文章编号:1004-0609(2013)05-1269-06

晶界滑移对镍基合金失延开裂的影响

崔 巍,陈静青,陆 皓,陈俊梅

(上海交通大学 材料科学与工程学院,上海 200240)

摘 要:为了研究镍基合金焊材FM-52M的高温失延裂纹(DDC),采用改进的应变-裂纹(STF)实验方法,提出新的裂纹敏感性判据——晶界滑移量。并将之与裂纹数量相结合定量评估不同温度、不同变形量条件下材料的DDC敏感性。结果表明:本研究中所得到的材料临界变形量6%大于传统STF方法得到的4%的临界变形量。预热处理、峰值温度、变形速率等条件都能显著影响DDC的敏感性。此外,利用显微硬度标记了许多微区,并对实验前后的微区进行了SEM观察,探讨晶界滑移与析出物在DDC的萌生与扩展过程中的作用。

关键词:晶界滑移;高温失延裂纹;镍基合金

中图分类号:TG116 文献标志码:A

Influence of grain boundary sliding on ductility-dip cracking of Ni-based alloy

CUI Wei, CHEN Jing-qing, LU Hao, CHEN Jun-mei

(School of Materials Science and Engineering, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: According to the improved strain-to-fracture test (STF) method, the value of grain boundary sliding was used as a new criterion to evaluate the susceptibility of ductility-dip cracking (DDC) in Ni-based alloy filler metal 52M(FM-52M) under various temperature and deformation conditions. The results show that the threshold strain of the test is 6%, which is larger than 4% obtained by previous STF method. Heat pretreatment, peak temperature, strain rate all have a great influence on the DDC susceptibility. Microhardness was used to mark interested micro-regions, from which SEM images were made before and after the test in order to explain the roles of grain boundary sliding and precipitates in DDC.

Key words: grain boundary sliding; ductility-dip cracking; Ni-based alloy

迄今为止,核能发电已经得到广泛应用,核电设备的许多部件属于锻焊结构,常常在高温、高压、腐蚀、动载和辐射等多种恶劣环境并存的条件下工作,因此,对焊接接头的要求很高。在诸多核电金属材料中,Ni-Cr-Fe系列固溶强化合金因具有良好的高温力学性能以及优异的抗腐蚀能力,常被用于核电设备的关键部件。然而,近期研究发现,这类材料对高温失延裂纹(DDC)非常敏感[1-4]。

DDC是一种发生在固相线以下某一温度区间(通常为熔点温度的0.5到0.8倍)的沿晶裂纹。材料在这一温度区间表现出很低的延塑性,在高拘束焊接中极易出现微裂纹。由于DDC尺寸较小,很难被常规的检测方法检测,所以潜在危害很大。由NISSLEY等[5]提出的基于Gleeble热模拟机的STF实验方法是目前应用最广泛的DDC研究方法。通过比较不同温度、不同变形量条件下的裂纹数量和长度来确定材料的DDC敏感性。影响DDC敏感性的因素很多,包括合金体系、第二相析出物、晶粒尺寸、杂质元素的偏析、变形速率、晶界与力的角度关系等[6-10]。因此,DDC产生的机理十分复杂,目前仍存在3种假说:碳化物诱导裂纹机理[11]、杂质元素偏聚机理[12-13]和晶界滑移机理[14-17]。

为此,本文作者采用改进的STF实验方法,以晶界滑移量为判据,研究温度、预热处理、峰值温度和变形速率对镍基合金DDC敏感性的影响。并借助SEM探讨晶界滑移和析出物在DDC中的作用。

1 实验

1.1 实验材料

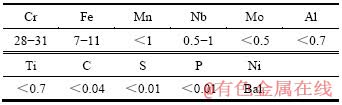

实验材料为FM-52M(ERNiCrFe-7A)合金,其成分如表1所列。

表1 FM-52M材料的化学成分

Table 1 Chemical composition of FM-52M material (mass fraction, %)

