铜冶炼过程中脱砷技术综述及展望

来源期刊:中国有色金属学报2021年第6期

论文作者:张煜 易小艺 李俊杰 葛哲令

文章页码:1582 - 1591

关键词:铜冶炼;砷;二次污染;形态;清洁回收

Key words:copper smelting; arsenic; secondary pollution; existing form; clean recovery

摘 要:铜冶炼过程主要采用电收尘烟灰脱砷、污酸脱砷、铜电解液脱砷等方法,砷以砷滤饼或黑铜泥的形式得到分离和富集,以此解决铜冶炼体系中砷的开路问题,得到的砷渣富含铜、铼、铅、锌等有价金属。砷的回收存在砷二次污染、资源浪费等难点,亟待突破。通过论述砷在铜冶炼过程中的分布,研究从含砷物料中砷的存在形态及反应机理入手,系统综述了脱砷技术在烟尘和电解过程中的应用,并对实际生产中遇到的瓶颈展开探讨。结合近年来砷的稳定性处理技术研究,对未来砷的清洁回收技术进行了展望。

Abstract: The methods of removing arsenic from electric precipitation dust, waste acid and electrolyte are mainly used to separate and enrich arsenic in the form of arsenic filter cake or black copper mud in the process of copper smelting, so as to solve the problem of open circuit of arsenic in copper smelting system. The arsenic slag is rich in valuable metals such as copper, rhenium, lead and zinc. There are some difficulties in arsenic recovery, such as secondary pollution and waste of resources. This paper discusses the distribution of arsenic in the processes of copper smelting, studies the existing form and reaction mechanism of arsenic in arsenic bearing materials, systematically summarizes the application of arsenic removal technology in the process of dust and electrolysis, and discusses the bottleneck encountered in actual production. Combined with the research on the stability treatment technology of arsenic in recent years, the future clean recovery technology of arsenic was prospected.

DOI: 10.11817/j.ysxb.1004.0609.2021-39737

张 煜1, 2,易小艺1,李俊杰2,葛哲令2

(1. 中南大学 化学化工学院,长沙 410083;

2. 阳谷祥光铜业有限公司,聊城 252000)

摘 要:铜冶炼过程主要采用电收尘烟灰脱砷、污酸脱砷、铜电解液脱砷等方法,砷以砷滤饼或黑铜泥的形式得到分离和富集,以此解决铜冶炼体系中砷的开路问题,得到的砷渣富含铜、铼、铅、锌等有价金属。砷的回收存在砷二次污染、资源浪费等难点,亟待突破。通过论述砷在铜冶炼过程中的分布,研究从含砷物料中砷的存在形态及反应机理入手,系统综述了脱砷技术在烟尘和电解过程中的应用,并对实际生产中遇到的瓶颈展开探讨。结合近年来砷的稳定性处理技术研究,对未来砷的清洁回收技术进行了展望。

关键词:铜冶炼;砷;二次污染;形态;清洁回收

文章编号:1004-0609(2021)-06-1582-09 中图分类号:TF811 文献标志码:A

引文格式:张 煜, 易小艺, 李俊杰, 等. 铜冶炼过程中脱砷技术综述及展望[J]. 中国有色金属学报, 2021, 31(6): 1582-1590. DOI: 10.11817/j.ysxb.1004.0609.2021-39737

ZHANG Yu, YI Xiao-yi, LI Jun-jie, et al. Review and prospect of technical research of removing arsenide in copper smelting process[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(6): 1582-1590. DOI: 10.11817/j.ysxb.1004.0609.2021-39737

砷是亲硫元素,常伴生于硫化矿中。铜精矿以硫化矿的分布较为广泛,而且世界范围内电解铜生产原料来自硫化矿。随着铜冶炼行业的高速发展,近几年,新建或改(扩)建铜冶炼企业如雨后般春笋建立起来,已造成开始开采含砷高的低品位铜精矿,开采量还逐渐增大,含砷物料逐年增多。砷在自然界中多以化合物形态存在,且分布分散。在空气、水、矿物质及陆生植物中主要以砷酸盐形式存在。砷通过提取分离得到的含砷产品常用于木材防腐、农药以及半导体材料[1-2]。含砷产品随着通讯信息技术的快速进步和人们生态价值观的改变逐渐淡出人们视线。1990年起,以砷化镓为代表的第二代化合物半导体的发展逐步停止;2013年起,有机砷类农药退出农药历史舞台。砷日益萎缩的应用领域,致使学者们开始转变研究方向,由砷产品的制备技术研究转向砷的稳定化处理技术研究,将从大自然中得到的砷以稳定态的砷再送回到大自然中。2019年,中南大学承担编制的国家环保标准《砷渣稳定化处置工程技术规范》也已开始征求意见,拟对砷渣稳定化技术进行统一规范。

