高能球磨制备Y-Al-Mg-Si-O-N氧氮微晶玻璃

唐武彪1, 3,罗志伟1, 3,朱立刚1, 2, 3,卢安贤1, 3

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 玉林师范学院 化学与生物系,广西 玉林,537000;

3. 中南大学 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083)

摘 要:研究高能球磨对Y-Al-Mg-Si-O-N氧氮玻璃原料的非晶化作用。通过X线衍射(XRD)和扫描电子显微镜(SEM)观察,研究球磨转速和球磨时间对Y-Al-Mg-Si-O-N氧氮玻璃原料粉末结构和形貌的影响。研究结果表明:在本实验条件下,随着球磨转速的增加和球磨时间的延长,粉末中的TiO2和MgO首先被非晶化,Y2O3和ZrO2随后也向非晶相转变,SiO2部分被非晶化,Si3N4和Al2O3未发生明显非晶化;在球磨过程中,粉末粒度逐渐变小,由大而薄的片状和纤维状逐步变成细小的球状;粉末的晶粒细化和非晶化促进粉末烧结过程的进行,对于3Y2O3-10Al2O3-3MgO-65SiO2-15Si3N4-2TiO2-2ZrO2体系粉末样品,烧结线收缩率最大达到4.97%,抗弯强度最大为78.1 MPa;而对于3Y2O3-10Al2O3-3MgO-50SiO2-30Si3N4-2TiO2-2ZrO2体系粉末样品,烧结线收缩率最大达到7.8%,最大抗弯强度为123.1 MPa。

关键词:氧氮玻璃;非晶化;高能球磨

中图分类号:TB321 文献标志码:A 文章编号:1672-7207(2010)02-0514-07

Preparation of Y-Al-Mg-Si-O-N oxynitride glass-ceramics by

high-energy ball milling

TANG Wu-biao1, 3, LUO Zhi-wei1, 3, ZHU Li-gang1, 2, 3, LU An-xian1, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083,China;

2. Department of Chemistry and Biology, Yulin Normal University, Yulin 537000, China;

3. Key Laboratory of Non-ferrous Materials Science and Engineering, Ministry of Education,

Central South University, Changsha 410083, China)

Abstract: Amorphouszing effect of high-energy ball milling on Y-Al-Mg-Si-O-N powder was studied. The effects of velocity and time of high-energy ball milling on the structure and the micrograph of Y-Al-Mg-Si-O-N powder were investigated. The results show that, with the increase of milling velocity and time, TiO2 and MgO are completely amorphousized, Y2O3 and ZrO2 are amorphousized, while SiO2 is partly amorphousized, whereas Si3N4 and Al2O3 have no evidence of amorphization. Through the milling process, the size of the powders gets smaller and the strain in the powder becomes larger. As a result, the powder changes from slice or fibre shape to particle shape. The refining and amorphousizing of the powder accelerate the sintering process. The largest linear shrinkage rate for 3Y2O3-10Al2O3-3MgO-65SiO2-15Si3N4-2TiO2-2ZrO2 and 3Y2O3-10Al2O3-3MgO-50SiO2-30Si3N4-2TiO2-2ZrO2 are 4.97% and 7.80%, respectively, and their bending strength are 78.1 MPa and 123.1 MPa, respectively.

