文章编号:1004-0609(2016)-07-1444-07

冷却速度对B2-NiSc金属间化合物组织的影响

常亚涛,郭学锋,崔红保,原志鹏,朱攀攀

(河南理工大学 材料科学与工程学院,焦作 454000)

摘 要:采用真空电弧熔炼水冷铜模吸铸法制备Ni-50%Sc合金(摩尔分数,下同),采用程序计算、光学和扫描电子显微镜分析B2-NiSc金属间化合物急冷快速凝固组织的演化规律,采用XRD和EDS分析合金组织的相组成。结果表明:以名义成分Ni-50%Sc配制合金,真空水冷铜模吸铸成d 2、d 5和d 8 mm急冷试样对应的凝固速率分别为3112、497.9和194.5 K/s。Ro=1.5 mm为临界尺寸,对应着凝固速率的骤然变化。因Sc含量的损失,枝晶间出现了共晶(Ni2Sc+NiSc)组织;R>Ro(d5和d 8 mm试样),凝固组织为粗大枝晶B2-NiSc+共晶(Ni2Sc+NiSc)组织;R<Ro(d 2 mm试样)为细小球状枝晶B2-NiSc+少量共晶(Ni2Sc+NiSc)组织。经Image-Pro Plus面积分析和计算,合金熔化过程中Sc烧损约为3.25%~3.31%,从理论上,通过亚快速凝固不能获得单相B2-NiSc。急冷快速凝固后组织经(970 ℃,72 h)均匀热处理后,d 2 mm试样组织为粒状B2-NiSc+球状颗粒Ni2Sc,d5和d8 mm组织为粒状B2-NiSc+长条颗粒Ni2Sc。

关键词:金属间化合物;NiSc化合物;组织演化;急冷快速凝固

中图分类号:TG146.1 文献标志码:A

室温下,Al的滑移临界分切应力为1 MPa,Ni的滑移临界分切应力为3 MPa,而金属间化合物,如具有B2结构NiAl的滑移临界分切应力为30 MPa。可见,金属间化合物是典型的高强度金属材料。与匀晶、共晶、包晶和偏晶等合金凝固相比,部分金属间化合物凝固具有共熔特点,其结构具有复杂的混合键(金属、离子和共价键),性能介于金属和陶瓷之间,即轻、强、刚和耐腐蚀。因此,适合于制备交通运输、发电和化工设备的零部件[1]。但是,金属间化合物室温脆,应用受限。为了提高塑性,一般选择具有结构对称性的金属间化合物外,同时,采取各种材料制备工艺,如偏离准确计量化合物成分配制合金、经高温淬火获得无序结构、通过掺质(如硼)等[2-4]。即使如此,在已知的数以千计的金属间化合物中,仅有数十种具有工程上可以接受的韧塑性[1]。

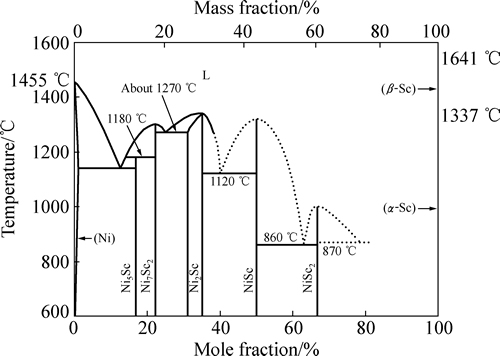

NiSc是具有B2结构的金属间化合物,然而查阅国内外相关文献研究大多集中在Ni-Sc二元系统的热力学性质,很少有对其本征性能的研究[5-8],因此,对NiSc的研究具有重要意义,对后续研究也有着比较重要的借鉴作用。图1所示为Ni-Sc二元相图。从图1中可以看出,成分为Ni-50%Sc(摩尔分数)时,可以获得B2结构的NiSc金属间化合物。当Sc含量低于50%Sc时,得到的是“初生NiSc+共晶(Ni2Sc+NiSc)”;反之是“初生NiSc+共晶(NiSc+NiSc2)”。由于B2-NiSc是线性金属间化合物,在平衡或近平衡凝固实验条件下,无论选用纯度多高的纯金属,也无法得到均质单相金属间化合物。除此之外,Sc是一种银白色的过渡性金属,一般在空气中迅速氧化而失去光泽[9],它的易氧化性[10]使其在熔炼过程中难免不发生损失,这就使得获得B2-NiSc成为一种几率性事件,通常情况下必然会同时会伴随第二相出现。如何获得均质单相B2-NiSc是研究其本征塑性的关键。快速凝固技术的发展[11-13],使在非平衡或极端不平衡条件下得到的合金具有超细的晶粒度,无偏析或少偏析的微晶组织,具有与常规合金不同的组织和结构特征[14-15]。另外,根据晶体中空位与温度的关系[16],