1.2 试样制备

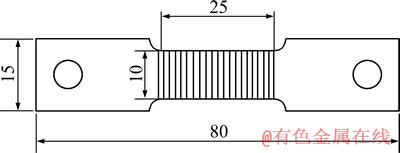

通过TIG焊将FM-52M焊丝堆焊在厚度为10 mm的碳钢上,堆焊层厚度约为9 mm。然后,用线切割取距表面3 mm的堆焊层,并加工成STF的拉伸试样,如图1所示。

图1 STF试样尺寸

Fig. 1 Dimensions of STF specimen (unit: mm)

为研究析出物对晶界滑移以及DDC敏感性的影响,在750 ℃下对部分试样进行5 h的预热处理。在此温度和时间下保温的样品没有明显的晶粒长大,但满足析出物析出的条件。

STF试样经过粗磨、抛光后,用细砂纸沿拉伸方向划线,作为观察晶界滑移的刻线。之后,用高铬酸进行电解腐蚀。

传统的STF法通过引伸计测量标距内的平均变形,但Gleeble热模拟机采用电阻法加热,试样上存在明显的温度梯度,试样中心的均温区(温差在20 ℃以内)只有4 mm,这时引伸计测定的变形已经不能反映均温区内的变形。为了获得局部变形量,需用激光在试样中间沿垂直于拉伸方向每隔1 mm划线,将标距段细分成20个条状区域,并分别编号,如图1所示。用激光打标法代替传统的引伸计可以很精确地得到每个条状区在实验中的变形。

均温区变形量由宏观显微镜标出,为均温区内变形最大的3个条状区的平均值;裂纹数量在光学显微镜下统计,为上述3个区裂纹数量的总和;晶界滑移量在SEM下标出,为上述3个区中所有晶界滑移量的平均值。

