DOI: 10.11817/j.ysxb.1004.0609.2020-35889

Ti-22Al-26Nb-2Ta-0.5Y合金热变形行为

周 璇1,王克鲁1,鲁世强1,李 鑫1,陈虚怀1,周 毅2, 3,曹京霞2, 3,黄 旭2, 3

(1. 南昌航空大学 航空制造工程学院,南昌 330063;

2. 中国航空发动机集团有限公司 北京航空材料研究院,北京 100095;

3. 中国航空发动机集团有限公司 先进钛合金重点实验室,北京 100095)

摘 要:采用Gleeble-3500热模拟试验机对Ti-22Al-26Nb-2Ta-0.5Y合金进行等温恒应变速率压缩实验,研究其在变形温度900~1150 ℃、应变速率0.001~10 s-1范围内的热变形行为,根据DMM模型得到了3D加工图。结果表明:流动应力随变形温度的升高而降低,随应变速率的增大而增大;利用BP神经网络建立的合金本构关系模型具有较高的精度,其相关性系数达到0.9932,平均相对误差为7.64%,预测值偏差在15%以内的数据点达99.22%。通过对加工图分析和微观组织验证得知,失稳区域为(900~985 ℃, 0.003~0.56 s-1)、(1060~1120 ℃, 0.001~0.01 s-1)和(990~1030 ℃, 1~10 s-1),变形机制是局部流动、绝热剪切和裂纹;稳定区域为(900~1000 ℃, 0.001~0.03 s-1),变形机制是超塑性。Ti-22Al-26Nb-2Ta-0.5Y合金最佳变形工艺参数为温度900~1000 ℃、应变速率0.001~0.03 s-1。

关键词:Ti-22Al-26Nb-2Ta-0.5Y合金;热变形行为;BP神经网络;3D加工图

文章编号:1004-0609(2020)-10-2295-11 中图分类号:TG146.23 文献标志码:A

Ti2AlNb是以有序正交结构O相作为主要构成相的金属间化合物合金(简称Ti2AlNb基合金)[1],该合金不仅有较高的高温强度、延展性、比刚度及耐蚀性等优异的性能,而且密度较低,在航空航天领域得到了广泛应用[2-3]。近年来,为了改善合金性能,通过添加β相稳定元素Ta、Y、Si等,开发出新的Ti2AlNb基合金产品,使其成为最具有潜力的航空航天轻质高温结构材料[4]。

目前,国内外对Ti2AlNb基合金热变形行为进行了一定的研究。韩国强等[5]研究了Ti2AlNb合金高应变率下的流动应力特征,改进Johnson-Cook本构模型,通过实验对比得出,改进后的模型能够较好地描述Ti2AlNb合金在高应变率下的流动应力。SUN等[6]研究了Ti-22Al-25Nb合金的热变形行为,得出了不同区域的变形机理,优化了合金的热加工工艺参数。MA等[7]根据Murty原则建立了Ti-22Al-25Nb的加工图并分析了该合金的变形行为,认为合金在两相区温度低应变速率下的变形机理主要为α相球化。

传统建立的本构关系模型,多采用Arrhenius型方程应用数理统计或回归模型获得经验公式[8],但由于流动应力的影响因素很多,因此所建立的数学模型与真实变形情况相差较大,导致建模过程较为复杂,工作量较大,所建立的模型精度也很难达到要求。近年来,BP神经网络技术发展迅速,其在建模方面的便捷性可以很好地解决这一难题。采用神经网络建模时无须对研究对象做任何假设,所建立的模型能够以其良好的映射逼近能力逼近真实的变形过程。利用BP神经网络技术探索出实验数据之间的内在规律,能够避免传统本构模型的不足,且有效地建立出高精度本构模型。迄今为止,国内学者利用BP神经网络建立了一些材料的本构关系模型,均取得了较为理想的预期效果[9-10]。

加工图可以预测材料在热变形条件下的“稳定区”和“失稳区”,也可以分析材料在不同工艺条件下的变形机制,如动态回复、动态再结晶、超塑性、局部流动、绝热剪切和裂纹等,从而优化热变形工艺参数[11-12]。加工图方法已得到了广泛的应用[13],其中3D加工图能直观地反映出各参数之间的变化规律,也逐渐应用于金属材料的热变形行为研究,如镁合金[14]、铝合金[15]、钛合金[16]等。