,单位面积内的空位数nν随着温度T升高而增多。通过快速凝固,将空位固定下来,有可能在偏离严格Ni-50%Sc情况下获得更为接近均质B2金属间化合物,从而可以接近更真实揭示其本征性能。因此,本文作者利用快速凝固技术研究了具有B2金属间化合物成分Ni-50%Sc合金的组织演变特点,分析了快速凝固对组织的影响。

,单位面积内的空位数nν随着温度T升高而增多。通过快速凝固,将空位固定下来,有可能在偏离严格Ni-50%Sc情况下获得更为接近均质B2金属间化合物,从而可以接近更真实揭示其本征性能。因此,本文作者利用快速凝固技术研究了具有B2金属间化合物成分Ni-50%Sc合金的组织演变特点,分析了快速凝固对组织的影响。

图1 Ni-Sc二元平衡相图

Fig. 1 Binary phase diagram of Ni-Sc alloy

1 实验

以纯度99.99%镍粒和99.99%钪块(质量分数)为原料,按照名义成分Ni-50%Sc(摩尔分数),用FA2004天平(精度0.1 mg)称量配料。实验前,镍粒用浓硝酸清洗,然后用酒精冲洗吹干,单质钪用砂纸打磨成银白色,超声波清洗,然后用酒精冲洗吹干。采用真空电弧熔炼水冷铜模吸铸d 2、d 5和d 8 mm 3组试样。为免污染,放入原材料前,电弧炉和铜模用10%(体积分数)硝酸酒精溶液清洗吹干。然后,将按名义成分称量好的原材料放入电弧炉中。为避免熔炼过程中原材料损失,将电弧炉腔抽真空至2.0×10-3 Pa,反充高纯氩气至0.05 MPa,并反复3次。然后,在氩气氛围下,预熔Ti块,以消耗炉内残余氧气,之后熔炼合金。为了获得成分均匀的金属间化合物,合金经“熔化—冷 却—翻转”6次循环后,将合金移至连通吸铸水冷铜模的熔炼池中熔化吸铸成不同直径的柱状试样。为了提高合金的均匀性,将真空吸铸的试样封装在高纯氩气保护的石英管内,经(970 ℃,72 h)长时间高温均匀化热处理。

不同状态下试样经打磨抛光后,用(V(HF): V(HNO3):V(H2O)=1:4:5)溶液腐蚀,用MA系列金相显微镜观察组织演化规律。用日本SmartLab公司生产的高分辨X射线衍射仪(XRD)分析合金的相组成,扫描范围:20°~120°,步长为4 (°)/min。用德国Merlin Compact公司生产的场发射扫描电子显微镜(SEM)配备Quantax X射线能谱仪(EDS)分析合金相的成分和微细组织,加速电压为20 kV。

2 结果与分析

2.1 Ni-50%Sc急冷快速凝固组织与组成

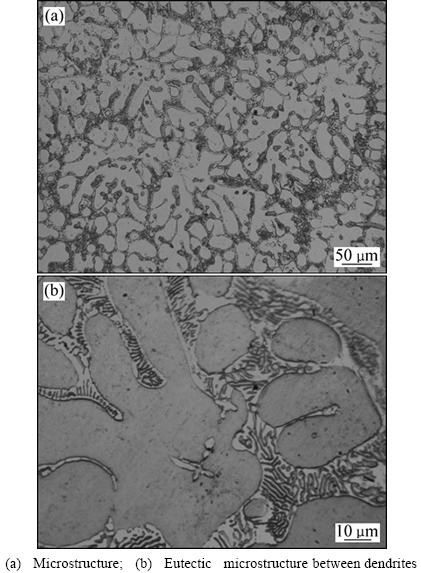

图2所示为成分为Ni-50%Sc合金,通过真空电弧熔炼水冷铜模吸铸尺寸为d 8 mm横截面中心区域的急冷组织。凝固组织中,枝晶方式生长的初生相为B2-NiSc金属间化合物,如图2(a)所示,枝晶臂和枝晶间为片状共晶组织,如图2(b)所示。

