DOI: XX.XXXX/j.issn.1672-7207.2019.06.012

基于更新Kriging模型的双重螺旋法加工齿面的重构方法

邓辰1, 2,严宏志1, 2, 3,陈义忠2, 3,伊伟彬2, 3

(1. 中南大学 轻合金研究院,湖南 长沙,410083;

2. 中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083;

3. 中南大学 机电工程学院,湖南 长沙,410083)

摘要:针对双重螺旋法加工的螺旋锥齿轮采用常用样条曲线重构误差较大、影响啮合仿真精度的问题,基于更新Kriging模型提出一种提高齿面重构精度的方法。根据双重螺旋法成型原理,推导大、小轮齿面方程,由此提取出小轮齿面的型值点,并对其归一化,然后基于高斯核的Kriging模型进行重构,以复相关系数为约束条件,评判重构结果、更新样本点集,通过循环Kriging模型得到控制顶点,最后通过蒙面法重构齿面。以双重螺旋法加工的螺旋锥齿轮小轮齿面为例,比较基于更新Kriging模型的重构方法与常用样条曲线所建模型的重构精度。研究结果表明:更新Kriging模型提高了齿面重构精度。

关键词:双重螺旋法;螺旋锥齿轮;更新Kriging模型;齿面重构;蒙面法

中图分类号:TH132.4 文献标志码:文献标识码:A 文章编号:1672-7207(2019)06-1351-06

Tooth surface reconstructing method of spiral bevel gear generated by duplex helical method based on renewal Kriging model

DENG Chen1, 2, YAN Hongzhi1, 2, 3, CHEN Yizhong2, 3, YI Weibin2, 3

(1. Light Alloys Research Institute, Central South University, Changsha 410083, China;

2. State Key Laboratory of High Performance Complex Manufacturing, Central South University,Changsha 410083,China;

3. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: To overcome the impact of large errors on the precision of reconstruction in the tooth surface of outputted model after simulation processfor spiral bevel gears generated by duplex helical method, a fitting method based on renewal Kriging model was proposed. According to the forming principle of duplex helical method, the tooth surface equations of gear and pinion were established, and thus the initial data points on the tooth surface of pinion were extracted. Then they were treated with normalization, and fitting by the model of Kriging with the Gaussian kernel. Taking multiple correlation coefficients of the fitting data as constraints, the results of reconstruction were judged, and then the set of sample points was renewed. With this fitting method being circulated, control vertexes were obtained. Finally, the reconstruction of tooth surface was accomplished through skinning method. Taking a pinion tooth surface of spiral bevel gear drive manufactured by duplex helical method for example, the accuracy of reconstruction models generated by this method was compared with that of the common spline curve fitting method. Ther esults show that the precision of the proposed ideas has goocl superiority.

Key words: duplex helical method; spiral bevel gear; renewal Kriging model; reconstruction of tooth surface; skinning method