本文通过对Ti-22Al-26Nb-2Ta-0.5Y合金进行等温恒应变速率压缩实验,得到了流动应力曲线,分析了不同工艺参数对Ti-22Al-26Nb-2Ta-0.5Y合金流动应力的影响。利用BP神经网络建立了合金本构关系模型,并通过预测数据与实验数据的对比分析, 验证模型的适用性。基于动态材料模型(Dynamic material model, DMM )的方法,构建了功率耗散图和失稳图,并分析了不同应变下工艺参数对功率耗散系数和失稳参数的影响规律。通过加工图预测和微观组织验证,得到了Ti-22Al-26Nb-2Ta-0.5Y合金的最佳工艺参数范围,可为其热加工工艺参数优化提供理论依据。

1 实验

实验材料为铸态 Ti2AlNb 基合金,其名义成分为Ti-22Al-26Nb-2Ta-0.5Y。在Gleeble-3500热模拟机上进行等温恒应变速率压缩实验。样品的尺寸为d 8 mm×12 mm。用砂纸打磨试样两端,并涂上石墨润滑剂,以减少摩擦的影响。变形温度范围为900~1150 ℃,压缩前,所有试样均以5 ℃/s的升温速率加热至变形温度,保温300 s,使温度均匀化。然后,在0.001~10 s-1的应变速率下对试样进行热压缩变形。高度压下率为70%(对应的真应变约为1.2),压缩后立即用水将样品冷却至室温。在实验过程中,该装置自动采集真实应力、真应变和温度等数据。将变形后的试样沿轴向切割,然后对与压缩方向平行的表面进行研磨和抛光,采用体积比为V(HF):V(HNO3):V(H2O)=1:3:7的腐蚀液进行腐蚀,通过XJP-6A光学显微镜观察金相组织,原始组织如图1所示。

图1 Ti-22Al-26Nb-2Ta-0.5Y合金的原始组织

Fig. 1 Original microstructure of Ti-22Al-26Nb-2Ta-0.5Y alloy

2 流动应力行为分析

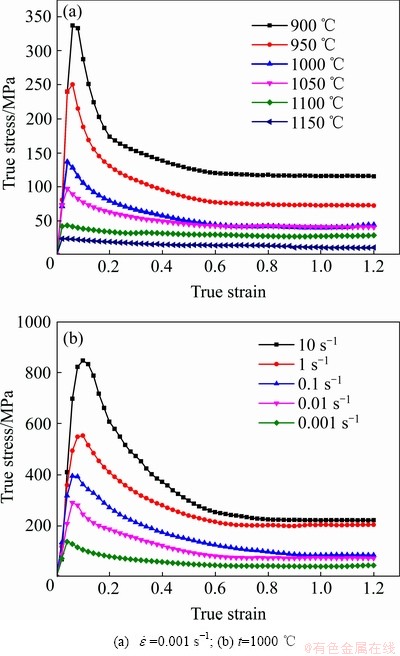

图2所示为变形温度900~1150 ℃、应变速率0.001~10 s-1条件下Ti-22Al-26Nb-2Ta-0.5Y合金真应力-真应变曲线,反映了变形温度、应变速率和真应变对流动应力的影响。从图2中可以看到,流动应力会随着变形温度的升高而减小,随着应变速率的增大而增大,表明Ti-22Al-26Nb-2Ta-0.5Y合金是正应变速率敏感材料。主要原因可能是:随着变形温度的升高,合金组织容易发生动态回复和动态再结晶,使材料发生软化,并且降低了材料的加工硬化效应[17],最后导致流动应力减小。随着应变速率的增大,在相同变形程度下,材料的变形时间大大缩减,材料来不及通过位错的滑移或攀移运动进行充分的软化行为,从而导致该合金的流动应力增大[18-19]。当真应变超过0.6时,随应变量的增加,该合金的流动应力变化不明显[20-21],其位错增殖引起的应变硬化和位错的相互作用抵消及重排引起的软化之间达到动态平衡。

图2 Ti-22Al-26Nb-2Ta-0.5Y合金的真应力-真应变曲线

Fig. 2 True stress-true strain curves of Ti-22Al-26Nb-2Ta- 0.5Y alloy

3 BP神经网络本构模型

3.1 BP神经网络

考虑到各因素对流动应力的影响和BP神经网络强大的非线性建模能力,建立三层BP神经网络结构(即输入层、隐含层、输出层)。我们研究的是变形温度、应变速率和应变对Ti-22Al-26Nb-2Ta-0.5Y合金流动应力的影响,所以输入层包含三个节点,就是变形温度、应变速率和应变,而输出层只有一个节点,就是流动应力参数;隐含层节点数目的选取较为复杂,隐含层节点数量较少则会导致训练出来的网络不够强壮,不能精准识别未参与训练的样本,而隐含层节点数量较多则会导致学习时间较长,不能保证误差在最佳范围内。最优隐含层节点数的选取参照式(1):

