DOI: 10.11817/j.ysxb.1004.0609.2020-37588

Mg含量对高真空压铸AlSi10MgMn合金时效强化的影响

胡 宸,赵海东,王雪灵,郑凌波

(华南理工大学 国家金属材料近净成形工程技术研究中心,广州 510640)

摘 要:完成不同Mg含量AlSiMgMn合金高真空压铸实验,采用扫描电镜(SEM)、透射电镜(TEM)对合金微观组织进行分析,得出不同Mg含量下时效析出β″相的密度,并讨论其对力学性能的影响。通过差示扫描量热法(DSC)对不同Mg含量的合金时效析出动力学进行分析,结合Arami-Johnson-Mehl方程计算析出相的析出动力学参数。结果表明:Mg含量较少时,时效强化效果不明显,随着Mg含量的提高,时效强化效果逐渐提高;Mg含量的增加显著提高合金中β″相的数密度,β″相为合金时效强化的主要影响因素;随着Mg含量的增加,达到峰值时效的时间越长,且β″相析出激活能增大。

关键词:AlSi10MgMn合金;高真空压铸;时效强化;析出动力学

文章编号:1004-0609(2020)-07-1481-10 中图分类号:TG166.3 文献标志码:A

AlSiMg系合金由于其铸造性能好,具有良好的力学性能、物理性能和抗腐蚀性能,且可通过热处理进一步强化性能,得到了广泛的关注与应用[1]。压铸是铝合金精确成型的主要工艺之一,孔洞是压铸件中常见缺陷[2-3],不仅降低压铸件力学性能,热处理过程中还会膨胀使压铸件表面出现起泡[4]。为了减少压铸件的孔洞缺陷,高真空压铸工艺得到了研究与发展[5-6]。高真空压铸通过抽除型腔中的气体,使型腔真空度达到5 kPa以下,消除或大幅度减少了压铸件的孔洞缺陷,同时,使其采用高温固溶热处理进一步提高力学性能成为可能[7-8]。

轻量化的进程对汽车结构件的性能提出了新的要求,出现了多种高强韧压铸铝合金,AlSiMgMn合金[9-10]便是其中一种,研究者对其组织及性能进行了许多研究。BOSCH等[11]进行了不同Mn含量的AlSi10Mg合金的微观组织与力学性能的研究,发现了m(Mn)/m(Fe)为1时合金拥有较好的力学性能;TIMELLI等[12]进行了固溶处理温度和时间对压铸AlSi7MgMn合金微观组织及力学性能的研究,发现较高温度固溶处理的合金在时效后有更高的强度;SRIVASTAVA等[13]对AlSi9MgMn合金热处理后元素分布、共晶Si粒子形貌和力学性能进行了研究;XU等[14]通过正交分析方法研究了固溶和时效处理参数对AlSiMgMn合金的影响。

尽管进行了上述研究,但高真空压铸AlSiMgMn合金在实际生产中力学性能波动大,有时明显偏低[15]。因此,研究该合金的时效析出强化相特征与相应的动力学,对控制该合金力学性能具有重要意义。本文通过高真空压铸制备了不同Mg含量(0.2%、0.33%、0.42%、0.62%,质量分数)的AlSiMgMn合金,采用SEM和TEM分析了AlSiMgMn合金的微观组织及时效析出相,并研究了对力学性能的影响;利用DSC分析技术,结合AJM方程,研究了Mg对时效参数与析出动力学的影响。

