文章编号: 1004-0609(2006)06-1100-08

大型排土场细菌浸出新工艺

吴爱祥1, 王洪江1, 王 劼1, 2, 潘 伟1

(1. 中南大学 资源与安全工程学院, 长沙 410083; 2. 山东理工大学 资源与环境工程学院, 淄博 255049)

摘 要: 在浸出-萃取-电积工艺处理排土场物料过程中, 浸出是最薄弱的一个环节。 分析了排土场堆浸现行工艺中存在的问题, 阐释了细菌浸矿热量传递规律、 氧气传输规律, 提出了管注法浸出新工艺, 并用两个矿山实例来说明4种不同类型的排土场浸出新工艺设计原则。 研究表明: 排土场分层表面风化、 压实是渗透性差的原因, 堆内氧气不足、 温度变化幅度大直接影响到细菌的繁殖和浸矿效果; 采用水平渗透代替垂直渗透、 人工供气和控制浸堆温度是排土场强化浸出技术的核心; 采用管注法新工艺可使溶浸液覆盖率由30%提高到95%, 满足浸出反应所需氧量, 浸堆温度控制在15~40℃, 浸出液浓度提高2倍, 生产能力扩大3倍, 利润比旧工艺提高3.8倍。

关键词: 排土场; 管注浸出法; 浸出新工艺; 传热规律; 氧气传输规律 中图分类号: TD853.37

文献标识码: A

New techniques of bacterial leaching in large dump of copper mine

WU Ai-xiang1, WANG Hong-jiang1, WANG Jie1, 2, PAN Wei1

(1. School of Resource and Safety Engineering,Central South University, Changsha 410083, China;

2. School of Resource and Environmental Engineering,Shandong University of Technology, Zibo 255049, China)

Abstract: In the process of material in dump by L-SX-EW, leaching is the weakest link. The paper analyzed the question existing in the current technics of dump leaching, explained the rule of heat transfer and oxygen tranfer in bioleaching, offered the new technique of pipe-pouring leaching, and cased the two mine example to illuminate the design principe of new leaching technology used in four different kind dump. Studies have shown that the cause of weak permeation is weathering and compacting layer on the surface of dump, the influencing factor of bacterial breading and leaching effect are lack of oxygen and large varing range of temperature in dump. The core of the accelerating leaching technology are the level penetrating mode instead of vertival one, suppling oxygen by artifical draught and controlling temperature in dump. The new technics can raise the fraction of coverage of solution from 30% to 95%, meet the oxygen demand of leaching reaction, control temperature bewteen 15℃ and 40℃, increase lixivium density to 2 times, enlarge yield to 3 times, and heigthen profit to 3.8 times of the old one.

Key words: dump; pipe-pour leaching method; new leaching technique; heat transfer rule; oxygen tranfer rule

随着我国经济的不断发展, 矿产资源的开发力度也越来越大。 而开采条件较好、 品位高的矿产资源逐渐枯竭, 矿山低品位矿物开发利用日益迫切, 露天矿山排土场表外矿便是其中之一[1]。 在生物冶金工艺流程中的三大单元中, 萃取和电积工艺已经成熟, 而浸出环节相对薄弱[2], 是该项技术在露天矿山排土场应用中的主要障碍。

排土场特点是地形复杂、 堆体高度大、 矿石粒度变化范围宽、 品位低, 细菌浸出难度较大。 目前, 国内外大部分露天矿排土场浸出采用地表喷淋布液、 集液池收液工艺, 在生产实践中存在着布液不均匀, 渗透性差、 浸出浓度低等问题[3], 直接影响着浸出效果。 因此, 有必要对浸出率低下的原因进行分析, 并研究排土场浸出新工艺, 从根本上解决浸出工艺中存在的问题。

