文章编号:1004-0609(2012)07-2109-07

芦苇浆造纸黑液资源化处理新工艺

杨卫春1, 2,尤翔宇1,王云燕1, 2,赵 静1, 3,柴立元1, 2,舒余德1

(1. 中南大学 冶金科学与工程学院,长沙 410017;

2. 中南大学 国家重金属污染防治工程技术研究中心,长沙 410017;

3. 江苏交通科学研究院股份有限公司,南京 210017)

摘 要:针对芦苇浆造纸产生的浓缩黑液的特点,提出了黑液脱硅—酸析回收木质素—三维电极电解—苛化回收NaOH—出水返回生产的工艺流程。采用Ca(OH)2沉淀法去除黑液中的SiO2,黑液中硅含量由6.68 g/L降至0.12 g/L,脱硅率为98.20%;黑液脱硅后加入H2SO4去除COD并回收木质素,CODCr由220.648 g/L降至54.179 g/L左右,脱除率达到75.45%,每100 mL黑液可回收8.5 g木质素。FTIR、SEM和EDX的分析结果表明:酸析木质素结构以紫丁香基和对羟基的单体结构为主;采用三维电极反应器处理酸析液,残余CODCr为36.761 g/L,TOC的去除率达35.57%;利用苛化法回收残碱,用于制浆蒸煮工段,实现废水的零排放。苛化后的黑液中有效碱浓度为8.30 g/L,苛化度为78.60%,苛化后TOC降低了9.99%,残余CODCr浓度为33.085 g/L,可返回生产,实现了资源的综合回收与利用。

关键词:造纸黑液;脱硅;酸析;三维电极;木质素

中图分类号:X703.1; X793 文献标志码:A

Novel technology of resource recovery from reed black liquor

YANG Wei-chun1, 2, YOU Xiang-yu1, WANG Yun-yan1, 2, ZHAO Jing1, 3, CHAI Li-yuan1, 2, SHU Yu-de1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410017, China;

2. National Engineering Research Center for Pollution Control of Heavy Metals,

Central South University, Changsha 410017, China;

3. Jiangsu Transportation Research Institute Co., Ltd., Nanjing 210017, China)

Abstract: A novel process was proposed to treat reed black liquor: desilication—acidification—three-dimensional electrolysis—causticization—reuse in pulp making. The precipitation method was used to remove silicon by adding Ca(OH)2. The residual concentration of silicon decreases from 6.68 g/L to 0.12 g/L and the removal rate of silicon is maintained at 98.2%. Lignin was recovered by acidulation-precipitation after the addition of sulfuric acid. The residual concentration of CODCr can be reduced from 220.648 g/L to 54.179 g/L and its removal rate is maintained at 75.45%. 8.5 g lignin was recovered from 100 mL black liquor. Based on the analysis of FTIR, EDX and SEM, it is found that the structure of lignin consists mainly of syringyl monomers and hydroxyl groups, and the lignin particles are not fibrous but granular. The reed pulp black liquor pretreated by acidification method was treated by electrolysis with a three-dimensional electrode reactor. The removal rate of TOC is maintained at 35.57% and the residual concentration of CODCr can be reduced to 36.761 g/L. Then, causticization was adopted to recovery residual alkali from the black liquor, which can be reused in the paper mill. After causticization, the concentration of effective alkali is 8.30 g/L and the causticization rate of the solution is about 78.60%, the residual concentration of CODCr in the black liquor is further reduced to 33.085 g/L and the removal rate of TOC is 9.99%.

Key words: papermaking black liquor; desilication; acidulation; three-dimensional electrode; lignin

造纸黑液是造成环境污染和破坏的主要工业污染源之一。2008年,造纸工业废水CODCr的排放量为 128.8万t,约占全国重点统计企业CODCr排放总量的32.4%;排放废水量为40.77亿t,占全国重点统计企业废水排放总量的17.0%。发达国家由于森林覆盖率高,普遍采用木材纤维原料作为造纸原料,碱回收工艺基本解决了造纸废水的污染问题[1]。而我国由于森林覆盖率低,草浆等非木材造纸在我国造纸工业中占有重要地位[2],CODCr排放量占整个造纸工业的60%以上,是主要的污染源。毒性大、浓度高且难以生化降解的草浆黑液一直以来都是国内外水处理研究的 难点。