工程技术人员及学者们在铜冶炼过程中关于砷的清洁回收技术做了大量工作并取得了很大成果。本文主要详细阐述砷的回收技术及应用,并对未来砷的清洁回收技术进行了展望。

1 砷的分布及形态

1.1 砷的分布

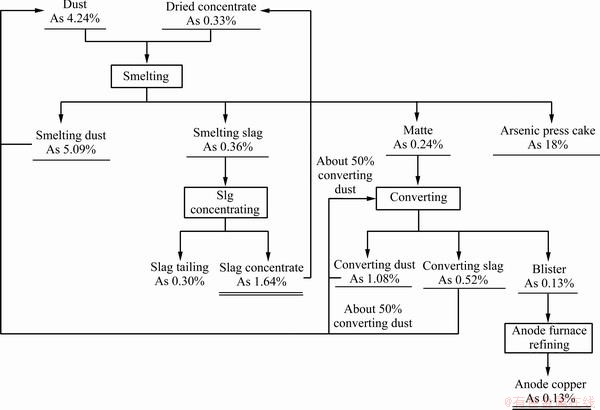

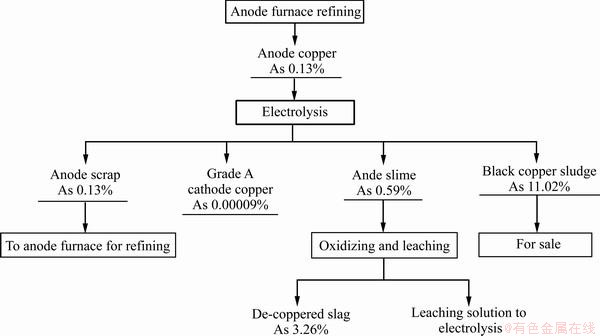

铜精矿生产阴极铜的冶炼方法分为两大类:火法冶金和湿法冶金。本实验中所涉及的铜冶炼过程主要包括熔炼、吹炼、火法精炼、电解精炼。铜冶炼过程中砷随着烟尘、熔炼渣、阳极铜带入废酸、电解液[3-4],经进一步处理,砷最终附属在砷滤饼、黑铜泥、尾渣中(见图1和2)。根据冶炼工艺特点,若烟尘开路,将从烟尘中脱砷;若烟尘不开路,大部分的砷将在系统内不断循环。

1.2 砷的形态

铜冶炼过程中砷的形态转化复杂、步骤反应多,通过对铜冶炼过程中各种含砷中间产物包含了烟尘、阳极铜、电解液、中间产物阳极泥以及附属产物黑铜泥进行较为全面的调查和分析,了解砷元素的转变途径。

图1 铜火法冶炼过程中砷的分布

Fig. 1 Distribution of arsenic in copper pyrometallurgy process

图2 铜电解过程中砷的分布

Fig. 2 Distribution of arsenic in copper electrolysis

1.2.1 铜火法冶炼过程中砷的形态

1) 烟尘中砷的形态

通过火法冶炼以Cu2S·As2S3、Cu3AsS4和Cu12As4S13为主的硫化矿物,经过和氧气反应,含砷物料被氧化,砷以三氧化二砷的形态进入烟尘,Cu2S·As2S3+O2→Cu2S+SO2+As2O3;As2S3+O2→ As2O3+SO2;Cu3AsS4+O2→CuO+As2O3+SO2;Cu12As4S13+O2→CuO+As2O3+SO2。此外,烟尘中还富集有铜、锌、铅、铋、锑等有价金属,锌主要以硫酸锌、氧化锌等形式存在,铅主要以硫酸铅、氧化铅、砷酸铅等形式存在,铜、铋、锑主要以氧化物、硫酸盐、硫化物等形式存在[5]。

2) 阳极铜中砷的形态

阳极铜中的砷的形态如下:一是以固溶体的形式存在;二是以金属间化合物或单质砷夹杂于铜晶界和晶隙上;三是以复杂氧化砷的夹杂物分布于铜基体中[6]。阳极铜中的砷或以α固溶体的形式存在于铜基体,或以Cu3As等金属间化合物在铜基体中夹杂,Cu3As结构为正二十面体,在温度988 K时开始进行热分解,生成单质铜和As4。当温度达到1438 K时,生成单质As,具体形式和阳极铜中砷的含量有密切关系。易克俊[7]认为铜熔炼过程渣相中的AS2O5可与金属氧化物Cu2O、CuO和PbO结合成稳定的砷酸盐(Cu3(AsO4)2、Pb3(AsO4)2)等复杂化合物形式。

1.2.2 铜电解过程中砷的形态

1) 电解液中砷的形态

阳极铜经电解精炼,阳极铜中的砷通过电化学溶解进入电解液并不断富集,As3+在Cu2+催化条件下逐渐氧化成As5+,As3++H2O→HAsO2+3H+;As3++H2O→AsO++2H+,电解液中的砷主要以HAsO2分子、H3AsO4分子、AsO+离子的形态存在。

2) 阳极泥中砷的形态

由于砷的电位与铜电位接近,阳极铜中的一部分砷在电解液中析出或通过机械夹杂进入阳极泥。铜阳极泥中砷的形态有As2O3﹒H2O,Cu2O﹒As2O3[8]。当存在Sb3+、Bi3+时,As5+与这两种离子可以生成溶度积很小的化合物SbAsO4和BiAsO4形成漂浮性阳极泥,漂浮性阳极泥对阴极铜的质量危害极大。

3) 黑铜泥中砷的形态

多数铜电解车间采用诱导法脱砷技术对电解液进行净化,得到含砷较高的黑铜泥。黑铜泥中的砷主要以铜砷化合物形式存在,王玉棉等[9]采用XRD对黑铜泥进行了物相表征,证实了黑铜泥中的铜、砷主要以Cu2As和Cu3As的合金形态存在;另外,部分砷以As2O5的形式与锑、铋、铅生成氧化物夹杂于铜基体中。