为了研究DDC起裂的机理,本研究中在显微观察方面也进行了改进,用显微硬度在试样上标记一些微区,便于实验前后对相同微区进行金相和SEM观察。

1.3 STF实验设计

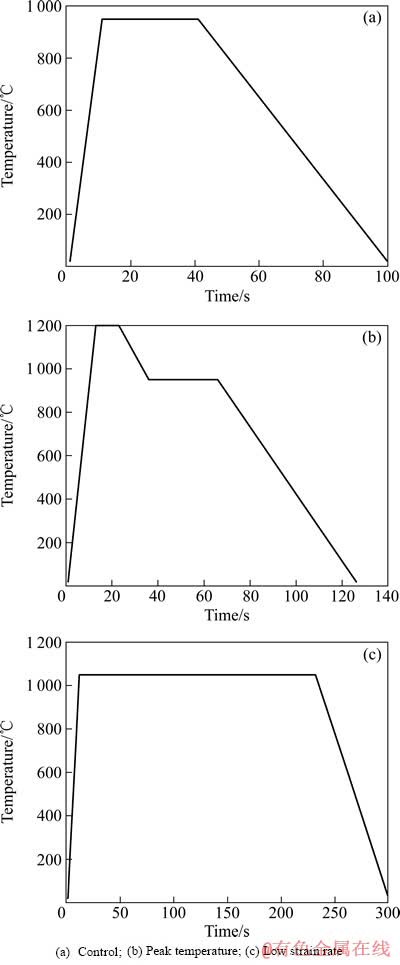

实验在Gleeble 3500热模拟机上进行,主要有3种实验方案,如图2所示。

1) 直接升温到指定温度后以0.1 mm/s的变形速率加载(图2(a))。

2) 先升温到1 200 ℃,保温10 s,再降温到950 ℃进行加载(图2(b))。

3) 升温到1 050 ℃后以3 μm/s的变形速率加载(图2(c))。

2 实验结果

2.1 STF实验结果

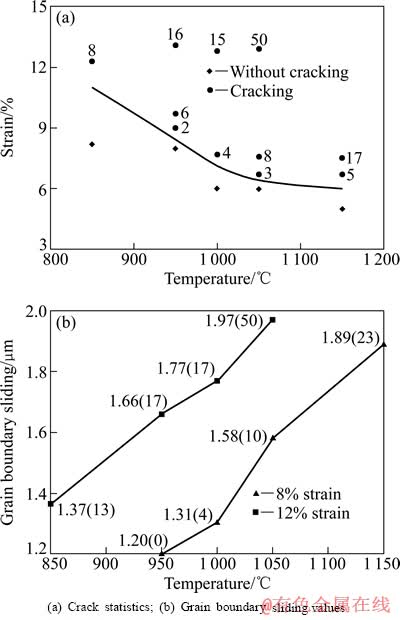

图3(a)所示为裂纹与温度和变形量的关系(括号外数据为晶界滑移量,μm;括号内数据为裂纹数量)。由图3(a)可以看出,裂纹最敏感的温度区间是1 000~1 150 ℃。裂纹开裂的临界变形量为6%。由于局部变形量测量的引入,实验结果比传统STF实验方法下得到的临界变形量4%大。

图3(b)所示为晶界滑移量随温度的变化曲线(括号外数据为晶界滑移量,μm;括号内数据为裂纹数量)。图3(b)中每个实验点的上方都标出了晶界滑移量和裂纹数量。当变形量相同时,温度越高,晶界滑移量越大。因为随温度的升高,晶界强度比晶内强度下降的快,晶界滑移更容易发生。此外,不同温度下材料对晶界滑移的敏感性也不同。温度越高,出现裂纹的临界晶界滑移量越大。一方面是因为受力的不同,要达到相同的晶界滑移量,低温时需要更大的外力驱动;另一方面是晶粒内部对晶界滑移的协调能力不同,温度越高,位错运动越活跃,晶界滑移导致的应变集中能够更好地被转移。

图2 STF实验示意图

Fig. 2 Schematic diagrams of STF process

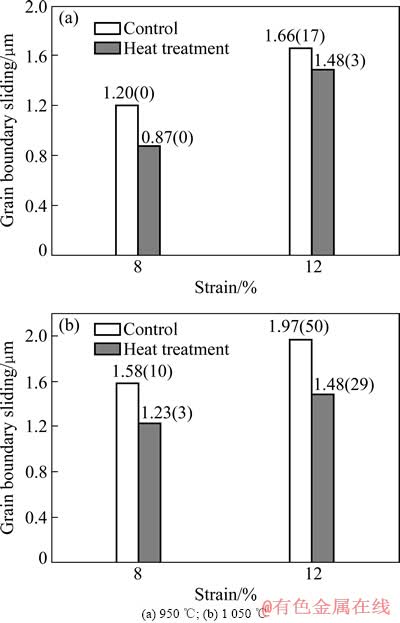

2.2 热处理对晶界滑移的影响

由于FM-52M是单相奥氏体组织,析出物对材料性能的影响很大。在本研究中采用两种试样,一种是未经热处理,称为原试样;另一种是热处理试样(750 ℃,5 h)。图4 (a)所示为950 ℃时8%和12%两种变形量下原试样和热处理试样晶界滑移量的对比(括号外数据为晶界滑移量,μm;括号内数据为裂纹数量);图4(b)所示为1 050 ℃的对比结果。由图4可以看到,热处理试样的晶界滑移量和裂纹数量都小于原试样的晶界滑移量和裂纹数量。这表明晶界析出物可以阻碍晶界滑移,降低DDC的敏感性。

图3 STF实验结果

Fig. 3 STF results

图4 不同热处理温度对晶界滑移量的影响

Fig. 4 Influence of heat treatment on grain boundary sliding at different temperatures