Key words: oxynitride glass; amorphousizing; high-energy ball milling

早期的氧氮玻璃是在烧结氮化硅陶瓷过程中发现的。氮化硅陶瓷在液相烧结时需要添加各种氧化物(Y2O3,La2O3,MgO,CaO和Al2O3等)以促进烧结,这些氧化物在烧结时,会与氮化硅反应形成液相,当温度下降时,这些残余的液相就形成玻璃相存在于氮化硅的晶界间[1-3],而这些玻璃相的性质对氮化硅陶瓷的力学性能有较大的影响[4-7]。由于氧氮玻璃中的N原子可取代玻璃中的O原子进入玻璃网络中,N可以与3个Si连接,因而,可使玻璃的强度和密度大大增加,所以,氧氮玻璃具有比氧化物玻璃更优良的性能。研究表明:随着氮含量的增加,氧氮玻璃的密度、弹性模量、黏度、表面张力、折射率、抗酸碱腐蚀等性能增加,玻璃的转变温度和软化温度提高,热膨胀系数下降[8-14]。氧氮玻璃的这些优点导致了这类玻璃被广泛用作高温绝缘材料、窗口材料、核废料封装材料、氮化硅和碳化硅焊接材料及抗碱腐蚀材料等[15-16]。然而,与氧化物玻璃相比,氧氮玻璃的熔化温度高达 1 500~1 750 ℃[17],难以通过传统熔融冷却法制得,而且用传统熔融冷却法获得玻璃中的氮含量也较低,所以,通常采用溶胶-凝胶法来制备氧氮玻璃,以降低玻璃的熔融温度,增加氮含量。但是,用溶胶-凝胶法一般需要利用较昂贵的金属醇盐或是金属无机盐,而且制备条件苛刻,制备量较少。与溶胶-凝胶法相比,高能球磨法可以达到凝胶-溶胶法同样的效果,除使物料的混合达到纳米级或非晶化、制出过饱和的固溶体外,同时还具备操作简单、易制备出大量粉末的特点。

本文作者旨在探讨用高能球磨工艺制备氧氮玻璃和氧氮微晶玻璃的可能性,先将原料磨成非晶,再进行烧结,并对其结构和性能进行表征。

1 实验

1.1 样品制备

本实验选用氧氮玻璃的化学组成如表1所示。原料纯度均为分析纯(AR),将各原料按表1称量,充分混合后放入不锈钢球磨罐中进行球磨(球磨机的型号为QM-1SP),磨球为淬火钢球,取大、小钢球的质量比为1?1,大球直径为20 mm,小球直径为8 mm,以氩气为保护气氛。球磨工艺如图1所示。将1号和2号原料按图1所示的球磨工艺进行球磨,对全部球磨后的样品进行XRD和SEM分析,将全部球磨后的粉末压制成长度为55.10 mm的长条进行烧结。为便于比较,将1号原料经不同工艺球磨后的样品标记为1-1,1-2,1-3和1-4;同理,将2号原料经不同工艺球磨后的样品标记为2-1,2-2,2-3和2-4(见表2)。所有样品在热压烧结炉中进行烧结,烧结炉的型号为:FVPHP-R-10FRET-40,以氩气为保护气氛,烧结工艺为:以20 ℃/min从室温升到1 300 ℃,保温10 min,再随炉冷却,得到微晶玻璃样品。

1.2 结构与性能测试

将粉末原料、各球磨条件下球磨后的样品在玛瑙研钵中充分研磨,过孔径为50 μm的筛,采用日本理学电机株式会社生产的 Rigaku D/max 2550 PC 型全自动X线衍射仪测定各个样品的X线衍射谱。实验 条件如下:Cu 靶,扫描范围为10?~80?,扫描速度为8(?)/min,测试温度为室温。

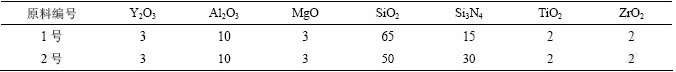

表1 氧氮玻璃化学组成

Table 1 Chemical composition of oxynitride glass

图1 氧氮玻璃原料的球磨工艺

Fig.1 Milling processes of oxynitride glass raw material

表2 粉末的球磨工艺

Table 2 Milled process of powder

将粉末原料、各球磨条件下球磨后的混合料及烧结后的试样在玛瑙研钵中喷金后进行SEM观察,实验设备的型号分别为JSM5600LV和KYKY2800。

精确测量样品烧结前后的长度,计算经各球磨流程后试样的收缩率,收缩率计算公式为δ=[(L0-L1)/L0]×100%。其中:L0为烧结前压制样品的长度,本实验中L0=55.10 mm;L1为烧结后样品的 长度。