2 铜火法冶炼过程中砷的清洁回收技术

2.1 烟尘中砷的脱除技术进展

据统计,火法冶炼中烟尘率在2%~8%之间,砷属于易挥发元素,主要分布在熔炼系统的烟灰中,若烟灰是循环物料,这使砷在系统内循环积累的问题更为突出。因此,从高砷烟尘将砷脱除开路是解决国内外铜冶炼厂原料含砷升高的重要途经之一[10]。烟尘主要以焙烧的方式分离砷与其他有价金属。烟尘在焙烧炉中进行,若采用的焙烧炉密闭性差,存在着低空污染的风险,热效率也比较低;烟尘在焙烧炉中焙烧,得到的三氧化二砷纯度低;此外,烟尘焙烧温度过高导致能源消耗大,提高了能源成本。上述因素均对烟尘中砷的清洁回收产生了不良影响。

烟尘若直接氧化焙烧可有效提高铜等有价金属的浸出率。将烟尘在500 ℃氧化焙烧1 h,铜的浸出率可提高到94%以上[11],可有效实现砷与铜等有价金属的分离,提高硫化物的浸出率,但砷挥发现象严重。

为了解决砷挥发的问题,通过加入适量焦炭或硫化物等,对三氧化二砷、砷酸盐进行还原焙烧,在焙烧过程中,加热到700~800 ℃使三氧化二砷挥发进入烟气中冷凝富集,砷脱出率可超过80%。美国某厂将含砷烟尘与燃料、矿石等混合焙烧,冷却后收集砷(含砷90%~95%),再经焙烧升华、冷凝产生纯度99%~99.5%的白砷,残余渣量少,砷产品纯度高。日本某冶炼厂将铜冶炼烟尘和砷渣混合,干燥后经焙烧升华、冷凝收砷,二次烟尘再经焙烧得到纯度大于99%的As2O3[12]。上述两家公司均采用反射炉焙烧技术,目前,使用卡尔多炉可解决反射炉密闭性差的问题。

另外,通过采用硫酸化焙烧或真空挥发技术解决了焙烧温度高的问题。含砷烟尘与硫酸在350~

450 ℃下混合焙烧,砷挥发进入烟气,砷挥发率在70%~95%。李思唯等[13]采用烟尘水浸-硫酸化焙烧-水浸工艺,在200 ℃下,将烟尘水浸渣与硫酸混合,焙烧1 h,砷、铁、铜的浸出率大于90%。真空挥发技术主要是利用砷与其他物质的饱和蒸汽压区别,实现砷与其他金属在真空下的分离。0.101 MPa压力,As2O3的沸点为457 ℃,196 ℃时升华。As2O5在315 ℃时可分解为As2O3和O2。李学鹏等[14]采用250℃相对低温焙烧的方法对含砷铜烟尘焙烧120 min,选择性分离砷,获得了砷挥发率95.68%的良好指标。

2.2 阳极铜中砷的脱除技术进展

目前,关于阳极铜中砷的研究较少,可追溯的阳极铜中砷的清洁回收主要是在粗铜制备过程中以添加熔剂的形式脱除砷。KUCHARSKI[15]采用碳酸钠熔剂,通过控制铜液含氧量、熔剂加入时间等工艺条件,碳酸钠熔剂以喷入的形式添加到铜液中,砷以砷酸钠的形式从铜液中脱除。然而,阳极铜中钠含量过高,在后续的电解中会影响电解液的饱和度,进而影响电解铜的质量,因此,碳酸钠熔剂不建议大量多次的使用。此外,学者们也采用了碳酸钾、碳酸锂以及生石灰[16]作为熔剂脱除砷的技术,也具有较好的脱砷效果。

3 铜电解过程中砷的清洁回收技术

3.1 电解液中砷的脱除技术进展

研究学者也根据砷的形态给出了不同的脱除砷技术。王学文等[17-20]指出铜电解过程中砷是以As3+的形式从阳极电化学溶解进入电解液,之后又被溶解在电解液中的氧气氧化成As5+,通过控制阳极铜中Sb与Bi的相对质量比,达到需要的Sb3+与Sb5+摩尔比5:1,加快砷锑酸盐在铜电解液中的沉淀析出。郑雅杰等[21]通过还原铜电解液中As5+和Sb5+,当电解液中As5+与As3+、Sb5+与Sb3+的物质的量比分别为0.4时,铜电解液中砷的脱除率可达到62%。NAVARRO等[22]通过活性炭吸附铜电解液中的As5+,取得了较好的吸附砷的效果。CIFUENTES等[23]通过电渗析法分离砷,可将H2SO4-CuSO4中的砷由3 g/L降至0.016 g/L。

铜电解液净化技术具有显著脱砷效果,能够有效消除电解液中以固体粒子、悬浮或漂浮物等形式存在的含砷物质,避免了阴极铜表面机械夹杂造成产品质量恶化的情况。但该技术难以运用到实际生产中,首先,通过电解液本身进行净化,由于阳极铜每批次元素含量不同,需要经常性地调节电解液组分浓度,工艺得不到有效动态控制;然后,通过添加锑、铋调节砷锑铋比例,砷锑铋形成的化合物进入阳极泥,对于具有稀散稀贵金属回收能力的企业来说,增加了处理阳极泥的困难。

3.2 阳极泥中砷的脱除技术进展

铜电解精炼产生的阳极泥砷含量在5%左右,阳极泥火法处理过程中,砷易与铅发生反应:Pb2++AsO43-→Pb3(AsO4)2,降低了铅的回收率,由于金银等贵金属主要依靠铅进行回收,铅渣的形成直接影响了金银的直收率。因此,在阳极泥预处理过程中需要先将砷进行脱除。夏德长[24]利用氢氧化钾溶液选择性脱除阳极泥中的砷,考察了氢氧化钾溶液浓度、温度、固液比等工艺条件对砷浸出的影响,砷的浸出率可达85%,砷得到了较好的处理效果。胡建辉等[25]通过优化铜阳极泥预处理脱铜工艺,砷以As5+的形式进入脱铜液中,砷的分散问题得到了解决。周犇[26]通过将铜阳极泥中铜、砷元素合成铜砷化合物,对金银提取过程中砷害进行了综合治理研究,达到了治理砷害的目的。

