Influence of rapid thermal process on intrinsic gettering in fast neutron irradiated Czochralski silicon

CHEN Gui-feng(陈贵锋)1, LI Yang-xian(李养贤)1, LI Xing-hua(李兴华)1, CAI Li-li(蔡莉莉)1,

MA Qiao-yun(马巧云)2, NIU Ping-juan(牛萍娟)3, NIU Sheng-li(牛胜利) 4, CHEN Dong-feng(陈东风) 4

1. School of Materials Science and Engineering, Hebei University of Technology, Tianjin 300130, China;

2. School of Science, Tianjin University of Commerce, Tianjin 300134, China;

3. School of Information and Communication, Tianjin Polytechnic University, Tianjin 300160, China;

4. China Institute of Atomic Energy, Beijing 102413, China

Received 10 April 2006; accepted 25 April 2006

Abstract: A rapid thermal process (RTP) was first introduced into the intrinsic gettering (IG) processes of fast neutron irradiated Czochralski (CZ) silicon. The effect of RTP conditions on bulk microdefects (BMDs) and denuded zone (DZ) was investigated. Fourier transform infrared absorption spectrometer (FTIR) was used to measure the concentration of interstitial oxygen ([Oi]). Bulk microdefects were observed by optical microscope. The results show that, according to the variation of [Oi], it is found that RTP doesn’t change the processes of oxygen precipitation in fast neutron irradiated Czochralski silicon. Perfect denuded zone, dense oxygen precipitates and defects form in the bulk of irradiated samples. With increasing temperature of RTP, the width of denuded zone decreases. Increasing RTP cooling rate, the density of Bulk microdefects increases. DZ forms in the sample that annealed in nitrogen atmosphere.

Key words: neutron irradiation; Czochralski silicon; intrinsic gettering; FTIR

1 Introduction

RTP has been widely applied in the process of semiconductor device fabrication for it’s fast heating and exact temperature control. Magic denuded zone (MDZ) was formed on the surface of CZ silicon wafer by MEMC through the application of RTP to IG. The formation of MDZ is a rapid method of achieving reproducible and reliable IG. RTP installs a vacancy depth profile into the silicon wafer. The quenched-in vacancies can enhance the nucleation rate of oxygen precipitates greatly. During RTP, the behavior of oxygen precipitation is controlled by the distribution of vacancy. During the processes of IG in CZ silicon, RTP usually replaces the out diffusion annealing which is the first step of conventional three steps annealing[1]. During the following two steps annealing at low and high temperature, oxygen precipitates will form and grow. The annealing atmosphere is important for the formation of DZ. Generally, the width of DZ formed in oxygen atmosphere is wider than that in argon atmosphere and it is difficult to form DZ in nitrogen atmosphere[2].

If CZ silicon is irradiated by fast neutron, the processes of IG will be quite different. Stable defects introduced by fast neutron irradiation can be as cores for oxygen precipitation dispensing with the nucleation stage at low temperature[3]. Furthermore, supersaturated vacancies induced by fast neutron irradiation can decrease the crucial nucleation radius and can release misfit stress which generated during the process of oxygen precipitation. After annealing at high temperature, dense BMDs and perfect DZ will form in fast neutron irradiated CZ silicon. The process of oxygen precipitation can be accelerated greatly. In this study, RTP was first introduced into the IG processes of fast neutron irradiated CZ silicon. The effect of RTP on IG of fast neutron irradiated CZ silicon was studied.

2 Experimental

The sample was an n-type, <111>-orientation and dislocation-free CZ silicon crystal with an initial oxygen concentration ([Oi]) of about 1.08×1018 cm-3 and undetectable levels of carbon impurity (<1016 cm-3). One section of the sample (G1) had been irradiated by fast neutron at a dose of 2.4×1019 cm-2 at 45 ℃. Another section of the sample (G0) without irradiation was left to compare with the irradiated sample. Two parts of the crystal were cut to wafers and polished chemically. Some of the wafers were subjected to RTP for 50 s in argon and nitrogen atmospheres, respectively. The RTP temperature was 1 200, 1 250 and 1 280 ℃ and cooling rate was 5, 15 or 50 ℃/s, respectively. After RTP, the pretreated and non-pretreated samples of G1 were annealed at 1 100 ℃ for 10 h in single tube diffusion furnace in argon atmosphere. After annealing, the samples had been immersed in hydrofluoric acid to remove oxidizing layer. [Oi] was determined by ‘WQF-410’ FTIR with a calibrated coefficient of 3.14×1017 cm-2 at room temperature. For each spectrum, 64 scans were accumulated to improve the signal to noise ratio. The annealed samples were cleaved and the BMDs was observed by optical microscope after Wright etching for 15 min.