草浆黑液的成分复杂,硅含量高达3%(质量分数),再加上低聚糖含量高,致使其黏度高、固形物发热量和等温膨胀容积低,使得传统的碱回收技术存在诸多问题,如黏度高、难于滤水、蒸发器内结垢、蒸发强度下降,影响燃烧效果及白泥沉降等[3]。燃烧法相对比较成熟,但运行成本相对较高[4]。传统的处理方法并不适用于大多数草浆造纸企业的黑液处理,超临界水氧化技术作为一种高效的深度氧化技术已经成功应用于一些高浓度难降解有机废水的处理,但由于其操作条件苛刻,容器腐蚀和堵塞严重,影响了其推广应用[5]。因此,开发草浆黑液的高效污染治理技术一直是水处理技术研究的重点。

由于黑液中含有机硫化合物、不饱和脂肪酸、松香酸、聚戊糖和木质素等有机成分,所以开发一种清洁的黑液综合治理和资源回收技术具有十分重要的意 义[6]。本文作者根据芦苇浆黑液的特性,采用非燃烧法对黑液进行处理,使黑液中的有机物和无机物等按不同方式分别回收,从而实现草浆黑液的资源化回收利用。

1 实验

1.1 黑液样品

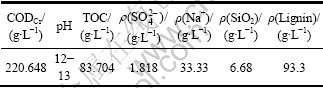

黑液取自湖南常德德山碱法制浆厂,为浓缩芦苇浆黑液,其性质见表1。

表1 黑液的性质

Table 1 Properties of black liquor

1.2 工艺流程

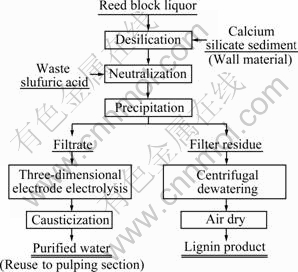

在综合考虑和比较造纸黑液各种处理技术的基础上,结合本研究中某芦苇料制浆公司产生的浓缩黑液的特点,提出了脱硅—酸析回收木质素—三维电极电解—苛化回收NaOH—返回生产的工艺流程,如图1所示。

图1 芦苇浆黑液处理的工艺流程图

Fig. 1 Technological process for treatment of reed black liquor

1.3 实验方法

1.3.1 脱硅实验

取一定量芦苇浆造纸黑液,加入Ca(OH)2,恒温振荡一段时间后过滤得到脱硅黑液,测其SiO2含量。

1.3.2 酸析实验

取一定量脱硅黑液,加入H2SO4调节pH值到预定值,反应一段时间后保温,再静置一段时间后过滤,测定滤液的CODCr,将滤渣过滤风干后得到木质素成品。

1.3.3 电解实验

三维电极实验装置示意图如图2所示。主体装置是一个带隔膜的三维电极电化学反应器,它主要由槽体、两个平板电极(阳极和阴极)和粒子电极组成。两个高纯石墨平板电极作馈电极,极板面积为5 cm×10 cm。在阳极和隔膜间填充活性炭(840 μm)作粒子电 极,粒子电极的有效填充体积为5 cm×5 cm×10 cm。槽体由PVC材料焊结而成,隔膜板为一块中部打孔 的PVC板,隔膜板距阴极0.5 cm,距阳极5 cm。外加电源以直流方式供给,采用DF1797B-8003型程控开关电源。

电解前,石墨电极用稀硫酸和稀氢氧化钠浸泡,再用去离子水反复冲洗以去除电极表面附着的污染物及其中间产物。在反应器内填充120 g 预先经酸析液吸附饱和的活性炭。量取300 mL酸析液置于500 mL烧杯中,将烧杯置于恒温水浴锅中控制水温,开启恒流泵,调节电流,开始进行电化学氧化,反应一段时间后取烧杯内溶液对TOC进行分析。每次实验前采 用电解纯水去除活性炭表面吸附的有机物,进行活化。

图2 三维电极电解反应装置示意图

Fig. 2 Schematic diagram of three-dimensional electrode reactor: 1—DC power; 2—Diaphragm frame; 3—Graphite cathode; 4—Outlet; 5—Reaction tank; 6—Graphite anode; 7—Inlet; 8—Water bath; 9—Constant flow pump; 10—Particle electrodes

1.3.4 苛化实验

将电解后的酸析液放入锥形瓶中,加热至70 ℃后加入过量石灰(≤3%,质量分数)磁力搅拌混合,在石灰消化的同时伴随着苛化反应,苛化反应1 h后,停止搅拌,苛化后的pH值达到13.28,然后静置澄清,得到上清液,测其苛化度和TOC值等。