1 现行工艺存在的问题

排土场是露天矿堆置剥离的表外矿、 废石或表层土的场地。 排卸方式采用分层排卸, 分层高度一般为15~30m。 在汽车沿排土台阶外缘排卸过程中, 块石沿矿堆倾斜面向下滚落, 使整个矿堆粒度发生偏析。 顶部经汽车反复辗压和风化崩解, 散体块度变小, 压实度提高。 瑞典戴纳帕研究院进行的试验表明[4], 采用重型自卸式汽车经反复辗压后, 压实的影响深度为10~20m。

在浸堆表面, 由于粗颗粒受到较高的接触压力, 受挤压而破碎, 其中大于40mm的粗颗粒普遍压碎而含量降低[5]。 经压实后, 平均粒径减小, 导致岩石孔隙的平均水力半径也相应变小。 而在水力坡降相同的前提下, 渗流速度与孔隙平均水力半径的平方根成正比, 孔隙平均水力半径变小, 使浸堆渗透性变差。 同时, 渗流速度与孔隙率成正比。 当孔隙率在压实度提高而下降后, 渗流速度按同一比例减小, 渗透性变差。

正是由于堆体表面汽车辗压、 岩石风化造成厚度达分层高度一半的弱透水层的存在, 从而恶化了矿堆渗透均匀性。 另一方面, 在现有的地表布液工艺中, 溶浸液在浸堆内主要呈垂直下渗方式, 接近浸堆底板时, 以水平渗流方式沿垫层进入收集池内。 在两种不同的渗流方向上, 其渗流性能有较大差异, 即水平方向的渗流系数比垂直渗流系数高1~2个数量级[6]。 因此, 应充分利用浸堆散体的渗流特性, 以水平渗流方式为主, 研究新的浸出工艺, 从而提高浸出速率和回收率。

在现有的露天矿山排土场浸出工艺中, 由于喷淋强度较小, 溶浸液以非饱和流的形式在浸堆内流动。 非饱和流为空气在浸堆内的流动创造了前提条件, 空气从浸堆边坡的孔隙进入矿堆, 从矿堆表面流出, 构成从下向上的流动迹线, 在孔隙中与溶浸液形成逆向气液两相流。 自然对流方式使空气流量小, 供氧量远远低于矿堆完全浸出的需氧量, 这是排土场浸出速率低的内因之一。

在排土场浸出过程中, 细菌的浓度和活性比较低, 浸堆内温度不适合细菌生长, 夏天堆内上、 中、 下各部最高温度分别达45、 39和30℃, 冬天堆内相应部位最低温度是5、 9和8℃[7], 不利于细菌的发育繁衍, 成为阻碍该项技术进步的另一个内因。

2 浸堆内细菌浸矿的传热规律

根据能量守恒原理, 流入一个系统内的能量应等于从该系统中流出的能量。 在浸堆中, 热源即细菌浸出矿物所产生的热流量, 系统的散热流量由3个方面组成, 可认为产生的热流量等于散热流量, 用下列方程表示为

q0=q1+q2+q3(1)

式中 q0为化学反应热量; q1为浸堆吸热量; q2为浸堆散热量; q3为流体吸热量, J/(m3·s-1)。

2.1 细菌浸出矿物反应热流量

根据热力学第一定律, 化学热效应采用反应焓变值来表示。 单位时间单位体积内细菌浸出矿物的热流量值为

式中 Ci为浸堆内元素i的品位, %; αi为元素i的浸出率, %; ρ为矿石的密度, kg/m3; ΔHi为矿物i在标准状态下浸出反应的焓变值, kJ/mol; Mi为元素i的摩尔质量, g/mol; t为浸堆浸出周期, s。

在浸堆内, 除了目的矿物被浸出外, 其它矿物也参与浸出反应。 单位体积的总热流量可表示为

2.2 矿石吸热量

根据比热容的定义, 可推导出下式:

2.3 浸堆向大气散热流量

浸堆向大气散热量可简化为热面朝上的平板模型, 流动类型属于自然对流。

利用自然对流传热中广泛使用的准数方程, 求出努塞尔数Num值[8]:

式中 γ为气体的运动粘度, m2/s; β为气体膨胀系数, 1/K。

由下式计算出浸堆的对流换热系数:

