文章编号:1004-0609(2012)08-2302-09

烧结助剂Y2O3和Pr6O11对Al2O3陶瓷

相对密度和热导率的影响

刘 兵,彭超群,王日初,王小锋,李婷婷,王志勇

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用高分子网络法制备混合纳米粉体,研究稀土氧化物Y2O3和Pr6O11加入量对Al2O3陶瓷相对密度和热导率的影响。采用阿基米德方法测定样品的体积密度,利用激光脉冲法测量试样的热扩散率并计算得出热导率。结果表明:两种添加剂都可以降低Al2O3陶瓷的烧结温度,提高Al2O3陶瓷的热导率,其中Y2O3的促进作用较强;当保温时间相同、烧结温度为1 500~1 650 ℃时,Al2O3陶瓷的相对密度和热导率都随烧结温度的升高而增大;当烧结温度相同、保温时间为30~120 min时,Al2O3陶瓷的相对密度和热导率也随保温时间的延长而增大。

关键词:Al2O3陶瓷;Y2O3;Pr6O11;烧结温度;保温时间;相对密度;热导率

中图分类号:TG174 文献标志码:A

Effects of sintering aids Y2O3 and Pr6O11 on relative density and thermal conductivity of Al2O3 ceramics

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting, WANG Zhi-yong

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of the amounts of Y2O3 and Pr6O11 on the relative density and thermal conductivity of the Al2O3 ceramics were investigated by preparing mixed nanometer powders through polymer network method. The bulk density of the Al2O3 ceramics was measured by the Archimedes method. The thermal diffusivity was measured by the laser pulse method, and the thermal conductivity was calculated. The results show that both sintering aids in the alumina powders can decrease the sintering temperature and improve the thermal conductivity, and the role of Y2O3 is more effective. When the holding time is the same and the sintering temperature is 1 500-1 650 ℃, the relative density and the thermal conductivity of Al2O3 ceramics increase with the increase of the sintering temperature. When the sintering temperature is the same and the holding time is 30-120 min, the relative density and thermal conductivity of Al2O3 ceramics also increase with the increase of the holding time. The causes affecting the thermal conductivity of Al2O3 ceramics are explained according to the microstructure and the theory of heat transfer by phonon.

Key words: Al2O3 ceramics; Y2O3; Pr6O11; sintering temperature; holding time; relative density; thermal conductivity

现代电子信息技术飞速发展,电子产品向小型化、便携化、多功能化方向发展。电子封装正在与电子设计和电子制造一起,共同推动信息化社会的发展[1]。电子封装基片材料的种类很多,包括陶瓷、环氧玻璃、金刚石、金属及金属基复合材料等[2]。其中,Al2O3陶瓷基片价格低廉,强度、硬度、化学稳定性和耐热冲击性能高,绝缘性和与金属附着性良好,是目前电子行业中综合性能较好、应用最成熟的陶瓷材料,占陶瓷基片总量的90%。

