DOI: 10.11817/j.issn.1672-7207.2015.07.052

同步还原焙烧法降低循环流化床固硫粉煤灰三氧化硫并回收铁精矿实验

刘汇东1,代世峰2,孙继华1,夹少辉1,张松峰1

(1. 中国矿业大学(北京) 地球科学与测绘工程学院,北京,100083;

2. 中国矿业大学(北京) 煤炭资源与安全开采国家重点实验室,北京,100083)

摘要:以重庆安稳电厂高烧失量、高SO3和铁质量分数的循环流化床固硫粉煤灰为例,运用同步还原焙烧—湿法弱磁选铁精矿方法对粉煤灰进行协同降硫和选铁实验:以粉煤灰中未燃尽碳作还原剂而无须额外添加,在一次还原焙烧工序中同步实现了粉煤灰中SO3载体矿物无水石膏(CaSO4)的分解以及赤铁矿(Fe2O3)的磁化;采用水淬法冷却,湿法弱磁选铁精矿,在水淬和湿法磁选阶段CaSO4分解产物CaS水化生成粉煤灰的有益组分Ca(OH)2;另一水化产物H2S气体亦予以回收利用。研究结果表明:循环流化床固硫粉煤灰经900 ℃下还原焙烧15 min,再经水淬快速冷却、湿法弱磁选铁精矿,可获得总铁回收率49.8%、品位52.9%的铁精矿;处理后的粉煤灰烧失量和SO3质量分数分别降至5.3%和1.32%,达到GB/T 1596—2005“用于水泥和混凝土中的粉煤灰”中的相应指标。

关键词:安稳电厂;循环流化床;固硫粉煤灰;同步还原;磁化焙烧;三氧化硫

中图分类号:TP 028.8 文献标志码:A 文章编号:1672-7207(2015)07-2762-08

Synchronous reduction roasting experiments for lessening of SO3 and iron recycling from circulating fluidized bed fly ash

LIU Huidong1, DAI Shifeng2, SUN Jihua1, JIA Shaohui1, ZHANG Songfeng1

(1. College of Geoscience and Surveying Engineering, China University of Mining and Technology (Beijing),

Beijing 100083, China;

2. State Key Laboratory of Coal Resources and Safe Mining, China University of Mining and Technology (Beijing),

Beijing 100083, China)

Abstract: The Anwen plant in Chongqing of China is characterized by high contents of loss on ignition (LOI), SO3 and iron. Experiments for recycling iron and reducing contents of SO3 and LOI in CFB desulfurization fly ash were carried out on the Anwen fly ash. A synchronous reduction roasting process was performed, with the unburned carbon in fly ash as the deoxidizer, followed by a wet magnetic separation. In only once reduction roasting process, the magnetization of hematite and the decomposition of anhydrite (CaSO4), sulfur trioxide’s carrier mineral, were completed simultaneously. During the procedures of water quenching cooling and wet magnetic separation, CaS, one of the decomposition products of CaSO4 was transformed to Ca(OH)2 by hydration; another decomposition product H2S was recovered and utilized. The results show that reductive roasting of the fly ash at 900 ℃ for 15 min, followed by recycling of iron using wet weak magnetic separator, an iron recovery rate of 52.9% and a concentrate grade of 49.8% are achieved. Meanwhile, the LOI and SO3 contents of the fly ash decrease to 5.3% and 1.32%, respectively. Thus, the treated fly ash satisfies the standard in GB/T 1596—2005 about fly ash used for cement and concrete production.

Key words: Anwen plant; circulating fluidized bed; desulfurization fly ash; synchronous reduction; magnetizing roast; sulfur trioxide