3.3 黑铜泥中砷的脱除技术进展

在铜电解液净化的电积工序中,电解阴极上产出的泥状物称为黑铜泥,其中铜、砷含量较大。目前,主要采用碱法和酸法处理黑铜泥。姚夏妍等[27]采用氧化碱浸的方法分离黑铜泥中的砷,考察了反应时间、NaOH用量、液固比、H2O2用量等对砷的浸出的影响,通过优化实验条件,砷和铜、锑、铋得到了很好的分离,砷的浸出率高达98%,铜、锑、铋主要存在于渣相。贺山明等[28]采用碱浸出工艺对黑铜泥进行脱砷,实现砷的浸出率达到95%以上,砷得到有效的选择性脱除。林泓富[29]通过对黑铜泥进行XRD分析,研究了砷在黑铜泥中以铜砷化合物的形式存在,进而选择采用硫酸浸出黑铜泥,砷浸出率92%以上。

4 砷的稳定性处理技术

铜冶炼过程中分离与富集后的含砷物料具有渣量大、成分复杂、砷含量高、易浸出等特点。目前,针对这些含砷物料的处置包括固化处理和稳定化处理。

4.1 固化处理技术

固化是指利用固化剂改变固废的工程特性(可压缩性、渗透性和强度等),将固废中有害元素组分包埋或固定于惰性基质内,使其具有化学稳定性或密封性。

4.1.1 水泥固化

水泥固化是在水泥水化过程中,含砷固废被有效的包裹(物理包裹和化学反应等)进胶凝材料当中,砷渣中的砷可以与钙形成 Ca—As 键,使砷被固定在水泥体内[30-31],从而实现含砷固废的无害化。由于水泥廉价易得,且固化过程操作简单、处理效果较好被广泛应用,也是美国环保局认为最行之有效的固化方法。但仍然存在增容比大、固化体成分不均一、长期稳定性差、易造成二次污染等问题。 汪吉章等[32]采用水泥对含砷飞灰进行固化处理,发现固化体中砷的浸出与pH关系密切,当pH<2和pH>11时,砷浸出量较大,中性环境下环境活性较低。

4.1.2 玻璃固化

玻璃固化是将含砷固废和玻璃形成材料混料后置于高温下进行煅烧、熔融反应,最后在急冷的过程中,网络形成体交联聚合形成玻璃体,同时污染物被固定在玻璃结构当中[33-34]。玻璃固化体具有结构稳定、长期稳定性能好、重金属浸出率低等优点,但成本高,操作复杂。玻璃固化常用于放射性固废、焚烧飞灰、电镀污泥、废电池等固废的安全处置[35-36]。SHI 等[37]采用B2O3修饰的铁磷酸盐固化体系对As2O3进行固化处理,发现砷在玻璃体系中参与了网络形成体的形成,即形成了P—O—As 键,从而实现了砷的固化。

4.1.3 有机聚合物固化

有机聚合物固化是将含砷固废与有机聚合物单体、催化剂等混合搅拌均匀,形成稳定的聚合物网络,从而达到无害化的目的。这类固化体能有效防止液体对固化体的侵蚀,防止重金属的释放,增容比小,但是存在固化剂被生物降解导致固化体破碎的可能性,因此固化体需用容器包装,增加了处理成本。FUOCO等[38]采用聚酯树脂对市政垃圾焚烧飞灰进行固化处理,浸出实验(pH=5.2,醋酸)结果表明,固化处理后有机污染物(PAHs、PCBs、OCPs)和重金属(Pb、Cd、Cu)的浸出浓度均低于规定阈值,环境风险显著降低;抗压强度测试实验表明,固化体的抗压强度远高于标准值。与常规水泥固化相比,聚酯树脂固化固定有机污染物和重金属的效果更好。SHAW等[34]利用新型水基质苯乙烯丁二烯及环氧树脂混合基体固化含砷固体吸附剂,固砷率超过60%,采用TCLP和CA-WET(废物提取实验)对固化体进行浸出研究,发现固化体具有良好的抗浸出性能;而且砷浸出浓度比常规水泥固化低一个数量级以上。

4.2 稳定化处理技术

稳定化处理技术即利用稳定剂改变物料中有害元素的物理化学性质,将高活性有毒有害的形态变成低迁移性、低溶解性和低毒性的形态,达到无害化的目的。

4.2.1 钙盐稳定化技术

钙盐稳定化技术是利用钙盐与砷发生反应,生成以砷酸钙为主的沉淀,以达到除砷目的,化学反应方程式如下:

4Ca2++ +2OH-= Ca3(AsO4)2·Ca(OH)2 (1)

+2OH-= Ca3(AsO4)2·Ca(OH)2 (1)

3Ca2++ =Ca3(AsO4)2 (2)

=Ca3(AsO4)2 (2)

钙盐稳定化技术工艺过程简单,适合在中性、碱性条件下使用,是目前最常用的稳定化处理方法;但是钙盐沉砷产生的砷酸钙具有渣量大、长期稳定性差等缺点,钙盐稳定化技术发展受到限制。