3 Results and discussion

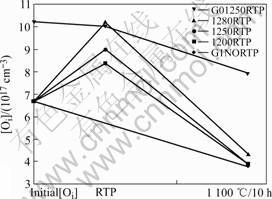

Fig.1 shows the changes of [Oi] in all samples at different stages. Before RTP, the [Oi] in sample G1 is 6.7×1017 cm-3 and far less than that in sample G0. The samples G1 and G0 were cut from the same crystal ingot.

The initial [Oi] in those samples is about the same value. The decrease of [Oi] in sample G1 is due to the generation of oxygen related defects during the process of fast neutron irradiation [4]. [Oi] in sample G1 increased after RTP. With the steady increase in temperature of RTP, the enhancement of [Oi] in sample

Fig.1 [Oi] in samples at different stages

G1 increased. While the [Oi] in sample G0 didn’t change after RTP. The increase of [Oi] is attributed to the disintegration vacancy-oxygen and other oxygen related complex which induced by fast neutron irradiation. The amount of the decomposed complex is affected by the temperature of RTP. Therefor, the enhancement of [Oi] in sample G1 increases with increasing the RTP temperatures. After annealing at

1 100 ℃ for 10 h, [Oi] in all samples decreased for the generation of oxygen precipitates. [Oi] in sample G1 is far less than that in the sample without irradiation, but is equal to that in non-pretreated sample. So the process of the oxygen precipitation in fast neutron irradiated CZ silicon was not accelerated by RTP.

Fig.2 shows the optical micrographs of cleavage plane in pretreated and non-pretreated samples of G1 after annealing at 1100℃ for 10h in argon atmosphere.

Fig.2 Optical micrographs of cleavage plane in pretreated and non-pretreated samples of G1 after annealing at 1 100 ℃ for 10 h in argon atmosphere: (a) No RTP; (b) RTP at 1 200 ℃; (c) RTP at 1 250 ℃; (d) RTP at 1 280 ℃

After annealing, perfect DZ forms in all the samples of G1. The width of DZ in non-pretreated sample is less than that in the sample that suffered RTP at 1 200 ℃ but is larger than those in the samples that suffered RTP at 1 250 ℃ and 1 280 ℃. The width of DZ in the pretreated samples decreases with increasing RTP temperature. While in non-irradiation CZ silicon, DZ width increases with the increase of RTP temperature due to the accelerated out-diffusion of vacancy by RTP[5]. In thin wafers, even a short time annealing (a few seconds) at 1 180-1 250 ℃ is enough to bring the concentration of vacancy and self-interstitial reach their equilibrium[6]. During the process of subsequent cooling, fast recombination results in survival only vacancies because the concentration of vacancies is larger than that of self-interstitial[7]. In neutron irradiated CZ silicon, the vacancy type defects will decompose during RTP and then the concentration of vacancy is larger than the equilibrium of vacancy at RTP temperature and the vacancy is in supersaturation. With increasing the temperature of RTP, the concentration of vacancy increased. The separation of vacancy from irradiation defects and the acceleration of vacancy out-diffusion by the increase of temperature are two opposite factors for the formation of oxygen precipitates. The DZ width decreases with increasing temperature because the generation of vacancy exceeds the out-diffusion of vacancy.

Fig.3 shows the optical micrographs of cleavage plane in sample G1 after RTP at 1 250 ℃ with different cooling rates and annealing at 1 100 ℃ for 10 h. In Fig.3(a), the cooling rate of RTP is 5 ℃/s while in Fig.3(b) it is 50 ℃/s. DZ formed in two samples. The width of DZ in Fig.3(a) is wider than that in Fig.3(b), while the density of BMDs in Fig.3(a) is lower than that in Fig.3(b). The cooling rate affects the formation of DZ and oxygen precipitate. Fast cooling will shorten the out-diffusion distance of vacancy[8]. Then the DZ will narrow down. Fast cooling will freeze lots of vacancy in wafers and accelerate oxygen precipitation.

