文章编号:1004-0609(2010)S1-s0188-05

医用钛合金的微弧氧化膜层组织及其磨损性能

王艳玲,惠松骁,叶文君,米绪军

(北京有色金属研究总院,北京 100088)

摘 要:采用微弧氧化方法对医用钛合金表面进行改性,利用X射线衍射分析(XRD)、扫描电镜(SEM)对微弧氧化膜层的表面形貌和化学成分进行分析,通过小振幅往复摩擦磨损试验测量膜层的耐磨损性能。结果表明:钛合金经过微弧氧化表面处理后,所得膜层存在不同尺寸的放电微孔,氧化膜内层相对外层较为致密;膜层主要由大量金红石型TiO2相、非晶相SiO2及少量锐钛矿型TiO2相组成;与基体相比,微弧氧化膜层的初期摩擦因数从0.7降低至0.1,耐磨性提高。

关键词:钛合金;医用钛合金;微弧氧化;磨损性能

中图分类号:TG146.23;TG174.45 文献标志码:A

Microstructure and its wear property of micro-arc oxidation coating on biomedical titanium alloy

WANG Yan-ling, HUI Song-xiao, YE Wen-jun, MI Xu-jun

(General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: The coating prepared by micro-arc oxidation (MAO) on biomedical titanium alloy was investigated. The surface morphology and chemical composition of MAO coating were analyzed by X-ray diffractometry and scanning electron microscopy (SEM). The anti-wear property of the coating was measured through small amplitude oscillatory reciprocating friction and wear test. The results show that the MAO coating has some micropores with different dimensions and the inner layer of the coating is denser compared with the outer layer. The composition of the coating comprises majority of rutile TiO2 and amorphous phase SiO2. A fraction of the composition is anatase TiO2. The preliminary friction coefficient of the coating decreases from 0.7 to 0.1. The micro-arc oxidation treatment improves the anti-wear property of the titanium alloy.

Key words: titanium alloy; biomedical titanium alloy; micro-arc oxidation; wear property

在生物医学领域,钛及其合金凭借高比强度、与骨骼相近的弹性模量、良好的生物相容性和生物环境下优良的抗腐蚀性能,在用于人体硬组织修复和替换材料方面已逐渐成为主要的金属医用材料[1-2]。但钛及其合金的耐磨损性能差,生成的磨屑游离于植入体附近,容易引起炎症。因此,钛及其合金表面改性的研究是十分有意义的。

微弧氧化(Microarc oxidation, MAO)是一种在Al、Mg和Ti等有色金属表面原位生长氧化物陶瓷膜的新技术[3-4]。本文作者主要研究一种医用钛合金Ti-39Nb- 6Zr经过微弧氧化处理后,所得陶瓷膜层的表面形貌、化学成分和耐磨损性能。

1 实验

1.1 实验材料及方法

原始材料为Ti-39Nb-6Zr钛合金厚板材,尺寸为12 mm×90 mm×L,厚板材经过冷加工变形,变形量为95%,在经过冷变形加工板材上切取20 mm×20 mm试样,试样表面均用1000#水砂纸进行打磨。

微弧氧化试验采用北京师范大学WHYH-40型40 kW微弧氧化控制电源及装置。以碱性硅酸盐溶液(主要为Na2SiO3)作为微弧氧化电解液,微弧氧化电压在-120~500 V之间,工作时间为1 h。微弧氧化工艺如下:表面清洗→微弧氧化处理→清洗→烘干。

用Philips APD10 X射线衍射仪Cu Kα射线分析微弧氧化膜层相组成。管电压为40 kV,管电流为20 mA,测量步长为4 (°)/min。

在JSM-840型扫描电镜上观察微弧氧化膜层表面形貌,同时利用扫描电镜上附加配置NORAN- VARTAGE-DI4105能谱仪进行EDS成分分析。

在CETR公司Universal Micro-Tribo-tester-2微动摩擦试验机上进行小振幅往复摩擦磨损试验。对磨擦副采用直径为4 mm的GR15钢球,采用点接触进行摩擦,法向载荷为1 N,频率为1 Hz,行程为4 mm。使用Talysurf sp-120型表面形貌仪测量磨痕截面面积。