循环流化床(circulating fluidized bed, CFB)锅炉技术是近年来迅速发展起来的一项高效清洁燃烧技术。与煤粉炉相比,CFB锅炉对燃料的适应性好,可以燃用煤矸石及煤泥等高灰、高硫劣质燃料[1];最佳燃烧温度为830~930 ℃[2],属低温燃烧,NOx排放量更小[1-2]。随着我国优质煤炭资源的日渐稀缺和环保要求的逐步提高,未来几年我国循环流化床锅炉技术仍将得到进一步快速发展[3]。随之产生的问题是CFB粉煤灰产量也将快速增长。CFB炉普遍采用石灰石(粉)燃中固硫,产出的粉煤灰称为固硫粉煤灰,其中SO3含量普遍偏高[4]。较低的燃烧温度也导致了有机质燃烧不彻底,粉煤灰烧失量(loss of ignition,LOI,用于近似表征未燃尽碳含量)过高。以上2个问题严重限制了CFB固硫粉煤灰在水泥和混凝土领域的应用。很多学者研究了循环流化床粉煤灰的回燃[5]、浮选[6-7]及摩擦电选[8-10]等技术工艺来降低粉煤灰LOI以及回收精碳,通过高温再煅烧法[11]使SO3载体CaSO4在1 200 ℃以上高温下分解并重新结晶生成C3S,C2S,C3A和C4AF等水硬活性成分同时降低SO3含量。以上方法存在的问题是综合能耗高,经济附加值偏低,不利于调动企业生产的积极性,从而难以实现规模化应用。此外,魏绍荣等[12]开展了粉煤灰专用高效除硫剂的研究,对三氧化硫的去除效果较好,但除硫剂成分未予以公开。煤中硫的主要载体是黄铁矿(FeS2)。CFB炉普遍燃用的高灰、高硫煤或矸石中高含量的黄铁矿可造成CFB粉煤灰中铁的富集。对全国205家电厂粉煤灰常量元素的统计[13]显示,粉煤灰中铁质量分数在5%以上的有66家,其质量分数最高者达到11.87%。根据经验,粉煤灰中铁质量分数达到5%以上即具有回收利用价值[14]。本文作者针对CFB固硫粉煤灰高碳、高硫、高铁的一般特征,拟通过同步还原焙烧-湿法弱磁选铁精矿实验,在一套工序中同步实现CFB固硫粉煤灰LOI和SO3质量分数的下降以及铁精矿产品的回收。以回收铁精矿较高的经济附加值作为补偿,带动粉煤灰的有效消纳,从而实现经济效益与环境效益的协同发展。

1 样品采集及研究方法

安稳电厂采用石灰石粉燃中固硫,配备2套双室四电场静电除尘器,采用气力输灰。以松藻煤矿高灰、中高硫—高硫无烟煤和煤矸石为燃料,年产CFB固硫粉煤灰约30 万t。由于LOI和SO3含量大幅超标而长期无法得到有效利用,现基本全部堆存于灰场,为企业运营和周边环境带来双重压力。

本研究样品采自重庆松藻电力公司安稳电厂2台480 t/h循环流化床锅炉(分别编号1号和2号)。每天上午、下午各采样1次,每次约500 g,1号和2号锅炉分别共连续采得粉煤灰样品8个和13个。

采用美国Thermo Fisher公司的ADVANT’ XP+型X线荧光光谱仪测定了粉煤灰样品中的Si,Al,Fe,Ca和Ti等常量元素含量。为保证测试精度,所有待测样品均预先依照ASTM 标准进行了高温灰化,以消除粉煤灰中有机质的干扰作用,再以加拿大Claisse公司的TheBee-10 型电熔样机对高温灰样品进行熔片法制样,最终选用美国国家标准与技术研究院(NIST)的2089,2090和2091号标准样品进行测试数据的校准。粉煤灰LOI依照ASTM D3174—11标准测定,最高灰化温度为750 ℃,可避免粉煤灰中无水石膏分解对LOI测定精度造成干扰。SO3含量依照GB/T 176—2008中所述方法测定。

采用日本Rigaku公司的D/Max 2500CP型X线衍射仪(XRD,Cu靶,Kα射线,步长0.02°,功率40 kV,150 mA)对粉煤灰样品的矿物组成进行分析。粉煤灰样品粉末直接压片后上机测试,扫描速度为2 (°)/min,扫描范围为2.6°~70.0°。采用澳大利亚联邦科学与工业研究组织(CSIRO)根据Rietveld原理设计开发的SiroquantTM全套技术,对粉煤灰样品进行矿物(包含非晶质体)组成进行定量分析。

强磁选采用江西赣州绿洲选矿设备制造有限公司生产的XCQS-50×70 型湿法强磁选机。该型磁选机以齿状板做聚磁介质,磁感应强度最高为3.2 T,连续可调,常用作低品位氧化铁矿石的强磁选实验。

磁化焙烧实验采用带有温度调节功能的马弗炉,由天津中环电炉公司生产。弱磁选实验采用煤炭科学研究总院唐山研究院研制的CXG-90A 型磁选管,磁感应强度在0~350 mT范围内连续可调。

2 CFB固硫粉煤灰的物质组成

2.1 粉煤灰的LOI及常量元素组成

粉煤灰LOI及常量元素含量如表1 所示。根据GB/T 1596—2005“用于水泥和混凝土中的粉煤灰”中对粉煤灰的分级,Ⅰ,Ⅱ和Ⅲ 级粉煤灰对应的LOI上限分别为5%,8%和15%,SO3质量分数均不能高于3%。由表1可知:LOI和SO3 含量过高应该是造成安稳粉煤灰大规模积压的直接原因。循环流化床锅炉的气固分离装置将烟气中大颗粒固体物质分离下来进行循环燃烧,因而循环流化床粉煤灰通常都具有良好的细度。安稳电厂粉煤灰45 μm 筛余量小于12%,达到Ⅰ级粉煤灰标准。因而开发简洁高效的减碳、降硫技术,提高粉煤灰的经济附加值,是解决安稳电厂粉煤灰积压问题的有效途径。此外,1号和2号锅炉粉煤灰中铁质量分数分别达到12.25%和13.30%,具备较好的回收利用价值。

