文章编号:1004-0609(2010)S1-s0473-05

TiNbTaZr合金在轧制过程中的马氏体转变

王立强,位倩倩,吕维洁,覃继宁,张 帆,张 荻

(上海交通大学 金属基复合材料国家重点实验室,上海 200240)

摘 要:利用真空自耗熔炼方法和热加工技术制备Ti-35Nb-2Ta-3Zr β钛合金,采用单向轧制和交叉轧制对合金进行冷变形。通过对轧制态试样的微观组织分析,研究不同轧制方式下的马氏体转变特征。结果表明:单向轧制和交叉轧制过程中产生应变诱发马氏体相,随着变形量的增大,马氏体形貌由针状逐渐转变为粗大的变体;交叉轧制更有利于马氏体相的转变,当冷变形量为40%时,马氏体的转变量达到79.63%,并在随后的冷变形过程中,马氏体转变量基本保持不变。

关键词:β钛合金;轧制;马氏体;相变

中图分类号:TG146.4 文献标志码:A

Martensite phase transformation of TiNbTaZr alloy during cold rolling

WANG Li-qiang, WEI Qian-qian, LU Wei-jie, QIN Ji-ning, ZHANG Fan, ZHANG Di

(State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: Ti-35Nb-2Ta-3Zr β titanium alloy was fabricated by vacuum consumable arc melting furnace followed by hot pressing. Direct-rolling and cross-rolling were carried out. Microstructure was investigated to study the characterization of martensite phase transformation during direct-rolling and cross-rolling. The results show that stress-induced martensite phase transformation takes place. With the increase of the deformation, the microstructure of martensite phase changes from acicular to variant crossed and cross-hatched. Cross-rolling is propitious to martensite phase transformation. When the deformation reduction ratio is 40%, the amount of martensite phase arrives at 79.63%, which keeps nearly the same with the increase of deformation reduction ratio.

Key words: beta titanium alloys; rolling; martensite; phase transformation

由于具有好的形状记忆效应,Ti-Ni形状记忆钛合金在医用金属材料领域得到广泛的应用。由于Ni元素具有生物毒性,使得Ti-Ni合金的长期安全应用受到一定的限制[1-3]。目前,含有Nb、Zr、Pd和Ta等无毒元素的新型β钛合金得到了广泛的关注[4]。一些Ti-Nb、Ti-Ta和Ti-Zr等高强度低弹性模量的新型钛合金相继被开发[5-7]。由于该类合金为体心立方结构,因而在冷变形过程中具有很好的加工性。很多学者研究了β钛合金在单向轧制过程中的变形特点[8-15],但鲜见关于β钛合金在交叉轧制过程中的变形特点的报道。因此,比较β钛合金在单向轧制和交叉轧制过程中的马氏体转变和形貌特征具有重要的意义。本文作者系统研究了Ti-35Nb-2Ta-3Zr β钛合金在单向轧制和交叉轧制过程中的马氏体转变特征。

1 实验

采用真空自耗技术熔炼TiNbZrTa合金锭,然后打磨除去表面氧化皮和缺陷。在950 ℃将合金锻为180 mm×70 mm×30 mm的板坯。采用二辊轧机对合金进行单向轧制和换向交叉轧制。冷变形量分别为20%、40%、60%、80%、90%和99%,道次冷变形率控制在2%~5%。根据不同的冷变形率,在轧制前将热锻板坯用线切割机切成厚度不同的轧制试样,然后经砂纸打磨,去掉表面缺陷后,进行轧制。利用金相显微镜和透射电镜观察微观组织、马氏体形貌。利用X射线衍射仪分析合金的相组成。

2 结果和讨论

2.1 马氏体微观组织

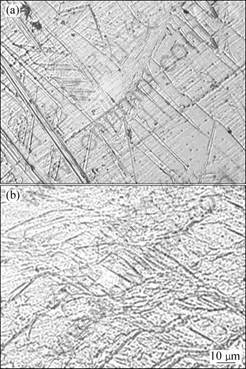

图1所示为单向轧制冷变形20%和60%后的马氏体微观组织。如图1(a)所示,在单向轧制过程中,当冷变形量为20%时,可以看到平行分布的细小微孪晶。当合金冷变形60%时,“蝴蝶状”马氏体被拉长,其外观形貌为平行于轧制方向的粗大片体。由于大的冷变形率,马氏体逐渐粗化,同时具有明显的取向特征。相比较于20%冷变形马氏体特征,当冷变形量为60%时,马氏体逐渐粗化,并呈现交叉、镶嵌的特征。