2 结果与讨论

2.1 微弧氧化膜层表面形貌分析

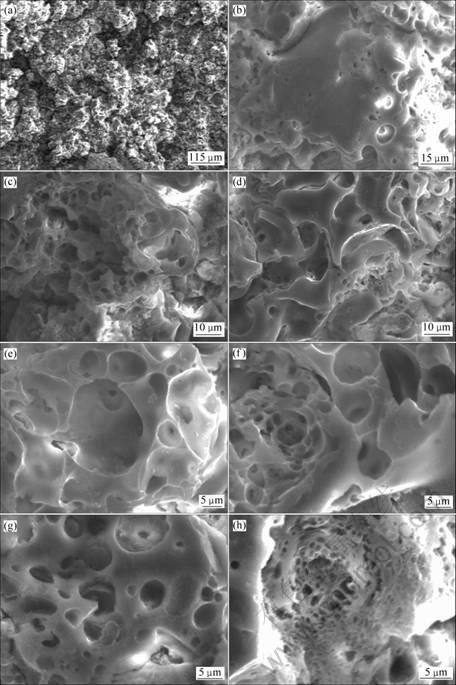

图1所示为微弧氧化膜层不同放大倍率的表面形貌。各种特征形貌的出现与微弧氧化膜层形成机理有很大关系。由图1(a)可以看出,膜层由许多颗粒状物质组成,表明粗糙度很高,膜层疏松。由图1(b)可知,在整体疏松氧化层局部,存在平坦光滑区域。由图1(c)可清晰看到,微弧氧化膜层表面是多孔的。图1(c)不同的是,图1(d)中在各放电微孔之间表面有小平坦光滑区域,这可能是图1(b)中大的平滑区域中细小微孔放电产生的结果。由图1(e)可清晰观察到膜层表面由直径20 μm左右和大量几微米左右的孔洞组成。在图1(f)中,大孔洞中间又出现许多几微米甚至更小的放电气孔,类似火山口处又出现多个喷发点,大孔洞内部进一步放电,造成孔洞深浅、大小不一。图1(h)所示为典型的火山喷发式微孔放电残留形貌。

图1 不同放大倍率时微弧氧化膜层的表面形貌

Fig.1 Surface morphologies of MAO coating at different magnifications

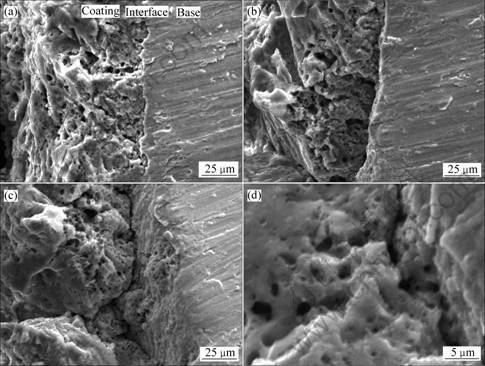

图2所示为砂轮锯断试样的原始断面形貌。图2(a)中基体上留有清晰的砂轮锯过痕迹,而膜层没有明显痕迹,这从基体与膜层形貌上很容易得到解释,基体为致密金属,膜层为颗粒状陶瓷氧化物,膜层间有许多微弧放电时留下的孔洞,孔洞使得陶瓷氧化物间结合力降低,另外陶瓷氧化物硬度高,砂轮锯到陶瓷氧化物时,没有直接把陶瓷氧化物锯断,而是在样品结合力较薄弱的部位断开。图2(b)所示为陶瓷氧化物绷断部位留下的断面形貌,这是最原始的断面形貌。图2(c)所示为试样同一位置倾斜30?后的断面形貌。图2(d)所示为图2(c)的局部放大图。由图2(c)和(d)可知,接近基体处,膜层仍然有大量不同尺寸的微孔,大部分孔洞尺寸为纳米量级,孔洞平均尺寸远小于表面膜层孔洞尺寸,氧化膜内层相对外层较为致密。

2.2 微弧氧化膜层成分分析

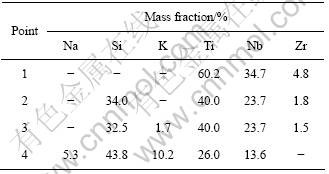

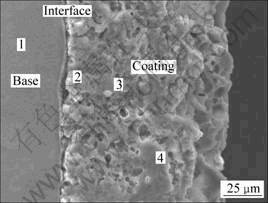

用扫面电镜能谱分析微弧氧化膜层的成分,对微弧氧化断面成分进行分析,其结果如表1所列。微弧氧化膜层,从邻近基体处至膜层表面,依次选取3个点,如图3中膜层截面形貌上所标位置,所选位置相对平整,使成分点数据准确度提高。从表1可知,在靠近界面2点处的Si元素含量已经达到34%(质量分数),说明微弧氧化点解液中硅元素已扩散到膜内层,且膜层中硅元素含量趋于平稳;Na和K元素从膜层中部位置开始出现,越到膜表层含量越高。

表1 微弧氧化膜层的成分

Table 1 Chemical compositions of MAO coating in Fig.3

图2 微弧氧化膜层的原始断面形貌

Fig.2 Original cross section morphologies of MAO coating at different magnifications

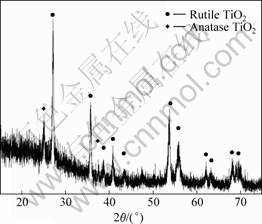

用水砂纸对微弧氧化膜层打磨,磨掉表面疏松层,剩余30~40 μm致密层,进行XRD分析,其XRD谱如图4所示。

图3 微弧氧化膜的断面形貌

Fig.3 Cross section morphology of MAO coating

图4 微弧氧化膜层的XRD谱

Fig.4 XRD pattern of MAO coating

由以上分析得出,钛合金微弧氧化陶瓷膜层含有金红石型TiO2和锐钛矿型TiO2相。根据衍射峰相对衍射强度可推知,金红石含量比锐钛矿含量高。

微弧氧化膜层相组成主要为TiO2,没有探测到Nb的氧化物相,Nb原子可能固溶在TiO2中,因为在锐钛矿结构的TiO2中,至少20%的Ti原子可以被Nb取代[5]。

