过热器/再热器管道壁面温度的预测

徐鸿,赵志渊,林振娴

(华北电力大学 能源动力与机械工程学院,北京,102206)

摘要:为了得到过热器/再热器管壁温度分布特性,通过对过热器/再热器管道的传热过程进行研究,并与经验公式相结合建立具有氧化膜的炉管传热的物理模型。分析在不同的管道几何尺寸、烟气温度、蒸汽流量和温度的情况下,管道外壁温度、氧化层/基体界面温度和氧化层/蒸汽界面温度的变化过程,最后定量地解释管道外壁温度、氧化膜/基体温度随运行时间增长而升高的原因,得到了它们的温升系数Aw和An与氧化层引起的温升系数B之间的关系为: (其中,

(其中, 和

和 分别为管外壁、氧化层/基体界面对氧化膜增长的敏感程度)。

分别为管外壁、氧化层/基体界面对氧化膜增长的敏感程度)。

关键词:氧化膜;温度;传热;预测

中图分类号:TG171 文献标志码:A 文章编号:1672-7207(2011)09-2865-10

Prediction of wall temperature diversification of

superheater and reheater tubes

XU Hong, ZHAO Zhi-yuan, LIN Zhen-xian

(School of Energy, Power & Mechanical Engineering, North China Electric University, Beijing 102206, China)

Abstract: In order to get the wall temperature distribution characteristics of superheater/reheater tubes, a heat-transfer physical model of tubes with the oxide film was established by studying the heat transfer process of superheater/reheater tubes and the empirical formula. The temperature changing processes of tube outer-wall, the oxide scale/substrate interface and the oxide scale/steam interface were analyzed at different tube geometries, gas temperatures, steam flows, pressures and temperatures. Finally, the reason why the tube outer-wall temperature and the oxide scale/substrate interface temperature increase with the increase of the running time is quantitative interpreted, and the relationship between Aw, An and B is as follows:  , in which

, in which  and

and  represent the sensitivity of tube outer-wall and the interface between oxide scale and substrate to the growth of oxide scale.

represent the sensitivity of tube outer-wall and the interface between oxide scale and substrate to the growth of oxide scale.

Key words: oxide scale; temperature; heat transfer; prediction

随着电力工业的快速发展,电站机组向着大容量、高参数方向发展,超临界以及超超临界机组已成为火力发电的主力机组。机组参数的提高使得锅炉受热面蒸汽侧的氧化膜引起的各种问题日益受到关注。Port等[1]研究发现:90%的管道失效是由于过热器、再热器或者水冷壁等管件长期在过热的条件下运行的,而管道内壁的氧化层的形成是使壁温增加的主要原因。Clarck等[2-4]通过超声波无损检测的方法对锅炉受热面管道内壁氧化膜厚度进行测量,从而根据经验公式推导出炉管的当量温度以及剩余寿命。可见:氧化膜的厚度与炉管的温度有着直接的联系。边彩霞等[5-8]通过运用ANSYS有限元软件对氧化膜对炉管温度的影响进行了模拟研究。但是,他们并没有对烟气/基体界面温度、氧化膜/基体界面温度、氧化膜/蒸汽界面温度进行详细的研究。本文作者通过建立物理模型即具有氧化膜的炉管传热现象模型,自主编程对该物理模型进行计算,得到解析解。通过分析,得到了氧化膜的生长对各个界面温度的影响的规律。

1 数值模型

1.1 数值模型建立的假设条件

在建立数值模型时,需要遵循以下假设条件:

(1) 基体与氧化膜、氧化膜与氧化膜之间结合得很好,无氧化膜剥落现象出现;

(2) 管基体和氧化膜都是弹性,连续且各向同性的;

(3) 符合能量守恒定律;

(4) 不考虑管道基体、金属氧化膜受热膨胀、蠕变、疲劳等因素;

(5) 管道基体在受热过程中,未发生显微结构的变化;