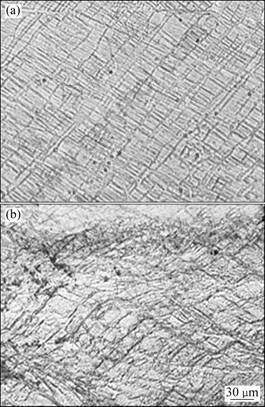

图2所示为交叉轧制冷变形20%、60%后的马氏体微观组织。可以看出,应变诱发马氏体外观形貌表现为“蝴蝶状”马氏体。这种马氏体微观形貌与单向轧制过程中的马氏体微观形貌相似。20%冷变形试样中出现针状无取向的马氏体相。在变形过程中,在应变诱发马氏体相出现的同时,由于母相的塑性变形也会出现位错、孪晶等缺陷,它们的交截作用为马氏体的形核提供了更多的位置。随着变形率的增大,在轧制切应力的交错作用下,诱发形成的马氏体相也出现交截作用,并且在这种交错切应力下,片状的规则马氏体相被剪切为细层状。在图2(b)所示的60%冷变形样中可看到流水状的不连续层状组织。同时,在交织切应力的作用下,马氏体变体沿单一方向的取向不是很明显。

图1 单向冷轧后的马氏体微观组织

Fig.1 OM microstructures of TiNbTaZr plates cold rolled with reductions of 20% (a) and 60% (b)

图2 交叉轧制后的马氏体金相微观组织

Fig.2 OM microstructures of TiNbTaZr plates cross rolled with reductions of 20% (a) and 60% (b)

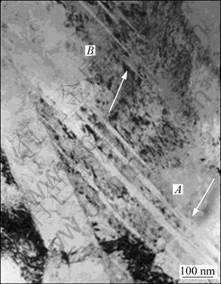

图3所示为单向轧制20%的马氏体形核TEM像。从图3可以看到宽度小于100 nm的针状马氏体组织。由于马氏体形核位置的不连续分布,使得应变诱发产生的马氏体不连续分布于基体上。在马氏体较早形核的区域,如箭头所示A区域,存在较多的马氏体针状组织,这种平行分布的针状马氏体的平均厚度为40 nm左右。在箭头所示B区域,出现少量的应变诱发马氏体相。由于B区域马氏体形核时间较晚,这种针状组织长大迹象不明显。这种平行分布的针状马氏体相的平均厚度为20 nm左右。在A区域和B区域之间的过渡区域,没有马氏体形核特征。在马氏体相周围有较为密集的位错线,同时出现明显的位错缠结的特征,如图3中箭头所示。从应变诱发马氏体相的形核位置可看到,位错缺陷处有利于马氏体的形核。

图3 单向轧制20%的马氏体形核TEM像

Fig.3 TEM image of specimen direct rolled at reduction of 20% showing nucleation of martensite

2.2 应变诱发马氏体转变量

采用一种简单的X射线法测算混合物中各个相的相对含量。根据衍射强度理论,各个不同相的衍射线条的强度随着该相在混合物中的相对含量的增加而增强。衍射强度计算公式为

(1)

(1)

式中P、F、φ(θ)和e-2M为一种晶体的单相物质的衍射参量。按照衍射强度公式,令:

(2)

(2)

(3)

(3)

那么,多晶体的衍射强度可以表示为

(4)

(4)

式中:K为与衍射物质种类及含量无关的常数;R取决于θ、hkl以及待测物质的种类;V为该物质的体积;u为试样的吸收系数。当样品中存在母相奥氏体和马氏体相时,用含有角标γ的组分表示奥氏体;用含有角标α的组分表示马氏体。那么,母相奥氏体和马氏体相的衍射强度表达式为