Al2O3陶瓷烧结主要通过扩散完成致密化,Al2O3晶格能较大,离子键较强,烧结激活能大,结构比较稳定,质点扩散系数低(Al3+在1 700 ℃时扩散系数仅为10-11 cm-2/s),因此,烧结温度较高[3]。99-Al2O3的烧结温度高达1 800 ℃,95-Al2O3的烧结温度在1 650~1700 ℃之间,能耗大,生产成本高。如此高的烧结温度也使得晶粒长大、气孔难以排除,导致陶瓷的气密性变差、力学性能降低,产品难以达到技术要求。在较低的温度下烧结出质地致密、性能良好的Al2O3陶瓷基片材料一直是人们努力的方向。一般可在原料中添加适当的烧结助剂来降低Al2O3陶瓷的烧结温度,改善Al2O3陶瓷的微观组织结构,实现基片较高的相对密度和较低的气孔率,提高其热导率。传统烧结助剂按照促进烧结的作用机理不同可以分为两大类:一类是烧结过程中生成液相的烧结助剂;一类是与Al2O3生成固溶体的烧结助剂[4]。近年来,稀土元素作为烧结助剂的作用越来越受到人们的重视,已成为Al2O3陶瓷最有前途的烧结助剂之一。Y2O3对氧化铝陶瓷烧结和性能的影响国内外学者已经做了很多研究[5-9],但其能够改善Al2O3陶瓷烧结性能的机理目前还没有统一的结论。姚义俊等[6]发现,Y2O3的加入可以降低95-Al2O3瓷的烧结温度,缩短保温时间,改善烧结性能,提高Al2O3陶瓷的力学性能。微观结构分析表明:Y2O3可以抑止Al2O3晶粒的生长,细化晶粒,使晶粒尺寸均匀统一,形成致密化结构。穆柏春和孙旭东[7]发现,Y2O3倾向于分布在基体颗粒的表面,且易于形成低熔点液相,加上颗粒之间的毛细作用,促使颗粒间的物质向孔隙处填充,从而降低孔隙率,提高致密度,降低烧结温度。FANG等[8]认为Y2O3由于离子半径相对铝离子半径大很多,难以与Al2O3形成固溶体,因此主要在Al2O3的晶界上存在,且Y2O3体积较大,不仅自身难以迁移,而且还会阻碍其他离子的迁移,从而降低晶界移动速率,抑止晶粒生长,有利于形成致密结构[9]。将Pr6O11作为Al2O3陶瓷烧结助剂的研究报道较少。造成结论不同的和要原因是烧结助剂对假设前提和实验条件的变化异常敏感,研究者大多只研究了烧结助剂加入量对烧结过程和机理的影响,而对烧结助剂加入方式的影响研究较少。本文作者以工业α-Al2O3为原料,通过高分子网络法分别制备Al2O3与Y2O3和Pr6O11的混合纳米粉体,分别以两种混合纳米粉体为烧结助剂烧结Al2O3陶瓷,系统研究加入量、烧结温度和保温时间对Al2O3陶瓷相对密度和热导率的影响,总结Y2O3和Pr6O11烧结助剂的烧结机理。

1 实验

1.1 原料制备

主要原料α-Al2O3由河南济源兄弟材料有限公司提供,纯度为99.8%(质量分数),平均粒径为1.5 μm。氧化钇(Y2O3)和氧化镨(Pr6O11)由湖南技术开发有限公司提供,纯度为99.99%。为使稀土氧化物与Al2O3粉体混合更均匀,先采用高分子网络法分别制备Al2O3与Y2O3和 Pr6O11的混合纳米粉体,再将混合纳米粉体作为烧结助剂加入到Al2O3粉体中。高分子网络法制备纳米粉体的工艺流程如图1所示。

1.2 样品制备

分别制备纯Al2O3浆料和添加Y2O3和 Pr6O11(质量分数为0.5%~2%)的浆料,以Al2O3球为球磨介质,置于高密度聚氨酯球磨罐中,在行星球磨机上球磨24 h,用凝胶注模成型方法[10]制成d 13 mm×4 mm圆片,干燥后在空气中排胶、烧结,烧结温度为1 550、1 550、1 600、1 650和1 680 ℃,保温时间为30、60、90、120和180 min。

图1 高分子网络法制备纳米粉体流程图

Fig. 1 Flow diagram of polymer network to preparing nanometer powder

1.3 性能测试

采用阿基米德方法测定样品的体积密度,测定前用SiC砂纸将样品磨平以除去表面开口气孔。Al2O3理论密度为3.985 g/cm3。采用JSM-5600Lv型扫描电镜观察样品的表面形貌和断口形貌。采用JR-3激光导热仪,利用激光脉冲法(闪光法Flash Method)测量试样的室温热扩散率,计算得到试样的室温热导率。

2 结果与讨论

2.1 烧结助剂加入量对Al2O3陶瓷性能的影响

分别添加不同质量分数的Y2O3和Pr6O11两种稀土氧化物烧结助剂的Al2O3陶瓷在1 650 ℃烧结120 min后,所得试样的相对密度与烧结助剂加入量的关系曲线如图2所示。由图2可以看出,烧结助剂的加入可显著提高Al2O3陶瓷的相对密度,且在加入量小于1.5%的加入范围内,相对密度随加入量的增加呈上升趋势。可见,烧结助剂的加入可以降低Al2O3陶瓷的烧结激活能,加快其致密化进程,促进烧结。稀土氧化物对Al2O3烧结的作用方式主要体现在以下几个方面:1) Y2O3和Pr6O11中存在的阳离子半径( = 0.093 nm,