式中 L为浸堆特征尺寸, m; λm为流体导热系数, J/(m·K·s)。

最终计算出浸堆向大气的散热流量:

式中 A为浸堆面积, m2; V为浸堆体积, m3。

2.4 浸堆需要调节的热流量

根据热量平衡原理, 由流体携带的热流量为:

2.5 浸堆内流体强制对流传热

浸堆需要调节的热流量即流体对流传热流量, 属于强制对流传热的范畴。

根据牛顿冷却公式可求出对流传热系数α3:

求出努塞尔准数Nu:

根据多颗粒群强制对流传热规律[9]、 传质与传热规律的相似性, 由传热公式可推出雷诺数Re为

并由雷诺数的定义可求出溶浸液流速:

3 浸堆内氧气传输规律

在细菌浸出体系中, 氧的需求量分为两个方面: 一是细菌自身繁殖的需氧量, 另一个是浸出反应的需氧量。 细菌自身繁殖需氧量较小, 一般为2~3mg/L。 而浸矿反应需氧量很大, 与氧的溶解度相差几个数量级[10]。

3.1 细菌浸出硫化矿反应需氧量

一般认为细菌浸矿作用机理为直接作用与间接作用的复合机理[11], 即在细菌及其中间产物Fe3+作用下, 硫化矿物被氧化为酸溶性的二价金属离子。 此时, 反应需要大量的氧作为氧化剂。 在所有的铜矿物中, 黄铜矿消耗氧量最大, 1mol黄铜矿的耗氧量为2mol。 故在相同条件下, 黄铜矿浸出速度最慢, 在铜矿物中最难浸出。

在硫化矿中, 一般伴生有黄铁矿, 黄铁矿被氧化的同时消耗大量的氧, 1mol黄铁矿的耗氧量为1.75mol。

从浸矿反应动力学角度讲, 黄铁矿浸出速度快于黄铜矿, 两者发生竞争性耗氧[12], 严重地影响了黄铜矿的浸出, 特别是那些黄铁矿与原生铜矿比率高的硫化矿。 随着黄铁矿与硫化铜矿的比例不同, 耗氧系数也不同, 如表1所列。

表1 黄铁矿含量与单位矿物耗氧系数关系

Table 1 Variance of pyrite content by oxygen consumption of leaching unit mineral

3.2 溶浸液内所需氧浓度

根据黄铜矿耗氧量以及浸出液浓度, 可按下式计算溶浸液内所需的氧浓度:

式中 c1为溶浸液内所需总氧浓度, mol/m3; ρ3为浸出液浓度, g/L; β0为单位矿物耗氧系数, mol/mol; M为铜的相对分子质量。

可见, 浸出反应所需氧浓度与浸出液浓度成正比, 当氧气不足时, 浸出液浓度必然低下。

3.3 氧气传递规律

根据扩散通量的定义, 可求出氧气在溶浸液内于矿石颗粒表面处的扩散通量为

从传质的唯象公式中, 可求出传质系数Kc:

在气泡向液膜传质过程中, 修吾德准数与气泡直径有关, 即:

根据气泡传质相似准则方程可求出气体流动的雷诺数[13]:

4 管注法浸出新工艺

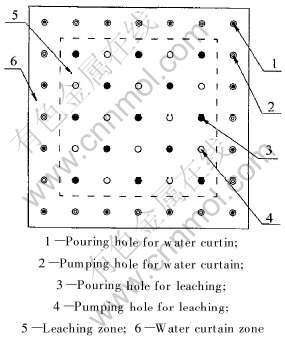

浸出新工艺是通过注液钻孔、 堆顶喷淋系统将溶浸液注入浸堆内, 浸出液由抽液钻孔抽至地表, 称其为管注浸出法[14], 如图1所示。

4.1 新工艺的特点

原地溶浸工艺就是采用钻孔系统将溶浸液注入到矿层中, 通过抽液系统将浸出液提升到地表。 但单纯将原地溶浸技术应用于排土场浸出, 在矿堆顶部、 边坡部位会出现浸出盲区。 因此, 厚大排土场浸出的合理技术途径还需要地表堆浸工艺辅助。