(6) 管道周围烟气温度均匀,不考虑管道的排列问题。

1.2 数值模型的建立

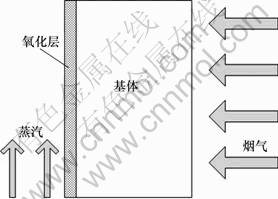

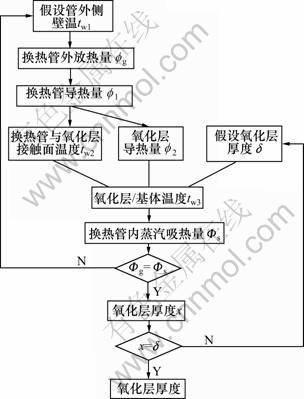

基于以上6个假设条件,建立数值模型,如图1所示。

图1 数值模型

Fig.1 Numerical model

由于过热器、再热器管道被烟气所包围,此处烟气温度为800~1 000 ℃,主要以对流换热为主,不考虑辐射换热。所以,整个模型的传热过程主要分为以下阶段:

(1) 烟气与炉管外壁之间进行对流换热;

(2) 炉管之间、炉管和氧化膜之间、氧化膜之间进行传导换热;

(3) 蒸汽与氧化膜之间进行对流换热。

2 传热过程的分析

2.1 蒸汽侧换热过程分析

蒸汽侧氧化膜通常是双层的(内层是尖晶石,主要成分是(Fe, Cr)3O4;外层是磁铁矿,主要成分是Fe3O4)和3层的(内层是尖晶石,中间层是磁铁矿,外层是赤铁矿)。在本文中,氧化膜的主要成分被认为是单一的,即为磁铁矿Fe3O4。

由于炉管内蒸汽的流速较快,通常认为与炉管内壁间的换热为强制对流换热。并且蒸汽是被加热的气流,所以,它的努谢尔特数为[9]:

(1)

(1)

其中:Res为蒸汽的雷诺数, ;Q为蒸汽的质量流量;d为管道的内径;μ为蒸汽的动力黏度;Prs为蒸汽的普朗特数,

;Q为蒸汽的质量流量;d为管道的内径;μ为蒸汽的动力黏度;Prs为蒸汽的普朗特数, ;Cps为蒸汽的比热容;λs为蒸汽的导热系数。所以,蒸汽的换热系 数为:

;Cps为蒸汽的比热容;λs为蒸汽的导热系数。所以,蒸汽的换热系 数为:

(2)

(2)

由以上可知蒸汽的吸热量为:

(3)

(3)

其中:l为管长;ts为蒸汽的温度;tw1为氧化膜/蒸汽界面的温度。

2.2 氧化层间换热过程分析

本文所研究的氧化层的性能良好,并无孔洞出现。所以,氧化层间的换热是导热问题。氧化层的导热量为:

(4)

(4)

其中:tw2为氧化膜/基体界面的温度;δ为氧化膜的厚度;λ0为氧化膜的导热系数。

2.3 管道基体间的换热过程分析

本文所研究的管道基体未发生微观结构的变化。基体间的换热是导热问题。所以,基体的导热量为:

(5)

(5)

其中:tw3为烟气/基体界面的温度即管道外壁的温度;D为管道的外径;λF为管道基体的导热系数。

2.4 烟气侧的换热过程分析

当流体绕过过热器/再热器管束时,边界层内流体的压强、流速以及流向都将沿弯曲面发生很大的变化,本文将此过程看成是外掠管束的换热过程。参考文献[10],得到其换热系数为:

(6)

(6)

(7)

(7)

(8)

(8)

(9)

(9)

其中:λg为烟气的导热系数;μg为烟气的运动黏度;G为烟气的质流密度;Wg为烟气质量流量;Nw为管排数;St为管道的横向间距;Cpg为烟气的比热容。

由以上可知烟气的放热量为:

(10)

(10)

其中:tg为烟气的温度。

2.5 循环迭代准则

根据拉-米公式,确定了温度与氧化膜间的关系可以用下式表示[11-15]:

(11)

(11)

(12)

(12)