表1 安稳电厂粉煤灰LOI及常量元素组成(质量分数)

Table 1 Contents of major elements and LOI of fly ash from Anwen plant %

2.2 粉煤灰的矿物学组成

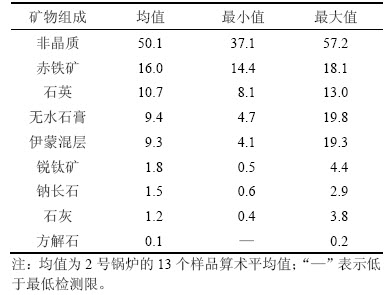

粉煤灰的XRD 矿物定性及Siroquant 定量分析结果见表2。粉煤灰中铁的基本全部以赤铁矿形式赋存;赤铁矿的比磁化系数小,常规磁法选别的难度将较大。

3 CFB固硫粉煤灰的强磁选实验

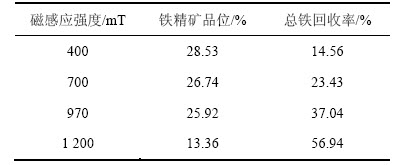

首先对安稳粉煤灰共进行了不同磁场强度的4 次湿法强磁选实验,结果如表3 所示。铁精矿品位与回收率整体呈负相关性(图1):磁感应强度为400 mT下精矿品位为28.53%,回收率仅为14.56%;升高磁感应强度至1 200 mT后总铁回收率升至最高的56.94%,但此时铁精矿品位已降至13.36%。

初步实验结果表明:安稳粉煤灰强磁选难以取得良好的铁精矿品位与回收率指标。赤铁矿磁性弱,与其他矿物颗粒的比磁化系数差异较小,是造成这一情况的主要原因。

表2 安稳粉煤灰的SiroquantTM矿物定量结果

Table 2 Quantitative analysis of minerals in fly ash by means of SiroquantTM technology %

表3 安稳粉煤灰强磁选铁精矿实验结果

Table 3 Data of high-intensity magnetic separations of Anwen fly ash

图1 强磁选铁精矿品位与总铁回收率关系

Fig. 1 Relationship between concentrate grades and iron recovery rates

4 CFB固硫粉煤灰的还原焙烧-磁 选铁精矿、减碳、降硫实验

4.1 磁化焙烧—磁选铁精矿实验

Jozwiak等[15]认为,在采用其他选矿方法不能得到较好经济技术指标时,磁化焙烧—弱磁选法分选赤铁矿是回收弱磁性铁矿石的有效选矿方法。其原理为通过还原焙烧,使原矿中的弱磁性含铁矿物(赤铁矿、褐铁矿等) 磁化为强磁性的磁铁矿(Fe3O4),进而以弱磁选机磁选回收铁精矿[16-17]。罗立群等[17]采用流态化闪速还原炉,在弱还原气氛(CO气体作还原剂)下,740~800 ℃磁化焙烧60 s以内,弱磁选获得了铁品位为5.51%~55.35%的铁精矿。郭学益等[18]在镍红土矿加压浸出渣中添加质量分数20%的无烟煤作还原剂,750 ℃下焙烧60 min,水冷后弱磁选(磁感应强度为245 mT)铁精矿,铁品位和回收率分别为64%和94%。

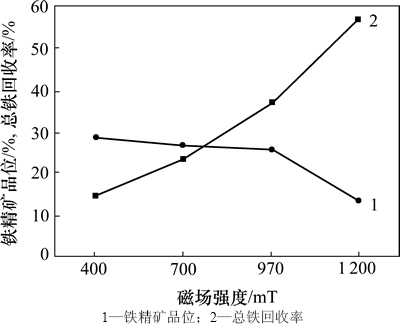

结合上述研究,针对安稳电厂粉煤灰含铁矿物主要为弱磁性的赤铁矿这一特征,又设计了4 因素3 水平正交实验,以研究安稳粉煤灰磁化焙烧并磁选铁精矿的最佳条件。所用安稳CFB固硫粉煤灰LOI为9.0%,铁质量分数为8.90%,SO3质量分数为9.6%。磁化焙烧设备为具有自动控温功能的马弗炉和带盖陶瓷坩埚等,还原剂为低灰、低硫、高热值的无烟煤(破碎至粒度小于76 μm)。磁选设备选用CXG-90A型磁选管。实验方案及结果如表4所示。