能谱分析显示微弧氧化膜层中硅元素含量超过30%,图4中未出现SiO2的衍射峰,这说明氧化膜层中除含有金红石和锐钛矿外,还含有大量SiO2非晶相。SiO2从溶体形成非晶态的临界冷却速度只有2×10-4 K/s,极易形成非晶态物质。

2.3 微弧氧化膜层耐磨损性能

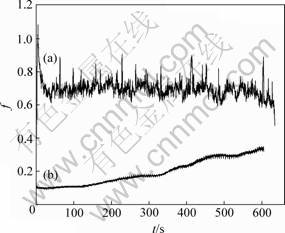

微弧氧化膜层经水砂纸打磨掉疏松层,剩余20 μm左右的致密层,对基体和打磨后膜层进行摩擦磨损试验,图5所示为基体与微弧氧化膜层摩擦因数f随时间的变化曲线。从图5观察到,基体与对磨幅之间的摩擦因数f为0.7左右;微弧氧化膜层样品表面与Gr15球对磨,摩擦初期,因数f仅为0.1;2 min后,摩擦因数缓慢增大。

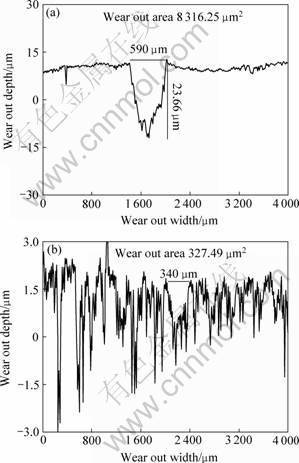

基体与打磨后微弧氧化膜层对应的磨痕截面图如图6所示。由图6(a)基体磨痕轮廓可以看出,磨损主要是微切削和犁沟磨损,这主要是因为Gr15的硬度比钛合金的高一个数量级,磨痕呈现擦伤特征,磨痕深度较深。图6(b)所示为微弧氧化膜层的磨痕曲线。由图6(b)可知,膜层表面高低不平,这是因为膜层内存在微孔。微弧氧化磨痕和基体磨痕相比,磨损面积仅为其3.9%,磨损量大大降低。这体现出微弧氧化陶瓷膜能显著提高合金的耐磨损性能。

图5 基体与打磨后微弧氧化膜层摩擦因数随时间的变化曲线

Fig.5 Change of fraction coefficient with time of matrix (a) and MAO coating after polishing (b)

图6 基体与微弧氧化膜层磨痕曲线

Fig.6 Worn-out depth curves of matrix and MAO coating: (a) Matrix; (b) MAO coating

3 结论

1) 钛合金经过微弧氧化表面处理,所得膜层存在不同尺寸的放电微孔,相对外层氧化膜内层较为致密,作为生物医用钛合金,放电微孔的存在有利于新生骨的生长。

2) 膜层主要由大量金红石型TiO2相、非晶相SiO2及少量锐钛矿型TiO2相组成。

3) 微弧氧化膜层耐磨损性能与基体相比,初期摩擦因数从0.7降低至0.1,大大提高合金的耐磨损性能。

REFERENCES

[1] BRANEMARK P, BREINE U, LINDSTORM J, et al. Intraosseous anchorage of dental prostheses: (Ⅰ) Experimental studies[J]. Scand J Plastic Reconstr Surg, 1969, 3: 81-82.

[2] BRANEMARK P, HANSSON B, ADELL R, et al. Osseointegrated implants in the treatment of edentulous jaw: experience from a 10-year period[J]. Scand J Reconstr Surg Suppl, 1977, 16: 1-4.

[3] MALYSCHEV V. Mikrolichtbogen oxidation[J]. Matalloberfl?che, 1995, 49(8): 606-608.

[4] 薛文斌, 邓志威, 来永春, 汪新福, 陈如意. 铝合金微弧氧化膜的形成过程及其特性[J]. 电镀与精饰, 1996, 18(5): 3-6.

XUE Wen-bin, DENG Zhi-wei, LAI Yong-chun, WANG Xin-fu, CHEN Ru-yi. Formation and characteristics of coatings formed by microarc oxidation on aluminate alloy[J]. Plating and Finishing, 1996, 18(5): 3-6.

[5] HIRSCH J. Walztexturentwicklung in Kubisch-Fl?chen- Zentrierten Matallen[M]. Germany: Aachen University, 1984: 292-313.

(编辑 龙怀中)

通信作者:王艳玲;电话:010-82241172;E-mail: sophia0825@yahoo.com.cn