图2 d 8 mm真空吸铸Ni-50%Sc合金横截面中心区域的显微组织

Fig. 2 Central region microstructures of Ni-50%Sc alloy by rapidly solidified in water cooled copper mold with d8 mm diameter:

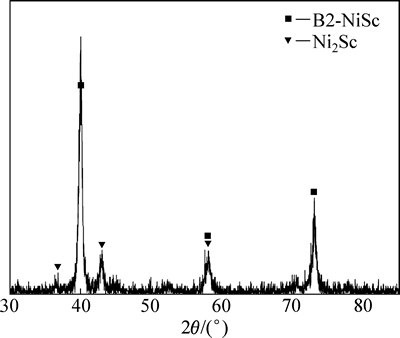

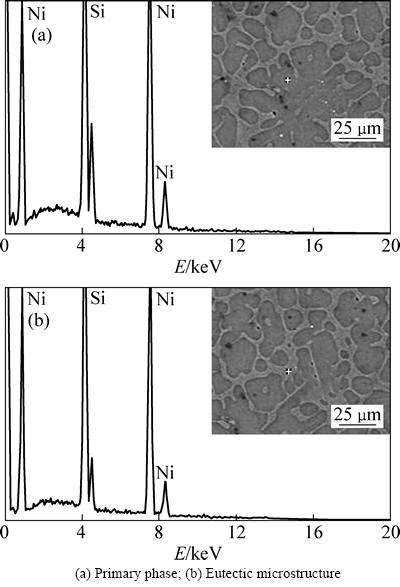

合金XRD分析结果如图3所示。合金组织由B2-NiSc和Ni2Sc两相组成。EDS分析表明,枝晶成分为Ni-49.94%Sc,是B2-NiSc线性金属间化合物;共晶成分为Ni-40.88%Sc,是(Ni2Sc+NiSc)共晶混合物,如图4所示。

由以上分析可知,按照Ni-50%Sc名义成分不能够熔配得到100%的B2-NiSc金属间化合物。实验过程中微量O与Sc会发生强烈反应,导致Sc的损失,使得到的实际成分偏向线性B2-NiSc金属间化合物左侧。这种偏移,在实验上难以控制,具有很大的随机性。由此可见,理论上通过实验获得100%的B2-NiSc金属间化合物完全是小概率事件,任何后续B2-NiSc金属间化合物的物性和力性研究,都具有一定的近似性和不确定性。

图3 d 8 mm真空吸铸Ni-50at%Sc合金XRD谱

Fig. 3 XRD pattern of Ni-50%Sc alloy by rapidly solidified in water cooled copper mold with d 8 mm diameter

图4 d 8 mm真空吸铸Ni-50%Sc合金EDS能谱分析结果

Fig. 4 EDS analyses results of Ni-50%Sc alloy by rapidly solidified in water cooled copper mold with d 8 mm diameter:

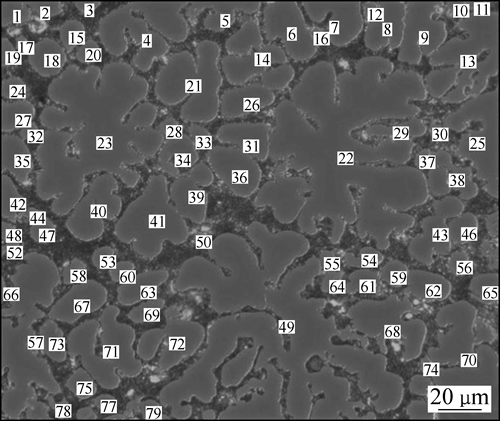

为了能够知道第二相的分数和分布,判断偏离B2-NiSc金属间化合物成分的程度,采用Image-Pro Plus面积计算软件分析组织中初生B2-NiSc和共晶(Ni2Sc+NiSc)的体积分数和各相实际含量。然后利用杠杆定律,近似计算试样中实际各元素所占配比,从而可以计算实验过程中Sc损失量。图5所示为d 8 mm横截面中心组织,经过计算,Sc含量为46.69%(摩尔分数,下同),熔化过程中Sc烧损3.31%。同样,对其他试样进行多次计算,最终得到在合金熔化过程中Sc烧损约为3.25%。

图5 d 8 mm横截面中心组织Image-Pro Plus体积分数分析金相照片

Fig. 5 Image-Pro Plus software analysis of phase volume fraction on central cross section of specimen with d 8 mm diameter