根据表4 所示实验结果,综合考虑铁精矿品位和总铁回收率,本次正交实验以实验2 的结果最为理想:铁精矿品位达到53.3%,回收率达到54.6%。由表2还可知:优选的实验条件为添加10%的还原剂(低灰无烟煤),800 ℃下焙烧30 min,以1.5 A的激磁电流(磁感应强度为160 mT)湿法磁选铁精矿。而本次正交实验未包含该理论优选方案。

补充实验依照理论优选方案的实验条件进行,实验结果显示,铁精矿品位为49.5%,总铁回收率仅为37.5%,二者均低于实验2 的结果。这可能与实验条件之间的交互作用有关;还原剂过量也可能导致过还原反应的发生,使磁铁矿转化为弱磁性的方铁矿(FeO)[19]。

表4 安稳粉煤灰磁化焙烧-磁选铁精矿L9(34)正交实验方案及结果

Table 4 Condition and result of magnetizing roasting-magnetic separation L9(34) orthogonal test of Anwen fly ash

4.2 CFB固硫粉煤灰中三氧化硫的还原分解

粉煤灰中三氧化硫(SO3)的实际载体是无水石膏(CaSO4)。石膏在水泥中起调节凝结时间的作用。水泥水化过程中,适量的CaSO4与铝酸三钙(C3A)生成钙矾石薄膜包裹于C3A表面,阻碍C3A内部的继续水化从而达到使水泥缓凝的目的,但过量的钙矾石会因吸水而引发显著体积膨胀[20],对水泥或混凝土构件的安定性造成危害。

纯净的石膏在非还原气氛中的分解起始温度在1 000 ℃以上[21-22]。诸多研究表明,还原气氛下硫酸钙分解反应的起始温度可以大大降低[23-24]。张雪梅 等[25]分别对以H2,CH4,CO及C作还原剂时CaSO4的分解反应及可能存在的副反应进行了热力学计算,结果表明以上还原剂的加入均可显著降低CaSO4的分解温度。朱凯等[26]对CO 气氛下磷石膏的分解行为研究表明,900 ℃下CO浓度和反应温度的增加可以提高CaSO4的分解速率和转化率;且SiO2,Fe2O3等成分对CaSO4分解反应具有较好的催化作用[26-27]。CaSO4与C可能发生如下的反应[28]:CaSO4+C→CaS+CO2;CaSO4+C→CaO+SO2+CO2;CaSO4+C→CaS+CO2+CO。

此外还可能发生CaSO4 的热分解,以及CaSO4,CaS,CaO与CO,CO2,SO2相互之间的极为复杂的副反应[25]。但在CaSO4与C摩尔比确定之后,其还原焙烧始终处于相对密闭的环境下,因而可以近似认为上述各反应物及生成物的比例是焙烧温度和焙烧时间的函数,即焙烧温度和焙烧时间决定了反应最终CaSO4的分解率。因此,可以不引入CO,CO2和SO2分压等参数而只考察焙烧温度和焙烧时间2个因素,来探讨CaSO4的还原分解率。

通过上述分析,在磁化(还原)焙烧阶段,应当存在焙烧温度和焙烧时间的某个区间,在此区间内可以同步实现赤铁矿较高的磁化率和CaSO4较高的分解率。即通过控制焙烧温度和焙烧时间,来降低CFB固硫粉煤灰中SO3含量,使之适用于水泥和混凝土生产;由此将能较为经济地解决CFB固硫粉煤灰的利用问题。

根据电子守恒原理,并通过保守计算,即以粉煤灰中全部Fe2O3和CaSO4被还原为Fe3O4和CaS,C被氧化为CO计(亦即Fe3+→Fe8/3+,S6+→S2-,C0→C2+),在密闭环境下,以上反应所需还原碳的质量分数为5.8%,仍低于安稳粉煤灰中所含未燃尽碳质量分数(9.0%),因而可以保证焙烧始终处于还原气氛下进行。