1 实验

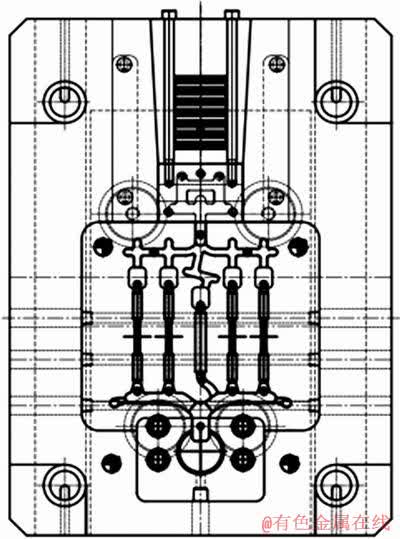

通过高真空压铸制备了4组不同Mg含量的AlSiMgMn合金,实验原料为深圳鑫申新材料生产的AlSiMgMn铸锭、湖南恒博新材料生产的AlMg50中间合金(Al-50.3%Mg),铸锭及各组合金具体成分如表1所列。实验所用压铸机为TOYO BD-250,配备万达真空系统,压铸过程中实测真空度约4800 Pa。合金采用电阻炉熔化,在680 ℃浇注,模具预热温度为180 ℃,高速速度为2 m/s,增压压力为80 MPa。实验用模具为拉伸试棒模具,其装配图如图1所示,由4根片状拉伸试样和一块矩形片状试样组成,拉伸试样厚度从右到左依次为6 mm、4 mm、8 mm和2 mm,拉伸试样具体尺寸如图2所示。由前期研究[16]发现4 mm壁厚的拉伸试样力学性能最好,因此,本实验采用该拉伸试样用于微观组织及力学性能的研究。

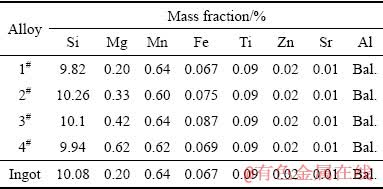

表1 四种AlSiMgMn合金的化学成分

Table 1 Chemical compositions of four AlSiMgMn alloys

图1 高真空压铸实验模具装配图

Fig. 1 Assembly drawing of die for high vacuum die casting experiment

图2 拉伸试样尺寸

Fig. 2 Shape and dimensions of tensile specimen (Unit: mm)

采用扫描电镜(SEM)和透射电镜(TEM)进行观察合金微观组织。SEM分析的样品直接取自于拉伸试样,经过砂纸打磨、抛光后,用0.5%HF溶液(体积分数)进行腐蚀,观察设备为FEI NONA430电子扫描显微镜。TEM样品采用电解双喷和离子减薄进行制备,电解双喷仪器为Struers TenuPol-5,所用电解液由10%高氯酸和90%酒精(体积分数)组成,电解温度为-30~-20 ℃,电压为40~50 V,控制电流在 100 mA 以下。离子减薄在Gantan 695仪器上进行,所用电压为3 kV,角度为5°,减薄时间约为1 h。TEM表征在TEI Tecnai G2 S-TWIN F20上进行,拍摄至少10张TEM明场像图片用于析出相的统计分析。DSC试样尺寸为d 3 mm×2 mm,使用仪器为NETZSCH STA449C同步热分析仪,加热速率10 ℃/min,保护气体为氩气,升温范围为25~500 ℃。力学性能测试于岛津万能材料试验机(AG-X 100 kN),拉伸速度为2 mm/min,取6根拉伸试样测试结果的平均值代表力学性能。

2 实验结果与分析

2.1 力学性能

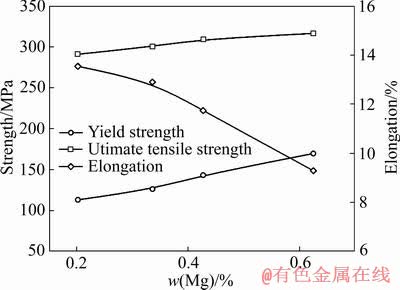

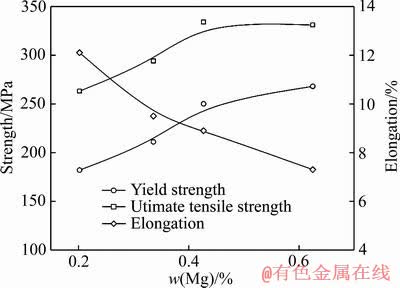

图3所示为铸态时不同Mg含量高真空压铸AlSiMgMn合金的力学性能,可以看到随着Mg含量从0.2%增加到0.62%,合金的屈服强度和抗拉强度有明显的提高,伸长率呈下降趋势。当合金Mg含量为0.2%时,其屈服强度、抗拉强度和伸长率分别为113 MPa、291 MPa和13.5%。当合金Mg含量提升到 0.62%时,其屈服强度和抗拉强度分别提高了50.4%和8.6%,达到170 MPa和316 MPa,而伸长率为9.3%,降低了31.1%。