= 0.093 nm, = 0.101 3 nm,

= 0.101 3 nm, = 0.09 nm)远大于Al3+的离子半径(

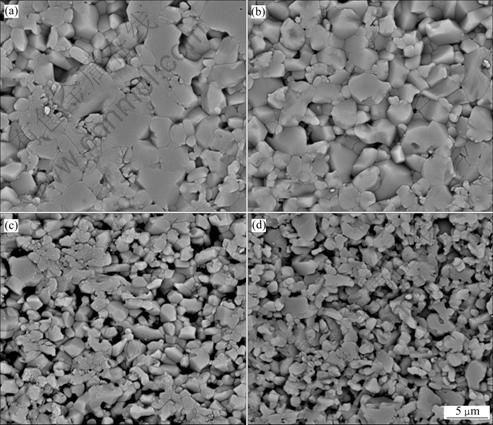

= 0.09 nm)远大于Al3+的离子半径( =0.041 nm),当形成固溶体时,Al2O3晶格发生畸变,周围产生应力场,具有较高缺陷形变能,可促进质点的迁移扩散,加速烧结过程[11];2) Y2O3和Pr6O11存在的三价、四价阳离子会使Al2O3晶体结构中产生阳离子空位,有利于质点的迁移,促进烧结过程的进行[11];3) 由于添加的稀土氧化物离子半径相对铝离子要大得多,因此与Al2O3形成固溶体的数量很少,稀土主要还是存在于Al2O3陶瓷的晶界上[8],稀土氧化物由于其较大的体积,不仅自身迁移阻力较大,而且还会阻碍其他离子的迁移,从而降低Al2O3晶界的迁移速率[12],抑止晶粒生长,使颗粒之间紧密性好、气孔率小,提高陶瓷的相对密度。对于添加Y2O3的陶瓷试样,随着Y2O3加入量的增加,Al2O3陶瓷试样的相对密度值呈上升趋势,刚开始上升速度较快,而后减慢。当加入量为1.5%时,陶瓷的相对密度达到最大值;继续增大加入量,Al2O3陶瓷的相对密度值减小;当加入量较少时,Y2O3大部分与Al2O3形成固溶体,Al2O3的晶格发生畸变,周围产生应力场,具有较高能量,促进质点的迁移扩散,加速烧结过程。Y2O3加入量为0.5%的扫描照片如图3(a)所示,可以看出,Al2O3晶粒大小相差较大,部分晶粒出现异常长大现象,气孔分布在晶间。加入量达到1.5%时,所添加的Y2O3已超过Al2O3陶瓷的固溶度,不能全部与Al2O3形成固溶体,而有一部分Y2O3和Al2O3形成钇铝石榴石(YAG)[13-14],YAG的生成会抑制晶粒异常长大,使得晶粒大小更加均匀,如图3(b)所示。加入量达到2%时,钇铝石榴石(YAG)的大量存在会降低Al2O3的致密化速率,使其相对密度降低。图3(c)所示为Pr6O11加入量为0.5%的Al2O3陶瓷的微观形貌。可以看出,Al2O3陶瓷气孔较多,晶粒大小分布不均匀,小颗粒生长在大颗粒表面,表面致密化程度较低。图3(d)所示为Pr6O11加入量为1.5%的扫描照片,可以看出,晶粒大小分布更加均匀,气孔明显减少。