与传统的“五刀法”加工螺旋锥齿轮相比,双重螺旋法具有高效、绿色制造的特性[1-8]。张宇等[7]对双重螺旋法的切齿原理以及螺旋锥齿轮的动静态啮合性能等方面进行了研究。由于螺旋锥齿轮齿面形状复杂,不能使用显示函数表达。为了分析及优化螺旋锥齿轮的啮合性能,一般基于机床调整参数仿真加工形成螺旋锥齿轮齿面。由于已有软件仿真加工齿面精度较低,不适合作为后续动静力学分析的模型,因此,目前大多数集中在NURBS函数的拟合研究。其中,林家春等[9]利用数据点进行NURBS曲面拟合,建立齿面三维参数化模型,解决了特大型齿轮特征线测量问题;ZHAN等[10-11]在NURBS齿面重构基础上对拟合后的曲面进行最小二乘法再次优化逼近。一些三维软件建模都用类似的样条曲线拟合三维曲面,但因结果受其控制点及权因子等多方面因素的影响,最终精度不理想。与多项式最小二乘法、样条曲线等插值方法相比,Kriging作为一种估计方差最小的无偏估计模型,具有全局近似与局部随机误差相结合的特点,它的有效性不依赖于随机误差的存在,对非线性程度较高和局部响应突变问题具有良好的拟合效果,能够对拟合点进行误差控制,由此Kriging模型在近些年得到了广泛运用。杨丽等[12]运用Kriging模型预测了齿轮啮合刚度,由此以齿轮动态传动误差响应波动最小为目标对齿轮修形参数进行了优化;CHEN等[13]将Kriging模型与支持向量回归结合,对受噪声影响的数据进行了精确预测;佟操等[14]基于MonteCarlo法,结合Kriging预测,提出一种主动学习可靠度计算方法;陈志英等[15]将粒子群优化算法引入Kriging模型,快速准确地预测了轮盘危险点的应变变程;李小刚等[16]提出了一种双层更新的Kriging模型,对某型号大型汽轮发电机定子端部绕组锥环固定结构动态特性进行了稳健优化设计。MUKHOPADHYAY等[17]对比了不同Kriging模型的精度和计算效率,研究了不同协方差函数的比较性能,然后利用随机Kriging法解决了噪声在不确定传播中的作用。本文作者以实现双重螺旋法加工螺旋锥齿轮三维几何精确建模为目标,通过提取适当的型值点,进行基于更新Kriging模型的齿面重构研究,以便为双重螺旋法螺旋锥齿轮啮合性能准确分析提供支持。

1 双重螺旋法齿轮加工原理

依据螺旋锥齿轮双重螺旋法成型原理,大轮使用成形法加工,小轮使用双重螺旋法加工。与小轮双重螺旋法加工相比,大轮加工不附带刀倾机构与螺旋运动机构,而且摇台不需要在绕自身转动的同时还要沿其轴线方向做进给运动,其大轮理论齿面方程可参考文献[2-6],因此,在此主要介绍小轮的双重螺旋法加工原理。

小轮刀盘侧刃切削面的其次坐标方程为

(1)

(1)

式中:rt1为刀盘名义半径;W1为刀顶距;u1为切削刃上任意一点到刀尖的距离;α1刀具齿形角;θ1为刀盘相位角;凸面取“-”,凹面取“+”。

同理,刀盘侧刃切削点处的法向量nt1与切向量tt1分别为:

(2)

(2)

(3)

(3)

式(2)中小轮轮齿凹面取“-”,凸面取“+”;式(3)中小轮轮齿凹面取“+”,凸面取“-”。

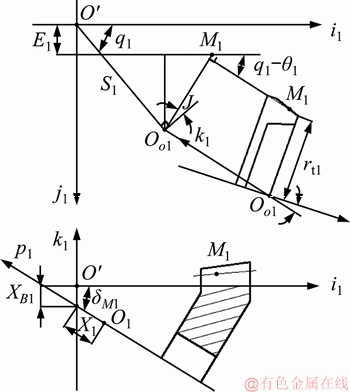

图1所示为小轮加工坐标系σ1={O';i1,j1,k1},其中,O' 为机床中心,O1为小轮设计交叉点,Oo1为刀盘中心;i1-j1所在平面为机床平面;S1为径向刀位,q1为角向刀位,XB1为床位,X1为轴向轮位,E1为垂直轮位,I为刀倾角,J为刀转角,δM1为小轮轮坯安装角。产形轮的轴向与k1轴方向相同,用单位矢量 表示。

表示。

小轮产形面方程位置矢量在机床坐标系的表达为:

(4)

(4)

(5)

(5)

(6)

(6)

式中:Mo1o′为刀盘坐标系到机床坐标系的坐标变换矩阵;Mdz和Mdq分别为小轮刀盘经过刀倾角和刀转角的坐标变换矩阵;Lo1o′,Ldz和Ldq分别为Mo1o′,Mdz和Mdq的三阶主子式。

而小轮交叉点O1到机床中心O′的位移矢量为

(7)

(7)