(1)

(1)

式中:n1为隐含层的节点数;ni为输入层的神经元;mo为输出层神经元;a为1~10之间的常数。通过反复实验进行比较,最后发现:具有两个隐含层节点数为8时最好。

将Sigmoid函数作为隐含层神经元的激励函数,Purelin函数作为输出层神经元的激励函数,由输入层至隐含层的第p个训练样本j的输出Opj为:

(2)

(2)

式中:隐含层的第j个神经元的输入为Nj;输入层中第j个神经元向隐含层的输出为Xj;Wij为隐含层和输入层之间的连接权值;θj为输入层到隐含层的阀值。

适当地对各个神经元之间的阀值和连接权值进行调整,可以使复杂非线性对象的建模更加精确。如果网络的初始阀值被随意地进行设定,对于每种输入模式P,期望输出和网络实际输出会存在很大程度上的误差Ep。网络训练的误差目标函数E为:

(3)

(3)

式中:mt为训练样本;no为网络输出节点数; 为网络实际输出;ypj为期望输出;Wjk为隐含层和输出层之间的连接权值;

为网络实际输出;ypj为期望输出;Wjk为隐含层和输出层之间的连接权值; 为隐含层到输出层的阀值。

为隐含层到输出层的阀值。

3.2 数据归一化处理

以应变速率、变形温度和应变量的实验数据作为BP神经网络的输入参数,流动应力作为BP神经网络的输出参数。如果BP神经网络输入节点的数据相差过于悬殊,就会给隐含层到输入层之间权值调节上造成不便,最终导致BP神经网络满足不了精度要求。这里,对训练样本的输入、输出参数进行归一化处理来克服这一缺陷:

(4)

(4)

式中:Ni为第i个输入、输出参数的归一化值; 为第i个输入、输出参数输出;Nmax和Nmin分别表示相对应的输入、输出参数的最大值和最小值。

为第i个输入、输出参数输出;Nmax和Nmin分别表示相对应的输入、输出参数的最大值和最小值。

BP神经网络层间传递函数分别选用tansig、tansig、purelin函数,训练函数采用L-M算法(Levenberg-Marquardt)的trainlm函数来对BP算法进行优化。优化后的BP比传统BP具有算法迭代少、精度高和收敛速度快的优点[22]。设定目标迭代次数为3000,目标误差为10-5,学习速率为0.3。

3.3 结果与分析

表1 Ti-22Al-26Nb-2Ta-0.5Y合金样本划分

Table 1 Sample classification of Ti-22Al-26Nb-2Ta-0.5Y alloy

Ti-22Al-26Nb-2Ta-0.5Y合金样本划分如表1所示,t为测试数据,c为训练数据。选取变形温度为900、1000和1100 ℃为训练样本,950、1050和1150 ℃为测试样本,利用BP神经网络模型的精度进行测试。采用相关系数R 和平均相对误差E定量描述合金BP神经网络模型的精确度,两者的计算公式如下:

(5)

(5)

(6)

(6)

不同条件下的BP模型预测值与实验数据对比如图3所示。从图3中可以看出,通过BP神经网络建立的Ti-22Al-26Nb-2Ta-0.5Y合金的本构模型,其实验值和预测值有良好的吻合度。

采用模型相关系数R和平均相对误差E对Ti-22Al-26Nb-2Ta-0.5Y合金BP模型的精确度进行定量分析。对BP得到预测值和实验值进行整理后作出对比图,如图4所示。按照式(5)和(6)计算出R与E值,经计算,基于BP神经网络模型的预测值与实验值的相关系数R为0.9932,平均相对误差E为7.64%,偏差在15%以内的点约占总验证数据点数的99.22%,预测值与实验值的吻合度良好。

图3 不同条件下BP模型预测值与实验数据对比

Fig. 3 Comparison of predicted values and experimental data of BP model under different conditions

图4 Ti-22Al-26Nb-2Ta-0.5Y合金流动应力实验值与预测值的比较

Fig. 4 Comparison of flow stress experimental values and prediction values of Ti-22Al-26Nb-2Ta-0.5Y alloy

