文章编号:1004-0609(2008)02-0260-06

反应磁控溅射沉积工艺对Cr-N涂层微观结构的影响

石永敬1,龙思远1,方 亮2,潘复生3,杨世才4

(1. 重庆大学 机械工程学院,重庆 400044;

2. 重庆大学 数理学院,重庆 400044;

3. 重庆大学 材料科学与工程学院,重庆400044;

4. Teer Coatings Ltd, West Stone House, Berry Hill Industrial Estate,Droitwich, Worcestershire, WR9, 9AS, United Kingdom)

摘 要:研究在不同工艺条件下用直流反应磁控溅射技术在T10衬底上制备Cr-N涂层,并采用光电子能谱仪和XRD依次分析Cr-N涂层的表面结构和工艺参数对Cr-N涂层成分及相组成的影响。结果表明,Cr-N涂层在存放一段时间后表面产生复杂的Cr2O3相以及Cr(O,N)x相;常温下随着N2含量的增加,涂层相结构逐渐由Cr转变为化学比的CrN相。当N2含量为33.3%时,Cr-N涂层的相成分主要为Cr2N+CrN。并发现衬底偏压直接影响Cr-N系涂层的晶态及取向特征,当偏压增加到-130 V时,Cr-N涂层中β-Cr2N相结构逐渐转变为(110)和(300)取向结构。

关键词:铬氮涂层;磁控溅射;T10;Cr2N;CrN

中图分类号:TG 174.44 文献标识码:A

Effect of depositing process on microstructure chromium nitride coatings deposited by reactive magnetron sputtering

SHI Yong-jing1, LONG Si-yuan1, FANG Liang2, PAN Fu-sheng3, YANG Shi-cai4

(1. College of Mechanical Engineering, Chongqing University, Chongqing 400044, China;

2. College of Mathematics and Physics, Chongqing University, Chongqing 400044, China;

3. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

4. Teer Coatings Ltd, West Stone House, Berry Hill Industrial Estate, Droitwich, Worcestershire,WR9, 9AS, United Kingdom)

Abstract: A series of chromium-nitride coatings deposited on T10 substrates were prepared by direct current reactive magnetron sputtering with variable processing conditions, the phase and composition variation with different depositing processes were analyzed by X-ray diffraction, and surface structure of Cr-N coatings was analyzed by X-ray photoelectron spectroscopy. The results indicate that complicated Cr2O3 and Cr(O, N)x occur on surface of Cr-N coatings after these samples are deposited, under normal temperature conditions the phase changes from Cr to stoichiometry CrN with reactive gas N2 increasing. Phase composition of chromium-nitride coatings is mainly β-Cr2N+CrN when N2 content is 33.3%. Substrate bias voltage has significant effect on the phase state and the lattice orientation of the coating. As the bias voltage increases to -130 V, the diffraction summit of β-Cr2N phase gradually transfers into preferential orientations of (110) and (300).

Key words: chromium-nitride coatings; magnetron sputtering; T10; Cr2N; CrN

近年来,对Cr-N涂层的研究及应用已经证明氮化铬具有低的摩擦因数、高的表面硬度、较高的韧性以及良好的耐蚀性能[1-3]。因此,Cr-N涂层作为耐磨和耐蚀涂层广泛应用于刀具、轴承机件以及模具等领域[4-5]。例如,NiAs结构Cr2N和NaCl结构CrN的显微硬度HV分别为29.5 kN/cm2和18 kN/cm2[6],但CrN涂层比Cr2N涂层的耐磨性能好[7]。此外,CrN涂层在酸溶液(HCl、H2SO4)和NaCl溶液里展示出良好的耐蚀性能[8-9],CrN涂层的抗氧化温度达到700 ℃[10]。为了研究工艺参数对Cr-N涂层的微观结构的影响,通过直流平面磁控溅射技术沉积Cr-N涂层。本文作者通过X射线光电子能谱(XPS)和X射线衍射仪分析了不同制膜工艺条件下在工具钢表面制备的Cr-N涂层的相组成及晶体取向特征,并采用扫描电镜(SEM)分析了Cr-N涂层的表面和断面形貌特征。

1 实验

实验设备为JGP450型直流磁控溅射镀膜机,简单示意图如图1所示。靶材为纯金属Cr靶,纯度为99.95%。衬底材料为T10工具钢,衬底尺寸为d 30 mm×3 mm。衬底经打磨抛光后,表面粗糙度Ra≤0.3 μm。