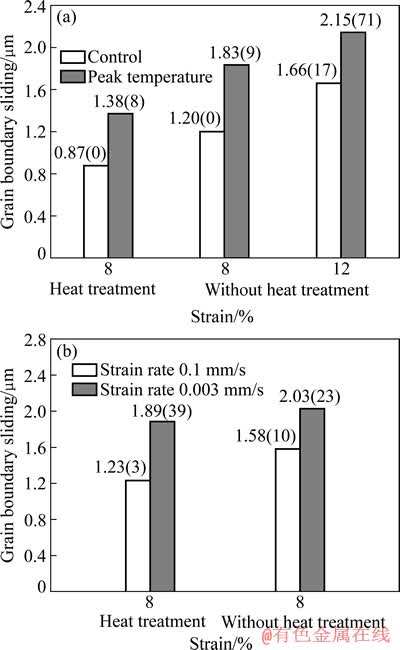

2.3 峰值温度对晶界滑移的影响

图5(a)所示为950 ℃下两类试样在升温阶段和降温阶段加载时晶界滑移量和裂纹数量的对比。由图5(a)可以看到,降温阶段加载的试样晶界滑移量和裂纹数量都远远大于升温阶段加载的试样晶界滑移量和裂纹数量,它们的区别主要体现在是否经历峰值温度。降温阶段加载的试样在1 200 ℃下保温后,晶界上会有部分析出物重新分解,使得材料的晶界弱化。

2.4 变形速率对晶界滑移的影响

图5(b)所示为1 050 ℃下变形速率对晶界滑移的影响。变形速度越小,材料的晶界滑移量和裂纹数量越大。慢速拉伸对热处理试样的影响尤其明显,晶界滑移增加了0.66 μm,裂纹数量从3条增加至39条。一方面,慢速拉伸需在1 050 ℃停留210 s,此时会有大量析出物发生重溶,使晶界脆化;另一方面,当变形速度减慢时,扩散的影响变大,材料的失效更接近于蠕变的机制[18]。

3 分析与讨论

3.1 晶界滑移的作用

在DDC产生过程中,晶界滑移有两个主要作用。

图5 峰值温度和变形速率对晶界滑移的影响

Fig. 5 Influence of peak temperature (a) and strain rate (b) on grain boundary sliding

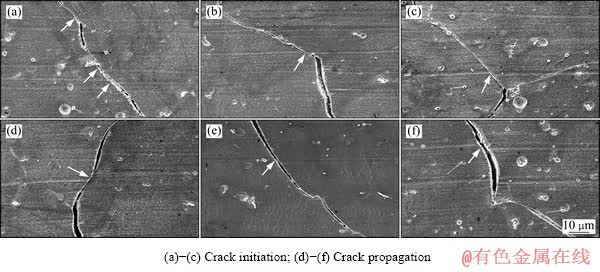

首先,在外力作用下,晶界上发生Rachinger滑移,晶界两边的晶粒产生相对位移,如果此过程无法得到协调,那么会在局部区域产生缺陷,进而转化成裂纹源。图6 (a)中的晶界较为平直,微裂纹易在结合力弱的晶界处出现;图6(b)中的裂纹出现在晶界拐点处,晶界滑移在此处受阻,从而产生应变集中;图6(c)中晶界滑移到三叉晶界处后被迫停止,产生应变集中,裂纹常在临近的晶界上形核。

图6 晶界滑移产生裂纹的机理

Fig. 6 Crack formation mechanism of grain boundary sliding

其次,在沿晶裂纹的扩展过程中,晶界主要受垂直于晶界的拉应力和平行于晶界的剪切应力作用。当晶界与外力方向垂直时,拉应力达到最大,裂纹的张开位移较大;当晶界与外力方向呈45°角时,切应力最大,裂纹的张开位移较小,此时裂纹尖端的晶界会在剪切力的作用下发生滑移,促使裂纹向下一个敏感区域扩展。图6(d)中的裂纹从下向上扩展,中间的晶界没有开裂,但通过晶界滑移使裂纹在上方晶界得到延续。图6(e)中虽有析出物阻碍了裂纹扩展,但裂纹仍可通过晶界滑移,绕过析出物继续扩展。图6(f)中,裂纹受到晶界拐点和析出物的双重抑制,停止扩展。

可见,晶界滑移在DDC中发挥非常重要的作用,它不仅可以定量评估DDC敏感性,也是DDC起裂的重要机理之一。为减轻晶界滑移的影响,一方面可以通过改善材料对晶界滑移的协调作用,消除局部应变集中;另一方面可以通过添加微量元素,改变晶界形貌、增加晶界上析出物的数量,从而阻碍晶界滑移。