4 加工图

4.1 理论基础

根据动态材料模型理论,材料在热加工过程中单位体积内吸收的能量P可以分为耗散量G和协耗散量J两个部分,如式(7)所示[23]:

(7)

(7)

式中:G为耗散量,表示材料在塑性变形引起的功率

消耗,其中大部分转化成黏塑性热(见式(8));J为协耗散量,表示材料变形过程中与组织演变有关的功率耗散(见式(9))。

(8)

(8)

(9)

(9)

功率耗散效率η为

(10)

(10)

式中:ms为应变速率敏感因子;η为功率耗散效率,无量纲参数,它随应变速率和温度的变化便形成了功率耗散图。功率耗散图上的η等值线表示与材料的微观结构演变相关的相对熵产率。一般来说,高η值的区域对应着较好的加工性能区。

同时,PRASAD等[24]提出了塑性失稳判据:

<0 (11)

<0 (11)

功率耗散图和失稳图叠加即可得到加工图。

4.2 功率耗散图

图5 不同应变下热加工参数对η值的影响

Fig. 5 Influence of hot processing parameters on η value at different strains

功率耗散效率η值反映了组织的动态变化。如图5所示,构建了不同应变下的功率耗散效率η值与温度之间的关系。从整体上看,在应变速率为0.01 s-1、0.1 s-1和1 s-1时,随着应变的增加,η值随温度的变化波动较小。但在应变速率为0.001 s-1和10 s-1的情况下,η值随温度有较大的波动,应变为0.6、0.9、1.2时,功率耗散效率值变化规律相似,在温度为950 ℃和1100 ℃时,功率耗散效率值都较高,应变为0.3时,其最高值出现在温度1100 ℃时。功率耗散效率值高的区域表明该区材料的热加工性能较好。

图6所示为功率耗散效率值随变形温度、应变速率和应变变化的三维分布图。由图6可以看出,当温度为900~1150 ℃,应变速率为0.001~0.01 s-1时,功率耗散效率值较高,随着应变的增加,功率耗散效率值较高的区域逐渐减少。当温度为900~1000 ℃,应变速率为0.01~10 s-1时,功率耗散效率值较低,当应变为0.9时,功率耗散效率值低的区域最大。

4.3 失稳图

失稳参数ξ是预测材料在热加工过程中可能发生组织失稳缺陷(如绝热剪切带、局部流动、楔形裂纹、空洞等)的判断依据,即通过该参数所界定的区域可表征材料在热变形时应注意避开的工艺参数范围。如图7所示,建立了不同应变下失稳参数ξ与温度的关系。

图6 Ti-22Al-26Nb-2Ta-0.5Y合金三维功率耗散图

Fig. 6 3D power dissipation diagram of Ti-22Al-26Nb-2Ta- 0.5Y alloy

从整体上看,在不同的应变下,应变速率为0.001、0.01、0.1和1 s-1时,ξ值随温度的波动较小,但在应变速率为10 s-1的情况下,ξ值随温度的波动较大。温度为900~975 ℃、应变速率为0.01 s-1和0.1 s-1时,ξ值都为负值。随着应变的增加,应变速率为10 s-1、温度为1000 ℃和应变速率为0.001 s-1及0.01 s-1、温度为1100 ℃时,ξ值也出现了负值。

图7 不同应变下热加工参数对ξ值的影响

Fig. 7 Influence of hot processing parameters on ξ value at different strains

图8所示为失稳参数随变形温度、应变速率和应变变化的三维分布图,黑色区域代表稳定区域,红色区域代表失稳区域。从整体上看,失稳区域主要集中在(900~1000 ℃, 0.004~0.1 s-1)和(1050~1150 ℃, 0.001~0.01 s-1)之间。当应变为0.6时,温度为1000~ 1030 ℃、应变速率为1~10 s-1和温度为1000~1030 ℃、应变速率为1~10 s-1时,可以看到出现失稳区域。