图1 JGP450型直流反应磁控溅射镀膜机示意图

Fig.1 Schematic illustration of JGP450 type DC reactive magnetron sputtering apparatus

涂层沉积总压控制在0.5 Pa,靶材与基片距离为70 mm。磁控溅射镀膜机先抽到7.0×10-4 Pa,然后充入工作气体Ar。当Ar气压达到0.2 Pa时开始靶材预溅射以清除靶材表面存在的化合物,时间为10 min。为了增加涂层附着性能,溅射100 nm厚的Cr夹层,靶功率为13 W。然后以1 cm3/min的速度逐渐加入N2,至N2达到所要求的流量。涂层沉积厚度为2~4 μm。

元素成分分析采用PHI-5400型多功能X射线光电子能谱(XPS)检测,AlKα(1 486.84 eV)激发和大面积XL透镜模式。为减少样品表面吸附污染对真实结果的影响,用仪器自带的AG21氩离子枪对样品表面刻蚀5 min,以进行表面清洁。分析室真空度为5.0×10-8 Pa,X光能量为12 kV,20 mA。涂层相分析采用Rigaku Dmax-3C衍射仪,衍射仪由石墨单色器滤波,CuKα辐射,在管电压40 kV管电流30 mA的条件下测定,掠入射角θ为2?,2θ扫描,扫描范围2θ为30?~85?。表面形貌分析采用XT30型ESEM-TMP环境扫描电镜。

2 结果与分析

2.1 XPS表面分析

CrN涂层的表面分析如图2和图3所示,其中图2所示为氮化铬涂层表面XPS全扫描谱,图3所示为涂层中N1s和Cr2p的窄扫描结合能拟合谱,采用Lorentzian-Gaussian函数拟合,背景减除方法采用Shirley函数,并计算使得chi-square值最小。图中气体N2含量根据下式计算[11]:

图2 不同衬底温度下CrN涂层元素全扫描谱

Fig.2 Survey scanning patterns of CrN coatings at different substrate temperatures: P=180 W, φ(N2)=33.3%, Vb=-100 V

图3 Cr2p和N1s高斯曲线拟合谱

Fig.3 Fitting spectrum of Cr2p and N1s: P=180 W, φ(N2)= 33.3%, Vb=-100 V, t=250 ℃

由图2可知,在无溅射清洗的全元素扫描谱存在明显的C1s和O1s元素峰,但在刻蚀20 min以后C1s峰消失,而O1s峰仍然存在,但O含量已从表面的32%~40%降低到4%~5%。研究表明,Cr-N涂层沉积过程中由于真空室内还残留部分氧分压,所沉积的涂层中会出现点阵氧,其含量不超过5%。由图3(a)可知,涂层中N1s 3个结合能峰位值分别为400.29、398.02和396.82 eV,所属化合物依次为Cr(O,N)x、Cr2N和CrN。根据文献资料,N在密排六方结构中的结合能为397.75 eV[12],在面心立方结构中的结合能为397.20和396.75 eV[12-13],在Cr(O,N)x中的结合能为400.02 eV[13],结合能漂移了0.1~0.3 eV,但仍在±0.3 eV允许的范围内。由图3(b)可知,Cr2p3/2结合能峰位值依次分别为576.54、575.46和574.40 eV,所属化合物依次为Cr2O3(结合能为576.6 eV),Cr(O,N)x(结合能为575.3 eV)和Cr2N[12-14]。结果表明,在室温条件下CrN涂层的表面形成一层污染氧化层,原因是制备的样品在存放一段时间后,表面吸附的氧所致。这层污染氧化层内含有复杂的Cr2O3和Cr(O,N)x结构,这与MILO?EV等[13]的研究结果一致。与热氧化相区别的是,在污染氧化层中存在氮离子,因此还有少量的氮化铬存在。

2.2 XRD分析

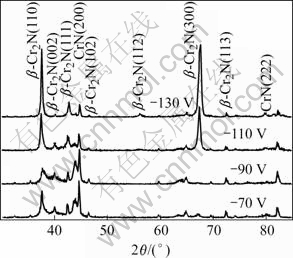

Cr-N涂层的相成分以及结构变化分析衍射谱如图4~6所示, 其中图4为不同N2含量条件下沉积Cr-N涂层的X射线衍射谱,图5所示为不同温度条件下沉积Cr-N涂层的X射线衍射谱,图6所示为不同偏压条件下沉积Cr-N涂层的衍射谱。其中表2中半高宽(FWHM)角度值为2θ值。

