文章编号:1004-0609(2007)07-1034-07

Al-Cu-Mg合金的断裂韧性与拉伸延性模拟

宋旼,袁铁锤,张福勤,黄伯云,陈康华

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:基于铝合金中的脆性结晶相在外力作用下发生断裂而形成微裂纹的过程服从Weibull分布,建立了Al-Cu-Mg合金断裂韧性与拉伸延性的细观力学模型。模型的解析表明,在外力作用下由结晶相断裂而形成的微裂纹的体积分数随着外加应力的增加而增加;在相同的外加应力作用下,结晶相含量较高时微裂纹的体积分数也较高。同时模型的计算表明,Al-Cu-Mg合金的拉伸延性及断裂韧性与结晶相的含量及尺寸有很大关系;拉伸延性与断裂韧性随着结晶相体积分数与尺寸的增加而减小;因此通过对铝基体的纯化,减少Fe与Si元素的含量或者通过强化固溶处理可以降低结晶相的体积分数与尺寸,从而提高Al-Cu-Mg合金的拉伸延性与断裂韧性。

关键词:铝合金;拉伸延性;断裂韧性;Weibull分布

中图分类号:TG 249.9 文献标识码:A

Modeling on fracture toughness and tensile ductility of Al-Cu-Mg alloy

SONG Min, YUAN Tie-chui, ZHANG Fu-qin, HUANG Bai-yun, CHEN Kang-hua

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: A meso-scaled model was developed for the fracture toughness and tensile ductility of Al-Cu-Mg alloy based on the fact that the volume fraction of microcracks caused by the constituents cracking satisfies Weibull distribution under externally applied stress. Model analysis indicates that the volume fraction of microcracks caused by the constituents cracking increases with the externally applied stress. Under the same externally applied stress, the volume fraction of the microcracks increases with that of the constituents. The model calculation indicates that the fracture toughness and tensile ductility of Al-Cu-Mg alloy decrease as the size and volume fraction of the constituents increase. Thus, both purification and enhanced solution treatment can improve the tensile ductility and fracture toughness of Al-Cu-Mg alloy by decreasing the volume fraction and size of the constituents.

Key words: Al-Cu-Mg alloy; tensile ductility; fracture toughness; Weibull distribution

铝合金由于具有高强度和低密度而被广泛地运用于航天航空领域。然而,通常在提高铝合金强度的同时会降低其伸长率与断裂韧性,从而影响铝合金更广泛的商业用途。因此,如何能够在不降低强度的基础上提高断裂韧性和拉伸延性成为铝合金性能优化的重要内容。减少杂质含量、调整合金成分以及改进热处理制度都不失为改善铝合金断裂韧性和拉伸延性的有效手段。实际上,关于铝合金拉伸延性及断裂韧性与显微组织的关系已有大量研究[1-10]。这些研究指出粗大的结晶相是铝合金(特别是高强铝合金)的裂纹萌生源。基于这些研究,一些研究者假定结晶相为铝合金中的预制微裂纹,并发展了一系列力学模型用于计算铝合金断裂韧性及拉伸延性与结晶相体积分数的关 系[5-10]。然而,从裂纹萌生的本质上来说,结晶相断裂形成微裂纹是一个逐级萌生的过程,形成微裂纹的结晶相占所有结晶相的体积分数是外加载荷的函数,而不是预制裂纹。因此,早期的模型[5-10]有待于进一步优化。一些研究[11-13]表明,对于韧性材料,结晶相及夹杂形成微裂纹源的过程服从Weibull分布。作为初步尝试,本文作者通过引入Weibull分布来描述结晶相断裂(微裂纹体积分数)与外加应力和结晶相体积分数的关系,并通过研究微裂纹之间韧带区内的微观临界应变场与裂纹临界张开位移之间的关系来计算铝合金的宏观断裂韧性及拉伸延性。