图8 Ti-22Al-26Nb-2Ta-0.5Y合金三维失稳图

Fig. 8 3D instability diagram of Ti-22Al-26Nb-2Ta-0.5Y alloy

4.4 加工图分析

图9所示为真应变为0.6和1.2时Ti-22Al-26Nb- 2Ta-0.5Y合金的加工图,图9中的等值线是功率耗散效率η值,一般来说,高η值的区域对应着较好的加工性能区,而阴影区域为热变形时发生流动失稳的参数范围。从图9(a)可以看出,在真应变为0.6时,有两个峰值区域,第一个区域:变形工艺参数在(900~ 1000 ℃, 0.001~0.03 s-1)范围内,合金热变形时的功率耗散效率值均大于0.65,在变形工艺参数为(940 ℃, 0.001 s-1)时,功率耗散效率值达到最大值0.75;第二个区域:变形工艺参数在(1050~1150 ℃, 1~10 s-1)范围内,合金热变形时的功率耗散效率值均大于0.34,在变形参数为(1100 ℃, 10 s-1)时,功率耗散效率值达到最大值0.55。对比两个区域,第一个峰值区域更适合合金进行热加工成形的变形工艺参数取值范围。而在变形工艺参数为(900~985 ℃, 0.003~0.56 s-1)、(980~ 1030 ℃, 0.56~10 s-1)和(1050~1130 ℃, 0.001~0.03 s-1)时合金出现了流动失稳,所以该区域不适合进行热加工。

Ti-22Al-26Nb-2Ta-0.5Y合金在真应变为1.2时的热加工图见图9(b),有两个峰值区域。第一个区域:变形工艺参数为(900~1000 ℃, 0.001~0.03 s-1)范围时,合金热变形时的功率耗散效率值均大于0.68;在变形工艺参数为(940 ℃, 0.001 s-1)时,功率耗散效率值达到了最大值0.78。第二个区域:变形工艺参数为(1050~ 1150 ℃, 3~10 s-1)范围时,合金热变形时的功率耗散效率值均大于0.45;在变形工艺参数为(1100 ℃, 10 s-1)时,功率耗散效率值达到了最大值0.49。对比两个区域,第一个峰值区域更适合进行合金热加工成形的变形工艺参数取值范围。而在变形工艺参数为(900~ 985 ℃, 0.003~0.56 s-1)、(990~1030 ℃, 1~10 s-1)和(1060~1120 ℃, 0.001~0.01 s-1)时,合金出现了流动失稳,所以该区域不适合进行热加工。对比图9(a)和(b)可以看出,在不同应变下,Ti-22Al-26Nb-2Ta-0.5Y合金适合热加工成形的区域变化不大。

图9 真应变为0.6和1.2时Ti-22Al-26Nb-2Ta-0.5Y加工图

Fig. 9 Processing maps of Ti-22Al-26Nb-2Ta-0.5Yalloy at true strain of 0.6(a) and 1.2(b)

4.5 微观组织验证

通过观察微观组织分析,并结合加工图进行验证,结果如图10和11所示。当变形工艺参数为(900 ℃, 0.01 s-1)和(1100 ℃, 0.001 s-1)时,如图10(a)和(b)所示,变形组织出现了局部流动现象,晶粒被压成长条状,且方向多样性。当温度为1000 ℃、应变速率为1 s-1时,如图10(c)所示,组织中可以看到绝热剪切现象,绝热剪切方向与压缩轴线方向约45°。这是由于钛合金的导热系数差,在变形过程中会产生明显的热效应,容易产生绝热温升,从而出现绝热剪切现象。局部流动和绝热剪切现象的出现,意味着材料出现了严重不均匀变形,在加工时应避开此区域。当温度为1000 ℃、应变速率为10 s-1时,如图10(d)所示,可以看到组织出现不同程度的裂纹,有些晶粒的晶界出现破碎现象。裂纹的形成对Ti-22Al-26Nb-2Ta-0.5Y合金的综合性能影响较大,在加工时应避开此区域。

图10 Ti-22Al-26Nb-2Ta-0.5Y合金失稳区微观组织

Fig. 10 Microstructures of instability zone in Ti-22Al-26Nb-2Ta-0.5Y alloy

图11 Ti-22Al-26Nb-2Ta-0.5Y合金稳定区微观组织

Fig. 11 Microstructures of stabilized zone of Ti-22Al-26Nb-2Ta-0.5Y alloy

在应变速率较低的区域,其功率耗散效率峰值较高。应变速率敏感指数是判断超塑性成形的一个重要指标,一般认为,若材料的应变速率敏感指数大于0.3,易发生超塑性成形[25]。当真应变为1.2、温度为900~ 1000 ℃、应变速率为0.001~0.03 s-1时,其功率耗散效率值达到最大值0.78,对应的应变速率敏感因子为0.64。如图11所示,观察Ti-22Al-26Nb-2Ta-0.5Y合金的显微组织,当变形工艺参数为(900 ℃, 0.001 s-1)、(950 ℃, 0.001 s-1)和(1000 ℃, 0.001 s-1)时,组织细小均匀,可以认为发生了超塑性成形。