采用CSS 44100型万能试验机测定微晶玻璃样品的抗弯强度,测定方式为三点弯曲法(GB 228—87),跨距为35 mm。

2 结果与讨论

2.1 球磨工艺对Y-Al-Mg-Si-O-N粉末结构的影响

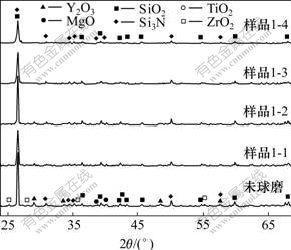

对未球磨1号和2号原料、样品1-1,1-2,1-3,1-4,2-1,2-2,2-3以及2-4进行XRD分析,结果如图2和图3所示。

图2 1号原料经不同工艺球磨后的XRD谱

Fig.2 XRD patterns of raw material 1 after ball milling by different processes

图3 2号原料未球磨和经不同工艺球磨后样品的XRD谱

Fig.3 XRD patterns of raw material 2 before and after ball milling by different processes

从图2和图3可以看出:随着球磨转速的增加或球磨时间的延长,Y2O3,MgO,TiO2和ZrO2晶体的X线衍射峰逐渐减小最终消失,其中:MgO和TiO2晶体的X线衍射峰最先消失,Y2O3和ZrO2晶体的X线衍射峰随后消失。这表明TiO2和MgO最先被非晶化,Y2O3和ZrO2随后被非晶化。SiO2在2θ=67?处的3个尖锐的衍射峰逐渐变平缓,这说明SiO2随着球磨转速的增加和球磨时间的延长逐渐被非晶化。

为探明球磨工艺对粉末的非晶化作用,据X线衍射谱,利用谢乐公式计算了球磨工艺中1号原料中SiO2粒度和应变的变化。谢乐公式如下:

式中:β为衍射峰的半高宽(以弧度表示);θ为衍射角;λ为X线的波长(0.154 06 nm);η为应变;d为晶粒度。式(2)中还有2个未知数,需要2组β和θ值进行求解,可以通过取同一晶体的2个衍射峰的半高宽和衍射角求解。本文选用SiO2的(100)峰和(101)峰计算SiO2的粉末直径和应变,计算前将重叠的峰分开,然后进行计算,结果见表3。

由表3可以看出:样品1-1的SiO2晶粒的晶粒度比样品1-2的晶粒度小,而应变比样品1-2的应变大。说明在其他因素条件不变的情况下,湿磨比干磨效果更好。对于干磨工艺,对比样品1-2和1-3以及样品1-3和1-4可知:随着球磨转速的增加和球磨时间的延长,粉末变得越来越细,粉末中的应变越来越大。从表3还可以看出:提高球磨转速比提高球料质量比和球磨时间对粉末的磨碎效果影响更大,更利于粉末样品的非晶化。另外,对比图2和图3可知:除了1号原料中Si3N4的含量比2号原料的低,导致1号样品中Si3N4的X线晶体衍射峰强度比2号样品的小,原料中其他组分的X线晶体衍射峰强度变化也较小。说明球磨工艺对原料中其他物质的非晶化没有明显影响。

表3 1号原料未球磨和球磨后SiO2晶粒的

晶粒度d和应变η

Table 3 d and η of SiO2 crystalline before and

after ball milling

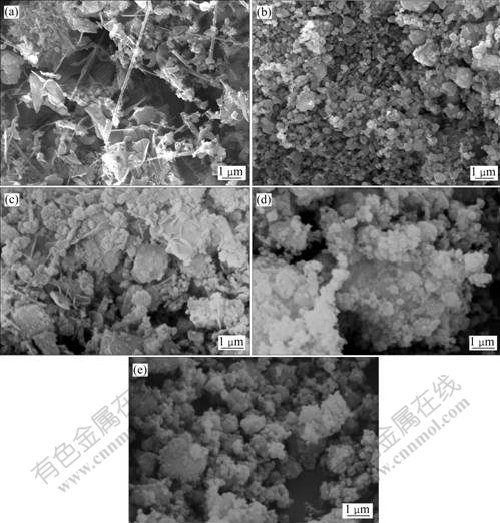

2.2 球磨工艺对Y-Al-Mg-Si-O-N粉末形貌的影响

2号原料未球磨和经不同工艺球磨后的SEM像如图4和图5所示。从图4(c)~4(e)可见:对于干磨后的样品,随着球磨转速的增加和球磨时间的延长,粉末的团聚明显减少,颗粒变得越来越细小,分布也越来越均匀。比较图4(b)和图4(c)可知:湿磨后的样品与干磨后的样品相比,团聚颗粒数目明显减少。