图4 不同N2含量条件下沉积的Cr-N涂层的X射线衍射谱

Fig.4 XRD patterns of Cr-N coatings deposited at different N2 contents: P=190 W, t=25 ℃, Vb=-100 V

图5 不同温度条件下沉积的Cr-N涂层X射线衍射谱

Fig.5 XRD patterns of Cr-N coatings deposited at different substrate temperatures: P=180 W, φ(N2)=33.3%, Vb=-100 V

图6 不同偏压(Vb)条件下沉积Cr-N涂层的X射线衍射谱

Fig.6 XRD patterns of Cr-N coatings deposited at different bias voltages (θ-2θ continuous scan): P=390 W, φ(N2)=40%, t=200 ℃

由图4可知,存金属Cr涂层表现为α-Cr(110)和α-Cr(200)取向;N2含量从40%增加到71%,XRD衍射峰由β-Cr2N(111)和(300)逐渐变化为CrN(111)和(220)。当反应气体N2含量为20%时,衍射谱表现为类似于馒头状的CrN(200)衍射峰,而DJOUADI等的研究表明,当N2含量很少时涂层中同样出现了CrN相,只是衍射峰为CrN(111)[14]。CrN(200)衍射峰的峰位处在Cr(110)和Cr2N(111)之间,并且半高宽宽化。因此,(200)衍射峰实际上是Cr(110)和Cr2N(111)的重叠峰,并且涂层中含有大量的微晶。结果表明常温下随着反应气体中N2含量的增加,Cr-N涂层相结构逐渐由Cr+Cr2N转变为CrN相。

由图5可知,温度分别为50、100、150、200和250 ℃条件下沉积Cr-N涂层相组成是β-Cr2N和CrN,温度升高衍射峰位无变化。但在温度增加以后,β- Cr2N(111)、(300)衍射峰以及CrN(111)的衍射强度增加,而β-Cr2N(002)和(112)衍射峰的衍射强度基本无变化。同时β-Cr2N(002)和(112)以及CrN(111)衍射峰的半高宽(FWHM)减小。

图6表明偏压在-70 V和-90 V时,Cr-N涂层中β-Cr2N相无取向特征,当偏压增加到-110 V和-130 V时,β-Cr2N相的(110)和(300)衍射峰的强度迅速增加,相结构为明显的(111)和(300)取向生长,同时(110)和(300)衍射峰半高宽(FWHM)随着衍射峰强度的增加而减小。由此可知,偏压对涂层相的晶体取向有重要的影响。

2.3 SEM分析

图7所示为在基底温度为200 ℃下沉积的Cr、Cr2N和CrN涂层断面的SEM形貌。由图7可知,溅射沉积的Cr-N涂层以接近垂直于衬底的柱状生长,大的柱状晶晶间夹有细小的纤维状晶粒。纯金属Cr涂层的晶间空隙最多,CrN最为密集。说明在相同的工艺条件下,随着涂层中N含量的增加,涂层的致密度也在增加。

图7 Cr-N涂层断面形貌

Fig.7 SEM morphologies of cross sections of Cr-N coatings: P=180 W, Vb=-100 V, t=200 ℃

3 讨论

根据XRD分析Cr-N涂层存在相结构组成,沉积工艺参数为P=180 W、φ(N2)=33.3%、Vb=-100 V条件下,涂层相成分为β-Cr2N+CrN。一些研究认为,随着N2流量的增加,Cr-N涂层相成分变化依次为α-Cr+ β-Cr2N、β-Cr2N、β-Cr2N+CrN和CrN[15-16],相成分变化如图8所示。但事实上,在磁控溅射工艺中入射离子以近乎垂直的方向轰击到阴极靶上,溅射原子流遵循余弦定律[17],溅射原子的能量分布遵守Maxwellian分布函数,到达衬底的溅射原子的能量与密度是不均衡的[18],少量能量较大的离子会轰击出原子团,这些原子团直接沉积在基底表面,因此高N的Cr-N涂层存在Cr金属原子团。多相合金表面表面能变化较大,在沉积氮化物涂层过程中表面吸附系数波动也较大。NiAs结构β-Cr2N和NaCl结构CrN均为间隙相结构,在Cr-N涂层中间隙原子N可以在一定范围内变化。当吸附到表面的N原子很少时,N原子固溶在bcc结构的Cr间隙中,形成缺位固溶体。实际上溅射原子在基底表面的分布是不均匀的,因此低N的Cr-N涂层中在某些区域也会形成CrN相,所出现的CrN相取向特征与工艺参数有关。