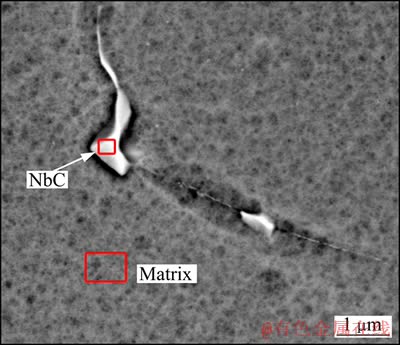

3.2 析出物的作用

图7 析出相的EDS能谱分析

Fig. 7 EDS analysis of precipitates

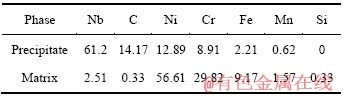

表2 析出相元素分析结果

Table 2 Elemental analysis results of precipitates (mass fraction, %)

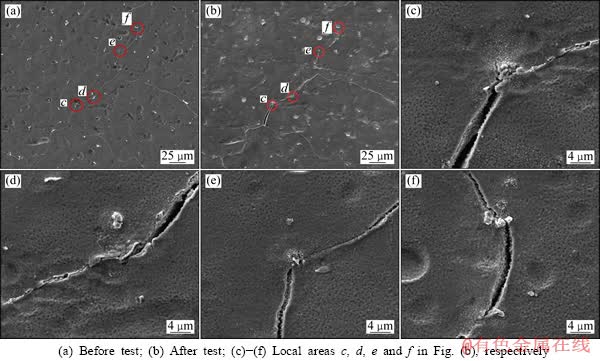

图8 实验前后析出物的SEM像

Fig. 8 SEM images of precipitates and cracking

如图7所示,FM-52M中主要析出物是NbC。经热处理后,晶界上析出物的数量明显增加。析出物的EDS能谱分析结果如表2所列。图8 (a)和(b)所示为热处理试样STF实验前后的SEM像。图8(c)~(f)分别是图8(b)中红圈区域的放大图。析出物对DDC的影响较为复杂。一方面,析出物会阻碍晶界滑移和沿晶裂纹的扩展,如图8(c)所示;另一方面,如果局部应变过大,部分与晶界结合力较弱的析出物反而会转变为新的裂纹源,如图8(d)~(f)所示。

4 结论

1) 采用改进的STF实验方法获得的临界变形量为6%,大于传统STF法得到的临界变形量4%。

2) 以晶界滑移量为判据研究温度、预热处理、峰值温度和变形速率对DDC的影响,结果表明析出物具有阻碍晶界滑移的作用。若试样在1 050 ℃以上停留时,部分析出物会重新分解,进而增强DDC的敏感性。

3) 当晶界上析出物较少时,晶界滑移非常严重,裂纹易在结合力弱的晶界处、晶界拐点处以及三叉晶界处出现;当晶界析出物的数量较多时,晶界滑移和裂纹扩展都受到了一定的抑制,但是,如果应变集中进一步增大,与晶界结合力弱的析出物又会转变成新的裂纹源。

REFERENCES

[1] 吴 伟, 陈佩寅, 张 锐. 镍基焊接材料DDC裂纹的研究现状及研究趋势[J]. 焊接, 2005(5): 5-8.

WU Wei, CHEN Pei-yin, ZHANG Rui. Development and research on ductility-dip cracking of filler metals of Ni-based alloy[J]. Welding and Joining, 2005(5): 5-8.

[2] RAMIREZ A J, LIPPOLD J C. High temperature behavior of Ni-base weld metal. Part 1: Ductility and microstructural characterization[J]. Materials Science and Engineering A, 2004, 380(1): 259-271.

[3] RAMIREZ A J, LIPPOLD J C. High temperature behavior of Ni-based weld metal. Part 2: Insight into the mechanism for ductility dip cracking[J]. Materials Science and Engineering A, 2004, 380(1): 245-258.

[4] 陈俊梅, 陆 皓, 陈静青, 崔 巍. 镍基合金焊缝DDC裂纹形成机制和调控研究进展[J]. 焊接, 2012(4): 7-13.