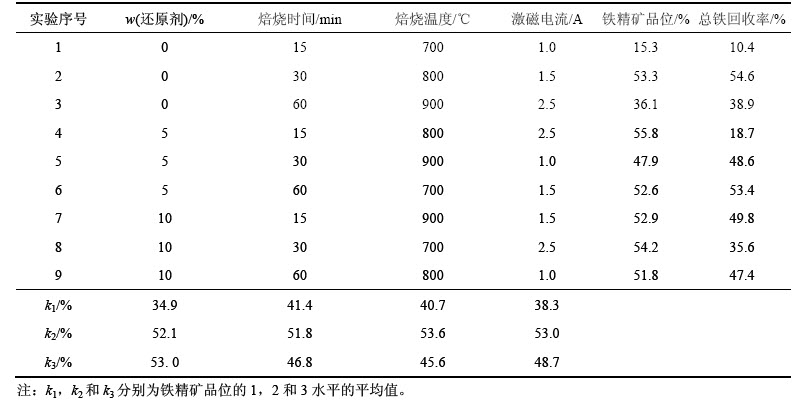

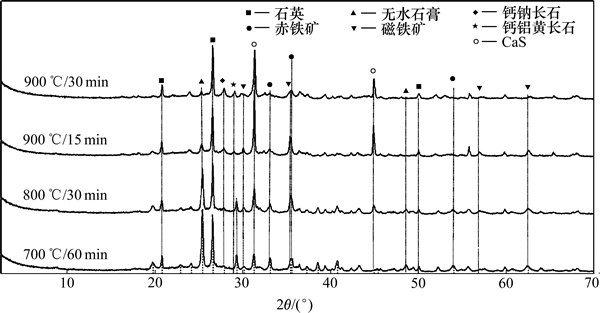

因此,SO3分解实验在赤铁矿磁化焙烧实验的基础上,不额外添加还原剂,进行了700 ℃/60 min,800 ℃/30 min,900 ℃/15 min和900 ℃/30 min 4次还原焙烧实验。对还原焙烧后的CFB固硫粉煤灰样品进行了XRD分析,结果如图2所示。

由图2可见:随焙烧温度升高,无水石膏的衍射峰强度降低,其分解产物CaS的衍射峰强度随之增大,并在900 ℃/15 min时达到最大值,延长焙烧时间至30 min后,CaS衍射峰强度略有下降,此时CaS可能发生了部分分解。CaS分解释放的Ca可能与粉煤灰 中Si和Al 反应生成了钙钠长石和钙铝黄长石等新矿物,XRD谱图中能观察到二者衍射峰强度的增加。磁铁矿的最大值也出现在900 ℃/15 min时;焙烧时间延长至30 min后磁铁矿铁矿有向赤铁矿转化的趋势。

综上所述,通过适当条件下的还原焙烧,弱磁性的赤铁矿可转化成强磁性的磁铁矿以利于磁法分选。

根据MTT 1017—2007“选煤用磁铁矿粉”,选煤用磁铁矿粉磁性物质质量分数>95%、小于45 μm 粒度的质量分数>80%(细粉)、硫质量分数<3%。从安稳CFB固硫粉煤灰中获得的磁铁矿粉小于45 μm粒度含量为88%、硫质量分数为0.6%、磁性物质质量分数约为100%,适用于重介质选矿(煤)行业。重介质选煤用磁铁矿细粉,含水5%的现价850 元/t,干粉现价1 300 元/t,综合经济效益显著。SO3载体矿物无水石膏(CaSO4)被同步还原生成CaS,粉煤灰中SO3质量分数大幅下降。以粉煤灰中较高含量的未燃尽碳作还原剂,无需外加,工序得到简化并节约了成本。石膏的分解和未燃尽碳的消耗使得粉煤灰LOI和SO3质量分数水平下降至水泥和混凝土生产允许的范围内。

图2 CFB 固硫粉煤灰还原焙烧样品XRD对比分析

Fig. 2 XRD contrastive analysis of reductive roasted CFB fly ash

4.3 还原焙烧—湿法弱磁选铁精矿实验

结合4.1和4.2中所进行的分析,分别进行800 ℃/30 min,900 ℃/15 min和900 ℃/30 min 3种条件下的CFB 固硫粉煤灰还原焙烧—磁选铁精矿实验,其余实验条件不变。本次实验采用水淬快速冷却的方式,使CaSO4的分解产物CaS与水反应生成H2S和Ca(OH)2。避免Fe3O4和CaS被重新氧化成Fe2O3和CaSO4。Ca(OH)2对粉煤灰活性产生预激发作用,同时为火山灰反应体系补充了所需的Ca2+,成为粉煤灰的有益组分[29];H2S以气体形式逸出,亦可加以回收利用[30-32];水淬冷却阶段还可引入简单浮选工艺,作为进一步降低粉煤灰LOI的辅助措施,同时可获得部分精碳作为副产品。

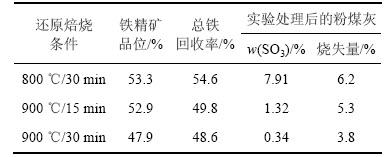

湿法磁选较干法磁选的选别效果更好,弱磁选能耗也较强磁选低。因而对经水淬冷却的粉煤灰料浆进行湿法弱磁选铁精矿操作,磁感应强度为160 mT。计算精矿和尾矿的LOI、铁和SO3质量分数以及总铁回收率,实验结果如表5所示。

表5 还原焙烧—湿法弱磁选铁精矿实验结果

Table 5 Data of reductive roasting-wet low-intensity magnetic separation of reductive roasted fly ash