图1 堆浸地表喷淋与管注法联合工艺示意图

Fig.1 Sketch of coordinate process of spraying on ground and pipe pouring in dump

浸出新工艺针对不同的排土场可采取不同的方案, 使溶浸液在堆内分布覆盖到各个部位; 氧气与溶浸液输送共用一条管道, 并满足细菌代谢与浸出反应所需的耗氧量; 通过溶浸液流量来调节堆内反应产生的热量, 使浸出温度处于适合细菌生长的范围内; 改善细菌繁殖的外部环境, 使细菌能够快速更替, 增强细菌的活性, 提高细菌的浓度, 可从根本上提高浸出速率和浸出回收率。

4.2 布液系统

地表布液系统有两种: 喷淋和滴淋系统, 其中后者是其发展方向。

堆内布液采用钻孔布液方式, 考虑不同类型的钻孔在生产中经常需要互换, 所有钻孔直径应统一。 钻孔为垂直孔, 最大允许斜度在100m内不超过1.5°。

钻孔在施工中, 须下套管来保护钻孔。 在套管壁上均匀钻凿一系列直径为1~2mm的小眼, 使套管与过滤器构成一个整体。

4.3 收液系统

采用钻孔系统作为收液系统。

对于浸堆高度小于30m的排土场, 采用潜水泵提升方式。 此时钻孔偏斜量容易控制, 并可适当放大钻孔网度。

浸堆高度大于30m的排土场, 空气提升方式适应性强, 因为此时浸出周期长, 浸堆厚大需要较大的钻孔密度, 浸出液较高的含砂浓度持续时间长, 空气提升虽然能耗大、 效率低, 但设备维修量小、 使用寿命长。

5 浸出新工艺强化浸出技术

为了使浸出环境适应于细菌的生长, 必须采用措施调节堆内氧气量及反应环境温度。

5.1 氧气的供应

在厚大排土场浸出过程中, 于每个注液钻孔内安装独立的氧气注入管路, 注入管末端安装气液混合器, 让氧气更充分地与溶浸液混合, 形成大量微小气泡。 气泡随溶浸液在孔隙内流动, 被颗粒表面吸附, 并发生崩溃现象。 空泡溃灭时将在空泡周围的极小空间内出现热点, 产生瞬时的高温(约5200K)和高压(50MPa以上), 并能形成强烈的冲击波和速度高达100m/s以上的微射流[15]。 在此复杂的条件下, 氧的溶解量大大增加, 满足了化学浸出的需氧量。

5.2 温度的调节

夏季, 为了使浸堆内温度不超过40℃, 必须加大溶浸液的流速, 将反应产生的热量迅速带出浸堆, 避免热量在散体颗粒表面聚集。

冬季, 由于气温的影响, 此时, 需要提高溶浸液的温度并加大溶浸液的流速, 将热量传递给散体颗料。 冬季浸堆温度的升高主要靠细菌浸矿来提供热量, 人工调温只是激发反应进程的一个手段。

5.3 溶浸液的输送

一般情况下, 喷淋强度为8~12L/(m2·h), 流体雷诺数为0.6, 溶浸液运动状态属于层流。 当根据工程传热要求加大溶浸液的速度后, 溶浸液运动状态变为过渡流状态。 一旦溶浸液渗流状态进入紊流区(Re>80), 单靠重力作用输送溶浸液已不可能, 必须采用加压泵送方式才能抵消过大的渗流阻力。

6 工程设计实例

影响排土场浸出工艺的主要因素有矿区气候和排土场服役现状。 矿区处于南方, 则温暖潮湿, 有利于细菌浸出的进行, 而北方矿区气候寒冷干燥, 浸出条件较差。 正在服役的排土场, 其分层排土工序与堆体表面浸出系统的布置相互干扰, 关闭之后的排土场浸出设施可以一次设置不再变动。 白银露天矿排土场和德兴铜矿排土场是两个较为典型的铜矿排土场, 前者属于气候寒冷干燥的退役排土场, 后者属于温暖潮湿的服役排土场。