4.2.2 硫化稳定化技术

硫化稳定化技术是利用硫化试剂与砷反应,生成硫化砷沉淀[39-40]。化学反应方程式如下:

Na2S+H2SO4=H2S+Na2SO4 (3)

2H3AsO3+3H2S=As2S3+6H2O (4)

2H3AsO4+5H2S=As2S5+8H2O (5)

硫化稳定化技术具有污泥产量少、效果好等特点,但是在实际的操作过程中可能会释放H2S,导致二次污染。

4.2.3 铁盐稳定化技术

铁盐稳定化技术是利用铁盐与砷生成难溶的砷酸铁类物质,在此过程中可添加锰盐,将As3+氧化成As5+,As5+毒性远低于As3+毒性,通过氧化过程改变砷存在价态降低毒性,且氧化后的As5+离子化合物可迅速与铁盐发生沉淀反应,以达到除砷目的[41-43]。陆俏利等[44]采用FeCl2处理含砷废渣,发现在铁砷摩尔比≥1.0,反应时间≥1h,体系pH为6.5~7.5时,浸出毒性(HJ/T 299—2007)由64.9 mg/L降到2.5 mg/L以下,实现了含砷废渣的稳定。

4.2.4 零价铁稳定化技术

零价铁(Zero-valent iron, ZVI)廉价易得,比表面积高,在处理重金属方面受到越来越多研究者的关注。目前,零价铁对砷的去除主要概括为吸附作用和共沉淀作用。由于零价铁的表面活性较大,在溶液中会与H+以及O2发生反应,生成多种价态的铁化合物。而这些生成的新鲜化合物通过吸附、共沉淀作用去除砷[45-46]。零价铁常用于去除水环境中的重金属[47-49],如Cr、Cd、As等重金属,通过调控工艺条件,重金属的去除率可以达到90%。马会强等[50]采用零价铁修复含砷地下水,发现通过调节pH、无机阴离子、重金属、腐殖酸等条件可有效去除砷,去除率超过95.0%,达到水质要求。研究发现[51-52],在酸性条件下,向硫化砷渣中添加适量机械力改性后的零价铁,砷的浸出浓度由1539 mg/L 降至1.3 mg/L,实现了硫化砷渣的稳定化。李阳文君[53]采用机械力改性的Fe-FeS2 复合稳定剂稳定砷渣,砷浸出浓度从639.15 mg/L降至4.74 mg/L,实现了砷渣的稳定。虽然利用机械球磨处理固体废物已经有较多的应用研究,但是球磨过程中的反应机理仍不明确,研究者们对机械球磨理论也没有统一的共识。因此,机械球磨处理固体废物的相关基础研究是目前国际上此领域的研究热点和必然趋势。

5 未来砷的清洁回收技术的展望

围绕源头减量-高效转化-清洁利用技术链,研究适应铜冶炼含砷固废资源化利用处理技术,是未来处理含砷固废的重中之重。虽然砷的稳定性处理技术研究大多处于实验室阶段,但随着砷的减量化、资源化等稳定性处理的目标日益清晰,学者们一致认为将砷转化为稳定的矿物进行安全堆存是较合理的途径。臭葱石浸出毒性低、符合减量化要求,是固定砷最合适的人工矿石。如何提高采用含砷固废制备臭葱石的收率和在大自然环境下长期稳定,降低并防止稳定化过程中产生的重金属对人和自然的危害,实现经济和自然的和谐发展,将会成为学者们努力研究的方向。

REFERENCES

[1] 于丽丽, 唐镇忠, 马晓军, 等. 铬化砷酸铜防腐处理木材对环境安全的影响综述[J]. 生物质化学工程, 2013, 47(1): 61-65.

YU Li-li, TANG Zhen-zhong, MA Xiao-jun, et al. The evaluation of the impact of chromated copper arsenate treated wood on the environmental safety[J]. Biomass Chemical Engineering, 2013, 47(1): 61-65.

[2] 赵巧云. 砷化镓材料发展状况概述[J]. 科技论坛, 2016, (18): 183-185.

ZHAO Qiao-yu. An overview of the development of GaAs materials[J]. Technology Forum, 2016, (18): 183-185.

[3] 李 石, 邱立莉, 张 鹏. 环保竣工验收中对铜冶炼产生固废的处理方法研究[J]. 再生利用, 2015, 8(3): 42-44.

LI Shi, QIU Li-li, ZHANG Peng. Treatment of solid waste from copper smelting in the envirommental protection acceptance check[J]. Recycling, 2015, 8(3): 42-44.

[4] 王 倩, 郭 莉, 陈绍华, 等. 辉光放电等离子体辅助碱浸铜冶炼烟灰中铜砷分离[J]. 化工学报, 2017, 68(5): 1932-1939.

WANG Qian, GUO Li, CHEN Shao-hua, et al. Separation of copper and arsenic in copper smelting dust by Na2S-NaOH leaching assisted with glow discharge plasma[J]. CIESC Journal, 2017, 68(5): 1932-1939.

[5] 王玉芳, 李相良, 周起帆, 等. 铜冶炼烟尘技术处理综述[J]. 有色金属工程, 2019, 9(11): 53-59.

WANG Yu-fang, LI Xiang-liang, ZHOU Qi-fan, et al. Review on copper smelting flue dust treatment technology[J]. Nonferrous Metals Engineering, 2019, 9(11): 53-59.

[6] CHEN T T, DUTRIZAC J E. The mineralogy of copper eletrorefining[J]. The Journal of the Minerals, Metals & Materials Society, 1990, 42(8): 39-43.