=0.041 nm),当形成固溶体时,Al2O3晶格发生畸变,周围产生应力场,具有较高缺陷形变能,可促进质点的迁移扩散,加速烧结过程[11];2) Y2O3和Pr6O11存在的三价、四价阳离子会使Al2O3晶体结构中产生阳离子空位,有利于质点的迁移,促进烧结过程的进行[11];3) 由于添加的稀土氧化物离子半径相对铝离子要大得多,因此与Al2O3形成固溶体的数量很少,稀土主要还是存在于Al2O3陶瓷的晶界上[8],稀土氧化物由于其较大的体积,不仅自身迁移阻力较大,而且还会阻碍其他离子的迁移,从而降低Al2O3晶界的迁移速率[12],抑止晶粒生长,使颗粒之间紧密性好、气孔率小,提高陶瓷的相对密度。对于添加Y2O3的陶瓷试样,随着Y2O3加入量的增加,Al2O3陶瓷试样的相对密度值呈上升趋势,刚开始上升速度较快,而后减慢。当加入量为1.5%时,陶瓷的相对密度达到最大值;继续增大加入量,Al2O3陶瓷的相对密度值减小;当加入量较少时,Y2O3大部分与Al2O3形成固溶体,Al2O3的晶格发生畸变,周围产生应力场,具有较高能量,促进质点的迁移扩散,加速烧结过程。Y2O3加入量为0.5%的扫描照片如图3(a)所示,可以看出,Al2O3晶粒大小相差较大,部分晶粒出现异常长大现象,气孔分布在晶间。加入量达到1.5%时,所添加的Y2O3已超过Al2O3陶瓷的固溶度,不能全部与Al2O3形成固溶体,而有一部分Y2O3和Al2O3形成钇铝石榴石(YAG)[13-14],YAG的生成会抑制晶粒异常长大,使得晶粒大小更加均匀,如图3(b)所示。加入量达到2%时,钇铝石榴石(YAG)的大量存在会降低Al2O3的致密化速率,使其相对密度降低。图3(c)所示为Pr6O11加入量为0.5%的Al2O3陶瓷的微观形貌。可以看出,Al2O3陶瓷气孔较多,晶粒大小分布不均匀,小颗粒生长在大颗粒表面,表面致密化程度较低。图3(d)所示为Pr6O11加入量为1.5%的扫描照片,可以看出,晶粒大小分布更加均匀,气孔明显减少。

图2 Al2O3陶瓷相对密度与烧结助剂加入量的关系

Fig. 2 Relationship between relative density of Al2O3 and sintering additives amount

添加0.2%和1%Y2O3烧结助剂的Al2O3陶瓷烧结试样的XRD谱如图4所示。由图4可以看出,当Y2O3加入量为0.2%时,Al2O3陶瓷烧结试样中无第二相出现。当加入量为1%时,Y2O3和Al2O3在烧结过程中通过反应生成了少量YAG (Y3Al5O12)。对于添加Pr6O11的陶瓷试样,当加入量在0.5%~1.5%(质量分数)之间时,Al2O3陶瓷的相对密度呈上升趋势,但是上升幅度很小。当Pr6O11的加入量达到1.5%(质量分数)时,Al2O3陶瓷的相对密度达到最大值。这可能是因为随着加入量的增加,Al2O3晶体结构中出现阳离子空位,陶瓷试样的缺陷浓度上升,有助于质点的扩散和致密化进程的加快。

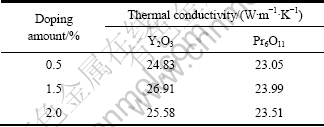

表1所列为分别添加不同含量的Y2O3和Pr6O11两种氧化物烧结助剂的Al2O3陶瓷经1 650 ℃烧结120 min后所得的室温热导率。从表1可以看出,加入两种烧结助剂的陶瓷试样,随着烧结助剂加入量的增加,热导率的变化趋势都是先增大后减小。当加入量为1.5%时,两者各自的热导率都达到最大值。Al2O3陶瓷主要靠声子进行热传导,气孔的含量和杂质的多少、晶界上第二相的性质和数量以及Al2O3颗粒大小均匀程度是影响陶瓷热导率的主要因素,气孔含量越低、杂质含量越少、晶界和表面越光滑、颗粒尺寸越大、大小越均匀,界面对声子的散射程度越小,声子平均自由程越大,热导率越高[15]。随着烧结助剂加入量的增加,试样的热导率的变化趋势与相对密度的变化趋势相对应,这说明相对密度是影响这两组Al2O3陶瓷试样热导率最主要的因素。当加入量为1.5%时,这两组试样的相对密度和热导率都达到最大值。这主要是由于随着加入量增加,气孔减少,声子散射减弱。当加入量为2%时,两组试样的热导率均比加入量为1.5%时的低。对于加入Y2O3的陶瓷试样,这可能是因为生成钇铝石榴石(YAG)的缘故,YAG第二相富集于晶界会对声子造成散射,散射会间断声子传播的连续性,从而使得热导率降低[14]。对于加入Pr6O11的陶瓷试样,可能是因为一方面Pr6O11的加入会对Al2O3的热导率起到“杂质”的作用;另一方面Pr6O11会和Al2O3生成更多的固溶体,使Al2O3晶体的完整性遭到破坏,晶体结构变得更加复杂,这两者都会使声子的平均自由程减小,导致热导率降低。在整个加入范围内,热导率随Pr6O11加入量的增加变化不大。