样品:(a) 未球磨;(b) 2-1;(c) 2-2;(d) 2-3;(e) 2-4

图4 2号原料未球磨和经不同工艺球磨后的低倍SEM像

Fig.4 Low magnification SEM images of raw material 2 before and after ball milling

样品:(a) 未球磨;(b) 2-1;(c) 2-2;(d) 2-3;(e) 2-4

图5 2号原料未球磨和经不同工艺球磨后的高倍SEM像

Fig.5 High magnification SEM images of raw material 2 before and after ball milling by different processes

从图5可见:2号原料含有较多的“纤维状”物质,随着球磨的进行,纤维状物质的纤维断裂,并以颗粒形式出现。粉末由大而薄的“片状”变为“小片状”(图5(c)),接着变为细小的“圆饼状”(图5(d)),最后变为更细小更分散的“球状”(图5(e))。从图5(b)和图5(c)可见:图5(b)中的粉末颗粒比图5(c)中的粉末颗粒小,说明湿磨比干磨的效果更好。

从图4和图5还可以看出:颗粒的粒度随着球磨转速的增加和球磨时间的延长而减小,这与XRD分析结果一致。从SEM像可见:颗粒粒度约为150 nm,比XRD分析计算得到的结果大2~3倍。这可能是因为XRD分析的是晶粒粒度,而SEM看到的是由几个晶粒组成的颗粒,两者并不一致。

2.3 球磨工艺对Y-Al-Mg-Si-O-N粉末烧结性能的 影响

将1号和2号原料球磨样品烧结后得到的微晶玻璃样品,按分析测试中的方法,计算了烧结后样品的线收缩率和抗弯强度。各个样品的线收缩率如图6所示。从图6可以看出:在干磨过程中,随着球磨转速和球磨时间的增加,线收缩率也增加。对于1号原料,收缩率由样品1-2的1.38%增加到样品1-3的4.90%和样品1-4的4.97%;对于2号原料,收缩率由样品2-2的3.63%增加到样品2-3的7.62%和样品2-4的7.80%;当球磨转速由200 r/min增加到300 r/min时,收缩率增加迅速;当球磨转速固定为300 r/min时,时间由 9 h增加到27 h,收缩率的增加速度变缓。由此可见:球磨转速的增加对粉末烧结性能的影响比球磨时间和球料比对粉末烧结性能的影响更加明显。从XRD谱可以看出:湿磨后粉末粒度变得更小,湿磨样品的烧结收缩率应该比干磨的大,这在2号原料中比较明显,湿磨收缩率为样品2-1的4.14%,干磨试样的收缩率为样品2-2的3.63%;但1号原料出现了相反的结果,湿磨的收缩率为样品1-1的1.05%,比干磨样品1-2的1.38%小,其原因有待研究。另外,从图6还可以看出:2号原料的收缩率比1号原料的大,表明随着Si3N4的含量增加,粉末的烧结性能提高,原因也有待进一步研究。

(a) 1号原料;(b) 2号原料

图6 不同样品烧结后的线收缩率

Fig.6 Line shrinking rates of different samples after sintering

烧结样品的抗弯强度如图7所示。可见:随着球磨转速的增加和球磨时间的延长,粉末试样烧结后的抗弯强度不断增加,1号原料的最大抗弯强度为78.1 MPa,2号原料的最大抗弯强度为123.1 MPa。

(a) 1号原料;(b) 2号原料

图7 不同样品烧结后的抗弯强度

Fig.7 Bending strengths of different samples after sintering

3 结论

(1) 随着球磨转速的增加和球磨时间的延长,Y-Al-Mg-Si-O-N粉末中的TiO2和MgO首先被非晶化,Y2O3和ZrO2随后被非晶化,SiO2也部分被非晶化;随着球磨转速的增加和球磨时间的延长,SiO2粉末不断的细化,粉末中的应变也不断的增大;增加球磨转速比延长球料质量比和球磨时间对球磨效果的影响更大,湿磨对粉末的细化效果比干磨更好。