图8 Cr-N二元系平衡相图[19]

Fig.8 Phase diagram of Cr-N system

偏压增加也即意味着轰击薄膜表面的离子能和离子流的增加,同时进一步促进了吸附到表面的气相原子的结合与解吸,并在压应力作用下促进涂层的取向生长[20],因此衬底偏压对Cr-N涂层的取向特征和相结构具有重要影响。造成涂层这种取向生长的因素主要有:1) 同压应力在涂层中深度变化有关[21];2) 表面能的最小化是取向生长的驱动力之一[22];3) 机械应力也是影响涂层取向生长的另一种特性[23];4) 低角掠射使得表面层的晶体取向突出[18]。

根据Thornton的涂层区域结构模型[24],沉积温度为50~250 ℃时(t/tm<0.3,其中t为衬底温度,tm为涂层材料熔点=,CrN涂层结构为Z1锥状晶区。这说明基底温度在t/tm<0.1时,吸附原子的徙动能很小,最初的形核趋向于在涂层表面易于捕获原子的方向,晶体组织生长受晶间阴影的影响,因此少部分原子来不及扩散迁移就在吸附点形核,形成大的锥状晶间隙许多细小的纤维状晶粒。而在基底温度升高到250 ℃ (0.1<t/tm<0.3)时,表面吸附原子的徙动能增大,吸附原子的迁移率增加,最初吸附的原子迅速向平衡位置自扩散,最终被较大的晶粒捕获,形成锥状结构(如图7所示),同时衍射峰强度增加,半高宽减小(如图5所示)。

4 结论

常温下Cr-N涂层被存放一段时间后,在表面形成一层污染氧化层。当N2含量为33.3%时,Cr-N涂层的相成分主要为β-Cr2N+CrN相;衬底温度升高,衍射峰强度增强,衍射峰半高宽减小。反应气体中N2含量增加,Cr-N涂层的相结构逐渐由Cr转变为CrN。当偏压增加到-130 V时,CrN涂层中β-Cr2N相结构逐渐转变为(110)和(300)取向结构。CrN涂层表面形貌为锥状结构。

REFERENCES

[1] KAWANA A, ICHIMURA H, IWATA Y, ONO S. Development of PVD ceramic coatings for valve seats[J]. Surf Coat Technol, 1996, 86/87: 212-217.

[2] GAUTIER C, MOUSSAOUI H, ELSTNER F, MACHET J. Comparative study of mechanical and structural properties of CrN films deposited by d.c. magnetron sputtering and vacuum arc evaporation[J]. Surf Coat Technol, 1996, 86/87: 254-262.

[3] HERR W, MATTHES B, BROSZEIT E, MEYER M SUCHENTRUNK R. Influence of substrate material and deposition parameters on the structure, residual stresses hardness and adhesion of sputtered CrxNy hard coatings[J]. Surf Coat Technol, 1993, 57(1/3): 428-433.

[4] FRIEDRICH C, BERG G, BROSZEIT E, RICK F, HOLLAND J. PVD CrxN coatings for tribological application on piston rings[J]. Surf Coat Technol, 1997, 97(1/3): 661-668.

[5] PANJAN P, CVAHTE P, ?EKADA M, NAVINSEK B, URANKAR I. PVD CrN coating for protection of extrusion dies[J]. Vacuum, 2001, 61: 241-244.

[6] HONES P, SANJIN?S R, L?VY F. Characterization of sputter-deposited chromium nitride thin films for hard coatings[J]. Surf Coat Technol, 1997, 94/95: 398-402.

[7] REBHOLZ C, ZIEGELE H, LEYLAND A, MATTHEWS A. Structure, mechanical and tribological properties of nitrogen-containing chromium coatings prepared by reactive magnetron sputtering[J]. Surf Coat Technol, 1999, 115: 222-229.