1 力学模型

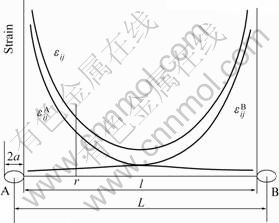

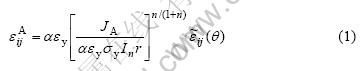

图1是本文作者发展的力学模型的几何图示。模型采用与早期的一些研究相类似的方法[6-7, 9],即假定A和B为变形过程中由结晶相断裂形成的微裂纹,通过分析微裂纹间韧带区内的微观塑性应变来计算材料的宏观塑性应变。然而,早期的研究均假定结晶相在外力作用下完全断裂(即为预制裂纹),而本文中结晶相的断裂机制服从Weibull分布,即外力作用下由结晶相断裂形成微裂纹的体积分数与外加应力及结晶相的体积分数密切相关。为简化数学上的处理,假定微裂纹呈周期性排列,其尺寸为2a,间距为L。则在微裂纹A的前端距微裂纹r处,由于微裂纹A和B的存在形成的应变张量可由下式表示[14-15]:

图1 断裂韧性与拉伸延性模型的几何图示

Fig.1 Geometric model for fracture toughness and tensile ductility

式中 J 为J积分,εy为屈服应变,σy为屈服应力,n为应变硬化指数的倒数,α为Ramberg-Osgood 本构关系中的材料常数[16],In 和 为HRR场中的正则化系数[14-15]。

为HRR场中的正则化系数[14-15]。

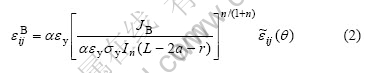

通常J积分包括两个部分:弹性分量 (Je) 和塑性分量 (Jp) 。对于铝合金,弹性分量远小于塑性分量,因此,J积分可表示为[17]

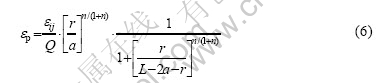

式中 εp 是塑性应变, 。 将式 (3) 分别代入式(1)和(2),可以得到

。 将式 (3) 分别代入式(1)和(2),可以得到

式中  。将式 (4)和(5)相加,可得

。将式 (4)和(5)相加,可得

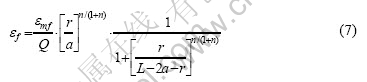

当韧带区中距微裂纹A距离为r处的有效应变εij达到基体的断裂应变εmf,则塑性应变εp将达到材料的临界断裂应变εf或者是材料的拉伸延性。于是,式(6)可变换成

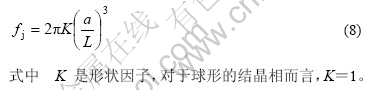

对于裂纹的周期性分布,其体积分数(fj)可表示为裂纹平均半径a与间距L的函数:

本研究与早期的一些研究[5-10]的主要差别在于在外力作用下,结晶相并不是完全断裂形成微裂纹,其断裂的分数与外加应力及结晶相的体积分数密切相关。一些实验[11-13]表明,合金中结晶相的断裂分数服从Weibull分布,即结晶相断裂的体积分数(Pf)可表示为

结晶相断裂的体积分数可表示为fj=fcPf,则式(8)可表示为

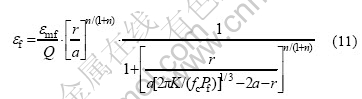

将式(10)代入式(7),可得

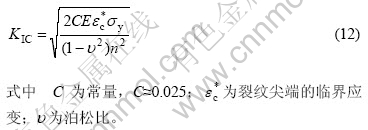

从唯象表达的角度,材料断裂韧性KIC与主裂纹尖端临界应变密切相关[17],可表示为

对于 与

与 之间的大致关系,不论是理论分析还是实验结果都证实[18],

之间的大致关系,不论是理论分析还是实验结果都证实[18], ≈

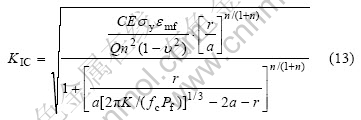

≈ /2,由此联立式(11)和(12)可得到断裂韧性的表达式为

/2,由此联立式(11)和(12)可得到断裂韧性的表达式为

结合式(11)、(13)以及实验研究,通过测量含不同结晶相含量和不含结晶相的材料的拉伸延性和断裂韧性,即可得到材料的相对拉伸延性和相对断裂韧性随结晶相含量的变化趋势。定义εf(0) 和KIC(0)为参考的拉伸延性与断裂韧性(即不含结晶相时材料的拉伸延性与断裂韧性),则用εf 除以εf(0)可以得到相对的拉伸延性;用KIC 除以KIC(0)可以得到相对的断裂韧性:

2 实 验

合金的化学成分为Al-8Cu-0.5Mg-0.2Mn,其中Mn用于细化晶粒。合金在充氩气的感应炉中熔炼而成,经450 ℃均匀化退火10 h后,然后空冷到室温。在450 ℃下锻造,变形系数为5.5。锻造后的合金采用两种固溶工艺处理:常规固溶和强化固溶。常规固溶工艺为450 ℃下固溶处理400 min;强化固溶工艺为450 ℃下固溶处理400 min,然后以5 K/h的速率将固溶温度升高至500 ℃。用KYKY-1000B型扫描电子显微镜(带能谱分析)分析两种固溶制度处理后样品中结晶相的分布与组成,用单轴拉伸实验测量拉伸延性,用紧凑拉伸实验测量断裂韧性,从而研究不同固溶工艺及结晶相含量对拉伸延性与断裂韧性的影响。

3 模型预测

3.1 外加应力对Al-Cu-Mg合金结晶相断裂分数的 影响

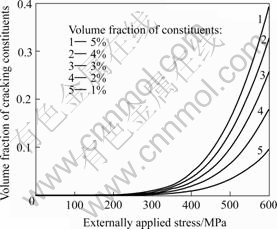

铝合金中的结晶相很脆,在外力作用下容易断裂而形成微裂纹。但是在外力作用下脆性结晶相并不 是全部断裂(即非预制裂纹),而是服从Weibull分 布[11-13]。对于热处理可强化的Al-Cu-Mg合金,其显微组织通常包含结晶相与析出相。其中析出相一般为在时效过程中析出的强化相Al2Cu(θ′)和Al2CuMg(S′),而结晶相通常为含Al、Si、Fe和Cu等元素形成的粗大的且强度较低的相。研究[10]表明: Al-Cu-Mg合金中的结晶相的断裂强度σf =437 MPa,Weibull常数m=5.8。由于铝合金中结晶相的含量通常较小(小于5%),作为一级近似,可以假定外加应力即是结晶相所受的力。因此利用式(9)可以计算出结晶相断裂分数与外加应力的关系。

图2所示为Al-Cu-Mg合金结晶相断裂分数与外加应力关系曲线。从图可以看出,当外加应力小于300 MPa时,结晶相基本上不发生断裂。当应力超过300 MPa时,结晶相的断裂分数急剧上升。同时还可以看出,结晶相的断裂分数与结晶相的总体含量有关。结晶相的总体含量越高,在相同外加应力下的断裂分数越高。这是由于当结晶相的含量较高时,结晶相之间的间距较小,在外加载荷下由于弹性模量差异在结晶相上形成的应力集中,将会相互叠加而增加结晶相所受的应力,从而增加结晶相断裂的可能性。

图2 Al-Cu-Mg合金中结晶相的断裂分数与外加应力的关系

Fig.2 Relationship between volume fraction of fractured constituents and externally applied stress in Al-Cu-Mg alloy

3.2 结晶相体积分数对Al-Cu-Mg合金拉伸延性及断裂韧性的影响

在Al-Cu-Mg合金中,结晶相通常为球形或近球形,因此形状因子K可取值为1。模型用到了一个参数r,它表示韧带区中某一点(用于模型的计算)距裂纹尖端的间距。当此处的有效应变达到基体的断裂应变时,材料发生断裂(拉伸延性)。关于r取值的问题,目前还没有定论。文献[19]指出,在一级近似的条件下,r可取两个相邻裂纹的中点,即r=l/2= (L-2a)/2。由于式(11)和(13)中的裂纹体积分数不能设置为零,假定结晶相体积分数为0.01%时材料不含裂纹(即假定含结晶相体积分数为0.01%的合金为参考材料)。