2.2 冷却速度对Ni-50%Sc凝固组织的影响

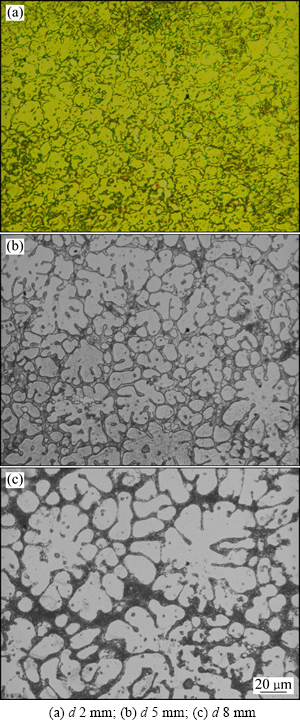

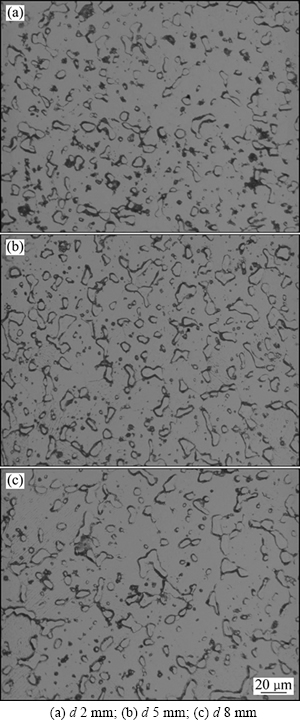

图6所示为成分为Ni-50%Sc的合金,通过真空电弧熔炼水冷铜模吸铸后3个不同直径d 2、d 5和d 8 mm横截面中心急冷组织。可以看出,急冷强度对组织影响大,直径越小,急冷能力越强,得到的组织越细小,共晶组织也越少。

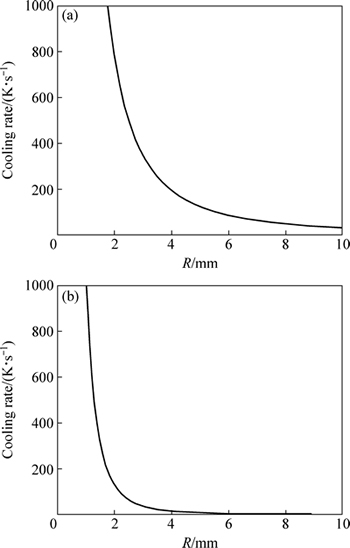

合金从熔点Tm冷却到室温Tg所用的冷却时间τ与合金半径R的关系可表示为[17-18]:

(1)

(1)

式中:κ为合金的热扩散速率,κ=K/c,K为导热系数,c为比热容。则合金的冷却速度 (K·s-1)为

(K·s-1)为

(2)

(2)

根据合金相图,Tm=1543 K,Tg=298 K,K=0.01W·mm-1·s-1·K-1,c=4×10-3 J·mm-3·K-1,则

(3)

(3)

图6 Ni-50%Sc合金不同急冷速率下试样横截面中心组织

Fig. 6 Central region microstructures of Ni-50%Sc alloy by rapidly solidified in water cooled copper molds with different diameters:

由式(3)计算所得的结果如图7所示。冷却速度随吸铸试样尺寸的减小,呈几何倍数递增,说明试样尺寸对冷却速度影响较大。从图7冷却速度与试样半径关系曲线还可以看出,当吸铸尺寸从d 8 mm( =194.5 K/s)减小到d 5 mm(

=194.5 K/s)减小到d 5 mm( =497.9 K/s)时,凝固速率变化不大;当吸铸尺寸从d 5 mm减小到d 2 mm(

=497.9 K/s)时,凝固速率变化不大;当吸铸尺寸从d 5 mm减小到d 2 mm( =3112 K/s)时,

=3112 K/s)时, =16,d 2 mm试样冷却速度比d8 mm试样的大16倍;

=16,d 2 mm试样冷却速度比d8 mm试样的大16倍; =6.25,d 2 mm试样冷却速度比d5 mm试样大6倍多。冷速变化率如式(4)所示:

=6.25,d 2 mm试样冷却速度比d5 mm试样大6倍多。冷速变化率如式(4)所示:

(4)

(4)