[8] BERTRAND G, MAHDJOUB H, MEUNIER C. A study of the corrosion behaviour and protective quality of sputtered chromium nitride coatings[J]. Surf Coat Technol, 2000, 126(2/3): 199-209.

[9] CREUS J, IDRISSI H, MAZILLE H, SANCHETTE F, JACQUOT P. Improvement of the corrosion resistance of CrN coated steel by an interlayer[J]. Surf Coat Technol, 1998, 107(2/3): 183-190.

[10] NAVIN?EK B, PANJAN P, MILO?EV I. Industrial applications of CrN (PVD) coatings, deposited at high and low temperature[J]. Surf Coat Technol, 1997, 97(1/3): 182-191.

[11] VANCOPPENOLLE V, JOUAN P Y, WAUTELET M, DAUCHOT J P, HECQ M. Glow discharged mass spectrometry study of the deposition of TiO2 thin films by direct current reactive magnetron sputtering of a Ti target[J]. J Vac Sci Technol A, 1999, 17(6): 3317-3321.

[12] SANJIN?S R, HONES P, L?VY F. Hexagonal nitride coatings: Electron and mechanical properties of V2N, Cr2N and δ-MoN[J]. Thin Solid Films, 1998, 332(1/2): 225-229.

[13] MILO?EV I, STREHBLOW H H, NAVIN?EK B. Comparison of TiN, ZrN and CrN hard nitride coatings: Electrochemical and thermal oxidation[J]. Thin Solid Films, 1997, 303(1/2): 246-254.

[14] DJOUADI M A, NOUVEAU C, BEER P, LAMBERTIN M. CrxNy hard coatings deposited with PVD method on tools for wood machining[J]. Surf Coat Technol, 2000, 133/134: 478-483.

[15] HURKMANS T, LEWIS D B, BROOKS J S, M?NZ W D. Chromium nitride coatings grown by unbalanced magnetron (UBM) and combined arc/unbalanced magnetron (ABSTM) deposition techniques[J]. Surf Coat Technol, 1996, 86/87: 192-199.

[16] ZHAO Z B, REK Z U, YALISOVE S M, BILELLO J C. Nanostructured chromium nitride films with a valley of residual stress[J]. Thin Solid Films, 2005, 472(1/2): 96-104.

[17] 曲敬信, 汪泓宏. 表面工程手册[M]. 北京: 化学工业出版社, 1998: 364-366.

QU Jing-xin, WANG Hong-hong. Surface engineering manual book[M]. Beijing: Chemical Industry Press, 1998: 364-366.

[18] SERIKOV V, NANBU K. Monte Carlo numerical analysis of target erosion and film growth in a three-dimensional sputtering chamber[J].J Vac Sci Technol A, 1996, 14(6): 3108-3123.

[19] REBHOLZ C, ZIEGELE H, LEYLAND A, MATTHEWS A. Structure, mechanical and tribological properties of nitrogen-containing chromium coatings prepared by reactive magnetron sputtering[J]. Surf Coat Technol, 1999, 115(2/3): 222-229.

[20] OECHSNER H. Process controlled micro-structural and binding properties of hard physical vapor deposition films[J]. J Vac Sci Technol A, 1998, 16(3): 1956-1962.

[21] NAM K H, JUNG M J, HAN J G. A study on the high rate deposition of CrNx films with controlled microstructure by magnetron sputtering[J]. Surf Coat Technol, 2000, 131(1/3): 222-227.

[22] SUNDGREN J E. Structure and properties of TiN coatings[J]. Thin Solid Films, 1985, 128(1/2): 21-44.

[23] PELLEG J, ZEVIN L Z, LUNGO S, CROITORU N. Reactive-sputter-deposited TiN films on glass substrates[J]. Thin Solid Films, 1991, 197(1/2): 117-128.

[24] JOHN A. Thornton. Influence of apparatus geometry and deposition conditions on the structure and topography of thick sputtered coatings[J]. J Vac Sci Technol A, 1974, 11(4): 666-670.

基金项目:重庆大学研究生科技创新基金资助项目(200609Y1B0060165)

收稿日期:2007-03-20;修订日期:2007-11-20

通讯作者:石永敬,博士研究生;电话:023-65112626; E-mail: yjshi001@yahoo.com.cn

(编辑 陈爱华)