式(7)中床位XB1会随着加工过程发生变化,与螺旋运动系数有关[8]。

设产形轮的角速度为1,即 ,小轮转速为

,小轮转速为 ,其中,

,其中, 为加工小轮时的滚比,而小轮产形轮与工件之间的相对角速度

为加工小轮时的滚比,而小轮产形轮与工件之间的相对角速度 与相对速度

与相对速度 分别为:

分别为:

(8)

(8)

(9)

(9)

式中:Hl为小轮双重螺旋法加工的一阶螺旋运动系数。

最后,将小轮齿面方程表示在以小轮设计交叉点O1为原点的坐标系中,即可得到小轮的齿面方程:

(10)

(10)

2 Kriging模型及齿面重构优化方法

2.1 Kriging模型

对待求曲面基于Kriging模型进行拟合可表示为

(11)

(11)

式中:y(x)为未知的Kriging模型; ,为其中一个输入样本,n为输入的样本维数,

,为其中一个输入样本,n为输入的样本维数, 为第

为第 维中有m个样本点;

维中有m个样本点; 为回归多项式基函数向量,p为回归多项式的数量;

为回归多项式基函数向量,p为回归多项式的数量; 为多项式参数向量;z(x)为Gaussian随机过程函数,其期望为0,方差为σ2,协方差矩阵为

为多项式参数向量;z(x)为Gaussian随机过程函数,其期望为0,方差为σ2,协方差矩阵为

(12)

(12)

式中:xi与xj为不一样的随机变量;R(θ,  xj)有多种函数形式可以选择,在此,选择参数

xj)有多种函数形式可以选择,在此,选择参数 的高斯函数作为相关系数,R(θ,

的高斯函数作为相关系数,R(θ,  xj)表示为

xj)表示为

图1 小轮加工坐标系

Fig. 1 Coordinate system to manufacture pinion

(13)

(13)

式中:θk为未知的相关参数。

根据Kriging理论,在未知点x的预测值为

(14)

(14)

式中: ,为试验点在预测点处的响应向量,m为试验点数。

,为试验点在预测点处的响应向量,m为试验点数。

考虑Gaussian随机过程,为确保预测值无偏且预测均方误差最小,采用拉格朗日乘数法求最小值,可得

(15)

(15)

式中:F为n个样本构成的设计矩阵。将式(15)代入式(14)可得

(16)

(16)

对于回归问题 ,由最小二乘法可得多项式参数向量:

,由最小二乘法可得多项式参数向量:

(17)

(17)

再将式(17)代入式(16)得

(18)

(18)

式中:r*可通过已知设计点的残差计算得到,即 。

。

为了使预测值无偏差且预测均方误差最小,在未知点x处的Kriging预测值的均值uG(x)和方差 分别为:

分别为:

(19)

(19)

(20)

(20)

式中:u(x)=FTR F-f(x)具体推导过程见文献[18]。

F-f(x)具体推导过程见文献[18]。

2.2 基于Kriging模型的齿面重构优化方法

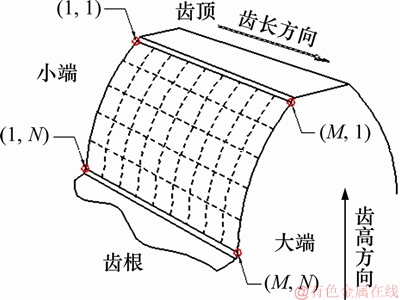

1) 采样点的选择。只有选择按齿面上按一定规律分布的采样点才能得到光滑的齿廓曲面。一般地,采样点越多,拟合的齿面和理论齿面越接近,但是相应的计算时间也会越长。因此,在满足精度要求的前提下,尽量使用较少的型值点进行曲面重构。齿面型值点的采集如图2所示。以每个加工仿真齿面上齿高、齿长方向的N×M个数据点作为初始采样的型值点进行齿面拟合。

图2 齿面型值点的采集

Fig. 2 Extraction of initial data points on tooth surface

2) 数据归一化处理。对型值点的数据进行归一化,即

(21)

(21)