[7] 易克俊. 砷在铜冶炼过程的分布及其控制[J]. 湖南有色金属, 2001, 17: 1-2.

YI Ke-jun. Distribution and control of arsenic in copper smelting process[J]. Hunan Nonferrous Metals, 2001, 17: 1-2.

[8] 董效林. 电感耦合等离子体原子发射光谱法测定铜阳极泥中8种元素[J]. 冶金分析, 2011, 31(8): 69-73.

DONG Xiao-lin. Determination of eight elements in copper anode mud by inductively coupled plasma atomic emission spectrometry[J]. Metallurgical Analysis, 2011, 31(8): 69-73.

[9] 王玉棉, 黄 雁, 周 兴, 等. 黑铜泥综合回收工艺研究[J]. 兰州理工大学学报, 2012, 38(1): 12-15.

WANG Yu-mian, HUANG Yan, ZHOU Xing, et al. Study of comprehensive recycling of black copper sludge[J]. Journal of Lanzhou University of Technology, 2012, 38(1): 12-15.

[10] 刘志宏. 中国铜冶炼节能减排现状与发展[J]. 有色金属科学与工程, 2014, 5(5): 1-12.

LIU Zhi-hong. Current situation and development of energy saving and waste reduction in Chinese copper smelting industry[J]. Nonferrous Metals Science and Engineering, 2014, 5(5): 1-12.

[11] 张晓峰, 曹佐英, 肖连生, 等. 焙烧对高砷白烟灰中铜浸出率的影响及其热力学分析[J]. 矿业工程, 2012, 32(5): 86-89.

ZHANG Xiao-feng, CAO Zuo-ying, XIAO Lian-sheng, et al. Effects on copper leaching rate in high-arsenic copper smelting ash by roasting and its thermodynamics[J]. Mining and Metallurgical Engineering, 2012, 32(5): 86-89.

[12] 徐宝强, 史腾腾, 杨 斌, 等. 含砷烟尘的处理及利用研究现状[J]. 昆明理工大学学报(自然科学版), 2019, 44(1): 1-11.

XU Bao-qiang, SHI Teng-teng, YANG Bin, et al. Research status on treatment and utilization of arsenic containing dust[J]. Journal of Kunming University of Science and Technology(Natural Science), 2019, 44(1): 1-11.

[13] 李思唯, 刘志宏, 刘智勇, 等. 铜闪速熔炼电收高砷烟尘硫酸化焙烧脱砷试验研究[J]. 湿法冶金, 2017, 36(4): 336-341.

LI Si-wei, LIU Zhi-hong, LIU Zhi-yong, et al. Removal of arsenic from ESP dust of copper flash smelting by sulphating roasting[J]. Hydrometallurgy of China, 2017, 36(4): 336-341.

[14] 李学鹏, 刘大春, 王 娟. 含砷铜烟尘砷的选择性分离实验[J]. 材料导报, 2018, 32(18): 3110-3115.

LI Xue-peng, LIU Da-chun, WANG Juan. Selective separation experiments of As from copper dust containing As[J]. Material Guide, 2018, 32(18): 3110-3115.

[15] KUCHARSKI M. Arsenic removal from blister copper by soda injection into melts[J]. Scandinavian Journal of Metallurgy, 2002, 31(4) : 246-250.

[16] HANS W F. Process for the removal of arsenic, antimony, tin and other acid oxide producing impurities from copper: US 3,262,773[P]. 1966-07-26.

[17] 王学文, 王明玉, 王兴明. 一种铜电解液净化工艺: CN104962738[P]. 2015-10-07.

WANG Xue-wen, WANG Ming-yu, WANG Xing-ming. A purification process of copper electrolyte: CN104962738[P]. 2015-10-07.

[18] WANG Xue-wen, CHEN Qi-yuan, YIN Zhou-lan, et al. Homogeneous precipitation of As, Sb and Bi impurities in copper electrolyte during electrorefining[J]. Hydrometallurgy, 2010, 105(3): 355-358.

[19] 王学文, 陈启元, 肖连生, 等. 一种铜电解液净化除杂方法: CN 101260539[P]. 2008-09-10.

WANG Xue-wen, CHEN Qi-yuan, XIAO Lian-sheng, et al. A purification and impurity removal method of copper electrolyte: CN 101260539[P]. 2008-09-10.

[20] 王学文, 王明玉, 王兴明. 一种铜电解液吸附脱杂净化方法: CN104060295[P]. 2014-09-24.

WANG Xue-wen, WANG Ming-yu, WANG Xing-ming. A purification method of adsorption and impurity removal of copper electrolyte: CN104060295[P]. 2014-09-24.

[21] 郑雅杰, 周文科, 彭映林, 等. 砷锑价态对铜电解液中砷锑铋脱除率的影响[J]. 中南大学学报(自然科学版), 2012, 43(3): 821-826.

ZHENG Ya-jie, ZHOU Wen-ke, PENG Ying-lin, et al. Effect of valences of arsenic, antimony on removal rates of arsenic, antimony and bismuth in copper electrolyte[J]. Journal of Central South University (Science and Technology), 2012, 43(3): 821-826.

[22] NAVARRO P, ALGUACIL F J. Adsorption of antimony and arsenic from a copper electrorefining solution onto activated carbon[J]. Hydrometallurgy, 2002, 66(1): 101-105.

[23] CIFUENTES L, CRISOSTOMO G, IBANEZ J P, et al. On the electro-dialysis of aqueous H2SO4-CuSO4 electrolytes with metallic impurities[J]. Journal of Membrane Science, 2002, 207 (1): 1-16.