6.1 白银露天矿排土场

白银露天矿矿区位于祁连山脉北山东端山区, 为典型大陆性气候, 干旱少雨, 温差大, 春秋短冬夏长。

由于地处北方干旱地区, 地表布液系统采用滴淋方式。 滴水器采用孔口消能滴头, 溶液通过干管、 支管和毛管, 从分布在毛管上的滴头流出。 干、 支管道采用PVC管, 管径分别在150~250mm、 50~100m之间。 毛管采用PE管, 管径在10~20mm之间。

钻孔采用牙轮钻机向下钻凿而成, 孔径250mm, 孔深到排土场底板。 钻孔形成后, 孔内插入套管, 材质为增强厚壁PVC管, 内径为150mm, 壁厚为15mm。 沿套管全长四周均布直径为4mm小眼, 孔隙率为20%, 套管兼作过滤管。 在距孔口2m处设置一人工隔塞, 并采用速凝水泥进行封口。

布孔方式采用梅花形, 即注液孔与抽液孔间隔布置, 孔距与排距相等, 均等于钻孔水力影响半径的倍。 注液孔与抽液孔可定期互换, 有利于减小注液孔周围的堵塞现象, 改善浸堆的渗透性。

由于排土场规模较大, 需划分矿块进行有序生产。 每个矿块周围采用水幕来控制溶浸液流动范围, 即在矿块周围布置一排孔, 以清水为介质, 在注液孔注入, 由抽液孔抽出, 防止溶浸液向矿块外渗流, 如图2所示。

图2 浸出区周围水幕布置示意图

Fig.2 Sketch of water curtain laying around leaching area

对于白银露天矿排土场, 浸堆温度控制主要是如何提高溶浸液温度。 冬季, 排土场浸出以堆内布液为主, 地表滴淋装置可拆卸并检修。 集液池设置在室内, 冬季采用工业余热将循环液温度控制在25℃左右。 在室外输送管道上加石棉绝热层进行保温, 使浸堆温度高于10℃。

在注液孔内插入压气管, 材质均为PVC管。 在压气管的的末端安装气液混合器[15], 此混合器上分布有直径为1~2mm的小孔, 孔隙率为20%。 气液混合器应插入孔底, 此处压力高, 氧气溶解度最大。

6.2 德兴铜矿排土场

德兴铜矿位于江西省东北部, 属于亚热带气候, 潮湿多雨, 温差小。

德兴铜矿排土场地表喷淋系统仍保留, 在此基础上再增设一套堆内布液、 收液系统即可。

与关闭排土场不同之处在于, 服役的排土场布液系统始终随着排土场的排放而逐渐形成。 在已形成的排土场分层内, 钻凿大直径深孔, 具体工艺与关闭排土场相同。 排土场在继续排卸废石的同时, 采取价格低廉的水泥管构成抽、 注液孔。 水泥管内径为250mm, 壁厚为50mm。 水泥管外侧预留直径为10mm的小孔作过滤孔, 孔隙率仍控制在20%以内。 为了便于施工, 水泥管采用倾斜方式铺设, 其倾角与排土场边坡倾角一致, 如图3所示。

图3 服役排土场浸出管道布置示意图

Fig.3 Sketch of leaching pipe layout in dump being on active

在生产孔内, 除了设置用于空气提升浸出液所用的压气管外, 还需设置一条用于向浸堆供气的管道, 材质均为PVC管。 空气提升管直径为50mm, 插入孔内液面下方10m左右即可, 保持沉没比为0.4~0.5。 而供气管直径为25mm, 外表面分布1~2mm小孔, 插入深度直到孔底为止。