综合加工图和显微组织分析可知,温度为900~ 1000 ℃、应变速率为0.001~0.03 s-1时,对应区域内的变形机制为超塑性变形,该区域为Ti-22Al-26Nb-2Ta- 0.5Y合金适宜的热加工工艺参数范围。

5 结论

1) Ti-22Al-26Nb-2Ta-0.5Y合金高温压缩变形时的流动应力与变形温度和应变速率有关,流动应力会随着变形温度的升高而降低,随着应变速率的增大而增大,表明Ti-22Al-26Nb-2Ta-0.5Y合金是正应变速率敏感材料。

2) 基于BP神经网络建立的Ti-22Al-26Nb-2Ta- 0.5Y合金的高温本构关系模型,具有较高的精度,其相关性系数达到0.9932,平均相对误差为7.64%,预测值偏差在15%以内的数据点达到92.22%,表明该BP神经网络本构关系模型具有良好的预测能力,能够准确预测合金的流动应力。

3) 通过分析功率耗散图和失稳图得出:功率耗散效率值较高的区域主要集中在900~1150 ℃,应变速率为0.001~0.01 s-1,失稳区域主要集中在(900~1000 ℃, 0.004~0.1 s-1)和(1050~1150 ℃, 0.001~0.01 s-1)之间。

4) 通过组织观察发现,Ti-22Al-26Nb-2Ta-0.5Y合金主要以局部流动((900~985 ℃, 0.003~0.56 s-1)和(1060~1120 ℃, 0.001~0.01 s-1))、绝热剪切(990~ 1030 ℃, 1~10 s-1)和裂纹(990~1030 ℃, 1~10 s-1)形式失稳。最佳的加工参数范围为温度900~1000 ℃、应变速率0.001~0.03 s-1,材料变形机制为超塑性变形。

REFERENCES

[1] BANERJEE D, GOGIA A K, NANDI T K, JOSHI VA . A new ordered orthorhombic phase in a Ti3AlNb alloy[J]. Acta Metallurgica, 1988, 36(4): 871-882.

[2] LI Shi-qiong, MAO Yong, ZHANG Jian-wei, LI Jun-tao, CHENG Yun-jun, ZHONG Zeng-yong. Effect of microstructure on tensile properties and fracture behavior of intermetallic Ti2AlNb alloys[J]. Transactions of Nonferrous Metals Society of China, 2002, 12(4): 582-586.

[3] SHAGIEV M R, GALEYEV R M, VALIAKHMETOV O R, SAFIULLIN R V. Improved mechanical properties of Ti2AlNb-based intermetallic alloys and composites[J]. Advanced Materials Research, 2009, 59: 105-108.

[4] GERMANN L, BANERJEE D, GUEDOU J Y, STRUELJL. Effect of composition on the mechanical properties of newly developed Ti2AlNb-based titanium aluminide[J]. Intermetallics, 2005, 13(9): 920-924.

[5] 韩国强, 谢兰生, 陈明和, 司松社, 吴荣华. Ti2AlNb合金高应变率下流动应力特征与本构关系[J]. 稀有金属材料与工程, 2019, 47(3): 847-852.

WU Guo-qiang, XIE Lan-sheng, CHEN Ming-he, SI Song-she, WU Rong-hua. Flow stress characteristics and constitutive relation of Ti2AlNb alloy under high strain rate[J]. Rare Metal Materials and Engineering, 2019, 47(3): 847-852.

[6] SUN Yu, ZHANG Heng, WAN Zhi-peng, REN Li-li, HU Lian-xi. Establishment of a novel constitutive model considering dynamic recrystallization behavior of Ti-22Al- 25Nb alloy during hot deformation[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(3): 546-557.

[7] MA X, ZENG W D, XU B, SUN Y, XUE C, HAN Y F. Characterization of the hot deformation behavior of a Ti-22Al-25Nb alloy using processing maps based on the Murty criterion[J]. Intermetallics, 2012, 20(1): 1-7.

[8] SAJJADI S A, CHAICHI A, EZATPOUR H R, MAGHSOUDLOU A, KALAIE M A. Hot deformation processing map and microstructural evaluation of the Ni-based superalloy IN-738LC[J]. Journal of Materials Engineering and Performance, 2016, 25(4):1269-1275.