图3 铸态下不同Mg含量高真空压铸AlSiMgMn合金的力学性能

Fig. 3 Mechanical properties of high vacuum die casting AlSiMgMn alloys with different Mg contents under as-cast condition

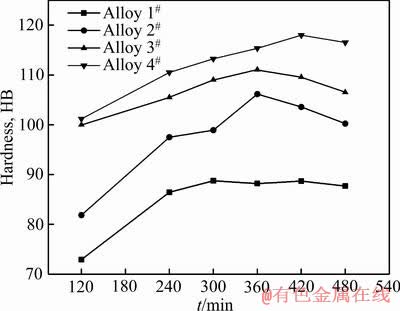

为使热处理后Mg元素能够充分固溶在Al基体中,选择固溶温度为530 ℃,固溶时间为3 h。同时为了确定各组合金在185 ℃时效达到峰值的时间,测量了它们的时效硬化曲线,结果如图4所示。从图4中可以看到,1#~4#合金达到峰值时效的时间分别为5 h、6 h、6 h和7 h,表明随着合金中Mg含量的增加,合金达到峰值时效的时间也越长。在Mg含量较低的1#合金中,峰值时效时的硬度较低,为89 HB,表明时效处理对其力学性能提高较小。而对于Mg含量较高的合金(2#、3#、4#),可看到在峰值时效时硬度有较为明显的提升。最终确定1#~4#合金时效温度为185 ℃,时效时间分别为5 h、6 h、6 h和7 h。其中2#和3#合金达到峰值的时间均为6 h,原因为设置的时效时间梯度为1 h,而2#和3#合金Mg含量差距较小,均在6 h时表现出硬度最大值,在3.2节的计算结果中可以看到2#和3#合金达到峰值时间存在差异。

图4 不同Mg含量高真空压铸AlSiMgMn合金在185 ℃时效的硬度曲线

Fig. 4 Hardness curves of high vacuum die casting AlSiMgMn alloys with different Mg contents aged at 185 ℃

图5所示为不同Mg含量高真空压铸AlSiMgMn合金经过T6热处理后的力学性能。与铸态时合金的性能相比,各组合金经过T6热处理后屈服强度都有显著的提高,伸长率有轻微的下降,但对于Mg含量较低的1#合金,T6热处理后的抗拉强度为263 MPa,比铸态降低了9.6%,可能原因为合金中Mg含量较低,T6热处理后析出的强化相数量少,固溶后共晶区域减少,两者导致性能下降[6]。随着合金Mg含量的提升,T6热处理后合金的力学性能变化与铸态时具有相同的趋势,即Mg含量越高,抗拉强度和屈服强度越高,伸长率越低。但不同的是,当Mg含量提高到0.42后,合金的抗强度变化变小,增长趋势变的较为平缓。

图5 T6态下不同Mg含量高真空压铸AlSiMgMn合金的力学性能

Fig. 5 Mechanical properties of high vacuum die casting AlSiMgMn alloys with different Mg contents under T6 condition

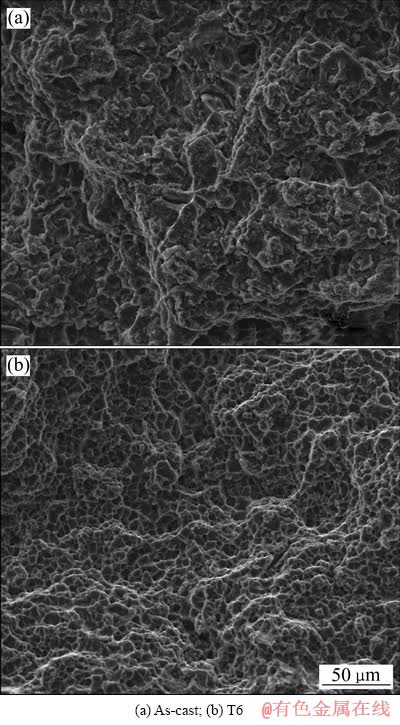

由于各组合金拉伸断口形貌没有明显区别,选用3#合金铸态及T6态拉伸断口形貌为代表进行分析。从图6中可以看到,铸态拉伸断口上存在着大量高密度的短且弯曲的撕裂棱,表现为典型的准解理断裂特征, 而T6态拉伸断口由数量众多且细小的韧窝组成,为明显的韧性断裂特征。断口形貌差异主要是由于铸态共晶Si粒子呈纤维状,容易产生应力集中,导致裂纹的产生,而经过T6热处理后,共晶Si粒子形貌转变为球状,大大减少了应力集中。