其中:P为拉-米参数;C为材料常数。

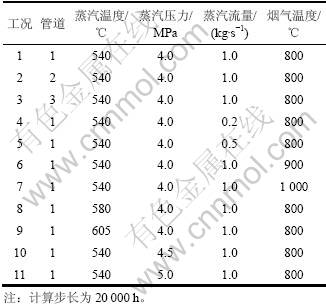

3 迭代计算过程

根据传热学的基本理论,放热量等于换热量等于吸热量,通过迭代计算,能够准确计算出在管道运行过程中各个界面的壁温以及氧化膜的厚度。其迭代计算逻辑关系如图2所示。

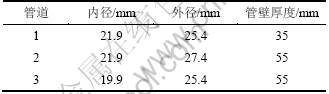

4 计算工况列表及计算结果分析

4.1 计算工况

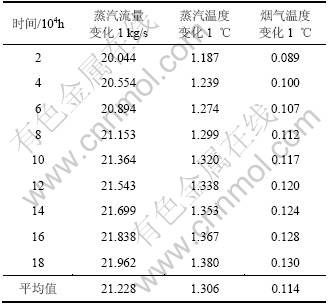

本文计算工况如表1所示,管道的几何尺寸如表2所示。

4.2 计算结果分析

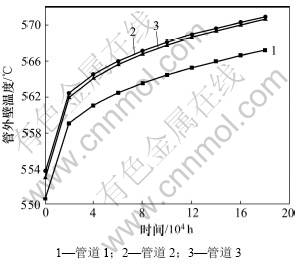

4.2.1 管外壁温度变化的分析

图3所示为管径对管外壁温度的影响。从图3可以看出:在内径相同、外径不同的情况下,外径越大,管外壁温度就越大(如图3中管道1和管道2);在外径相同、内径不同的情况下,内径越小,管外壁温度也就越大(如图3中的管道1和管道3),也就是说,管外壁温度与管壁的厚度有关系,管壁越厚,管外壁温度就会越高。比较管道2和管道3的温度曲线,在管道壁厚相同的情况下,外径对管外壁温度的影响略大于内径对其的影响。

图2 迭代计算逻辑关系图

Fig.2 Iterative calculation logic diagram

表1 计算工况列表

Table 1 Calculation conditions

表2 管道的几何尺寸

Table 2 Geometry of tubes

图3 管径对管外壁温度的影响

Fig.3 Influence of tube geometry on outer wall temperature

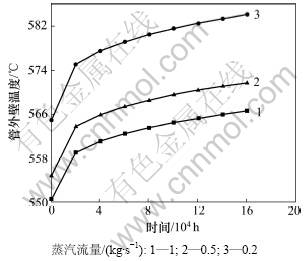

图4所示为蒸汽流量对管外壁温度的影响。从图4可以看出:随着蒸汽流量的增加,管道外壁温度逐渐减小;当蒸汽流量减小时,管外壁温度增长速度越来越快。这主要是由于蒸汽在管内进行的是强迫对流换热,其换热量与蒸汽的流量成正比。

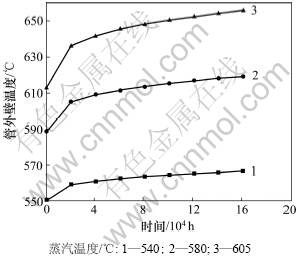

图5所示为蒸汽温度对管道外壁温度的影响。从图5可以看出:随着蒸汽温度的升高,管道外壁温度随之增大,并且管道的外壁温度的增长速率也随之增大。

图4 蒸汽流量对管外壁温度的影响

Fig.4 Influence of steam flow on outer wall temperature

图5 蒸汽温度对管道外壁温度的影响

Fig.5 Influence of steam temperature on outer wall temperature

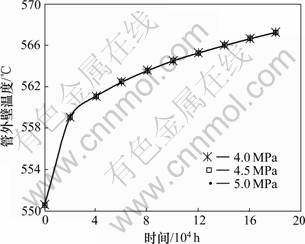

图6所示为蒸汽压力对管道外壁温度的影响。从图6可以看出:随着管道的运行时间的增长,管道外壁温度逐渐增大;但是,随着蒸汽压力变大,管道外壁温度基本没有变化。可见,管道压力对于管道的温度影响很小。