1.4 分析方法

黑液中SiO2含量的测定:用硝酸和硫酸等消解氧化黑液中的有机物质,其中以硅酸钠形式存在的SiO2生成硅酸沉淀,硅酸经浓硫酸脱水后变成二氧化硅沉淀,然后过滤、干燥和称取质量。

钙离子浓度测定:采用EDTA二钠滴定法;木质素含量测定:采用分光光度法。

COD测定:采用重铬酸钾法测定黑液处理前后COD的含量,记为CODCr。

采用傅里叶红外光谱仪(美国热电公司生产,Nicolet Nexus670)测定样品的红外光谱;采用能谱仪(美国EDAX公司生产,GENESIS-60S)测定样品的能谱;采用扫描电子显微镜(日本电子公司生产,JSM- 6360LV)观察样品的表面形貌。采用总有机碳测定仪(日本岛津公司生产,TOC-VCPH)测定TOC。采用紫 外-可见分光光度计(日本日立公司生产,U-4100)对脱硅黑液、酸析液、电解液和苛化液的紫外全波扫描进行分析。

2 结果与讨论

2.1 不同处理工序对黑液成分的影响

2.1.1 黑液脱硅

在芦苇浆黑液中加入一定量的Ca(OH)2,与黑液中以硅酸钠形态存在的硅在一定条件下发生反应,形成稳定性比硅酸钠更强的硅酸钙(溶度积常数为Ksp= 2.5×10-8)[7]而沉淀,从而达到脱硅的目的,其反应方程式为

Na2SiO3+Ca(OH)2→CaSiO3↓+2NaOH (1)

升温有利于黑液的脱硅反应,在反应温度为65 ℃左右,加入的Ca(OH)2为固态,物料比为6:1,恒温振荡60 min,一次性加料,脱硅后黑液性质见表2,黑液中剩余SiO2值为0.12 g/L,脱硅率为98.20%。脱硅后黑液CODCr为219.608 g/L。原液的CODCr为220.648 g/L,偏差不大,推断Ca(OH)2 优先与SiO2反应,并未与木质素生成木质素磺酸钙,即未发生木质素的碱析反应,脱硅过程不会对木质素的回收产生影响。

表2 脱硅后黑液的性质

Table 2 Properties of desilicated black liquor

2.1.2 酸析回收木质素

黑液中的主要有机物成分为木质素和糖类等。原生木质素是一类具有三维空间结构的芳香族高分子化合物,由苯丙烷基结构组成,含有大量的酚羟基、甲氧基和酚醚键等,其通式为R—OH。草本类木质素由图3所示结构构成[8]。

在制浆蒸煮过程中,由于烧碱作用,醚键断裂,木质素大分子逐步降解为碱木质素,即以木质素钠盐的形式存在,其完全溶于黑液中,为亲水胶体。当用酸中和黑液时,发生亲电取代反应,氢离子取代碱木质素中的钠离子,使碱木质素的胶体受到破坏,生成了难溶或不溶于水的木质素[9]。其反应方程式为

2R—ONa+H2SO4→2ROH+Na2SO4 (2)

在一定温度下,难溶的木质素聚集成不定形的颗粒,从溶液中沉淀出来。通过机械过滤与黑液分离,得到麦草木质素。

图3 草本类木质素化学结构

Fig. 3 Chemical structures of monocotyledonous angiosperm lignin: (a) 2-methoxy-4-(2,3,3,4,4-pentamethylpentan-2-yl)- phenol; (b) 2,6-dimethoxy-4-(2,3,3,4,4-pentamethylpentan-2- yl)phenol; (c) 4-(2,3,3,4,4-pentamethylpentan-2-yl)phenol