在浸堆的监测孔内, 可安装一系列的热电偶对浸堆内的温度进行实时监测, 并且温度控制的重点在于对浸堆降温。 若温度超过40℃, 通过加大地表喷淋量或加快溶浸液的循环流量, 把反应产生的热量及时带出浸堆, 防止热量在堆内聚集。

7 经济技术指标

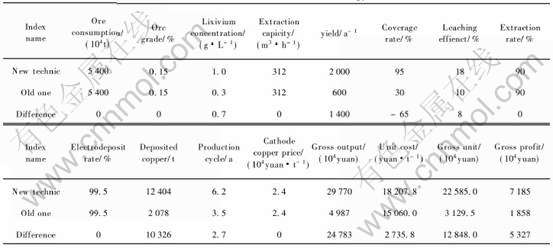

以德兴铜矿堆浸厂为例, 进行新旧工艺经济指标对比, 以一个浸出单元矿量为基准, 面积为500m×500m, 高度为80m, 预测经济效益如表2所示。 采用新工艺后, 能够较快地达到设计指标, 与旧浸出工艺相比, 浸出浓度提高了2倍, 生产能力增大3倍。 新工艺可以对堆中95%的矿石进行浸出, 浸出铜量提高6倍, 生产周期由3.5年延长至6.2年。 新工艺生产成本高于旧工艺, 致使单位利润比旧工艺的低, 但由于回收的金属量增加了, 总产值上升幅度较大, 总利润比旧工艺的高3.8倍。

表2 新工艺预测效益与旧工艺的对比

Table 2 Forecasted economic benefit of new technology contrast with old one

8 结论

1) 在排土场形成过程中, 由于矿堆粒度的偏析、 表面风化、 汽车辗压造成一厚度较大的弱透水层的存在, 是排土场浸透均匀性变差的主要原因。 堆内氧气不足, 直接影响到细菌的繁殖以及浸矿速率。 堆内温度随气温变化幅度过大, 致使细菌生长环境恶化, 浸出效率低下。

2) 排土场强化浸出技术主要是从供氧和调节堆内温度两方面进行。 供氧采用压气方式通过气液混合器供给, 气体随溶浸液一起在浸堆内流动, 在矿物颗粒表面被吸附、 崩溃而释放。 堆内温度调节以反应放出的热量为控制对象, 以堆内温度监测为手段, 通过地表布液系统的生产或关闭、 钻孔溶浸液流量的加大或减小、 溶浸液本身温度的调整, 控制反应进程的快慢。

3) 对于已关闭的排土场, 浸出设备设施可一次布设而成, 抽液设备采用潜水泵。 对于正在服役的排土场, 浸出设施必须分次设置, 钻孔采用水泥管顺坡构成, 抽液设备以空气提升方式主。 南方排土场地表布液系统采用喷淋方式, 堆内温度主要控制高温的生成。 北方排土场则采用滴淋方式进行布液, 温度控制以提高堆内温度为主。

REFERENCES

[1]Murr L E. Theory and practice of copper sulphide leaching in dumps and in-situ[J].Min Sci Eng, 1980, 12(3): 121-189.

[2]李广胜. 综合利用酸性废水浸出含铜废石的分析[J]. 有色矿山, 1995(4): 57-61.

LI Guang-sheng. The analysis on leaching lower grade copper ore by synthetic utilization to acidic waste water[J]. The Nonferrous Mine, 1995(4): 57-61.

[3]刘久清. 德兴铜矿湿法炼铜工艺现状及存在问题[J]. 湿法冶金, 2003, 20(3): 123-127.

LIU Jiu-qing. Status and problems of copper hydrometallurgy in Dexing Copper Mine[J]. Hydrometallurgy of China, 2003, 20(3): 123-127.

[4]郭庆国. 粗粒土的工程特性及应用[M]. 郑州: 黄河水利出版社, 1998.

Guo Qing-guo. The Engineering Characteristic and Application of Coarse Grained Soil[M].Zhengzhou: Yellow River Water Conservancy Press, 1998.