图6 蒸汽压力对管道外壁温度的影响

Fig.6 Influence of steam pressure on outer wall temperature

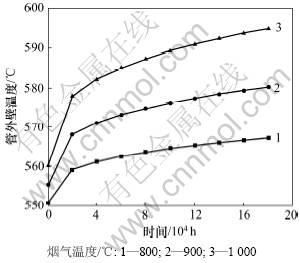

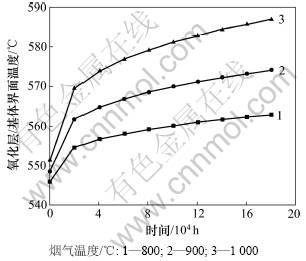

图7所示为烟气温度对管道外壁温度的影响。从图7可以看出:随着烟气温度的增大,管道外壁的温度逐渐增大,而且管道外壁的温度增长速率也是逐渐增大的。

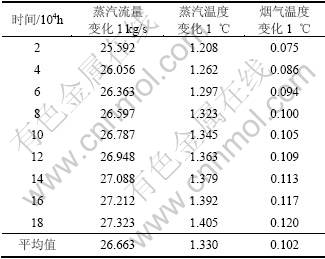

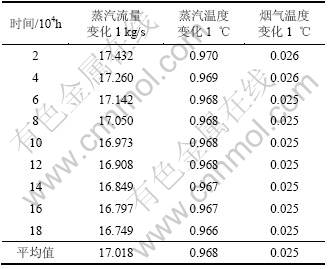

综合比较图3~7可以得到:随着管道运行时间的增长,管道的外壁温度是逐渐变大。通过分析上述几种因素对各界面温度变化的影响,可以知道蒸汽压力基本对界面温度变化无影响,而且在管道运行时,其尺寸已定,所以,进行敏感性分析时对此两项不再计算。外壁温度对其余因素的敏感性如表3所示。

图7 烟气温度对管道外壁温度的影响

Fig.7 Influence of flue gas temperature on outer wall temperature

表3 外壁温度的敏感性

Table 3 Sensitivity of outer wall temperature ℃

从表3可以知道:影响外壁温度的各个因素中,蒸汽的流量影响最大,而烟气温度的影响最小。其影响由大到小顺序为:蒸汽流量、蒸汽温度、烟气温度。蒸汽流量的改变造成管外壁温升是蒸汽温度的16.25倍,所以,在电厂的实际运行中,重点监测蒸汽流量的变化。

4.2.2 氧化层/基体界面温度变化分析

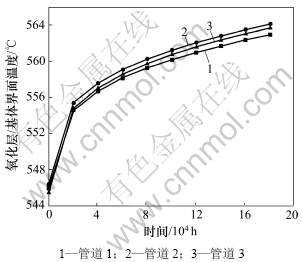

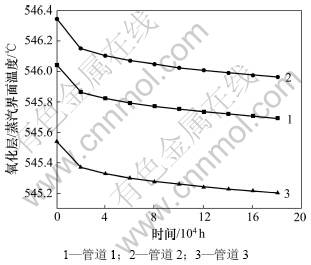

图8所示为管道尺寸对氧化层/基体界面温度的影响。从图8可以看出:在内径相同、外径不同的情况下,外径越大,氧化层/基体界面温度就越大(比如图3中管道1和管道2);在外径相同、内径不同的情况下,内径越小,氧化层/基体界面温度也就越大(比如图3中的管道1和管道3),也就是说,氧化层/基体界面温度与管壁的厚度有关系,管壁越厚,氧化层/基体界面温度就会越高。比较管道2和管道3的温度曲线,在管道壁厚相同的情况下,外径对氧化层/基体界面温度的影响略大于内径对其的影响。

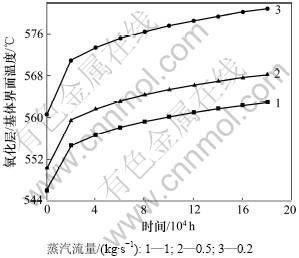

图9所示为蒸汽流量对氧化层/基体界面温度的影响。从图9可以看出:随着蒸汽流量的增加,管道氧化层/基体界面温度逐渐减小;当蒸汽流量减小时,氧化层/基体界面温度增长速度越来越快。这主要是由于蒸汽在管内进行的是强迫对流换热,其换热量与蒸汽的流量成正比。