[24] 夏德长. 从电解精炼铜阳极泥中选择性浸出砷和锑[J]. 湿法冶金, 1997(3): 61-64.

XIA De-chang. Selective leaching of arsenic and antimony from anode slime of electrorefining copper[J]. Hydrometallurgy, 1997(3): 61-64.

[25] 胡建辉, 张传福. 铜阳极泥预处理脱铜工艺优化[J]. 贵金属, 2002, 23(4): 1-5.

HU Jian-hui, ZHANG Chuan-fu. Optimization on process for copper removal from anode slime by pretreatment[J]. Precious Metals, 2002, 23(4): 1-5.

[26] 周 犇. 金银提取过程中砷害综合治理实践[J]. 有色金属(冶炼部分), 2002(3): 19-21.

ZHOU Ben. Arsenic comprehensive treatment practice in the Au and Ag extracting process[J]. Nonferrous Metals (Smelting Part), 2002(3): 19-21.

[27] 姚夏妍, 鲁兴武, 程 亮, 等. 氧化碱浸分离黑铜泥中砷的研究[J]. 有色金属工程, 2019, 9(6): 43-47.

YAO Xia-yan, LU Xing-wu, CHENG Liang, et al. Study on separation of arsenic from black copper slag by oxidation and alkali leaching[J]. Nonferrous Metals Engineering, 2019, 9(6): 43-47.

[28] 贺山明, 王瑞祥, 韩海军, 等. 黑铜渣氧压硫酸浸出脱铜脱砷实验研究[J]. 矿冶工程, 2018, 38(1): 84-87.

HE Shan-ming, WANG Rui-xiang, HAN Hai-jun, et al. Removal of arsenic and copper from black copper slag by oxygen pressure leaching with sulfuric acid[J]. Mining and Metallurgical Engineering, 2018, 38(1): 84-87.

[29] 林泓富. 黑铜渣铜砷浸出工艺研究[J]. 有色金属(冶炼部分), 2016(5): 10-12.

LIN Hong-fu. Technical study on leaching of copper and arsenic from black copper slag[J]. Nonferrous Metals (Smelting Part), 2016(5): 10-12.

[30] PHENRAT T, MARHABA T F, RACHAKORNKIJ M. A SEM and X-ray study for investigation of solidified/ stabilized arsenic-iron hydroxide sludge[J]. Journal of Hazardous Materials, 2005, 118(1): 185-195.

[31] SINGH T S, PANT K K. Solidification/stabilization of arsenic containing solid wastes using Portland cement, fly ash and polymeric materials[J]. Journal of Hazardous Materials, 2006, 131(1): 29-36.

[32] 汪吉章, 庞敏晖, 李善茂, 等. 含砷飞灰固化处理及浸出毒性试验研究[J]. 化学工程师, 2009, 23(5): 37-39.

WANG Ji-zhang, PANG Min-hui, LI Shan-mao, et al. Experimental study on solidification and leaching toxicity test of arsenic-containing fly ashes[J]. Chemical Engineer, 2009, 23(5): 37-39.

[33] 叶裕才. 有害固体废物的化学稳定和固化[J]. 重庆环境科学, 1984(5): 37-41.

YE Yu-cai. Chemical stabilization and solidification of hazardous solid waste[J]. Chongqing Environmental Science, 1984(5): 37-41.

[34] SHAW J K, FATHORDOOBADI S, ZELINSKI B J, et al. Stabilization of arsenic-bearing solid residuals in polymeric matrices[J]. Journal of Hazardous Materials, 2008, 152(3): 1115-1121.

[35] HRMA P, CRUM J V, BATES D J, et al. Vitrification and testing of a Hanford high level waste sample. Part 1: Glass fabrication, and chemical and radiochemical analysis[J]. Journal of Nuclear Materials, 2005, 345(1): 19-30.

[36] KUO Y M, CHANG J E, JIN C H, et al. Vitrification for reclaiming spent alkaline batteries[J]. Waste Management, 2009, 29(7): 2132-2139.

[37] SHI Mei-qing, LIANG Yan-jie, CHAI Li-yuan, et al. Raman and FTIR spectra of modified iron phosphate glasses containing arsenic[J]. Journal of Molecular Structure, 2015, 1081: 389-394.

[38] FUOCO R, CECCARINI A, TASSONE P, et al. Innovative stabilization/solidification processes of fly ash from an incinerator plant of urban solid waste[J]. Microchemical Journal, 2005, 79: 29-35.

[39] 崔 洁, 杜亚光, 刘 芫, 等. 工业硫化砷渣的性质研究与环境风险分析[J]. 硫酸工业, 2013(2): 41-46.

CUI Jie, DU Ya-guang, LIU Yuan, et al. Property research of industrial arsenic sulphide residue and environmental risk analysis[J]. Sulphuric Acid Industry, 2013(2): 41-46.

[40] 龙冬清, 贾军峰, 何田妹, 等. 硫化砷渣稳定化/固化处理及其效果评价[J]. 环保科技, 2014, 20(3): 7-11.

LONG Dong-qing, JIA Jun-feng, HE Tian-mei, et al. Stabilization/solidification of arsenic sulfide residue and effect evaluation[J]. Environmental Protection and Technology, 2014, 20(3): 7-11.

[41] PAKTUNC D, BRUGGEMAN K. Solubility of nanocrystalline scorodite and amorphous ferric arsenate: Implications for stabilization of arsenic in mine wastes[J]. Applied Geochemistry, 2010, 25(5): 674-683.