800 ℃/30 min条件下铁精矿品位和总铁回收率均最高,但CaSO4只有少部分分解,粉煤灰中SO3质量分数(7.91%)仍然超标。经900 ℃/15 min还原焙烧、磁选处理后的粉煤灰,SO3质量分数和烧失量(LOI)分别降至1.32%和5.3%,符合GB/T 1596—2005“用于水泥和混凝土的粉煤灰”中Ⅱ级粉煤灰标准(SO3质量分数<3%,烧失量<8%),但所得铁精矿品位和全铁回收率均较800 ℃/30 min时的低;这与4.2节中的XRD分析结论相悖。在实验过程中发现,900 ℃下粉煤灰有部分烧结现象,烧结块影响了粉煤灰磁选料浆的分散性,可能是造成上述情况的主要原因。900 ℃/ 30 min条件下铁精矿品位和全铁回收率进一步下降,但对于粉煤灰SO3含量和LOI的降低有利。

XRD分析显示:水化处理后的粉煤灰矿物成分并未发生明显变化,进而推断其活性所受影响有限。安稳电厂经降硫、减碳和除铁处理后的粉煤灰活性有待进一步研究。

5 结论

1) 通过控制调节还原焙烧温度和时间,可以同步实现循环流化床固硫粉煤灰中石膏较高的分解率、赤铁矿较高的磁化率以及LOI的显著降低;采用水淬快速冷却和湿法磁选可以有效避免了磁铁矿的重新氧化消磁并同时实现CaSO4还原产物CaS的水化反应,反应产物Ca(OH)2为水泥和混凝土用粉煤灰的有益组分,粉煤灰中SO3质量分数大幅降低。

2) 将安稳电厂循环流化床固硫粉煤灰900 ℃下还原焙烧15 min,经水淬冷却、湿式弱磁选铁精矿,磁场强度160 mT,最终可获得品位52.9%的铁精矿,总铁回收率达到49.8%,所得铁精矿磁性强、细度高,可用于重介质选矿领域,经济效益显著。处理后的粉煤灰SO3和LOI质量分数分别降至1.32%和5.3%,符合Ⅱ级粉煤灰指标(适当延长焙烧时间可使粉煤灰达到Ⅰ级粉煤灰指标)。

3) 通过以上综合利用技术方案,安稳电厂粉煤灰将得到有效消纳的同时,可获得磁铁矿粉产品。以铁精矿回收的经济效益作为补偿,推动循环流化床固硫粉煤灰的资源化利用,可实现环境效益和经济效益的协同发展。

参考文献:

[1] 岳光溪. 循环流化床技术发展与应用[J]. 节能与环保, 2003(12): 3-4.

YUE Guangxi. The development of circulating fluidized bed technology and application[J]. Energy Saving and Environmental Protection, 2003(12): 3-4.

[2] 史培甫. 工业锅炉节能减排应用技术[M]. 北京: 化学工业出版社, 2009: 142.

SHI Peifu. Application technology of energy saving and emission reduction of industrial boiler[M]. Beijing: Chemical Industry Press, 2009: 142.

[3] 黄从国. 大气污染控制技术[M]. 北京: 化学工业出版社. 2013: 24.

HUANG Congguo. Air pollution control technology[M]. Beijing: Chemical Industry Press, 2013: 24.

[4] 黄叶, 钱觉时, 王智, 等. 循环流化床锅炉固硫灰与煤粉锅炉粉煤灰的比较研究[J]. 粉煤灰综合利用, 2009(3): 7-13.

HUANG Ye, QIAN Jueshi, WANG Zhi, et al. Comparative study of circulating fluidized bed boiler solid sulfur ash and pulverized coal boiler fly ash[J]. Fly Ash Comprehensive Utilization, 2009(3): 7-13.

[5] 赵计辉, 王栋民, 惠飞, 等. 矸石电厂循环流化床灰渣特性分析及其资源化利用途径[J]. 中国矿业, 2014(7): 133-138.

ZHAO Jihui, WANG Dongmin, HUI Fei, et al. Characterization and resource utilization of circulating fluidized bed ash of gangue power plant[J]. China Mining, 2014(7): 133-138.

[6] 贾凯, 曹亦俊, 李国胜, 等. 电厂粉煤灰浮选脱碳实验研究[J]. 矿山机械, 2012, 40(3): 88-92.

JIA Kai, CAO Yijun, LI Guosheng, et al. Floatation experiment on decarbonization of fly ash from power plants[J]. Mining & Processing Equipment, 2012, 40(3): 88-92.

[7] 薛芳斌, 纪莹璐, 宋慧平, 等. 粉煤灰浮选脱碳实验研究[J]. 粉煤灰综合利用, 2013(4): 14-16.