图8 管道尺寸对氧化层/基体界面温度的影响

Fig.8 Influence of tube geometry on oxide scale-basic metal contact temperature

图9 蒸汽流量对氧化层/基体界面温度的影响

Fig.9 Influence of steam flow on oxide scale-basic metal temperature

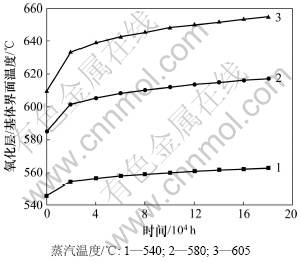

图10所示为蒸汽温度对氧化层/基体界面温度的影响。从图10可以看出:随着蒸汽温度的升高,管道氧化层/基体界面温度随之增大,并且管道的氧化层/基体界面温度的增长速率也随之增大。

图10 蒸汽温度对氧化层/基体界面温度的影响

Fig.10 Influence of steam temperature on oxide scale-basic metal temperature

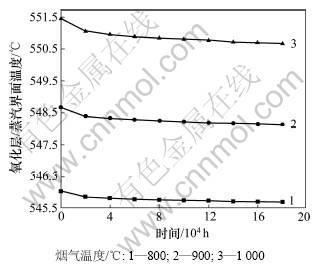

图11所示为烟气温度对氧化层/基体界面温度的影响。从图11可以看出:随着烟气温度的升高,管道氧化层/基体界面温度随之增大,并且管道的氧化层/基体界面温度的增长速率也随之增大。

图11 烟气温度对氧化层/基体界面温度的影响

Fig.11 Influence of flue gas temperature on oxide scale-basic metal temperature

通过分析上述几种因素对氧化层/基体界面温度变化的影响,可以知道:氧化层/基体界面温度随着运行时间的增长而升高,而且在管道运行时,其尺寸已定,所以,进行敏感性分析时对该项不再计算。氧化层/基体界面温度对其余因素的敏感性如表4所示。

表4 氧化层/基体界面温度的敏感性

Table 4 Sensitivity of oxide scale-basic metal contact temperature ℃

从表4可以知道:影响氧化层/基体界面温度的各个因素中,蒸汽的流量影响最大,而烟气温度的影响最小。其影响由大到小顺序为:蒸汽流量、蒸汽温度、烟气温度。蒸汽流量的改变造成管外壁温升是蒸汽温度的20倍。所以,在电厂的实际运行中,重点监测蒸汽流量的变化。

4.2.3 氧化层/蒸汽温度变化分析

图12所示为管道尺寸对氧化层/蒸汽界面温度的影响。从图12可以看出:在内径相同、外径不同的情况下,外径越大,氧化层/蒸汽界面温度就越大(如图3中管道1和管道2);在外径相同、内径不同的情况下,内径越小,氧化层/蒸汽界面温度也就越小(如图3中的管道1和管道3)。也就是说,氧化层/蒸汽界面温度与管壁的厚度无关。外径越大,内径越小,氧化层/蒸汽界面温度就会越高。

图12 管道尺寸对氧化层/蒸汽界面温度的影响

Fig.12 Influence of tube geometry on oxide scale-steam contact temperature

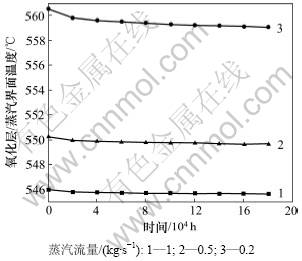

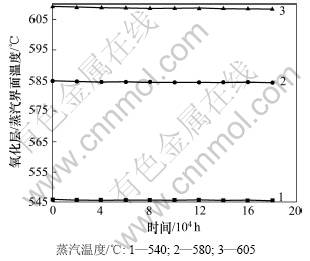

图13所示为蒸汽流量对氧化层/蒸汽界面温度的影响。从图13可以看出:随着蒸汽流量的增加,管道氧化层/蒸汽界面温度是逐渐减小的;当蒸汽流量减小时,氧化层/基体界面温度增长速度越来越快。