图3 分别添加不同质量分数Y2O3和Pr6O11的Al2O3陶瓷的微观形貌

Fig. 3 Morphologies of Al2O3 ceramics after adding different mass fractions of Y2O3 and Pr6O11: (a) 0.5% Y2O3; (b) 1.5% Y2O3; (c) 0.5%Pr6O11; (d) 1.5% Pr6O11

图4 不同Y2O3含量的Al2O3陶瓷烧结试样的XRD谱

Fig. 4 XRD patterns of Al2O3 ceramic after doped with different Y2O3 amounts

表1 不同烧结助剂加入量时Al2O3的室温热导率

Table 1 Room temperature thermal conductivity of alumina ceramics at different doping amounts of sintering additives

2.2 烧结温度对Al2O3陶瓷性能的影响

Al2O3陶瓷的相对密度与烧结温度的关系曲线如图5所示。此时,烧结助剂加入量为1.5%,保温时间为120 min。可以看出,在整个温度范围内,相对密度值随着烧结温度的升高而增大,当温度高于1 650 ℃时,相对密度的增加幅度趋于平缓。在相同烧结温度下,添加烧结助剂的试样比纯Al2O3陶瓷的相对密度都高。造成上述结果的原因是:在较低温度时,物质的传递主要以表面扩散为主,表面扩散只能改变气孔的形状而不能引起颗粒中心距的逼近,因此不能出现致密化过程;而在较高温度时,物质的传递主要以体积扩散为主,体积扩散可导致坯体致密化[11],因此,随着温度的升高相对密度呈增大趋势。当温度高于 1 650 ℃时,试样相对密度增大幅度趋于平缓,主要是由于烧结过程已进入烧结后期,继续升高烧结温度并不能提高相对密度值。当温度升高时,热缺陷浓度增加,烧结驱动力增大,烧结过程加快,小尺寸晶粒不断消失,大尺寸晶粒逐渐长大。当晶粒长大速率超过致密化速率时,气孔来不及排出就会被包裹在晶粒内部[11]。比较图6可以看出,随着烧结温度升高,Al2O3陶瓷的晶粒出现长大现象,气孔开始出现在晶内且数量减少,Al2O3陶瓷的相对密度增大。表2所列为分别添加1.5% Y2O3和1.5% Pr6O11两种烧结助剂的Al2O3陶瓷在不同温度下烧结120 min后,所得试样的室温热导率。结合图5和表2可以看出,Al2O3陶瓷试样的热导率的变化趋势与相对密度的变化趋势基本一致,即相对密度越高,热导率越大。这可用声子导热理论[16]解释,即相对密度越高、气孔率越低、对声子的散射越小,则声子的平均自由程越大,热导率越高。1 680和1 650 ℃烧结下的Al2O3的陶瓷热导率几乎没有差别。添加1.5% Y2O3的Al2O3陶瓷经1 650 ℃烧结后晶粒不断长大,烧结颈开始形成,晶粒间依面接触形式相互连接在一起,呈更紧密的排列,小尺寸颗粒不断消失,大尺寸颗粒逐渐长大,晶粒尺寸更加均匀,因此热导率升高。

图5 Al2O3陶瓷相对密度与烧结温度的关系

Fig. 5 Relationship between relative density of Al2O3 ceramics and sintering temperature