实验发现,pH值和反应温度对黑液的酸析处理 效果影响显著。酸析法处理黑液的最佳pH值为0.5。温度升高,木质素返溶,酸析液的CODCr明显升高,最佳酸析温度为25 ℃。酸析去除木质素的反应速率快,能在很短时间内就完成,最佳反应时间为30 min。黑液经酸析处理后析出的木质素呈湿泥状,吸收了大量水分,酸析后如果立刻过滤则速度慢,且滤饼体积大,含水率高,所得滤液体积小。升高温度木质素返溶,酸析残余CODCr随保温温度升高而增加。随着保温温度的升高,木质素颗粒长大,过滤性能得到显著改善,温度为70 ℃时,滤速最快,且木质素疏松、含水率很低,故选用保温温度为70 ℃。保温时间对黑液的酸析处理效果影响很显著。随着保温时间的延长,析出的木质素颗粒慢慢长大,包裹团聚了其他小颗粒,酸析液的CODCr降低。高温下保温时间过长,析出的木质素返溶,酸析液的CODCr又升高。保温时间为30 min时,黑液处理效果最好。综合考虑,选取适宜保温时间为30 min。陈放时间是指保温操作后,酸析液降至室温,使高温溶解的木质素在低温陈放析出所需时间。随着陈放时间的延长,CODCr逐渐降低后趋于稳定。陈放时间达到8 h时,CODCr为54.776 g/L,脱除率为75.11%。继续增加陈放时间,CODCr仍缓慢下降。考虑到生产效率,陈放时间取8 h。在实验确定的最佳条件下进行验证实验,酸析处理后3个平行样品的CODCr分别为54.276、54.076和54.186 g/L。酸析法中100 mL黑液加入6.3 mL浓硫酸,可得到8.5 g木质素。

酸析后黑液的成分见表3。造纸黑液的残余 CODCr约为54.179 g/L,脱除率达到75.45%,TOC去除率达74.22%。

表3 酸析后黑液的性质

Table 3 Properties of black liquor after treatment of desilication-acidification

2.1.3 三维电极电解

电催化氧化技术作为治理有机污染物的一条重要途径广受关注,该技术通过污染物在电极表面发生直接电化学反应或利用电极表面产生的强氧化活性物种(如·OH等)使有机污染物矿化[10-14]。本研究采用石墨电极作反应器的阳极和阴极,在两极中间填充活性炭作粒子电极,组成三维电极反应器,对酸析液进行 处理。

黑液经过脱硅-酸析处理后,直接通入三维电极反应器进行电解。TOC去除率随电流的增加先升高后降低。综合考虑节能和处理效果,选取最佳电流为 300 mA。进水pH值为2.5时,处理效果最佳,因此,酸析液不用调pH值就可直接通入进行电解。电解脱除效率随温度的增加逐渐降低。时间增加,酸析液的电解氧化反应更充分,时间为2 h时,反应基本进行完毕,处理效果最佳,之后时间再增加,脱除率基本不变。此时,酸析液中残余的TOC浓度为13.977 g/L,比电解前下降35.23%。

2.1.4 苛化回收碱

电解后黑液中残碱回收的目的是将其中的钠盐转化为氢氧化钠,回用于制浆蒸煮工段,实现废水的零排放。黑液经过酸析和电解之后,其中的碱已与水中的碳酸生成了碳酸钠,而碳酸钠必须经苛化生成氢氧化钠才能回用,反应方程式如下:

Na2CO3+Ca(OH)2→2NaOH+CaCO3 (3)

在此过程中,随着反应的进行,生成物NaOH浓度不断增加,OH-的同离子效应使得Ca(OH)2的溶解度递减,直至与CaCO3的溶解度接近,苛化作用此时达到平衡。

黑液经过脱硅、酸析和电解之后进行苛化回收 碱。苛化液参数见表4。苛化后黑液中有效碱浓度为8.3 g/L,苛化度为78.6%,TOC比苛化前降低了9.99%。电解中间产物在苛化过程中发生反应或随pH值升高从溶液中沉淀分离出来。

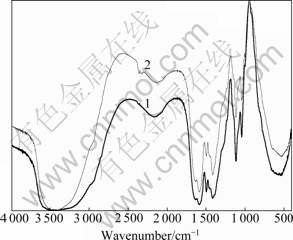

2.2 脱硅过程对黑液中木质素的影响

黑液脱硅前后固形物的红外光谱如图4所示。从3 150~3 700 cm-1间宽吸收峰—OH 基团峰的变化可以看出,脱硅前后黑液固形物的吸收峰基本相似,固形物化学结构并未发生明显变化。据此可知,脱硅处理未影响黑液的主要化学成分,木质素并未发生碱析或分解反应,即脱硅处理对木质素的回用不产生影响。

表4 苛化液的性质

Table 4 Properties of causticized black liquor

图4 黑液脱硅前后固形物红外光谱

Fig. 4 FT-IR spectra of black liquor before and after desilication-acidification treatment: 1—Before desilication- acidification; 2—After desilication-acidification