由式(4)得到的冷速变化率与试样半径关系如图7所示。当Ro=3/2 mm 时,是冷速变化的临界点;R<Ro时,冷却速率会陡然升高。因此,试验尺寸减少到d 2 mm时,凝固速率急剧上升,冷却速度很大。尽管如此,凝固速度仍然介于亚快速凝固范畴。观察金相组织可以看到,当吸铸尺寸为d 8 mm和d 5 mm时,枝晶的二次枝晶臂相当粗大。而吸铸尺寸为d 2 mm时,由于冷却速度很大,二次枝晶生长受到抑制,造成枝晶的二次枝晶臂很短小,组织中的枝晶基本上为球状颗粒,如图6所示。

图7 NiSc合金快速凝固冷却速度和冷速变化率与试样半径的关系

Fig. 7 Relationships between cooling rate (a) and variation of cooling rate (b) and radius of specimens

2.3 均匀化热处理后Ni-50%Sc组织形态

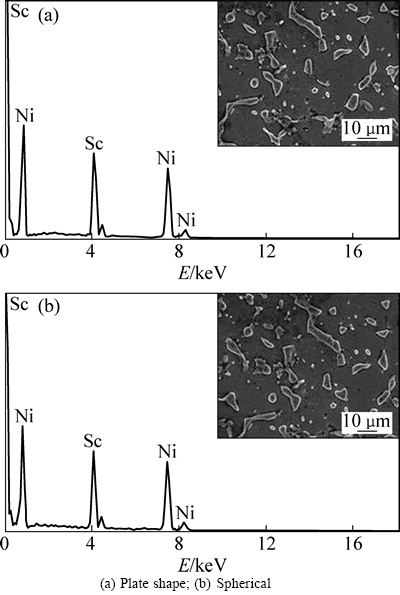

图8所示为Ni-50%Sc急冷快速凝固组织进行均匀化热处理后横截面中心组织。从图8中可以看出,经过970 ℃长时间的热处理后,初生B2-NiSc相枝晶形貌消失,晶间层片状共晶组织共晶(Ni2Sc+NiSc)中的共晶B2-NiSc相与初生相一起形成了新的晶粒,而Ni2Sc以颗粒状分布在晶界上,如图8所示。EDS分析表明,基体组织为B2-NiSc,不规则的球状颗粒(成分为Ni-36.20%Sc)或长条颗粒(成分为Ni-35.16%Sc)组织均为Ni2Sc相,如图9所示。

由于层片状组织的表面积与体积之比大于球状组织的表面积与体积之比,从而使得层片状组织比球状组织有更大的表面能,因此,层片状组织有自发转变成球状并聚集成大球团的趋势。这种自发过程是以扩散为基础,长时间的热处理后,合金组织发生原子的扩散迁移。其中,共晶中NiSc与初生相NiSc一起形成了新的晶粒,共晶中Ni2Sc在晶间形成了粒状,以不规则的球状颗粒或长条颗粒在晶间分布。实验中,冷速介于194.5~3112 K/s,亚快速凝固会引起组织内部表面能和应变能的升高,加速均匀化热处理速度。因此,原始凝固组织对均匀化热处理组织有显著影响。试样直径越小,急冷能力越强,凝固组织越细小,组织内部表面能和应变能也越大,经过长时间的热处理后,第二相Ni2Sc也越细小圆滑,形状多为圆球状均匀分布,如图9(a)所示。不同冷速对应不同组织,不同组织显然会影响到B2-NiSc本征性能的研究。

图8 不同急冷速率下Ni-50%Sc合金固溶热处理后试样横截面中心组织

Fig. 8 Central region microstructures underwent homogenization heat treatment of Ni-50%Sc alloy by rapidly solidified in water cooled copper molds with different diameters:

图9 d 8 mm真空吸铸Ni-50%Sc合金固溶热处理后EDS能谱分析结果

Fig. 9 EDS results after underwent homogenization heat treatment of Ni-50%Sc alloy by rapidly solidified in water cooled copper mold with d 8 mm diameter:

3 结论

1) 通过对名义成分Ni-50%Sc急冷快速凝固组织的研究,发现在凝固速度194.5~3112 K/s范围内,获得均质单相B2-NiSc组织概率很低。由于Sc含量损失,晶间出现了共晶(Ni2Sc+NiSc)组织。Image-Pro Plus软件相含量计算得到,合金熔炼过程中Sc烧损约3.25%~3.31%。