[9] YAN Jie, PAN Qing-lin, LI An-de, SONG Wen-bo. Flow behavior of Al-6.2Zn-0.70Mg-0.30Mn-0.17Zr alloy during hot compressive deformation based on Arrhenius and ANN models[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(3): 638-647.

[10] 孙 宇, 曾卫东, 赵永庆, 戚运莲, 韩远飞, 邵一涛, 马 雄. 基于BP神经网络Ti600合金本构关系模型的建立[J]. 稀有金属材料与工程, 2011,40(2): 220-224.

SUN Yu, ZENG Wei-dong, ZHAO Yong-qing, QI Yun-lian, HAN Yuan-fei, SHAO Yi-tao, MA Xiong. Modeling of constitutive relationship of Ti600 alloy using BP artificial neural network[J]. Rare Metal Materials and Engineering, 2011, 40(2): 220-224.

[11] 王克鲁, 鲁世强, 李 鑫, 董显娟, 杨化娟. Ti-6.5Al- 3.5Mo-1.5Zr-0.3Si合金本构关系的BP神经网络模型[J]. 特种铸造及有色合金, 2008, 28(8): 575-578.

WANG Ke-lu, LU Shi-qiang, LI Xin, DONG Xian-juan, YANG Hua-juan. A constitutive relation model for the Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy based on BP neural network[J]. Special Casting & Nonferrous Alloys, 2008, 28(8): 575-578.

[12] 肖宏超, 刘楚明, 徐 璐, 王 霄, 万迎春. Mg-10Gd- 4.8Y-0.6Zr镁合金热变形行为与加工图[J]. 中国有色金属学报, 2013, 23(2): 303-310.

XIAO Hong-chao, LIU Chu-ming, XU Lu, WANG Xiao, WAN Ying-chun. Deformation behavior and processing map of Mg-10Gd-4.8Y-0.6Zr magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 303-310.

[13] FAN Cai-he, PENG Ying-biao, YANG Hai-tang, ZHOU Wei, YAN Hong-ge. Hot deformation behavior of Al-9.0Mg-0.5Mn-0.1Ti alloy based on processing maps[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(2): 289-297.

[14] LI J Q, LIU J, CUI Z S. Characterization of hot deformation behavior of extruded ZK60 magnesium alloy using 3D processing maps[J]. Materials & Design, 2014, 56: 889-897.

[15] WU R H,LIU Y, GENG C, LIN QQ, XIAO Y F, XU J R, KANG W. Study on hot deformation behavior and intrinsic workability of 6063 aluminum alloys using 3D processing map[J]. Journal of Alloys and Compounds, 2017, 713: 212-221.

[16] SUN Y, FENG X Y, HU L X, ZHANG H, ZHANG H Z. Characterization on hot deformation behavior of Ti-22Al-25Nb alloy using a combination of 3D processing maps and finite element simulation method[J]. Journal of Alloys and Compounds, 2018, 753: 256-271.

[17] 欧阳德来, 鲁世强, 崔 霞, 董显娟, 吴 超, 邱 伟. 应用加工硬化率研究TA15钛合金β区变形的动态再结晶临界条件[J]. 航空材料学报, 2010, 30(2): 17-23.

OUYANG De-lai, LU Shi-qiang, CUI Xia, DONG Xian-juan, WU Chao, QIU Wei. Study on critical strains of dynamic recrystallization during β process in TA15 titanium alloy using working hardening rate[J]. Journal of Aeronautical Materials, 2010, 30(2): 17-23.

[18] 杨建辉, 张 鹏, 赵升吨. TC4-DT钛合金热变形本构方程[J]. 塑性工程学报, 2016, 23 (2): 120-125.

YANG Jian-hui, ZHANG Peng, ZHAO Sheng-dun. Hot deformation constitutive equation of TC4-DT titanium alloy[J]. Journal of Plasticity Engineering, 2016, 23(2): 120-125.

[19] 王克鲁, 鲁世强, 李 鑫, 欧阳德来, 董显娟. Ti60合金热变形行为及微观组织[J]. 特种铸造及有色合金, 2016, 36(5): 473-476.

WANG Ke-lu, LU Shi-qiang, LI Xin, OUYANG De-lai, DONG Xian-juan. Hot deformation behavior and microstructure evolution of Ti60 alloy[J]. Special Casting and Nonferrous Alloys, 2016, 36(5): 473-476.

[20] ZANG Q H, YU H S, LEE Y S, KIM M S, KIM H W. Effects of initial microstructure on hot deformation behavior of Al-7.9Zn-2.7Mg-2.0Cu (wt%) alloy[J]. Materials Characterization, 2019, 151: 404-413.