图3所示是结晶相体积分数对Al-Cu-Mg合金拉伸延性与断裂韧性的影响(结晶相尺寸为10 μm且保持不变),图中还包括一些早期的实验数据[10, 20-21]。从图可以看出,模型的计算值与实验数据吻合较好。拉伸延性和断裂韧性随着结晶相体积分数的增加而减小。这表明低纯度,或者高体积分数的结晶相将会降低铝合金的拉伸延性与断裂韧性。因此,纯化是有效提高铝合金拉伸延性与断裂韧性的方法。同时可以看出,在结晶相含量较低时,拉伸延性和断裂韧性随结晶相体积分数的增加迅速下降,随着结晶相体积分数的继续增加,下降的趋势变得平缓。

图3 结晶相体积分数对Al-Cu-Mg合金相对拉伸延性和断裂韧性的影响

Fig.3 Effects of volume fraction of constituents on normalized tensile ductility(a) and fracture toughness(b) of Al-Cu-Mg alloy

3.3 结晶相尺寸对Al-Cu-Mg合金拉伸延性及断裂韧性的影响

图4所示是结晶相尺寸对Al-Cu-Mg合金拉伸延性及断裂韧性的影响(以含体积分数为0.01%的结晶相为参考态,相邻结晶相的中心间距为100 μm且保持不变)。从图可以看出,结晶相的尺寸对Al-Cu-Mg合金的拉伸延性与断裂韧性有很大的影响。随着结晶相尺寸的增加,拉伸延性与断裂韧性急剧下降。在实际变形过程中,由于结晶相与基体弹性模量的差异将会在界面和结晶相上形成较大的应变集中,结晶相尺寸的增加,加剧应变集中,与较小的结晶相相比,更容易形成裂纹。并且裂纹的尺寸较大,即使在较低应力和应变下也很容易发生失稳扩展。早期的研究[22]表明,结晶相所受的力(σc)与结晶相尺寸(2a)的负二分之一成正比。因此,通过改善热处理工艺,减小结晶相的尺寸,可以有效地提高铝合金的拉伸延性与断裂韧性。实际上,当微裂纹之间的间距一定时,较大的裂纹尺寸对应着较大的裂纹体积分数,在相同的应力条件下对应着较大的裂纹张开位移与J积分,这种高能量状态很容易造成裂纹的失稳扩展,从而降低了合金的拉伸延性与断裂韧性。

图4 结晶相尺寸(间距保持不变)对Al-Cu-Mg合金相对拉伸延性与断裂韧性的影响

Fig.4 Effect of size of constituents (distance between constituents remains constant) on normalized tensile ductility and fracture toughness of Al-Cu-Mg alloy

4 分析与讨论

方程式(11)、(13)、(14)和(15) 的解析表明,合金的拉伸延性和断裂韧性随结晶相(裂纹体积分数)的增加而降低,因此采用合适的方法减少结晶相的含量可以减少微裂纹的含量,从而提高合金的拉伸延性和断裂韧性。因此研究结晶相的化学组成对有效控制结晶相的含量,从而提高合金的延性与韧性有重要意义。

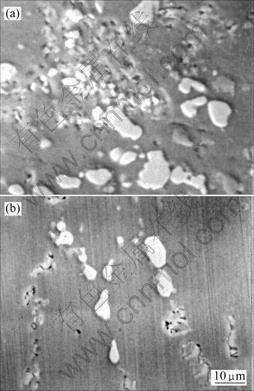

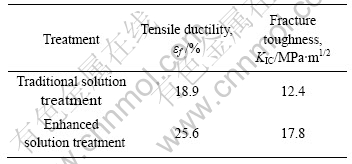

图5所示是Al-Cu-Mg合金经常规固溶及强化固溶处理后的显微组织。表1所列是Al-Cu-Mg合金经两种固溶制度处理后的拉伸延性与断裂韧性。从图可以看出,常规固溶处理后合金中的结晶相含量较高,尺寸较大;而强化固溶处理后合金中的结晶相含量较低,尺寸较小。这与早期的研究结果[23]类似,即通过强化固溶处理可以减少Al-Cu-Mg合金中结晶相的体积分数与尺寸,从而提高合金的拉伸延性与断裂韧性。能谱分析表明:这种结晶相的化学成分为Al(62.2%)-