2.3 保温时间对Al2O3陶瓷性能的影响

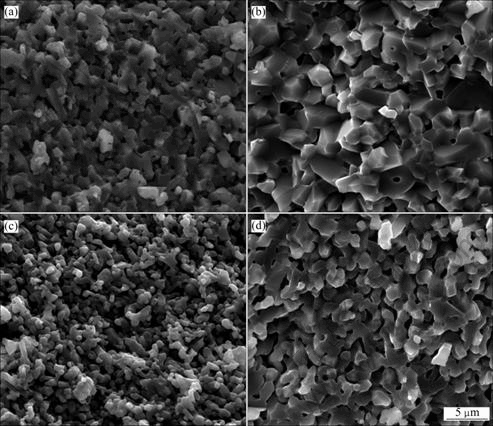

纯Al2O3陶瓷和分别添加Y2O3和Pr6O11两种烧结助剂的Al2O3陶瓷的相对密度与保温时间的关系曲线如图7所示。此时,烧结助剂加入量为1.5%,烧结温度为1 650 ℃。可以看出,随着保温时间延长,Al2O3陶瓷的相对密度都呈增大趋势, 添加烧结助剂的试样比纯Al2O3陶瓷的相对密度为高。当保温时间延长至120 min后,增大趋势减缓,可见如继续延长保温时间,Al2O3陶瓷的相对密度将基本不变,即烧结致密化速率随保温时间的延长而稳定下降,并会达到一个最终相对密度,此时烧结已进入后期阶段[17]。当保温时间为30 min时,添加Y2O3的试样相对密度较高,表明其致密化速率刚开始最快。添加Pr6O11的Al2O3陶瓷试样在整个保温时间范围内,相对密度都较低,表明Pr6O11对Al2O3陶瓷的助烧作用相对较弱。如图8所示,随着保温时间延长,晶粒逐渐长大且趋向一致,晶界气孔慢慢得以排除,微观上表现为晶粒排列更为致密,宏观表现为相对密度增大;气孔进入晶粒内部,气孔形状由不规则向圆形转变。表3所列为烧结助剂加入量为1.5%(质量分数)、烧结温度为1 650 ℃时不同保温时间下Al2O3陶瓷试样的室温热导率。从表3可以看出,添加Y2O3和 Pr6O11试样的热导率均随保温时间的延长而增大,与相对密度随保温时间的变化规律基本一致。经180 min保温的Al2O3陶瓷和经120 min保温的Al2O3陶瓷热导率几乎没有差别。从图8可以看出,延长保温时间可以改善Al2O3陶瓷的微观组织,随着保温时间延长,添加1.5% Pr6O11试样的微观组织都变得更加均匀,气孔明显减少,晶粒尺寸变大且趋于均匀、形状趋于规则,从而使得声子传播通道增大,热导率提高。

图6 不同烧结温度下保温120 min时分别添加Y2O3和Pr6O11的Al2O3陶瓷的断口形貌

Fig.6 Fractographs of Al2O3 ceramics doped with Y2O3 and Pr6O11 after sintering at different temperatures: (a) 1.5% Y2O3, 1 500 ℃; (b) 1.5% Y2O3, 1 650 ℃; (c) 1.5% Pr6O11, 1 500 ℃; (d) 1.5% Pr6O11, 1 650 ℃

表2 不同烧结温度下Al2O3陶瓷的室温热导率

Table 2 Room temperature thermal conductivity of Al2O3 ceramics at different sintering temperatures

2.4 添加烧结助剂的Al2O3陶瓷的烧结机理

Al2O3陶瓷线收缩率与烧结温度的关系曲线如图9所示。由图9可知,无论是纯Al2O3陶瓷还是添加烧结助剂的Al2O3陶瓷,当等速升温至1 450 ℃时,试样开始以较快的速率收缩,添加Y2O3的试样至1 650 ℃时,烧结体收缩基本完成,总收缩率为15%,而纯Al2O3陶瓷和添加Pr6O11的Al2O3陶瓷试样在1 680 ℃时收缩还没有完成。添加Y2O3的试样在1 500 ℃附近线收缩率出现最大值,之后线收缩速率降低;最大线收缩速率的出现预示着材料致密化机理的转变[18],在随后的烧结过程中,晶粒粗化将起主导作用。陶瓷的烧结通常有固相烧结和液相烧结两种。单一陶瓷粉体的烧结属于典型的固相烧结,即在烧结过程中没有形成液相。陶瓷坯体致密化主要是通过蒸发-凝聚、扩散等传质方式来实现的。其烧结过程主要由颗粒重排、气孔填充和晶粒生长等阶段组成[14]。液相烧结是指烧结过程有液相参与的烧结。由于陶瓷粉末中总有少量的杂质,因而大多数材料在烧结的过程中都会或多或少地出现液相。即使在没有杂质的纯固相系统中,高温下还会出现“接触”熔融现象,因而,纯粹的固相烧结实际上不易实现。有液相参与的烧结过程,陶瓷坯体的致密化主要通过黏滞流动与塑性流动和溶解-沉淀等传质方式来实现。液相烧结的流动传质速率比扩散传质快,容易实现低温下的烧结致密化,缩短烧结时间,提高相对密度。因此,将添加Y2O3和Pr6O11烧结助剂的陶瓷试样的烧结机理为稀土金属阳离子进入Al2O3晶体点阵中形成置换式固溶体,活化Al2O3的烧结。一方面,离子半径的差异使Al2O3晶格发生畸变,晶格周围产生应力场,具有较高的能量,可促进质点的扩散迁移,加速烧结致密化过程。另一方面,稀土金属阳离子与铝离子价态的差别使晶格发生畸变的同时,会产生晶格缺陷(如空位),晶格缺陷的形成有利于扩散传质的进行,促进烧结。当加入量比较大时,稀土氧化物会在晶界上形成第二相,第二相的存在可以抑制晶粒长大,从而提高陶瓷的相对密度。综上所述,当添加Y2O3和Pr6O11稀土氧化物烧结助剂时,Al2O3陶瓷的烧结机理以缺陷活化烧结即固相烧结为主,以液相烧结为辅。