图14所示为蒸汽温度对氧化层/蒸汽界面温度的影响。从图14可以看出:随着蒸汽温度的升高,管道氧化层/蒸汽界面温度随之增大,并且管道的氧化层/蒸汽界面温度的增长速率也随之增大。

图13 蒸汽流量对氧化层/蒸汽界面温度的影响

Fig.13 Influence of steam flow on oxide scale-steam contact temperature

图14 蒸汽温度对氧化层/蒸汽界面温度的影响

Fig.14 Influence of steam temperature on oxide scale-steam contact temperature

图15所示为烟气温度对氧化层/蒸汽界面温度的影响。从图15可以看出:随着烟气温度的升高,管道氧化层/蒸汽界面温度随之增大,并且管道的氧化层/蒸汽界面温度的增长速率也随之增大。

图15 烟气温度对氧化层/蒸汽界面温度的影响

Fig.15 Influence of flue gas temperature on oxide scale-steam contact temperature

通过分析上述几种因素对氧化层/蒸汽界面温度变化的影响,可以知道随着管道运行时间的增长,管道的氧化层/蒸汽界面温度变化不大,有减小的趋势,而且在管道运行时,其尺寸已定,所以,进行敏感性分析时对该项不再计算。各界面温度对其余因素的敏感性如表5所示。

表5 氧化层/蒸汽界面温度的敏感性

Table 5 Sensitivity of oxide scale-steam contact temperature ℃

从表5可以知道:影响氧化层/蒸汽界面温度的各个因素中,蒸汽的流量影响最大,而烟气温度的影响最小。其影响从大到小顺序为:蒸汽流量,蒸汽温度,烟气温度。蒸汽流量的改变造成管外壁温升是蒸汽温度的17.58倍。所以,在电厂的实际运行中,重点监测蒸汽流量的变化。

从表3~5可以知道:影响各界面温度的各个因素中,蒸汽的流量影响最大,而烟气温度的影响最小。其影响顺序从大到小为:蒸汽流量,蒸汽温度,烟气温度。

综合比较表3~5可以知道:蒸汽流量的改变对各界面温度影响从大到小为:氧化层/基体界面温度,外壁温度,氧化层/蒸汽界面温度。蒸汽温度的改变对各界面温度影响的排序和蒸汽流量的排序是一致的。烟气温度的改变对各界面温度影响从大到小为:外壁温度、氧化层/基体温度、氧化层/蒸汽界面温度。

5 原因分析

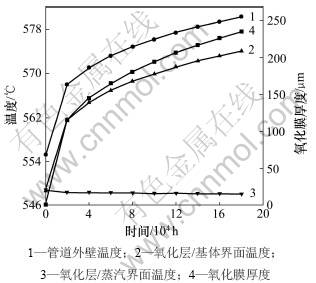

综合分析图3~15可以得到:随着管道运行时间的增长,管道外壁温度、氧化层/基体界面温度有所增大,而氧化层/蒸汽界面温度基本不变,有减小的趋势。究其原因,现以工况1为例详细说明。

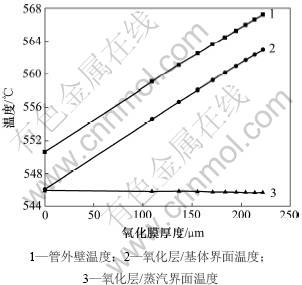

图16所示为管道运行过程中各界面温度及氧化膜厚度的变化情况。从图16可以看出:随着管道运行时间的增长,内壁氧化膜厚度、管道外壁温度、氧化层/基体温度都有所增加,而氧化层/蒸汽界面温度基本无变化。它们之间的关系如图17所示。

图16 管道运行过程中各界面温度及氧化膜厚度的变化情况

Fig.16 Changing of oxide scale thickness and contact temperatures when tube is operating