图5 常规固溶(a)和强化固溶(b)处理后Al-Cu-Mg合金中的结晶相的形貌与分布

Fig.5 Morphology and distribution of constituents in Al-Cu-Mg alloy after traditional solution treatment(a) and enhanced solution treatment(b)

Si(11.5%)-Mn(10.3%)-Fe(10.1%)-Cu(5.9%)。由于Cu是主要的合金元素,而Mn是重要的晶粒细化剂,因此Al-Cu-Mg合金中的结晶相来源于杂质元素Fe和Si。减少原材料中Fe和Si元素的含量,提高铝基体的纯度,可以减少结晶相的体积分数。同时,通过强化固溶处理增加了合金的固溶程度,这种热处理工艺制度减少了结晶相的体积分数和尺寸,使得合金的拉伸延性从18.9%提高到25.6%,断裂韧性从12.4 MPa?m1/2提高到17.8 MPa?m1/2。因此,提高原材料的纯度是提高铝合金延性和韧性的根本方法,而强化固溶热处理可以改善铝合金的拉伸延性与断裂韧性。

表1 两种固溶处理对Al-Cu-Mg合金拉伸延性和断裂韧性的影响

Table 1 Effects of two solution treatments on tensile ductility and fracture toughness of Al-Cu-Mg alloy

5 结论

1) 建立了Al-Cu-Mg合金断裂韧性与拉伸延性的Weibull模型。模型的解析值与实验结果较为吻合。研究表明,外力作用下Al-Cu-Mg合金中的结晶相并未完全断裂,而是服从Weibull分布。当外加应力小于300 MPa时,结晶相基本上不发生断裂。当应力超过300 MPa时,结晶相的断裂分数急剧上升。

2) 模型的计算表明,结晶相的含量与尺寸对Al-Cu-Mg合金的拉伸延性与断裂韧性有很大的影响。拉伸延性与断裂韧性随着结晶相体积分数与尺寸的增加而减小。对铝基体的纯化以及强化固溶处理均可降低结晶相的体积分数与尺寸,从而提高Al-Cu-Mg合金的拉伸延性与断裂韧性。

REFERENCES

[1] Dumont D, Deschamps A, Brechet Y. On the relationship between microstructure, strength and toughness in AA7050 aluminum alloy[J]. Mater Sci Eng A, 2003, A356(3): 326-336.

[2] Deshpande N U, Gokhale A M, Denzer D K, Liu J. Relationship between fracture toughness, fracture path, and microstructure of 7050 aluminum alloy: Part I. Quantitative characterization[J]. Metall Mater Trans A, 1998, A29(4): 1191-1201.

[3] Gokhale A M, Deshpande N U, Denzer D K, Liu J. Relationship between fracture toughness, fracture path, and microstructure of 7050 aluminum alloy: Part 2. Multiple micromechanisms-based fracture toughness model[J]. Metall Mater Trans A, 1998, 29(4): 1203-1210.

[4] Gokhale A M, Patel G R. Quantitative fractographic analysis of variability in tensile ductility of a squeeze cast Al-Si-Mg base alloy[J]. Materials Characterization, 2005, 54(1): 13-20.

[5] Liu G, Zhang G J, Ding X D, Sun J, Chen K H. Dependence of fracture toughness on multiscale second phase particles in high strength Al alloys[J]. Materials Science and Technology, 2003, 19(6): 887-896.

[6] 刘 刚, 张国军, 丁向东, 孙 军, 陈康华. 含有不同尺度量级第二相的高强铝合金断裂韧性模型 [J]. 中国有色金属学报, 2002, 12(4): 706-713.

LIU Gang, ZHANG Guo-jun, DING Xiang-dong, SUN Jun, CHEN Kang-hua. A model for fracture toughness of high strength aluminum alloys containing second particles of various sized particles[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(4): 706-713.