[42] 黄永炳, 董 婧, 王丽丽, 等. 除砷锰矿的稳定化处置研究[J]. 武汉理工大学学报, 2013, 35(9): 128-132.

HUANG Yong-bing, DONG Jing, WANG Li-li, et al. Stabilization treatment of manganese ore for arsenic removal[J]. Journal of Wuhan University of Technology, 2013, 35(9): 128-132.

[43] RAGHAV M, SHAN J, SAEZ A E, et al. Scoping candidate minerals for stabilization of arsenic-bearing solid residuals[J]. Journal of Hazardous Materials, 2013, 263(2): 525-532.

[44] 陆俏利, 瞿广飞, 吴 斌, 等. 矿区含砷尾矿及废渣稳定化研究[J]. 环境工程学报, 2016, 10(5): 2587-2594.

LU Qiao-li, QU Guang-fei, WU Bin, et al. Study on stabilization of arsenic tailings and waste residue[J]. Chinese Journal of Environmental Engineering, 2016, 10(5): 2587-2594.

[45] SUN Feng-long, OSSEOASARE K A, CHEN Yong-sheng, et al. Reduction of As(Ⅴ) to As(Ⅲ) by commercial ZVI or As(0) with acid-treated ZVI[J]. Journal of Hazardous Materials, 2011, 196(12): 311-317.

[46] 赵雅光, 万俊锋, 刘奉滨, 等. 零价铁(ZVI)治理水体砷污染研究进展[J]. 环境化学, 2013, 66(10): 1943-1949.

ZHAO Ya-guang, WAN Jun-feng, LIU Feng-bin, et al. Application of zero valent iron (ZVI) technology for arsenic removal from aqueous environment[J]. Environmental Chemistry, 2013, 66(10): 1943-1949.

[47] WU Yan-jun, ZHANG Jing-hui, TONG Yi-fei, et al. Chromium (Ⅵ) reduction in aqueous solutions by Fe3O4-stabilized Fe0, nanoparticles[J]. Journal of Hazardous Materials, 2009, 172(2): 1640-1645.

[48] BOPARAI H K, JOSEPH M, O'CARROLL D M. Kinetics and thermodynamics of cadmium ion removal by adsorption onto nano zero valent iron particles[J]. Journal of Hazardous Materials, 2011, 186(1): 458-465.

[49] MOSTAFA M G, CHEN Yen-hua, JEAN Jiin-Shuh, et al. Kinetics and mechanism of arsenate removal by nanosized iron oxide-coated perlite[J]. Journal of Hazardous Materials, 2011, 187(1): 89-95.

[50] 马会强, 师鹏飞, 石珍瑜, 等. 零价铁用于砷污染地下水修复的影响因素及效果[J]. 中国给水排水, 2017(1): 48-53.

MA Hui-qiang, SHI Peng-fei, SHI Zhen-yu, et al. Arsenic contaminated groundwater remediation using zero valent iron: Influencing factors and operation performance[J]. China Water and Wastewater, 2017(1): 48-53.

[51] LIANG Yan-jie, MIN Xiao-bo, CHAI Li-yuan, et al. Stabilization of arsenic sludge with mechanochemically modified zero valent iron[J]. Chemosphere, 2017, 168: 1142-1151.

[52] 王 密. 机械活化零价铁粉稳定含砷废渣的研究[D]. 长沙: 中南大学, 2015.

WANG Mi. Study on stabilization of arsenic-containing waste residue by mechanical activation of zero-valent iron powder[D]. Changsha: Central South University, 2015.

[53] 李阳文君. 铁基复合材料稳定含砷废渣的研究[D]. 长沙: 中南大学, 2017.

LI Yang-wen-jun. Study on the stability of arsenic- containing waste residue of iron matrix composites[D]. Changsha: Central South University, 2017.

ZHANG Yu1, 2, YI Xiao-yi1, LI Jun-jie2, GE Zhe-ling2

( 1. College of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China;

2. Yanggu Xiangguang Copper Company Limited, Liaocheng 252000, China)

Abstract: The methods of removing arsenic from electric precipitation dust, waste acid and electrolyte are mainly used to separate and enrich arsenic in the form of arsenic filter cake or black copper mud in the process of copper smelting, so as to solve the problem of open circuit of arsenic in copper smelting system. The arsenic slag is rich in valuable metals such as copper, rhenium, lead and zinc. There are some difficulties in arsenic recovery, such as secondary pollution and waste of resources. This paper discusses the distribution of arsenic in the processes of copper smelting, studies the existing form and reaction mechanism of arsenic in arsenic bearing materials, systematically summarizes the application of arsenic removal technology in the process of dust and electrolysis, and discusses the bottleneck encountered in actual production. Combined with the research on the stability treatment technology of arsenic in recent years, the future clean recovery technology of arsenic was prospected.

Key words: copper smelting; arsenic; secondary pollution; existing form; clean recovery

Foundation item: Project(2018CXGC1013) supported by the Major Scientific and Technological Innovation Program of Shandong Province, China

Received date: 2020-09-06; Accepted date: 2021-05-07

Corresponding author: ZHANG Yu; Tel: +86-18866353256; E-mail: yuzhangxuan@163.com

(编辑 龙怀中)

基金项目:山东省重大科技创新工程项目(2018CXGC1013)

收稿日期:2020-09-06;修订日期:2021-05-07

通信作者:张 煜,博士;电话:18866353256;E-mail:yuzhangxuan@163.com