2) 急冷强度对组织影响很大,Ro=3/2 mm是冷速(1383.1 K/s)变化的临界点。因此,R>Ro(d 5和d 8 mm试样),凝固组织初生相为粗大枝晶B2-NiSc和共晶(Ni2Sc+NiSc)复合组织。R<Ro(d 2 mm试样),冷却速度呈倍数递增的趋势,当冷速为3112 K/s,急冷能力增强,组织变得细小,共晶组织也相应减少,凝固组织初生相B2-NiSc为粒状晶。

3) 凝固速率对均匀热处理有显著影响,经(970 ℃,72 h)均匀热处理后,因固态扩散,组织为粒状B2-NiSc+Ni2Sc。R>Ro时,Ni2Sc主要以长条颗粒分布在晶粒晶界上。R<Ro时,Ni2Sc主要以球状颗粒分布在晶粒晶界上。

REFERENCES

[1] RUSSELL A M. Ductility in intermetallic compounds[J]. Advanced Engineering Materials, 2003, 5(9): 629-639.

[2] WANG Rui, WANG Shao-feng, YAO Yin, LIU Li-li, WU Xiao-zhi. The temperature-dependent elastic properties of B2-MgRE intermetallic compounds from first principles[J]. Physica B: Condensed Matter, 2012, 407(1): 96-102.

[3] González E, Jasen P, Marchetti J M, Brizuela G, Juan A. Density functional and bonding study of hydrogen and platinum adsorption on B2-FeTi (111) slab[J]. International Journal of Hydrogen Energy, 2012, 37(3): 2661-2668.

[4] Diakonova N P, Sviridova T A, Semina V K, Skakov Y A. Intermetallic phase stability on high energy treatments (rapid quenching, ion irradiation and mechanical milling)[J]. Journal of Alloys and Compounds, 2004, 367(1/2): 199-204.

[5] CAO Zhao-ping, LIU Shu-hong, FANG Xu, CHENG Kai-ming, GAO Qian-nan, DU Yong, WANG Jiong, ZHANG Jun, HUANG Wei-dong, TANG Cheng-ying. Experimental investigation and thermodynamic analysis of the Sc-Ni system supplemented with first-principles calculations[J]. Thermochimica Acta, 2014, 586(8): 30-39.

[6] Shevchenko M A, Ivanov M I, Berezutskii V V, Kudin V G, Sudavtsova V S. Thermodynamic properties of alloys of the Ni-Sc and Ni-Y systems[J]. Russian Journal of Physical Chemistry A, 2014, 88(6): 897-902.

[7] ZHU Dai-man, LI Chang-rong, GUO Cui-ping, DU Zhen-min, LI Jun-qin. Thermodynamic assessment of the Ni-Sc binary system[J]. CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry, 2015, 48: 106-112.

[8] Kardellass S, Servant C, Selhaoui N, Iddaoudi A, Ait Amar M, Bouirden L. Thermodynamic description of the Ni-Sc system[J]. CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry, 2013, 42: 59-65.

[9] 尹志民. 钪和含钪合金[M]. 长沙: 中南大学出版社, 2007.

YIN Zhi-min. Scandium and containing scandium alloys[M]. Changsha: Central South University Press, 2007.

[10] 林河成. 中国金属抗材料的发展现状及其前景[J]. 中国有色冶金, 2010, 39(2): 34-38.

LIN He-cheng. Status and development prospects of domestic metal scandium material[J]. China Nonferrous Metallurgy, 2010, 39(2): 34-38.

[11] 周书和, 刘 明, 孙占红, 迟志艳. 金属快速凝固理论及材料制备方法[J]. 科学之友, 2009(5): 29-30.

ZHOU Shu-he, LIU Ming, SUN Zhan-hong, CHI Zhi-yan. Metal rapid solidification theory and manufacturing technique[J]. Friend of Science Amateurs, 2009(5): 29-30.

[12] 梅策香, 柳 钰, 张小安. 快速凝固的非平衡效应研究[J]. 材料导报, 2009, 23(6): 90-93.

MEI Ce-xiang, LIU Yu, ZHANG Xiao-an. Study on non-equilibrium effect of rapid solidification[J]. Materials Review, 2009, 23(6): 90-93.

[13] 刘胜杰, 黄梦真. 快速凝固技术的应用研究[J]. 农业网络信息, 2013(3): 9-10.

LIU Sheng-jie, HUANG Meng-zhen. Rapid solidification technology and its application[J]. Agriculture Network Information, 2013(3): 9-10.

