERRER I, ELIAS-ZUNIGA A, et al. Influence of processing conditions on manufacturing polyamide parts by ultrasonic molding[J]. Materials & Design, 2016, 98: 20-30.

[13] DORF T, PERKOWSKA K, JANISZEWSKA M, et al. Effect of the main process parameters on the mechanical strength of polyphenylsulfone(PPSU) in ultrasonic micro-moulding process[J]. Ultrasonics Sonochemistry, 2018, 46: 46-58.

[14] MASATO D, BABENKO M, SHRIKY B, et al. Comparison of crystallization characteristics and mechanical properties of polypropylene processed by ultrasound and conventional micro-injection molding[J]. The International Journal of Advanced Manufacturing Technology, 2018, 99(1/2/3/4): 113-125.

[15] 张胜, 蒋炳炎, 彭华建, 等. 聚合物超声塑化过程中声场模拟与实验研究[J]. 中南大学学报(自然科学版), 2016, 47(8): 2661-2667.

ZHANG Sheng, JIANG Bingyan, PENG Huajian, et al. Sound field simulation and experimental study in polymer ultrasonic plasticizing process[J]. Journal of Central South University(Science and Technology), 2016, 47(8): 2661-2667.

[16] LIANG Xiong, WU Xiaoyu, XU Bin, et al. Phase structure development as preheating UHMWPE powder temperature changes in the micro-UPM process[J]. Journal of Micromechanics and Microengineering, 2016, 26(1): 015014.

[17] JIANG Bingyan, HU Jianliang, LI Jun, et al. Ultrasonic plastification speed of polymer and its influencing factors[J]. Journal of Central South University, 2012, 19(2): 380-383.

[18] 贾云龙, 蒋炳炎, 彭华建, 等. 微注射成型超声塑化中黏弹性生热效应[J]. 中南大学学报(自然科学版), 2016, 47(9): 2976-2983.

JIA Yunlong, JIANG Bingyan, PENG Huajian, et al. Viscoelastic heating effect in ultrasonic plasticization for micro injection molding[J]. Journal of Central South University(Science and Technology), 2016, 47(9): 2976-2983.

[19] BENATAR A, GUTOWSKI T G. Ultrasonic welding of PEEK graphite APC-2 composites[J]. Polymer Engineering and Science, 1989, 29(23): 1705-1721.

[20] MANO J F, VIANA J C. Stress–strain experiments as a mechanical spectroscopic technique to characterise the glass transition dynamics in poly (ethylene terephthalate)[J]. Polymer Testing, 2006, 25(7): 953-960.

[21] 蒋炳炎, 刘小超, 彭华建, 等. 一种无螺杆超声波熔融塑化聚合物微量注射成型装置及成型方法: 中国, CN201310121160.7[P]. 2013-04-09.

JIANG Bingyan, LIU Xiaochao, PENG Huajian, et al. Screwless Ultrasonic plasticization micro injection molding device and molding method: China, CN106124362A[P]. 2013-04-09.

(编辑 陈灿华)

收稿日期: 2019 -01 -25; 修回日期: 2019 -03 -27

基金项目(Foundation item):国家自然科学基金资助项目(51575540,51875582);中央高校基本科研业务费专项资金资助项目(2018zzts458)(Projects(51575540,51875582) supported by the National Natural Science Foundation of China; Project(2018zzts458) supported by the Fundamental Research Funds for the Central University)

通信作者:吴旺青,博士,副教授,从事微注射成型理论与应用研究;E-mail:csuwwq@csu.edu.cn