(5)

(5)

(6)

(6)

计算两相相对含量时可将上面两式相除。同时,可把材料近似为只由奥氏体和马氏体相组成,于是得到:

(7)

(7)

(8)

(8)

可得到

(9)

(9)

由式(9)可计算奥氏体和马氏体的相对体积分数。式中Iα/Iγ可由实验直接测出,Rγ/Rα可以由计算求得。

对于钛合金,由于母相和马氏体相单细胞体积近似相等,同时可忽略温度因素和吸收因素的影响,Rhkl可以近似表示为

(10)

(10)

本实验采用一种简单的方法即从母相和马氏体相中各测2条衍射线,组合成不同线对,再对所有线对的测算值进行平均,以消除择优取向的影响。在单向轧制和交叉轧制过程中的各相的相对含量的计算中,选择(110)和(200)为母相衍射线条,以(020)和(220)为与其对应的马氏体衍射线条。

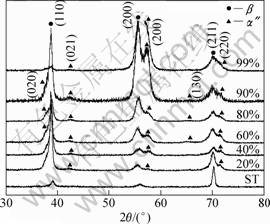

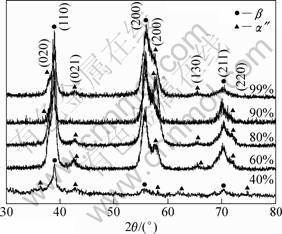

图4和5所示分别为单向轧制和交叉轧制后的相组成。冷变形量和马氏体相对含量的关系曲线如图6所示。对于单向轧制,冷变形量20%时,α″马氏体相的转变量超过56%。在轧制力作用下,随着变形率的增加,不稳定的β相逐渐转变为α″相,使得马氏体转变量逐渐增多;当累计变形量达到99%时,马氏体转变量达到78.93%。在交叉轧制过程中,在40%冷变形率时,合金中的马氏体转变量已经达到79.63%;随着变形率的增加,β相和α″相的相对体积含量基本不变;当冷变形量在99%时,马氏体的体积相对含量为79.29%,与40%冷变形时的含量相差不大。由上面的数据分析可以看出,冷变形方式和冷变形率对应变诱发产生的马氏体的转变量有重要的影响。交叉轧制更有利于马氏体的产生。在相对低的冷变形率下,交叉轧制过程中相互交错的剪切应力更有利于马氏体的形核,使得在40%冷变形时诱发马氏体转变量就达到了最大值。在残余β相转化为α″相的同时,母相出现机械稳定化,母相的逐渐硬化使得马氏体相变困难。所以在大变形率时,稳定化的β相很难继续转化为马氏体相。从上面的计算中发现,对于单向和交叉轧制的TiNbZrTa合金,马氏体的极限转化率均为79%左右。

图4 固溶和单向轧制后的XRD谱

Fig.4 XRD patterns of solid solution treated and unidirection rolled samples at different deformation rates

图5 交叉冷轧制变形后的X射线衍射谱

Fig.5 XRD patterns of cross rolled samples with cold reductions of 40%, 60%, 80%, 90% and 99%

图6 冷轧过程中冷变形率和马氏体相对含量的关系

Fig.6 Relationship between ratio of cold deformation and volume fraction of martensite during cold rolling: (a) direct rolling; (b) cross rolling

3 结论

1) 在单向轧制和交叉轧制过程中产生应变诱发马氏体相,随着冷变形率的增大,马氏体微观形貌发生变化。在单向轧制过程中,马氏体由针状的具有平直边界的细小层状组织逐渐变化为“蝴蝶状”马氏体,当冷变形量大于60%时,“蝴蝶状”马氏体被拉长,外观形貌为平行于轧制方向的粗大片体,并随着冷变形率的继续增大,这种粗大的片体沿着轧制方向呈交织状扩展。在交叉轧制过程中马氏体的变化特点与单向轧制有相似的规律,但是由于交叉轧制切应力的作用,使得马氏体生长没有明显的方向性。

2) 在单向轧制过程中,随着冷变形率的增大,马氏体转变量逐渐增大。当冷变形量为99%时,马氏体的最大转变量保持在78.93%左右。在交叉轧制过程中,在较小的冷变形量下(40%),马氏体的转变量达到79.63%,并且随着冷变形量的增大,马氏体的相对含量基本保持不变,在99%冷变形量时的马氏体相对含量为79.29%。

REFERENCES

[1] DUERIG T W, RICHTER D F, ALBRECHT J. Formation and reversion of stress induced martensite in Ti-10V-2Fe-3Al[J]. Acta Metall, 1982, 30: 2161-2172.