[21] SU Z X, WAN L,SUN C Y, CAI Y, YANG D J. Hot deformation behavior of AZ80 magnesium alloy towards optimization of its hot workability[J]. Materials Characterization, 2016, 122: 90-97.

[22] 任彦军, 王家伟, 张晓兵, 赵浩文. 基于LM算法BP神经网络的高炉-转炉界面铁水温度预报模型[J]. 钢铁, 2012, 47(9): 40-42.

REN Yan-jun, WANG Jia-wei, ZHANG Xiao-bing, ZHAO Hao-wen. Prediction model of hot metal temperature for BF-BOF interface based on LM BP neural network[J]. Iron & Steel , 2012, 47(9): 40-42.

[23] 李红英, 刘 洋, 胡继东, 曾翠婷, 魏冬冬. ZA27合金的热变形及加工图[J]. 中国有色金属学报, 2012, 22(2): 365-370.

LI Hong-ying, LIU Yang, HU Ji-dong, ZENG Cui-ting, WEI Dong-dong. Hot deformation and processing map of ZA27 alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 365-370.

[24] PRASAD Y V R K, GEGEL H L, DORAIVELU S M, MALAS J C, MORGAN J T, LARK K A, BARKER D R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242[J]. Metallurgical Transactions A, 1984, 15(10): 1883-1892.

[25] 马 超, 王高潮. TB6钛合金定m值法高温超塑性拉伸试验研究[J]. 锻压技术, 2016, 41(10): 88-91.

MA Chao, WANG Gao-chao. Superplastic tensile experiment by the fixed m value method at high-temperature for titanium alloy TB6[J]. Forging & Stamping Technology, 2016, 41(10): 88-91.

Hot deformation behavior of Ti-22Al-26Nb-2Ta-0.5Y alloy

ZHOU Xuan1, WANG Ke-lu1, LU Shi-qiang1, LI Xin1, CHEN Xu-huai1, ZHOU Yi2, 3, CAO Jing-xia2, 3, HUANG Xu2, 3

(1. School of Aeronautical Manufacturing Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. Beijing Institute of Aeronautical Materials, Aero Engine Corporation of China, Beijing 100095, China;

3. Key Laboratory of Advanced Titanium Alloys, Aero Engine Corporation of China, Beijing 100095, China)

Abstract: The isothermal constant strain rate compression test of Ti-22Al-26Nb-2Ta-0.5Y alloy was carried out by Gleeble-3500 thermomechanical simulator. The hot deformation behavior at temperature of 900-1150 ℃and strain rate of 0.001-10 s-1 was studied. The 3D processing map on the basis of DMM model was established. The results show that the flow stress decreases with the increase of deformation temperature, and increases with the increase of strain rate. The constitutive model of alloy established by BP neural network has high accuracy, whose correlation coefficient reaches 0.9932, the average relative error is 7.64%, the predictive value of deviation within 15% data points is up to 99.22%. Through processing map prediction and microstructure observation, the instability zones are (900-985 ℃, 0.003-0.56 s-1), (1060-1120 ℃, 0.001-0.01 s-1) and (990-1030 ℃, 1-10 s-1). The deformation mechanism of the instability zones is mainly flow localization, adiabatic shear and crack. The stable zone is (900-1000 ℃, 0.001-0.03 s-1). The deformation mechanism of the stable zone is mainly superplasticity. It is found that the suitable deformation parameters of Ti-22Al-26Nb-2Ta-0.5Y alloy are deformation temperature of 900-1000 ℃ and strain rate of 0.001-0.03 s-1.

Key words: Ti-22Al-26Nb-2Ta-0.5Y alloy; hot deformation behavior; BP neural network; 3D processing map

Foundation item: Project(20202ACBL204001) supported by the Natural Science Foundation of Jiangxi Province, China; Project (6141B090329) supported by the Aeronautics Power Foundation of China

Received date: 2019-12-12; Accepted date: 2020-06-18

Corresponding author: WANG Ke-lu; Tel: +86-13133804266; E-mail: wangkelu@126.com

(编辑 何学锋)

基金项目:江西省自然科学基金资助项目(20202ACBL204001);航空动力基金资助项目(6141B090329)

收稿日期:2019-12-12;修订日期:2020-06-18

通信作者:王克鲁,教授,博士;电话:13133804266;E-mail:wangkelu@163.com