式中:xi,nomalized为归一化后的第i维样本;i=1, 2,  ,m;k=1, 2,

,m;k=1, 2,  , n;

, n;  为型值点在第i维上的最小值;

为型值点在第i维上的最小值; 为第

为第 维上的m个数据点之间的最大距离。型值点归一化后再建立Kriging模型,可提高其精度和鲁棒性[19]。

维上的m个数据点之间的最大距离。型值点归一化后再建立Kriging模型,可提高其精度和鲁棒性[19]。

3) 拟合精度判断。基于Kriging模型的更新策略,用复相关系数R2作为全局精度的检验标准,其值越接近1,则模型的全局近似精度越高。

(22)

(22)

同时,以最大绝对误差为局部近似精度检验标准,其值越接近0,则模型的局部精度越高。

最大绝对误差 为

为

(23)

(23)

均方根误差 为

为

(24)

(24)

平均绝对误差 为

为

(25)

(25)

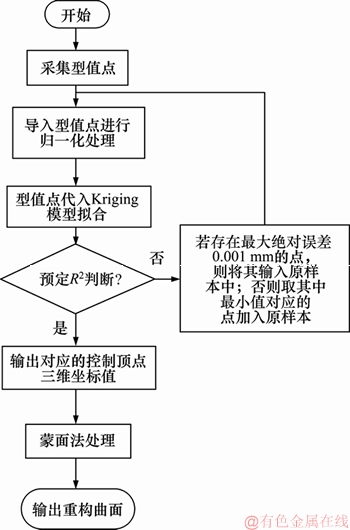

这些参数也作为检验曲面拟合精度的判据。首先,基于Kriging模型求出控制顶点的数据,再对拟合曲线的R2进行判断,若R2满足预定要求,则保留模型,输出控制顶点;否则,对模型进行更新。具体方法为:若求出控制顶点中最大绝对误差小于0.001 mm的点,则将这些数据作为新增样本加入初始样本点集中,以此加密样本从而提高局部精度;否则,将求出的控制顶点中最小值的点作为新增样本加入初始样本点集。再以新样本点集为基础继续进行归一化处理,然后重新进行新的Kriging拟合,直至R2满足预定要求为止。

4) 进行蒙皮操作。根据上一步所得的控制顶点,采用蒙皮法生成重构的齿面。

整个齿面重构流程如图3所示。

图3 齿面重构流程图

Fig. 3 Flow chart of reconstructing tooth surface

3 算例

以1对螺旋锥齿轮为例,其基本参数与机床调整参数如表1和表2所示。基于不同数目的型值点进行基于更新Kriging模型的曲面重构,并将其与在Pro/E中通过样条曲线拟合的齿轮模型进行对比,得到重构齿面误差特征值如表3所示。

表1 齿轮基本参数

Table 1 Basic parameters of gear and pinion

表2 齿轮机床调整参数

Table 2 Machine Setting Parameters of gear and pinion

表3 不同重构数据比较

Table 3 Comparison of reconstructing data for different models

由表3可得:通过样条曲线拟合出的Pro/E模型重构齿面平均绝对误差为采用本文更新Kriging模型的3.294 9×106倍。基于更新Kriging模型重构螺旋锥齿轮齿面精度更高。

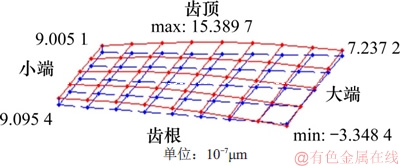

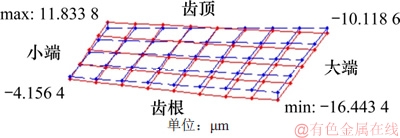

采用差曲面表达建模的误差可更直观反映重构精度。取法向偏差作为Kriging模型误差可得其差曲面如图4和图5所示。

图4 Kriging模型差曲面图

Fig. 4 Ease-off of Kriging model

图5 Pro/E模型差曲面图

Fig. 5 Ease-off of Pro/E model

从图4和图5可知:用基于更新的Kriging方法得到的拟合结果中,最大误差为1.539 0×10-6 μm,最小误差为-3.348 4×10-7 μm,拟合齿面点基本与理论齿面点坐标一致;而通过Pro/E生成的齿面,其最大误差为11.833 8 μm,最小误差为-16.443 4 μm。由此说明采用本文更新Kriging模型拟合齿面更接近理论齿面。