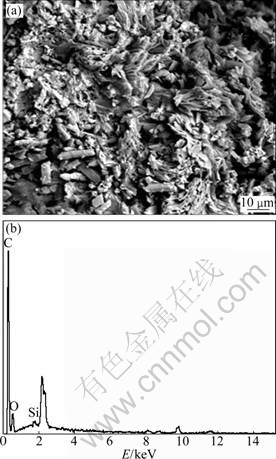

2.3 酸析木质素的表面形貌与结构分析

采用扫描电子显微镜和能量散射光谱对酸析木质素进行形貌表面分析及成分分析。结果分别如图5和表5所示。由图5可看出,芦苇浆酸析木质素颗粒细小,呈絮状或杆状,不呈纤维状。EDS分析结果表明,木质素中主要含有C、O、S和Si等元素,其中Si含量很低,其质量分数仅为0.81%,验证了预处理脱硅的效果。

采用傅立叶变换红外光谱仪对脱硅黑液酸析处理后得到的木质素进行表面有机基团分析及其官能团定性分析,结果如图6所示。由图6可知:木质素在 3 390 cm-1处出现明显—OH伸展振动峰,1 707 cm-1处的吸收峰对应非共轭羰基;1 601和1 514 cm-1处 为芳香环骨架振动吸收峰;在1 425 cm-1处对应甲基和亚甲基的C—H弯曲振动吸收峰;1 334 cm-1处为 缩聚型愈疮木基或紫丁香型苯环骨架振动;1 217和 1 115 cm-1分别对应典型的紫丁香醛芳环和紫丁香基苯环C—H的伸展振动峰;指纹区的833和1 047 cm-1处出现芳香环C—H弯曲振动吸收峰,分 别对应苯环的1,2,3,5-四取代和对位二取代[15-16],推断芦苇酸析木质素是以紫丁香基单体结构和对羟基单体结构为主。

图5 酸析木质素的SEM像及EDS分析结果

Fig. 5 SEM image (a) and EDS analysis results (b) of acidulation lignin

表5 酸析木质素的EDS分析结果

Table 5 EDS analysis results of lignin from acidification

2.4 紫外光谱分析

将脱硅黑液、酸析液、电解液和苛化液准确稀释(1:500)后,以蒸馏水作空白样,用池厚1 cm的石英样品池,在200~400 nm范围内进行紫外全波长扫描,分别测得黑液、酸析液、电解液和苛化液的紫外光谱,结果如图7所示。

图6 木质素的红外光谱

Fig. 6 FTIR spectrum of lignin

图7 黑液处理前后的紫外光谱

Fig. 7 UV spectra of black liquor before and after treatment: 1—Black liquor; 2—Acid pickling solution; 3— Electrolyte; 4—Causticized liquor

通过紫外吸收光谱的比较分析可得出,4个样品均在200 nm附近有很强的吸收峰,这与文献[15]中205 nm处的吸收峰相比发生了紫移。这可能是水样中的 —OCH、—OH和>C=O<,>C=C<等不饱和键所处的化学环境和溶液环境不同造成的。

黑液和酸析液在250 nm附近出现一个肩峰;在279 nm附近则有一个较平宽的吸收带,这与报道的麦草黑液中木质素的紫外光谱特性相似,但略有偏移。两者的峰型结构基本相似,进一步说明酸析过程并未改变原黑液中木质素的主要化学结构。纯麦草木质素的0.1 mol/L NaOH溶液在252 nm处有一个肩峰,在218 nm处出现很强的吸收峰,在280 nm处附近出现一个木质素芳香性特征的吸收峰。这是因为本研究中黑液和酸析液的紫外光谱是稀释后测得的,样品的环境要比纯麦草木质素样品的环境复杂得多。木质素种类不同,其结构单元也不同。不同种类的木质素,其紫外光谱中特征峰的位置也有所差异。以紫丁香基丙烷结构为主的阔叶木质素,其λmax为274~276 nm;以愈创木基丙烷结构为主的针叶木质素,其λmax为281~ 285 nm;而以对-羟基苯丙烷结构单元为主的禾草类木质素则在250 nm处有平宽的紫外光谱吸收峰[17]。结合图7分析,说明芦苇木质素含有以上3种结构单元,这与红外谱(见图6)的分析结果基本相同。