图6 3#合金拉伸断口典型形貌

Fig. 6 Typical fracture surfaces of Alloy 3#

2.2 微观组织

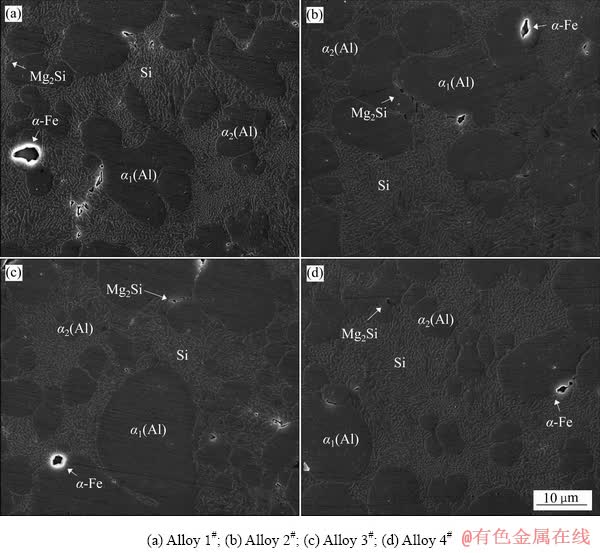

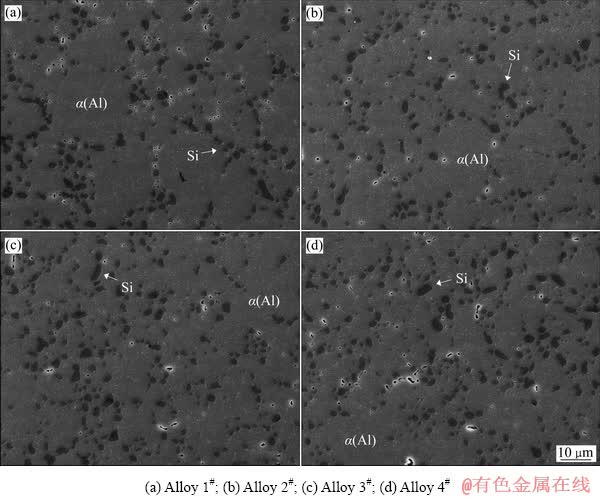

图7和图8所示分别为铸态和T6热处理后不同Mg含量高真空压铸AlSiMgMn合金的微观组织扫描电镜形貌。从图7可以看到,合金组织主要由α(Al)及Al-Si共晶区组成,其中α(Al)存在有两种不同的形貌,α1(Al)较为粗大,α2(Al)较为细小圆整。粗大的 α1(Al)被称为压室预结晶[17],为部分金属液在压室中形核生长而成,由于其形成时间较长,导致最终尺寸粗大。α2(Al)为铝液在模具腔体中生成,由于形成时间短且模具中冷却速度较快,使α2(Al)尺寸细小且圆整。共晶Si呈纤维状,在共晶区存在块状的Mg2Si相及α-Fe相。经过T6热处理后,共晶Si粒子的形貌发生了较大的改变,从成片的纤维状转变为球状,在合金组织中没有找到Mg2Si相的存在,表明固溶处理后Mg2Si相很好地固溶进基体中。共晶Si粒子的球化减少了合金在外力作用下的应力集中,同时Mg元素固溶进基体中,经过后续的时效处理形成弥散分布的沉淀相,使合金强度提高,两种机制的共同作用,使T6热处理后的合金拥有良好的综合力学性能。但是图8所示T6热处理后不同Mg含量的合金在微观组织上没有明显的区别,而从图5可知T6热处理后合金力学性能差异较大,为了揭示其主要影响因素,对合金组织进行了TEM观察。