XUE Fangbin, JI Yinglu, SONG Huiping, et al. Floatation experiment on decarbonization of fly ash[J]. Total Utilization of Fly Ash, 2013(4): 14-16.

[8] 陶有俊, 张杰, 王旭, 等. 旋转摩擦电选及其对粉煤灰脱炭研究[J]. 中国矿业大学学报, 2014(4): 672-677.

TAO Youjun, ZHANG Jie, WANG Xu, et al. Study of rotary triboelectrostatic separation and decarbonization of fly ash[J]. Journal of China University of Mining and Technology, 2014(4): 672-677.

[9] 马瑞欣, 石常省, 章新喜. 煤与单一矿物质在摩擦电选过程中的分离[J]. 中国矿业大学学报, 2010(2): 270-274.

MA Ruixin, SHI Changxing, ZHANG Xinxi. Separation of coal and mano-mineral using a triboelectrostatic beneficiation[J]. Journal of China University of Mining and Technology, 2010(2): 270-274.

[10] 李海生. 循环流化床锅炉粉煤灰摩擦电选脱炭的研究[D]. 徐州: 中国矿业大学化工学院, 2012: 191-240.

LI Haisheng. Study on the triboelectrostatic separation unburned carbon from circulating fluidized bed boiler fly ash[D]. Xuzhou: China University of Mining and Technology. College of Chemical Engineering, 2012: 191-240.

[11] 杨文, 谢晓闻, 黄羽雕, 等. 循环流化床锅炉飞灰综合利用初探[J]. 工业锅炉, 1999(1): 54-55.

YANG Wen, XIE Xiaowen, HUANG Yudiao, et al. Comprehensive utilization of CFB fly ash[J]. Industrial Boiler, 1999(1): 54-55.

[12] 魏昭荣, 何知宇, 高德友, 等. 粉煤灰专用高效除硫剂的研究[J]. 粉煤灰综合利用, 2005(6): 42-43.

WEI Zhaorong, HE Zhiyu, GAO Deyou, et al. Study on high efficiency desulphurizing reagent for fly ash[J]. Fly Ash Comprehensive Utilization, 2005(6): 42-43.

[13] 吴正直. 粉煤灰综合利用[M]. 北京: 中国建材工业出版社, 2013: 6-12.

WU Zhengzhi. Comprehensive utilization of fly ash[M]. Beijing: China Building Industry Press, 2013: 6-12.

[14] 韩怀强, 蒋挺大. 粉煤灰利用技术[M]. 北京: 化学工业出版社, 2002: 201.

HAN Huaiqiang, JIANG Tingda. Fly ash utilization technology[M]. Beijing: Chemical Industry Press, 2002: 201.

[15] Jozwiak W K, Kaczmarek E, Maniecki T P, et al. Reduction behavior of iron oxides in hydrogen and carbon monoxide atmospheres[J]. Applied Catalysis A: General, 2007, 326(1): 17-27.

[16] 李芸邑, 梁嘉良, 刘阳生. 从铁尾矿中回收铁的磁化技术研究[J]. 环境工程, 2014(S1): 634-638.

LI Yunyi, LIANG Jialiang, LIU Yangsheng. Recycling iron powder by magnetization and magnetic separation from iron ore tailings [J]. Environmental Engineering, 2014 (S1): 634-638.

[17] 罗立群, 余永富, 张泾生. 闪速磁化焙烧及铁矿物的微观相变特征[J]. 中南大学学报(自然科学版), 2009, 40(5): 1172-1177.

LUO Liqun, YU Yongfu, ZHANG Jingsheng. Flash magnetic roasting and microstructure characteristics & phase transformation of iron minerals[J]. Journal of Central South University (Science and Technology), 2009, 40 (5): 1172-1177.

[18] 郭学益, 公琪琪, 石文堂, 等. 镍红土矿加压浸出渣磁化焙 烧-弱磁选铁精矿的研究[J]. 中南大学学报(自然科学版), 2012, 43(6): 2048-2053.

GUO Xueyi, GONG Qiqi, SHI Wentang, et al. Magnetic roasting of pressure leaching residue of nickel laterite and weak magnetic separation of iron concentrate[J]. Journal of Central South University (Science and Technology), 2012, 43(6): 2048-2053.

[19] 黄红军, 胡岳华, 杨帆, 等. 某复杂难选红铁矿磁化焙烧-磁选工艺及机理研究[J]. 矿冶工程, 2010(6): 38-41.

HUANG Hongjun, HU Yuehua, YANG Fan, et al. Study on the technology and mechanism of magnetic roasting and separation of a refractory red iron ore[J]. Mining and Metallurgical Engineering, 2010(6): 38-41.

[20] 周士琼. 建筑材料[M]. 北京: 中国铁道出版社. 1991: 35.