图17 氧化膜的增长对各界面温度的影响

Fig.17 Impacted on contact temperature by oxide scale thickness

图17所示为氧化膜的增长对各界面温度的影响。从图17可以看出:随着氧化膜厚度的增加,管外壁温度、氧化层/基体界面温度均增加;而氧化层/蒸汽界面温度基本无变化。同时,管外壁温度、氧化层/基体界面温度均与氧化膜的厚度呈线性关系,这种关系可以表述如下。

管外壁温度:

(13)

(13)

式中:Tw为管外壁温度;Tw0为初始时刻管外壁温度;Aw为斜率,℃/μm。

氧化层/基体界面温度:

(14)

(14)

式中:Tn为管内壁温度;Tn0为初始时刻管内壁温度;An为斜率,℃/μm。

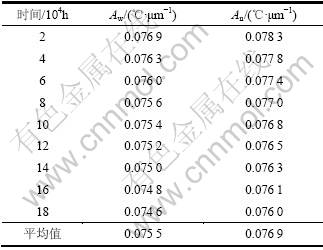

通过曲线拟合,可以获得每一时刻的斜率,如表6所示。从表6可以知道:Aw小于An,这说明管外壁温度的增长速率要小于氧化层/基体界面温度的增长速率,也就是说,氧化层/基体界面温度对氧化膜的增长更加敏感。

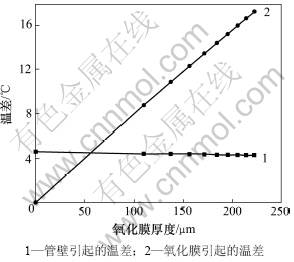

图18所示为氧化膜的增长对温差的影响。从图18可以看出:随着氧化膜厚度的增长,氧化层引起的温差呈线性增加,而管壁引起的温差基本不变。氧化层引起的温差与氧化层的厚度之间的关系可以表述为:

(15)

(15)

式中:ΔT为氧化层引起的温差;B为斜率,℃/μm。这是与French和Uhling论述的Parabolic-rate定律是一致的。

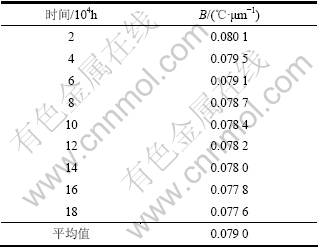

表6 温度斜率A

Table 6 Value of temperature slope A

图18 氧化膜的增长对温差的影响

Fig.18 Impacted on temperature difference by growth of oxide scale

通过曲线拟合,可以得到斜率B,如表7所示。

比较图17和图18可以说明:管外壁温度和氧化层/基体界面温度的增长是氧化层引起的温度差造 成的。

比较表6和表7 可以发现:Aw小于An,且Aw和An均小于B。Aw,An和B呈线性相关,通过数据拟合,它们之间的关系是:

(16)

(16)

可见:氧化膜引起的温度差对氧化层/基体界面温度的影响要大于对管外壁温度的影响。式(16)的一般表达式可以写成:

(17)

(17)

式中: 和

和 分别为管外壁、氧化层/基体界面对氧化膜增长的敏感程度。

分别为管外壁、氧化层/基体界面对氧化膜增长的敏感程度。

表7 温度斜率B

Table 7 Value of the temperature slope B

6 结论

(1) 影响各界面温度的各个因素中,蒸汽的流量影响最大,而烟气温度的影响最小。其影响由大到小顺序为:蒸汽流量、蒸汽温度、烟气温度。所以,在电厂的实际运行中,重点监测蒸汽流量的变化。

(2) 蒸汽流量的改变对各界面温度影响由大到小排序为:氧化层/基体界面温度、外壁温度、氧化层/蒸汽界面温度。蒸汽温度的改变对各界面温度影响的排序和蒸汽流量的排序是一致的。烟气温度的改变对各界面温度影响由大到小的排序为:外壁温度、氧化层/基体温度、氧化层/蒸汽界面温度。

(3) 证明了管道外壁的温升和氧化层/基体界面的温升是氧化膜的生长而引起的,它们之间呈现线性关系,并且它们的温升系数Aw和An与氧化层引起的温升系数B之间的关系为: 。

。

参考文献:

[1] Port R D, Herro H M. The nalco guide to boiler failure analysis[M]. New York: Nalco Chemical Company, McGraw-Hill Inc, 1991: 135-142.