4 结论

1) 基于更新Kriging模型,通过采样点选择、型值点归一化、Kriging模型的更新策略、蒙面法提出了齿面精确重构优化方法。

2) 与常用样条曲线拟合方法相比,本文重构方法所建模型更接近理论齿面,误差更小,精度更高,为后续的齿面接触分析(TCA)以及承载齿面分析(LTCA)提供更为可靠的模型基础。

参考文献:

[1] SIMON V V. Influence of tooth modifications on tooth contact in face-hobbed spiral bevel gears[J]. Mechanism and Machine Theory, 2011, 46(12): 1980-1998.

[2] 严宏志, 肖蒙, 胡志安, 等.基于Ease-off的螺旋锥齿轮齿面分区修形方法[J]. 中南大学学报(自然科学版), 2018, 49(4): 824-830.

YAN Hongzhi, XIAO Meng, HU Zhian, et al. A novel ease-off flank zoning modification method of spiral bevel gears[J]. Journal of Central South University (Science and Technology), 2018, 49(4): 824-830.

[3] 严宏志, 艾伍轶, 周腾飞, 等. 相对位置误差对双重螺旋法加工齿轮副接触性能的影响[J]. 机械科学与技术, 2018, 37(3): 364-371.

YAN Hongzhi, AI Wuyi, ZHOU Tengfei, et al. Influence of contact performance of spiral bevel gears generated by duplex helical method with relative position errors[J]. Mechanical Science and Technology for Aerospace Engineering, 2018, 37(3): 364-371.

[4] ZHANG Yu, YAN Hongzhi. New methodology for determining basic machine settings of spiral bevel and hypoid gears manufactured by duplex helical method[J]. Mechanism and Machine Theory, 2016, 100: 283-295.

[5] ZHANG Yu, YAN Hongzhi, ZENG Tao, et al. Tooth surface geometry optimization of spiral bevel and hypoid gears generated by duplex helical method with circular profile blade[J]. Journal of Central South University, 2016, 23(3): 544-554.

[6] 张宇, 严宏志, 曾韬. 弧齿锥齿轮双重螺旋法切齿原理及齿面接触分析研究[J]. 机械工程学报, 2015, 51(21):15-23

ZHANG Yu, YAN Hongzhi, ZENG Tao. Cutting principle and tooth contact analysis of spiral bevel and hypoid gears generated by duplex helical method[J]. Journal of Mechanical Engineering, 2015, 51(21): 15-23.

[7] 张宇, 严宏志, 曾韬, 等. 螺旋运动及刀具参数对双重螺旋法加工齿面特征的影响规律[J].机械工程学报, 2018, 54(5): 53-61.

ZHANG Yu, YAN Hongzhi, ZENG Tao, et al. Influence mechanisms between helical motion velocity coefficient and cutter parameters and characteristics of tooth surface generated by duplex helical method[J]. Journal of Mechanical Engineering, 2018, 54(5): 53-61.

[8] 曾韬. 螺旋锥齿轮设计与加工[M]. 哈尔滨: 哈尔滨工业大学出版社, 1989: 240-243

ZENG Tao. Design and manufacture of spiral bevel and hypoid gears[M]. Harbin: Harbin Institute of Technology Press, 1989: 240-243.

[9] 林家春, 石照耀, 潘晨光, 等.基于NURBS曲面拟合的特大型齿轮齿廓偏差评定[J].仪器仪表学报, 2016, 37(3): 533-539.

LIN Jiachun, SHI Zhaoyao, PAN Chenguang, et al. Profile error evaluation of large gears based on NURBS surface fitting[J]. Chinese Journal of Scientific Instrument, 2016, 37(3): 533-539.