图7 铸态下不同Mg含量高真空压铸AlSiMgMn合金SEM像

Fig. 7 SEM images of high vacuum die casting AlSiMgMn alloys with different Mg contents under as-cast condition

图8 T6态下不同Mg含量高真空压铸AlSiMgMn合金扫描电镜形貌

Fig. 8 SEM images of high vacuum die casting AlSiMgMn alloys with different Mg contents after T6 heat treatment

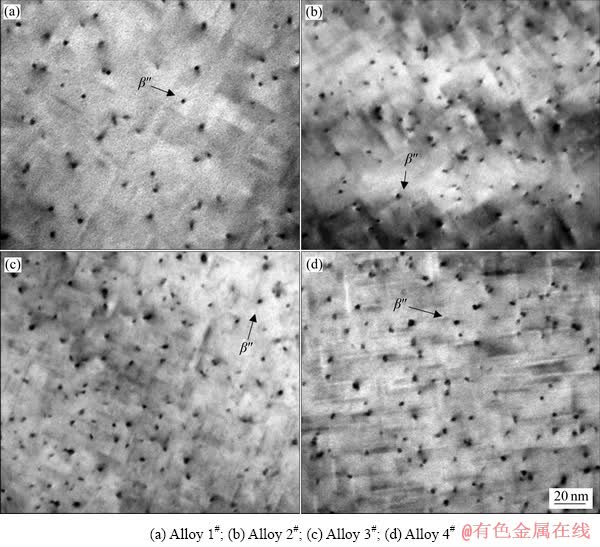

图9 不同Mg含量高真空压铸AlSiMgMn合金时效峰值时的TEM明场像

Fig. 9 TEM bright-field images of high vacuum die casting AlSiMgMn alloys with different Mg contents under aging peak

图10 β″析出相的高分辨图及对应的傅里叶变换图

Fig.10 HRTEM images(a) and corresponding FFT patterns(b) of β″ precipitate

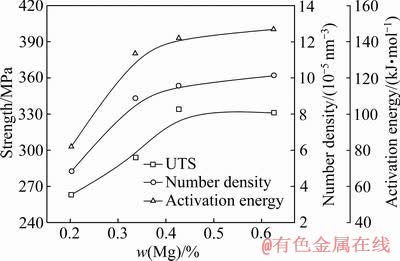

4种合金在时效峰值时的TEM明场像如图9所示,TEM观察均在 方向上进行。从4种合金的TEM明场像上可以看到Al基体中分布着大量均匀分布的针状析出相,其他研究者结果表明[18-20],β″相具有单斜结构,其点阵常数为:a=1.516 nm,b=0.405 nm,c=0.674 nm,图10所示为析出相的高分辨图及其傅里叶变换,与其他研究者的结果基本一致,可以确定针状析出相为β″相。表2所列为4种合金TEM明场像中β″相的统计结果,可以看到合金中β″相的数密度随着Mg含量的增加而提高,1#合金中β″相的数密度为4.82×10-5 nm-3,而4#合金中β″相的数密度为10.12×10-5 nm-3,提高了109.9%。1#合金在T6热处理过程中生成的β″相数量较低,未能提供基体足够的强化作用,因此导致1#合金T6热处理后抗拉强度的下降,如图3和图5所示。同时合金的力学性能变化规律与β″相的数密度变化规律相符合,表明β″相的数量为T6热处理后的AlSiMgMn合金力学性能的主要影响因素。而4种合金时效峰值β″相的平均长度和平均截面积没有呈现明显的规律性,可能原因为各组合金达到峰值的时间最大仅相差2 h,对β″相生长影响不大,故而没有明显规律性。