[2] Clarck K J, Paterson S R, Retting T W. Remaining life assessment of superheater and reheater tubes[M]. Sunnyvale, California: Aptech Engineering Services Inc, 1988: 7-10.

[3] Viswanathan R, Paterson S, Grunloh H. Life assessment of superheater reheater tubes in fossil boilers[J]. Journal of Pressure Vessel Technology, 1994, 116(1): 1-16.

[4] Viswanathan R, Grunloh H, Paterson S R. Life assessment of superheater/reheater tubes, American Society of Mechanical Engineers, Pressure Vessels and Piping Division (Publication) PVP, 1992, 240: 103-122.

[5] 边彩霞, 周克毅, 胥建群, 等. 锅炉过热器蒸汽侧氧化膜瞬态应力的有限元分析[J]. 动力工程, 2008, 28(5): 696-700.

BIAN Cai-xia, ZHOU Ke-yi, XU Jian-qun, et al. Finite element analysis on transient stresses of oxide scales at steam side of boiler superheater[J]. Journal of Power Engineering, 2008, 28(5): 696-700.

[6] 边彩霞, 周克毅, 胥建群, 等. 蒸汽侧氧化膜对超临界机组T92钢管壁温的影响[J]. 动力工程, 2009, 29(5): 502-506.

BIAN Cai-xia, ZHOU Ke-yi, XU Jian-qun, et al. Influence of steam-side oxide scale on wall temperature of T92 tubes for supercritial units[J]. Journal of Power Engineering, 2009, 29(5): 502-506.

[7] Bian C, Zhou K, Xu J, et al. Influence of steam-side oxide scales on heat transfer of T92 tube in power plants[C]//Asia-Pacific Power and Energy Engineering Conference. Wuhan, 2009: 1-4.

[8] Purbolaksono J, Khinani A, Rashid A, et al. Prediction of oxide scale growth in superheater and reheater tubes[J]. Corrosion Science, 2009, 51: 1022-1029.

[9] 章熙民, 任泽霈. 传热学[M]. 北京: 中国建筑工业出版社, 2002: 150-169.

ZHANG Xi-min, REN Ze-pei. Heat transfer[M]. Beijing: China Construction Press, 2002: 150-169.

[10] Ganapathy V. Industrial boilers and heat recovery steam generators: Design, applications, and Calculations[M]. Texas: ABCD Industries Abilene, 2003: 166-208.

[11] Seibi A C, Amateau M F. Finite element modelling and optimization for controlling the residual thermal stress of laminated composite tubes[J]. Composite Structures, 1998, 41: 151-157.

[12] Holper B, Mayer H, Vasudevan A K, et al. Near threshold fatigue crack growth in aluminium alloys at low and ultrasonic frequency: Influences of specimen thickness, strain rate, slip behaviour and air humidity[J]. International Journal of Fatigue, 2003, 25: 397-411.

[13] ZHAO Jie, HAN Shuang-qi, GAO Hong-bo, et al. Remaining life assessment of a CrMoV steel using the Z-parameter method[J]. International Journal of Pressure Vessels and Piping, 2004, 81: 757-760.

[14] Walter M, Schütze M, Rahmel A. Behavior of oxide scale on 12Cr-1Mo steel during thermal cycling[M]. Oxidation of Metals, 1993, 39: 389-410.

[15] Singh Raman R K, Muddle B C. High temperature oxidation in the context of life assessment and microstructual degradation of weldments of 2.25Cr-1Mo steel[J]. International Journal of Pressure Vessels and Piping, 2002, 79: 585-590.

(编辑 杨幼平)

收稿日期:2010-09-13;修回日期:2010-12-15

基金项目:中央高校基本科研业务费专项资金资助项目(09QX61);北京市教育委员会共建项目(X90017)

通信作者:赵志渊(1982-),男,河北邯郸人,博士研究生,从事锅炉受热面管道蒸汽侧氧化和管道剩余寿命评估的研究;电话:010-80791437;E-mail: willim-007@163.com