[10] ZHAN Rui, ADAYI·Xieeryazidan, DING Han. Formational principle and accurate fitting methodology for a new tooth surface of the spiral bevel gear[J]. International Journal of Simulation & Process Modelling, 2016, 11(1): 76.

[11] 丁撼, 阿达依·谢尔亚孜旦.球面渐开线齿面的形成理论及其NURBS精确拟合方法[J].中南大学学报(自然科学版), 2015, 46(6): 2052-2058.

DING Han, ADAYI·Xieeryazidan. Theory of forming spherical involute tooth surface and its accurate cubic NURBS fitting method[J]. Journal of Central South University (Science and Technology), 2015, 46(6): 2052-2058.

[12] 杨丽, 佟操, 陈闯, 等. 基于Kriging模型和遗传算法的齿轮修形减振优化[J]. 航空动力学报, 2017, 32(6): 1412-1418.

YANG Li, TONG Cao, CHEN Chuang, et al. Vibration reduction optimization of gear modification based on Kriging model and genetic algorithm[J]. Journal of Aerospace Power, 2017, 32(6): 1412-1418.

[13] CHEN Liming, QIU Haobo, JIANG Chen, et al. Support vector enhanced Kriging for metamodeling with noisy data[J]. Structural & Multidisciplinary Optimization, 2018, 57(4): 1611-1623.

[14] 佟操, 孙志礼, 杨丽, 等. 一种基于Kriging和Monte Carlo的主动学习可靠度算法[J]. 航空学报, 2015, 36(9): 2992-3001.

TONG Cao, SUN Zhili, YANG Li, et al. An active learning reliability method based on Kriging and Monte Carlo[J]. Acta Aeronautica ET Astronautica Sinica, 2015, 36(9): 2992-3001.

[15] 陈志英, 任远, 白广忱, 等.粒子群优化的Kriging近似模型及其在可靠性分析中的应用[J]. 航空动力学报, 2011, 26(7): 1522-1530.

CHEN Zhiying, REN Yuan, BAI Guangchen, et al. Particle swarm optimized Kriging approximate model and its application to reliability analysis[J]. Journal of Aerospace Power, 2011, 26(7): 1522-1530.

[16] 李小刚, 程锦, 刘振宇, 等.基于双层更新Kriging模型的机械结构动态特性稳健优化设计[J]. 机械工程学报, 2014, 50(3): 165-173.

LI Xiaogang, CHENG Jin, LIU Zhenyu, et al. Robust optimization for dynamic characteristics of mechanical structures based on double renewal Kriging model[J]. Journal of Mechanical Engineering, 2014, 50(3): 165-173.

[17] MUKHOPADHYAY T, CHAKRABORTY S, DEY S, et al. A critical assessment of Kriging model variants for high-fidelity uncertainty quantification in dynamics of composite shells[J]. Archives of Computational Methods in Engineering, 2017, 24(3): 495-518.

[18] BICHON B J, ELDRED M S, SWILER L P, et al. Efficient global reliability analysis for nonlinear implicit performance functions[J]. AIAA Journal, 2008, 46(10): 2459-2468.

[19] 韩忠华. Kriging模型及代理优化算法研究进展[J]. 航空学报, 2016, 37(11): 3197-3225.

HAN Zhonghua. Kriging surrogate model and its application to design optimization: a review of recent progress[J]. Acta Aeronautica ET Astronautica Sinica, 2016, 37(11): 3197-3225.

(编辑 赵俊)

收稿日期: 2018 -09 -05; 修回日期: 2018-12-11

基金项目(Foundation item):国家自然科学基金资助项目(51575533);中南大学研究生自主探索创新项目(502211809)(Project(51575533) supported by the National Natural Science Foundation of China; Project(502211809) supported by the Postgraduate Exploratory and Innovative Program of Central South University)

通信作者:严宏志,博士,教授,从事复杂曲面数字制造理论与技术研究;E-mail: yhzcsu@163.com