ZHOU Shiqiong. Building materials[M]. Beijing: Chinese Railway Publishing House. 1991: 35.

[21] 卢平, 章静. 脱硫石膏还原分解特性的试验研究[J]. 动力工程学报, 2012(3): 222-228.

LU Ping, ZHANG Jing. Study on reducing decomposition of the FGD gypsum[J]. Journal of Power Engineering, 2012(3): 222-228.

[22] 余苏, 李建锡, 马丽萍, 等. 磷石膏分解特性对磷石膏制硫酸联产水泥新工艺的影响研究[J]. 昆明理工大学学报(理工版), 2010(4): 80-84.

YU Su, LI Jianxi, MA Liping, et al. Thermal effects of phosphogypsum on co-production of acid and cement[J]. Journal of Kunming University of Science and Technology (Science and Technology Edition), 2010(4): 80-84.

[23] 杨秀山, 刘荆风, 余家鑫, 等. 磷石膏制硫酸的研究进展[J]. 现代化工, 2010(9): 8-12.

YANG Xiushan, LIU Jingfeng, YU Jiaxin, et al. Research progress in production of sulfuric acid from phosphogypsum[J]. Modern Chemical Industry, 2010(9): 8-12.

[24] 周丽娜, 周亮亮. CaSO4热分解反应机理的研究进展[J]. 化工中间体, 2013(5): 29-32.

ZHOU Lina, ZHOU Liangliang. Research progress in the reaction mechanism of thermal decomposition of CaSO4[J]. Chemical Intermediate, 2013(5): 29-32.

[25] 张雪梅, 徐仁伟, 孙淑英, 等. 硫酸钙的还原热分解特性研究[J]. 环境科学与技术, 2010(S2): 144-148.

ZHANG Xuemei, XU Renwei, SUN Shuying, et al. Study on the character of calcium sulfate reducing decomposition[J]. Environmental Science and Technology, 2010(S2): 144-148.

[26] 朱凯, 解桂林, 陈昭睿, 等. 磷石膏在一氧化碳气氛下的还原反应特性[J]. 硅酸盐学报, 2013(11): 1540-1545.

ZHU Kai, XIE Guilin, CHEN Zhaorui, et al. Reaction characteristics of phosphogypsum under carbon monoxide atmosphere[J]. Journal of the Chinese Ceramic Society, 2013 (11): 1540-1545.

[27] Mihara N,Kuchar D, Kojima Y, et al. Reductive decomposition of waste gypsum with SiO2, Al2O3, and Fe2O3 additive[J]. Journal of Material Cycles and Waste Management, 2007, 9(1): 21-26.

[28] Hong Y S, Byung S K. A novel cyclic reaction system involving CaS and CaSO4 for converting sulfur dioxide to elemental sulfur without generating secondary pollutants. 1. Determination of process feasibility[J]. Industrial & Engineering Chemical Research, 2002, 41: 3081-3086.

[29] 刘福. 离子组成对粉煤灰活性激发影响的研究[J]. 四川电力技术, 1999(1): 58-60.

LIU Fu. Excitation effects of ion composition on the activity of fly ash[J]. Sichuan Electricity Technology, 1999(1): 58-60.

[30] 薛丽梅, 张风华, 陈彬, 等. 硫化氢废气的综合利用方法[J]. 黑龙江科学, 2010(3): 48-50.

XUE Limei, ZHANG Fenghua, CHEN Bin, et al. Hydrogen sulfide gas comprehensive utilization method[J]. Heilongjiang Science, 2010(3): 48-50.

[31] 崔平, 曲克林, 张超群, 等. 一种利用含二氧化碳的硫化氢酸气制备硫氢化钠的方法: 中国, CN201310697615.X[P]. 2014-04-02.

CUI Ping, QU Kelin, ZHANG Chaoqun, et al. A method for preparation of sodium hydrosulfide by hydrogen sulfide gas containing carbon dioxide: China, CN201310697615. X[P]. 2014-04-02.

[32] 陈伟军. 硫化氢高附加值利用研究进展[J]. 广东化工, 2014(10): 223-224.

CHEN Weijun. Research of hydrogen sulfide with high additional value[J]. Guangdong Chemical Industry, 2014 (10): 223-224.

(编辑 杨幼平)

收稿日期:2014-08-21;修回日期:2014-10-11

基金项目(Foundation item):国家重点基础研究发展规划(973计划)项目(2014CB238902);教育部创新团队发展计划(IRT13099) (Project(2014CB238902) supported by the National Basic Research Development Program of China (973 Program); Project(IRT13099) supported by the Innovation Team Development Plan of Ministry of Education, China)

通信作者:代世峰,教授、博士生导师,从事煤岩学、煤地球化学及煤中稀有金属成矿理论方面研究;E-mail: daishifeng@gmail.com