方向上进行。从4种合金的TEM明场像上可以看到Al基体中分布着大量均匀分布的针状析出相,其他研究者结果表明[18-20],β″相具有单斜结构,其点阵常数为:a=1.516 nm,b=0.405 nm,c=0.674 nm,图10所示为析出相的高分辨图及其傅里叶变换,与其他研究者的结果基本一致,可以确定针状析出相为β″相。表2所列为4种合金TEM明场像中β″相的统计结果,可以看到合金中β″相的数密度随着Mg含量的增加而提高,1#合金中β″相的数密度为4.82×10-5 nm-3,而4#合金中β″相的数密度为10.12×10-5 nm-3,提高了109.9%。1#合金在T6热处理过程中生成的β″相数量较低,未能提供基体足够的强化作用,因此导致1#合金T6热处理后抗拉强度的下降,如图3和图5所示。同时合金的力学性能变化规律与β″相的数密度变化规律相符合,表明β″相的数量为T6热处理后的AlSiMgMn合金力学性能的主要影响因素。而4种合金时效峰值β″相的平均长度和平均截面积没有呈现明显的规律性,可能原因为各组合金达到峰值的时间最大仅相差2 h,对β″相生长影响不大,故而没有明显规律性。

表2 β″析出相的统计结果

Table 2 Statistics of β″ precipitate

3 析出动力学计算

3.1 DSC分析

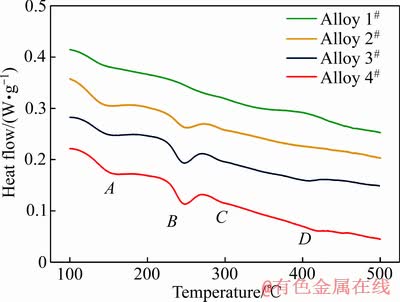

图11 不同Mg含量高真空压铸AlSiMgMn合金在淬火态下的DSC曲线

Fig. 11 DSC curves of high vacuum die casting AlSiMgMn alloys with different Mg contents under as-quenched condition

由文献[21-24]可知,AlSiMg系合金的时效析出序列为:过饱和固溶体→原子团簇→GP区→β″→ β′+Si→β(Mg2Si)+Si。图11所示为不同Mg含量高真空压铸AlSiMgMn合金固溶淬火后的DSC曲线。从DSC曲线上可以看到在100~450 ℃的温度区间存在着4个放热峰(分别标记为A,B,C,D),其中放热峰A的峰值温度在150 ℃左右,根据文献可判断其对应为Si、Mg原子团簇及GP的形成,合金经过固溶淬火后,Si、Mg元素溶入Al基体中,形成过饱和固溶体,随后在淬火形成的大量空位处产生原子团簇,随着时效的进行,Si、Mg原子团簇将聚集成Mg-Si原子团簇,并形成成分接近的GP区。放热峰B的峰值温度在250 ℃左右,对应于β″相的形成,β″相呈针状,与基体完全共格,是AlSiMg系合金峰值时效时主要的析出相。存在于300 ℃时的放热峰C是由于β″相向β′相转变时放热形成的,β′相主要存在于过时效的组织当中,当峰值时效后继续进行时效处理,β″相长大粗化,与基体失去共格关系,形成杆状的β′相,使性能恶化。420 ℃左右形成的放热峰为β相的形成。从图1可以看到,当Mg含量较低(1#)时,曲线上各个放热峰不是很明显,表明在该合金在整个升温过程中,形成的析出相较少。同时对比放热峰A、B,可以发现,随着Mg含量的提高,放热峰A、B的面积增大,表明Mg含量的提高能促进析出相的增加。

3.2 动力学参数计算

为了计算β″相析出动力学,将4组合金的B峰进行了基线扣除及优化处理,图12所示为4组DSC曲线上B峰处理后的曲线。

图12 β″析出相变的DSC曲线

Fig. 12 DSC curves of β″ precipitate transformation

铝合金中第二相的析出,一般可以采用Arami- Johnson-Mehl(AJM)方程进行分析[25-27],如下所示:

(1)

(1)

(2)

(2)

式中:Y为时间t内相转变的相对体积分数,可根据DSC曲线由式(3)求出;k是与形核和长大速度有关的常数;n的值取决于相变类型,针状的β″相的n值为1.5;k0为扩散系数振动频率因子;Q是激活能;R是摩尔气体常数。

(3)

(3)

式中: 为温度T时DSC曲线峰间的面积;Af为析出相对应的整个峰的面积。通过对式(1)求导可得:

为温度T时DSC曲线峰间的面积;Af为析出相对应的整个峰的面积。通过对式(1)求导可得:

(4)

(4)

(5)

(5)