电解液的紫外光谱明显与上述两者不同,不仅吸光度进一步降低,而且280 nm附近的吸收峰或吸收 带都已经消失,这进一步说明了黑液中木质素确实被三维电极电解氧化分解。苛化液的紫外光谱整体与电解液的相似,但其吸光度比电解液的进一步降低,且270 nm和250 nm处附近则出现一个较平宽的吸收带,证实电解过程产生的某些中间产物会随着苛化过程被降解或从溶液中析出。

图7中几个主要吸收峰的吸光度分别为黑液的λmax, 1=280 nm,吸光度A1=2.994,λmax, 2=200 nm,吸光度A2=4.336;酸析液的λmax, 1=279 nm,吸光度A1= 0.407,λmax, 2=200 nm,吸光度A2=2.066;电解液的λmax=200 nm,吸光度A=0.793;苛化液的λmax, 1=270 nm,吸光度A1=0.087,λmax, 2=200 nm,吸光度A2= 0.584。由上述数据可以粗略判断,黑液经过酸析、电解和苛化处理后,其有机物含量明显降低。在苛化液中还有一部分有机物质存在,但含量已比原液中的降低了很多,这与CODCr和TOC含量的分析结果相 吻合。

3 结论

1) 综合考虑和比较了造纸黑液现有各种处理技术,结合芦苇料制浆浓缩黑液的特点,提出了黑液脱硅—酸析木质素—三维电极电解—苛化回收NaOH—出水返回生产的工艺流程,实现了造纸黑液的资源化利用。

2) 加入Ca(OH)2去除芦苇纸浆黑液中的SiO2,黑液中剩余SiO2含量一般可达到0.12 g/L,脱硅率达98.2%。经过脱硅处理,黑液的组成和结构并未发生明显变化,木质素并未发生碱析和分解反应。本研究采用的芦苇浆黑液脱硅法,其药剂价格低廉,脱硅效果好,为后续工艺回收含硅量极低的木质素提供了依据,为进一步深加工木质素制取其他高端产品提供了可能,具有明显的环境效益和经济效益。

3) 黑液脱硅后再加入硫酸去除COD并回收木质素,酸析木质素的过滤性能好,硅含量低,可为中小型造纸厂处理黑液提供借鉴。

4) 采用三维电极电化学反应器处理酸析后芦苇浆造纸黑液,采用经活化的活性炭作为粒子电极, 与酸析液相比TOC的去除率可以达到35.57%。

5) 利用苛化法回收电解后黑液中的残碱,回用于制浆蒸煮工段,实现了废水的零排放。

REFERENCES

[1] 盛利元, 侯曼玲, 许秀兰, 宋 鸽. 隔膜电解法处理草浆黑液[J]. 中南工业大学学报: 自然科学版, 2001, 32(2): 150-153.

SHENG Li-yuan, HOU Man-ling, XU Xiu-lan, SONG Ge. The treatment of black liquor from straw pulp by electrolytic process [J]. Journal of Central South University of Technology: Science and Technology, 2001, 32(2): 150-153.

[2] 马晓伟, 代 斌, 杨兴华. 酸析法提取芦苇纸浆黒液中的木质素[J]. 化工技术与开发, 2007, 36(8): 44-46.

MA Xiao-wei, DAI Bin, YANG Xing-hua. Recovery of lignin from reed black liquor of paper-making by acidulation method [J]. Technology & Development of Chemical Industry, 2007, 36(8): 44-46.

[3] 中国造纸协会. 中国造纸工业2009年度报告[J]. 中华纸业, 2010, 31(11): 8-18.

China Paper Association. The annual report of China’s paper industry in 2009 [J]. China Pulp and Paper Industry, 2010, 31(11): 8-18.

[4] 罗 玲, 王安群. 制浆造纸废水的来源及其处理技术概况[J]. 精细化工中间体, 2011, 41(1): 11-15.

LUO Ling, WANG AN-qun. Source of pulp and papermaking wastewater and its treatment technologies [J]. Fine Chemical Intermediates, 2011, 41(1): 11-15.

[5] 谭万春, 李 芬, 王云波, 孙士权, 吴方同. 超临界水氧化法处理造纸黑液研究[J]. 水处理技术, 2010, 36(12): 77-80.

TAN Wan-chun, LI Fen, WANG Yun-bo, SUN Shi-quan, WU Fang-tong. Study on the treatment of black liquor by SCWO technology [J]. Technology of Water Treatment, 2010, 36(12): 77-80.