[7] 宋 旼, 陈康华, 齐雄伟. 含有不同尺度微裂纹的铝合金伸长率模型[J]. 特种铸造与有色合金, 2007, 27(1): 3-6.

SONG Min, CHEN Kang-hua, QI Xiong-wei. A model for the tensile ductility of aluminum alloy with various-sized microcracks[J]. Special Casting & Nonferrous Alloys, 2007, 27(1): 3-6.

[8] Liu G, Zhang G J, Ding X D, Sun J, Chen K H. The influences of multiscale-sized second-phase particles on ductility of aged aluminum alloys[J]. Metall Mater Trans A, 2004, A35(6): 1725-1734.

[9] 陈康华, 齐雄伟, 宋 旼. 含两种尺度微裂纹的高强铝合金的断裂韧性模型[J]. 中国有色金属学报, 2006, 16(10): 1678-1683.

CHEN Kang-hua, QI Xiong-wei, SONG Min. Model of fracture toughness for high-strength aluminum alloy containing two-scale-size microcracks[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(10): 1678-1683.

[10] Liu G, Sun J, Nan C W, Chen K H. Experiment and multiscale modeling of the coupled influence of constituents and precipitates on the ductile fracture of heat-treatable aluminum alloys[J]. Acta Mater, 2005, 53(10): 3459-3468.

[11] Lewis C A, Withers P J. Weibull modeling of particle cracking in metal matrix composites[J]. Acta Metall Mater, 1995, 43(11): 3685-3699.

[12] Llorca J. An analysis of the influence of reinforcement fracture on the strength of discontinuously-reinforced metal-matrix composites[J]. Acta Metall Mater, 1995, 43(1): 181-192.

[13] Ramakrishnan N. An analytical study on strengthening of particulate reinforced metal matrix composites[J]. Acta Mater, 1996, 44(1): 69-77.

[14] Hutchinson J W. Singular behavior at the end of a tensile crack in a hardening material[J]. J Mech Phys Solids, 1968, 16(1): 13-31.

[15] Rice J R, Rosengrn G F. Plane strain deformation near a crack tip in a power-law hardening material[J]. J Mech Phys Solids, 1968, 16(1): 1-12.

[16] Kanninen M F, Popelar C H. Advanced fracture mechanics[M]. New York: Oxford University Press, 1985: 300.

[17] Garrett G G, Knott J F. The influence of compositional and microstructural variations on the mechanism of static fracture in aluminum alloys[J]. Metall Trans A, 1978, 9(5): 1187-1201.

[18] Staley J T. Properties related to fracture toughness[J]. ASTM, STP, 1975, 605: 71-85.

[19] Chan K S. A fracture model for hydride-induced embrittlement[J]. Acta Metall Mater, 1995, 43(12): 4325-4335.

[20] Walsh J A, Jata K V, Starke E A. The influence of Mn dispersoid content and stress state on ductile fracture of 2134 type Al alloys[J]. Acta Metall, 1989, 37(9): 2861-2869.

[21] King F. Aluminum and its alloy[M]. Chichester: Ellis Horwood Limited, 1987: 27-42.

[22] Cox T B, Low J R. Investigation of the plastic fracture of AlSi 4340 and 18 nickel 200 grade maraging steels[J]. Metall Trans, 1974, 5(7): 1457-1470.

[23] 张国军, 刘 刚, 丁向东, 孙 军, 陈康华. 含有不同尺度量级第二相的高强铝合金拉伸延性模型[J]. 中国有色金属学报, 2002, 12(1): 1-10.

ZHANG Guo-jun, LIU Gang, DING Xiang-dong, SUN Jun, CHEN Kang-hua. Model for tensile ductility of high strength Al alloys containing second particles of various sized scales[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(1): 1-10.

(编辑 袁赛前)

基金项目:国家高技术研究发展计划资助项目(2006AA03Z567);湖南省科技计划重点资助项目(06FJ2007)

收稿日期:2006-08-25;修订日期:2007-06-07

通讯作者:宋旼,副研究员;电话:0731-8877880;E-mail: msong@mail.csu.edu.cn