[5]屈智炯, 何昌荣, 刘双光, 等. 新型石渣坝——粗粒土筑坝的理论与实践[M]. 北京: 中国水利水电出版社, 2002.

QU Zhi-jiong, HE Chang-rong, LIU Shuang-guang, et al. The Theory and Practice About the New Type of Mullock—Coarse Grained Soil Dam[M]. Beijing: China Irrigation and Hydroelectricity Press, 2002.

[6]郭熙灵, 李思慎. 水布垭水利枢纽页岩风化料击实和渗透特性试验研究[J]. 人民长江, 1996, 27(12): 18-21.

GUO Xi-ling, LI Si-shen. Compaction and permeability tests of weathered shale material[J]. Yangtz River, 1996, 27(12): 18-21.

[7]彭琴秀. 德兴铜矿含铜废石细菌浸出试验研究[J]. 湿法冶金, 2002(6): 83-87.

PENG Qin-xiu. Tests on bioleaching of copper from waste ore at dexing copper mine[J]. Hydrometallurgy of China, 2002(6): 83-87.

[8]梅炽. 冶金传递过程原理[M]. 长沙: 中南工业大学出版社, 1987.

MEI Chi. Metallurgical Transmittance Process Principle[M]. Hunan Changsha: Central South University of Technology Press, 1987.

[9]林瑞泰. 多孔介质传热传质引论[M]. 北京: 科学出版社, 1995.

LIN Rui-tai. The Porous Medium Conducts Heat and Spreads the Quality to Guide the Theory[M]. Beijing: Science Publishers, 1995.

[10]魏德洲. 资源微生物技术[M]. 北京: 冶金工业出版社, 1996.

WEI De-zhou. Resource Microorganism Technology[M]. Beijing: Metallurgy Industry Press, 1996.

[11]Boon M. Short communication: The mechanism of ‘direct’ and ‘indirect’ bacterial oxidation of sulphide minerials[J]. Hydrometallurgy, 2001, 62: 67-70.

[12]Bartleet R W. Solution Mining: Leaching and Fluid Recovery of Materials[M]. Gordon and Breach Scirnce Publishers, 1998.

[13]Sherwood T K, Pigford R L, Wilke C R. 传质学[M]. 时钧, 译. 北京: 化学化工出版社, 1988.

Sherwood T K, Pigford R L, Wilke C R. Mass Transfer[M]. SHI Jun, transl. Beijing: Chemistry Industry Press, 1988.

[14]王洪江, 吴爱祥, 李青松. 大型铜矿排土场浸出技术中几个亟待解决的关键问题[J]. 矿冶工程, 2004, 19(2): 15-19.

WANG Hong-jiang, WU Ai-xiang, LI Qing-song. Several key questions settled urgently on leaching technology in large copper mine dump pit[J]. Mining and Metallurgical Engineering, 2004, 19(2): 15-19.

[15]张凤华, 廖振方, 唐川林, 等. 空化水射流的化学效应[J]. 重庆大学学报, 2004, 27(1): 32-35.

ZHANG Feng-hua, LIAO Zhen-Fang, TANG Chuan-lin, et al. The chemical effects of cavitating water jets[J]. Journal of Chongqing University, 2004, 27(1): 32-35

[16]王海峰, 谭亚辉, 杜运斌, 等. 原地浸出采铀井场工艺[M]. 北京: 冶金工业出版社, 2002.

WANG Hai-feng, TAN Ya-hui, DU Yun-bin, et al. The Drilling Site Techniques of In-situ Leaching Uraniu[M]. Beijing: Metallurgical Industry Press, 2002.

基金项目: 国家重点基础研究发展规划资助项目(2004CB619205); 国家杰出青年基金资助项目(50325414); 国家创新群体基金资助项目(50321402)

收稿日期: 2005-09-12; 修订日期: 2005-11-22

通讯作者: 王洪江, 高级工程师; 电话: 0731-8830851; E-mail: hjw473@sohu.com

(编辑陈爱华)