图7 Al2O3陶瓷相对密度与保温时间的关系

Fig. 7 Relationship between relative density of Al2O3 ceramics and holding time

图8 1 650 ℃时不同保温时间下分别添加Y2O3和Pr6O11的Al2O3陶瓷的断口形貌

Fig. 8 Fractographs of Al2O3 ceramics at different holding times: (a) 1.5% Y2O3, 30 min; (b) 1.5% Y2O3, 120 min; (c) 1.5% Pr6O11, 30 min; (d) 1.5% Pr6O11, 120 min

表3 1 650 ℃时不同保温时间下Al2O3陶瓷的室温热导率

Table 3 Room temperature thermal conductivity of alumina ceramics at 1 650 ℃ for different holding times

图9 Al2O3陶瓷线收缩率与烧结温度的关系

Fig. 9 Relationship between relative shrinkage ratio of Al2O3 ceramics and sintering temperature

3 结论

1) Y2O3和Pr6O11烧结助剂的加入可以显著提高Al2O3陶瓷的相对密度,且相对密度随加入量的增加呈上升趋势,其中Y2O3的助烧作用相对较强, Pr6O11的相对较弱。当Y2O3加入量为1.5%、烧结温度为1 650 ℃、保温时间为120 min时,Al2O3陶瓷的相对密度达到最大值。

2) Al2O3陶瓷的相对密度值随着烧结温度的升高而增大,当温度高于1 650 ℃时,相对密度的增加幅度趋于平缓。Al2O3陶瓷热导率数值随着烧结温度的升高与相对密度的变化趋势基本一致,即相对密度越高,热导率越大。

3) 随着保温时间延长,Al2O3陶瓷的相对密度呈增大趋势,当保温时间延长至120 min后,增大趋势减缓。添加Y2O3和 Pr6O11试样的热导率均随保温时间延长而增大,与相对密度随保温时间的变化规律基本一致。保温180 min的Al2O3陶瓷和保温120 min的Al2O3陶瓷热导率基本相同。

REFERENCES

[1] 李婷婷, 彭超群, 王日初, 王小锋, 刘 兵. 电子封装陶瓷基片材料的研究进展[J]. 中国有色金属学报, 2010, 20(7): 1365-1374.

LI Ting-ting, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LIU Bing. Research progress in ceramic substrate material for electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1365-1374.

[2] 张海坡, 阮建明. 电子封装材料及其技术发展状况[J]. 粉末冶金材料科学与工程, 2003, 8(3): 216-223.

ZHANG Hai-po, RUAN Jian-ming. The development of materials and technology of electronic packaging[J]. Materials Science and Engineering of Powder Metallurgy, 2003, 8(3): 216-223.

[3] 尹衍升, 张景德. 氧化铝陶瓷及其复合材料[M]. 北京: 化学工业出版社, 2001.

YING Yan-sheng, ZHANG Jing-de. Alumina ceramics and its composite materials[M]. Beijing: Chemical Industry Press, 2001.

[4] 刘 兵, 彭超群, 王日初, 王小锋, 李婷婷, 王志勇. Al2O3陶瓷基片电子封装材料研究进展[J]. 中国有色金属学报, 2011, 21(8): 1893-1903.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting, WANG Zhi-yong. Research progress in alumina ceramics substrate material for electronic packaging[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(8): 1893-1903.