(2) 随球磨转速的增加和球磨时间的延长,粉末试样中的颗粒由原来的片状和纤维状逐步变成细小的球状。

(3) 粉末的非晶化对烧结有促进作用,随球磨转速的增加和球磨时间的延长,烧结线收缩率不断变大,抗弯强度不断提高。对于3Y2O3-10Al2O3-3MgO- 65SiO2-15Si3N4-2TiO2-2ZrO2粉末烧结样品,其线收缩率最大达到4.97%,抗弯强度最大为78.1 MPa;而对于3Y2O3-10Al2O3-3MgO-50SiO2-30Si3N4-2TiO2-2ZrO2粉末烧结样品,其线收缩率最大达到7.8%,抗弯强度最大为123.1 MPa。

参考文献:

[1] Loehman R E. Oxynitride glasses[J]. Journal of Non-Crystalline Solids, 1980, 42(1/3): 433-445.

[2] Hampshire S, Drew R A L, Jack K H. Oxynitride glasses[J]. Physics and Chemistry of Glasses, 1985, 26(5): 182-186.

[3] Liddell K, Thompson D P. Preparation of new oxynitride glass ceramic by controlled heat treatment schedules[J]. British Ceramic Transactions, 1998, 97(4): 155-161.

[4] Coon D N, Tallman R L, Neilson R M. Hot isostatically pressed Si3N4-Si3N4 joints bonded with oxynitride glass[J]. Advanced Ceramic Materials, 1988, 3(2): 154-158.

[5] Hampshire S. Oxynitride glasses and glass ceramics[J]. Materials Research Society Symp Proc, 1993, 287: 93-104.

[6] Ahn B G, Shiraishi Y. Joining of Si3N4 to Si3N4 with partially crystallized cordierite glass or oxynitride glass solders[J]. High Temperature Materials and Processes, 1998, 17(4): 245-252.

[7] Kim Y W, Lee Y I, Mamoru M, et al. Fabrication and mechanical properties of silicon carbide-silicon nitride composites with oxynitride glass[J]. Journal of the American Ceramic Society, 1999, 82(4): 1058-1060.

[8] Loehman R E. Preparation and properties of yttrium-silicon- aluminum oxynitride glasses[J]. Journal of the American Ceramic Society, 1979, 62(9/10): 491-494.

[9] Murakami M, Sakka S. Ab initio molecular orbital calculation of the interatomic potential and force constants in silicon oxynitride glass[J]. Journal of Non-Crystalline Solids, 1988, 101(2/3): 271-279.

[10] Rouxel T, Besson J L, Gault C, et al. Viscosity and Young's modulus of an oxynitride glass[J]. Journal of Materials Science Letters, 1989, 8(10): 1158-1160.

[11] Wusirika R. Alkali durability of oxynitride glass fibers[J]. Journal of the American Ceramic Society, 1991, 74(2): 454-456.

[12] Hampshire S. Yttrium oxynitride glasses: properties and potential for crystallization to glass-ceramics[J]. Journal of the European Ceramic Society, 1994, 14(3): 216-273.

[13] Hannelore K D, Eckebracht A, Frischat G H. Viscosity and surface tension of oxynitride glass melts[J]. Journal of the American Ceramic Society, 1995, 78(4): 1123-1124.

[14] Hannelore K D, Heinz F G. Drawing of oxynitride glass fibers[J]. Glass Science and Technology: Glastechnische Berichte, 1997, 70(4): 109-112.

[15] DING Yu-quan, DING Zi-shang, JING Zhang-hua. Formation and properties of Y-Al-Si-O-N glasses in the grain boundaries of Si3N4 ceramics[J]. Journal of Non-Crystalline Solids, 1989, 112(1/3): 408-412.

[16] GE Men-zhen, YANG Hui, JIANG Zhong-hua, et al. Ultrafine pure mullite powder prepared by sol-gel method[J]. Journal of Non-Crystalline Solids, 1992, 147/148: 565-568.

[17] Das T. Oxynitride glasses-an overview[J]. Bulletin of Materials Science, 2000, 23(6): 499-507.

收稿日期:2009-01-13;修回日期:2010-03-14

基金项目:国防军工新材料项目(JPPT-115-329)

通信作者:卢安贤(1960-),男,湖南安仁人,教授,从事无机非金属材料研究;电话:0731-88877057;E-mail: axlu@mail.csu.edu.cn

(编辑 陈爱华)