[2] TAKAHASHI E, SAKURAI T, WATANABE S, MASAHASHI N, HANADA S. Effect of heat treatment and Sn content on superelasticity in biocompatible TiNbSn alloys[J]. Mater Trans 2002, 43: 2978-2983.

[3] KIM J I, KIM H Y, INAMURA T, HOSODA H, MIYAZAKI S. Shape memory characteristics of Ti-22Nb-(2-8)Zr(at.%) biomedical alloys[J]. Mater Sci Eng A, 2005, 403: 334-339.

[4] NINOMI M. Mechanical properties of biomedical titanium alloys[J]. Mater Sci Eng A, 1998, 243: 231-236.

[5] ILYIN A A, KOLLEROV M Y, GOLOVIN I S. Hydrogen influence on plastic deformation mechanism of β-titanium alloys of Ti-Nb system[J]. J Alloys Compd, 1997, 253/254: 144-147.

[6] MIYAZAKI S, KIM H Y, HOSODA H. Development and characterization of Ni-free Ti-base shape memory and superelastic alloys[J]. Mater Sci Eng A, 2006, 438/440: 18-24.

[7] SAITO T, FURUTA T, HWANG J H, KURAMOTO S, NISHINO K, SUZUKI N, et al. Multifunctional alloys obtained via a dislocation free plastic deformation mechanism[J]. Science, 2003, 300: 464-467.

[8] FURUTA T, KURAMOTO S, HWANG J H, NISHINO K, SAITO T. Elastic deformation behavior of multi-functional Ti-Nb-Ta-Zr-O alloys[J]. Mater Trans, 2005, 46: 3001-3007.

[9] GROSDIDIER T, PHILIPPE M J. Deformation induced martensite and superelasticity in a β-metastable titanium alloy[J]. Mater Sci Eng A, 2000, 291: 218-223.

[10] KRENN C R, ROUNDY D, MORRIS J W, COHEN M L. Ideal strengths of bcc metals[J]. Mater Sci Eng A, 2001, 319/321: 111-114.

[11] GUTKIN M Y, ISHIZAKI T, KURAMOTO S, OVID’KO I A. Nanodisturbances in deformed gum metal[J]. Acta Mater, 2006, 54: 2489-2499.

[12] EISENBARTH E, VELTEN D, M?LLER M, THULL R, BREME J. Biocompatibility of β-stabilizing elements of titanium alloys[J]. Biomaterials, 2004, 25(26): 5705-5713.

[13] NIINOMI M, AKAHORI T, NAKAI M. In situ X-ray analysis of mechanism of nonlinear super elastic behavior of Ti-Nb-Ta-Zr system beta-type titanium alloy for biomedical applications[J]. Mater Sci Eng C, 2008, 28(3): 406-413.

[14] KARASEVSKAYA P, IVASISHIN O M, SEMIATIN S L, MATVIYCHUK Y V. Deformation behavior of beta-titanium alloys[J]. Mater Sci Eng A, 2003, 354(1/2): 121-132.

[15] YU Zhen-tao, ZHOU Lian. Influence of martensitic transformation on mechanical compatibility of biomedical β type titanium alloy TLM[J]. Mater Sci Eng A, 2006, 438/439/440: 391-394.

(编辑 袁赛前)

基金项目:国家高技术研究发展计划项目(2006AA03Z559);国家重点基础研究发展计划资助项目(2007CB613806);国家优秀博士论文资助项目(200332)

通信作者:王立强;电话:021-34202641;E-mail:wang_liqiang@sjtu.edu.cn