[6] 金 涌, 魏 飞. 循环经济与生态工业工程[J]. 中国有色金属学报, 2004, 14(s1): s1-s12.

JIN Yong, WEI Fei. Sustainable development and ecological process engineering [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(s1): s1-s12.

[7] 李梦龙, 蒲雪梅. 分析化学数据速查手册[M]. 北京: 化学工业出版社, 2009: 117.

LI Meng-long, PU Xue-mei. Chemical analysis data manual [M]. Beijing: Chemical Industry Press, 2009: 117.

[8] 蒋挺大. 木质素[M]. 2版. 北京: 化学工业出版社, 2009: 23-34.

JIANG Ting-da. Lignin [M]. 2nd. Beijing: Chemical Industry Press, 2009: 23-34.

[9] 秦毅红, 王云燕, 舒余德. 造纸黑液酸析法回收木质素[J]. 环境污染与防治, 1999, 21(4): 5-7.

QIN Yi-hong, WANG Yun-yan, SHU Yu-de. Recovery of lignin from black liquor of paper-making by acidulation method [J]. Environmental Pollution and Control, 1999, 21(4): 5-7.

[10] 黄 昱. 电-Fenton法预处理青霉素废水的研究[D]. 长沙: 湖南大学, 2007: 49-78.

HUANG Yu. Pretreatment of penicillin G wastewater by electro-Fenton process [D]. Changsha: Hunan University, 2007: 49-78.

[11] BRILLAS E, CALPE J C, CASADO J. Mineralization of 2, 4-D by advanced electrochemical oxidation processes [J]. Water Research, 2000, 34(8): 2253-2262.

[12] OTURAN M A. An ecologically effective water treatment technique using electrochemically generated hydroxyl radicals for in situ destruction of organic pollutants: Application to herbicide 2, 4-D [J]. Journal of Applied Electrochemistry, 2000, 30(4): 475-482.

[13] LI X Y, CUI Y H, FENG Y J, XIE Z M, GU J D. Reaction pathways and mechanisms of the electrochemical degradation of phenol on different electrodes [J]. Water Research, 2005, 39(10): 1972-1981.

[14] 柴立元, 尤翔宇, 舒余德, 杨 杰, 王云燕, 赵 娜. 三维电极电化学反应器降解有机废水中的EDTA[J]. 中南大学学报: 自然科学版, 2009, 41(4): 1240-1245.

CHAI Li-yuan, YOU Xiang-yu, SHU Yu-de, YANG Jie, WANG Yun-yan, ZHAO Na. Electrochemical degradation of organic wastewater containing EDTA with three-dimensional electrode reactor [J]. Journal of Central South University: Science and Technology, 2009, 41(4): 1240-1245.

[15] 卢涌泉, 邓振华. 实用红外光谱解析[M]. 北京: 电子工业出版社出版, 1989: 21-163.

LU Yong-quan, DENG Zhen-hua. Practical infrared spectroscopy analysis [M]. Beijing: Electronic Industry Press, 1989: 21-163.

[16] 陈云平, 陈瑞强, 程贤甦, 杨相玺, 吴耿云, 陈耀庭. 甘蔗渣高沸醇木质素光谱分析与结构测定[J]. 光谱学与光谱分析, 2006, 26(10): 1880-1883.

CHEN Yun-ping, CHEN Rui-qiang, CHENG Xian-su, YANG Xiang-xi, WU Geng-yun, CHEN Yao-ting. Spectra and structural analysis of high boiling solvent lignin from bagasse [J]. Spectroscopy and Spectral Analysis, 2006, 26(10): 1880-1883.

[17] 韩善明. 木质素生物降解机理及其在清洁高效制浆过程中的作用[D]. 北京: 中国林业科学研究院, 2008: 63-64.

HAN Shan-ming. Mechanism of bio-delignification and its effects on clean-efficient pulping [D]. Beijing: Chinese Academy of Forestry, 2008: 63-64.

(编辑 陈卫萍)

基金项目:国家自然科学基金重点项目(50830301);国家杰出青年科学基金资助项目(50925417);湖南省研究生科研创新项目(CX2010B121)

收稿日期:2011-06-08;修订日期:2011-10-19

通信作者:王云燕,副教授;电话:0731-88830577;E-mail: wyy@csu.edu.cn