[5] 张伟孺, 孙 峰, 田庭燕, 陈 波, 王 培. 低温制备≥99.5%多晶氧化铝陶瓷[J]. 人工晶体学报, 2007, 36(5): 1109- 1112.

ZHANG Wei-ru, SUN Feng, TIAN Ting-yan, CHEN Bo, WANG Pei. Preparation for ≥99.5% polycrystal alumina ceramics at low temperature[J]. Journal of Synthetic Crystals, 2007, 36(5): 1109-1112.

[6] 姚义俊, 丘 泰, 焦宝祥, 沈春英. 稀土氧化物对氧化铝瓷性能的影响[J]. 真空电子技术, 2004(4): 28-30.

YAO Yi-jun, QIU Tai, JIAO Bao-xiang, SHEN Chun-ying. The effects of rare earth oxide on the properties of alumina ceramics[J]. Vacuum Electronic, 2004(4): 28-30.

[7] 穆柏春, 孙旭东. 稀土对Al2O3陶瓷烧结温度、显微组织和力学性能的影响[J]. 中国稀土学报, 2002, 20(S): 104-107.

MU Bai-chun, SUN Xu-dong. Effect of rare earths on sintering temperature, microstructure and mechanical properties of Al2O3 ceramics[J]. Journal of the Chinese Rare Earth Society, 2002, 20(S): 104-107.

[8] FANG Jin-xin, MARK T, HARMER M P. Effect of Yttrium and Lanthanum on the final-stage sintering behavior of ultrahigh- purity alumina[J]. Journal of the American Ceramic Society, 1997, 80(8): 2005-2012.

[9] WANG Chong-Min, JUNGHYUN C, HELEN M C, HARMER M P, RICKMAN J M. Influence of dopant concentration on creep properties of Nd2O3-doped Al2O3[J]. Journal of the American Ceramic Society, 2001, 84(5): 1010-1016.

[10] 王小锋, 王日初, 彭超群, 李婷婷. 凝胶注模成型技术的研究与进展[J]. 中国有色金属学报, 2010, 20(3): 496-509.

WANG Xiao-feng, WANG Ri-chu, PENG Chao-qun, LI Ting-ting. Research and development of gelcasting[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 496-509.

[11] CHEN Chang-ping, GAO Jing-xia, YANG Hui-zhi, SUN Hong-wei, HU Xing. Effects of ternary compound additives on densification and microstructure of alumina[J]. Materials Science and Engineering, 2008, 477(2): 379-385.

[12] 徐光宪. 稀土[M]. 北京: 冶金工业出版社, 2002.

XU Guang-xian. Rare earths[M]. Beijing: Metallurgical Industry Press, 2002.

[13] SATO E, CARRY C. Yttria doping and sintering of submicrometer-grained α-Al2O3 alumina[J]. Journal of the American Ceramic Society, 1996, 79(8): 2156-2160.

[14] KORINEK S L, CARRY C, PRIESTER L. Multiscale aspects of the influence of yttrium on microstructure, sintering and creep of alumina[J]. Journal of the European Society, 2002, 22(9): 1525-1541.

[15] LI Yan-zun, WANG Chong-min, HELEN M C, RICKMAN J M, MARTIN P H. Codoping of alumina enhance creep resistance[J]. Journal of the American Ceramic Society, 1999, 82(6): 1497-1504.

[16] 奚同庚. 无机材料热物性学[M]. 上海: 上海科学技术出版社, 2010.

XI Tong-geng. Inorganic material thermal physical[M]. Shanghai: Shanghai Scientific and Technical Publishers, 2010.

[17] 陆佩文. 无机材料科学基础[M]. 武汉: 武汉工业大学出版社, 1996.

LU Pei-wen. Inorganic materials science foundation[M]. Wuhan: Wuhan Industrial University Press, 1996.

[18] YANN A, VINCENT G, ELISABETH D. Influence of green state processes on the sintering behaviour and the subsequent optical properties of spark plasma sintered alumina[J]. Journal of the European Ceramic Society, 2009, 29(16): 3363-3370.

(编辑 李艳红)

基金项目:国家民口配套科研项目(MKPT-03-182)

收稿日期:2011-06-24;修订日期:2012-11-15

通信作者:彭超群,教授,博士;电话:0731-88877197;E-mail: pcq2005@163.com