Fig.4 shows the optical micrograph of BMDs in sample G1 after RTP in nitrogen atmosphere and normal annealing at 1 100 ℃ for 10 h in argon atmosphere. The temperature of RTP is 1 200 ℃. What we can observaed is that DZ and dense bulk microdefects formed in the bulk of this sample. But some microdefects appeared in the DZ. The density of defects is higher than that pretreated in argon atmosphere with the same condition. During the RTP in nitrogen atmosphere, N reacts with Si on the surface of wafer and some vacancy implant into the bulk of the wafer[9]. Then the vacancy will accelerate the oxygen precipitation. The annealing atmosphere didn’t affect width of DZ. A small mount of defect is come from the inner diffusion of nitrogen[10].

4 Conclusions

According to the variation of [Oi] with annealing condition, RTP doesn’t accelerate the process of oxygen

Fig.3 Optical micrographs of cleavage plane in sample G1 that suffered RTP at 1 250 ℃ in argon atmosphere with different cooling rates: (a) 5 ℃/s; (b) 50 ℃/s

Fig.4 Optical micrographs of cleavage plane in sample G1 after RTP in nitrogen atmosphere and normal annealing at 1 100 ℃ for 10 h in argon atmosphere

precipitation in fast neutron irradiated CZ silicon. With the increase of RTP temperature, the width of DZ in fast neutron irradiated CZ silicon decreases. DZ and dense bulk microdefects form in the bulk of the sample that suffered RTP in nitrogen atmosphere. Cooling rate affects the width of DZ and the density of defects in fast neutron irradiated CZ silicon.

References

[1] AKATSUKA M, OKUI M, SUEOKA K. Effect of rapid thermal annealing on oxide precipitation behavior in silicon crystral [J]. Nucl Instrum Methods Phys Res, Sect B, 2002, 186(1-4): 46-54.

[2] FALSTER R, VORONKOV V V. The engineering of intrinsic point defects in silicon wafers and crystals [J]. Mater Sci Eng B, 2000, 73(1-3): 87-94.

[3] LI Y X, GUO H Y, LIU B D, LIU T J, HAO Q Y, LIU C C, YANG D R, QUE D L. The effects of neutron irradiation on the oxygen precipitation in Czochralski-silicon, [J]. J Cryst Growth, 2003, 253: 6-9.

[4] MA Q Y, HAO Q Y, YANG S, LIU T J, HUANG Q S, LIU C C, LI Y X. Effect of fast neutron irradiation on oxygen precipitation in CZ-Si[A]. Proceeding of 13th Semiconductor Silicon and Integrated Circuit Conference of China[C]. Shenzhen: Chinese Institute of Electronics, 2003. 399.

[5] YU X G, YANG D R, YANG J S ,MA X Y, LI L B, QUE D L. Effects of nitrogen on grown-in oxygen precipitates in large diameter Czochralski silicon [J]. Chin J Semicond, 2003, 24(1): 49-53

[6] VORONKOV V V, FALSTER R. Nucleation of oxide precipitates in vacancy-containing silicon, [J]. J Appl Phys, 2002, 91(9): 5802-5810.

[7] VORONKOV V V, FALSTER R. Effect of vacancies on nucleation of oxide precipitates in silicon [J]. Mater Sci Semicond Processing, 2002, 5(4-5): 387-390.

[8] FALSTER R, VORONKOV V V, QUAST F. On the properties of the intrinsic point defects in silicon A perspective from crystal growth and wafer processing [J]. Phys Stat Sol B, 2000, 222(1): 219-244.

[9] ZHU H L, YANG D R, WANG L, PEI Y L, QUE D L, ZHANG H J, HE P M. Direct-nitridation of silicon by heat-treating at high temperature in nitrogen ambience [J]. Chin J Semicond, 2003, 24(10): 1049-1052.

[10] SHUI Q, YANG D R, LI L B, PI X D, QUE D L. Intrinsic gettering of Czochralski silicon annealed in argon and nitrogen atmosphere[J]. Physica B, 2001, 307(1-4): 40-44.

(Edited by HE Xue-feng)

Foundation item: Project (50472034) supported by the National Natural Science Foundation of China; Project(E2005000048) supported by the Natural Science Foundation of Hebei Province, China; Project(20050080006) supported by the Specialized Research Fund for the Doctoral Program of Higher Education, China

Corresponding author: LI Yang-xian; Tel: +86-22-26582214; Fax: +86-22-60202214; E-mail: admat@jsmail.hebut.edu.cn.