CHEN Jun-mei, LU Hao, CHEN Jing-qing, CUI Wei. Formation mechanism and control of ductility-dip cracking in the weldment of Ni-based alloy[J]. Welding and Joining, 2012(4): 7-13.

[5] NISSLEY N E, LIPPOLD J C. Development of the strain-to-fracture test: A new test has been established for evaluating ductility dip cracking susceptibility in austenitic alloys[J]. Welding Journal, 2003, 82: 355-364.

[6] NISSLEY N E, LIPPOLD J C. Ductility-dip cracking susceptibility of nickel-based weld metals. Part 1: Strain-to-fracture testing[J]. Welding Journal, 2008, 87: 257-264.

[7] NISSLEY N E, LIPPOLD J C. Ductility-dip cracking susceptibility of nickel-based weld metals. Part 2: Microstructural characterization[J]. Welding Journal, 2009, 88: 131-140.

[8] COLLINS M G, LIPPOLD J C. An investigation of ductility dip cracking in nickel-based filler materials—Part 1[J]. Welding Journal, 2003, 82: 288-295.

[9] COLLINS M G, LIPPOLD J C. An investigation of ductility dip cracking in nickel-based filler materials—Part 2[J]. Welding Journal, 2003, 82(12): 348-354.

[10] 侯介山, 丛培娟, 周兰章, 秦学智, 袁 超, 郭建亭. Hf对抗热腐蚀镍基高温合金微观组织和力学性能的影响[J]. 中国有色金属学报, 2011, 21(5): 945-953.

HOU Jie-shan, CONG Pei-juan, ZHOU Lan-zhang, QIN Xue-zhi, YUAN Chao, GUO Jian-ting. Effect of element Hf on microstructure and mechanical behavior of hot corrosion resistant Ni-based superalloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 945-953.

[11] YOUNG G A, CAPOBIANCO T E, PENIK M A, MORRIS B W, MCGEE J J. The mechanism of ductility dip cracking in nickel chromium alloys[J]. Welding Journal, 2008, 87: 31-43.

[12] SAIDA K, TANIGUCHI A, OKAUCHI H, OGIWARA H, NISHIMOTO K. Prevention of microcracking in dissimilar multipass welds of alloy 690 to type 316L stainless steel by Ce addition to filler metal[J]. Science and Technology of Welding and Joining, 2011, 16(6): 553-560.

[13] NISHIMOTO K, SAIDA K, OKAUCHI H. Microcracking in multipass weld metal of alloy 690. Part 1: Microcracking susceptibility in reheated weld metal[J]. Science and Technology of Welding and Joining, 2006, 11(4): 455-461.

[14] NOECKER F F, DUPONT J N. Metallurgical investigation into ductility dip cracking in Ni-based alloys. Part 1[J]. Welding Journal, 2009, 88: 7-20.

[15] LIPPOLD J C, NISSLEY N E. Further investigations of ductility-dip cracking in high chromium, Ni-base filler metals[J]. Welding in the World, 2007, 51(9/10):24-30.

[16] TORRES E A, CARAM R, RAMIREZ A J. Grain boundary sliding phenomenon and its effect on high temperature ductility of Ni-base alloys[J]. Materials Science Forum, 2010, 638/654: 2858-2863.

[17] UNFRIED J S, RAMIREZ A J. Intergranular cracking in alloy 690 with Nb, Mo, and Hf additions: In situ SEM high temperature deformation study[J]. Materials Science Forum, 2012, 706/709: 945-950.

[18] 张 姝, 田素贵, 梁福顺, 于莉丽, 钱本江. 孔洞形态对镍基单晶合金蠕变行为的影响[J]. 中国有色金属学报, 2011, 21(4): 762-768.

ZHANG Zhu, TIAN Su-gui, LIANG Fu-shun, YU Li-li, QIAN Ben-jiang. Influence of cavity morphology on creep behaviors of single crystal nickel-base superalloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(4): 762-768.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(51204107,50975176)

收稿日期:2011-07-21;修订日期:2012-12-28

通信作者:陆 皓,教授,博士;电话:13701926033;传真:021-34202548;E-mail:luhao@sjtu.edu.cn