[14] 杨 伟, 陈寿辉, 张守银, 余 欢, 严青松, 蔡长春. 冷却速率对AZ91D镁合金非平衡凝固组织的影响[J]. 中国有色金属学报. 2014, 24(3): 593-599.

YANG Wei, CHEN Shou-hui, ZHANG Shou-yin, YU Huan, YAN Qing-song, CAI Chang-chun. Effect of cooling rate on non-equilibrium solidified microstructure of AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals. 2014, 24(3): 593-599.

[15] 蔡志勇, 王日初, 张 纯, 彭超群, 解立川. 快速凝固过共晶Al-Si合金的显微组织及其热稳定性[J]. 中国有色金属学报. 2015, 25(3): 618-625.

CAI Zhi-yong, WANG Ri-chu, ZHANG Chun, PENG Chao-qun, XIE Li-chun. Microstructure and thermal stability of rapidly solidified hypereutectic Al-Si alloys[J]. The Chinese Journal of Nonferrous Metals. 2015, 25(3): 618-625.

[16] ASKELAND D R, FULAY P P. Essentials of materials science and engineering[M]. American: Cengage Learning, 2013.

[17] Kissinger H E. Reaction kinetics in differential thermal analysis[J]. Analytical Chemistry, 2002, 29(11): 1702-1706.

[18] GUO Jin-bo, CAO Chong-de, GONG Su-lian, SONG Rui-bo, BAI Xiao-jun, WANG Jian-yuan, ZHENG Jian-bang, WEN Xi-xing, SUN Zhan-bo. Rapid solidification of Cu60Co30Cr10 alloy under different conditions[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(3): 731-734.

Effect of cooling rate on microstructure evolution of alloy mainly consisted of B2-NiSc intermetallics

CHANG Ya-tao, GUO Xue-feng, CUI Hong-bao, YUAN Zhi-peng, ZHU Pan-pan

(School of Materials Science and Engineering, Henan Polytechnic University, Jiaozuo 454000, China)

Abstract: Ni-50%Sc alloy was prepared with a vacuum arc smelting and water cooled copper mold suction-casting machine. The microstructure evolution of the rapidly solidified alloy which mainly consists of B2-NiSc phase was analyzed by optical metalloscopy and scanning electron microscopy. The microstructure constitutes was also calculated with an Image-Pro Plus software. XRD was used to identify phase microstructural components, and further more the composition of each phase was analyzed with EDS. The cooling rates for the solidified specimens with diameters of 2, 5 and 8 mm were 3112, 497.9 and 194.5 K/s, respectively. It is found that Ro=3/2 mm is a critical dimension which corresponds to an abrupt change in solidification rate. It is also found that eutectic mixture structure of (Ni2Sc+NiSc) is dispersed at grain boundary or between dendritic arms due to the loss of Sc element during melting. While R>Ro (corresponding to the specimens with diameters of 5 and 8 mm), the solidification structure consists with coarse B2-NiSc dendrite and eutectic (Ni2Sc+NiSc). While R<Ro (corresponding to the specimens with diameter of 2 mm), the solidification structure consists with fine globular B2-NiSc dendrite and relatively small amounts of eutectic (Ni2Sc+NiSc). Based on the phase volumetric analyzing of the microstructure with an Image-Pro Plus software, the loss of Sc element during melting is about 3.25%~3.31% in according with specimens diameters. Therefore, it could be concluded that B2-NiSc intermetallics without any second phase is difficult to achieve under the condition of sub-rapid solidification. Microstructures underwent (970 ℃, 72 h) homogenization heat treatment of the rapid solidified specimens were analyzed. Spherical Ni2Sc particles are dispersed on the B2-NiSc matrix for the specimen with 2 mm diameter, but the second phase Ni2Sc is in plate shape for the specimens with 5 and 8 mm diameters.

Key words: intermetallics; NiSc alloy; microstructure evolution; rapidly solidification

Foundation item: Projects(51271073, 51301063) supported by the National Natural Science Foundation of China

Received date: 2015-09-16; Accepted date: 2016-01-18

Corresponding author: GUO Xue-feng; Tel: +86-391-3986906; E-mail: guoxuef@hpu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51271073,51301063)

收稿日期:2015-09-16;修订日期:2016-01-18

通信作者:郭学锋,教授,博士;电话:0391-3986906;E-mail:guoxuef@hpu.edu.cn