式中: 为DSC升温速率(10 ℃/min);f(Y)为Y的隐函数,由式(1)和式(4)可得出:

为DSC升温速率(10 ℃/min);f(Y)为Y的隐函数,由式(1)和式(4)可得出:

(6)

(6)

根据式(2),式(4)和式(5)可得:

(7)

(7)

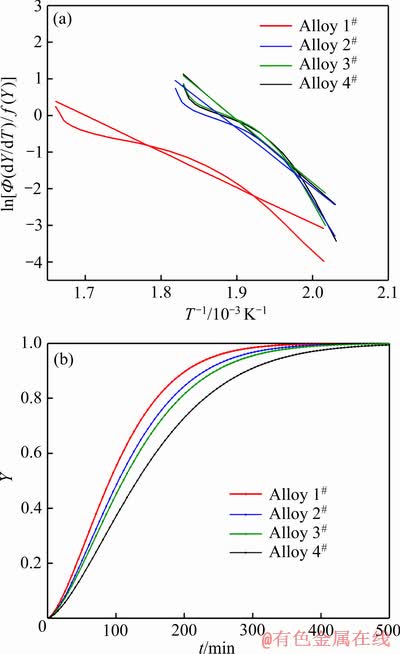

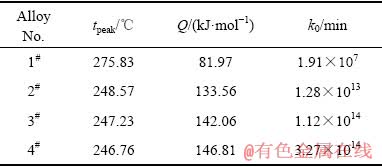

图13(a)所示为β″相计算结果,图中4条曲线一元线性拟合的相关系数均在0.9以上,说明拟合有较高的可信度。通过拟合结果可以求出直线的斜率以及截距,结合式(7),可以得到不同Mg含量的AlSiMgMn合金β″相析出激活能Q及扩散系数振动频率因子k0,相关参数汇总于表3中。由图13(b)的TTT曲线可以看到,在185 ℃时效过程中,随着Mg含量的增加,合金达到峰值时效的时间越长,1#~4#合金达到峰值的时间分别为287 min、328 min、350 min和415 min,与硬度试验的结果相吻合,表明AJM方程可以很好的预测β″相的析出。由表3汇总的动力学参数发现,随着Mg含量的增加,β″相析出激活能Q增大。可能原因为β″相的析出是空位扩散的结果,而合金中过量的Si元素大量占据了淬火形成的空位,同时合金中较多的Mg会生成更多的β″相,导致需要的激活能变大,β″相的析出时间变长。并且随着Mg含量超过0.42后,激活能的增加变小,与合金强度、β″相的数密度变化趋势相符合,如图14所示。

图13 ln[Φ(dY/dt)/f(Y)]-1/T拟合曲线以及185 ℃时效过程中β″相析出的体积分数随时间变化曲线

Fig. 13 Curves of ln[Φ(dY/dt)/f(Y)]-1/T(a) and relationship between volume fraction of β″ precipitate and time t at 185 ℃(b)

表3 β″析出相的动力学参数

Table 3 Kinetic parameters of β″ precipitate

图14 合金的抗拉强度、β″相数密度和β″相析出激活能随Mg含量变化曲线

Fig. 14 Curves of UTS, β″ precipitate number density and β″ precipitate activation energy with Mg content of alloys

4 结论

1) 随着Mg含量的提高,高真空压铸AlSiMgMn合金T6热处理后抗拉强度和屈服强度提高,时效强化效果逐渐提高,但是Mg含量超过0.42%后增长幅度趋于平缓。

2) β″相是高真空压铸AlSiMgMn合金时效强化的析出相,Mg含量的增加显著提高了该合金中β″相的数密度;低Mg含量时合金中β″相的数密度为4.82× 10-5 nm-3,高Mg含量时β″相的数密度为10.12×10-5 nm-3,数量相差2倍左右;但β″相的长度和截面积未呈现规律性。

3) 经过DSC和AJM方程计算分析,随着Mg含量的增加,高真空压铸AlSiMgMn合金达到峰值时效的时间越长,由于β″相析出数量的增加,析出激活能急剧增大;但Mg含量超过0.42%后,激活能增加较小,与抗拉强度、β″相的数密度变化吻合。

REFERENCES

[1] WANG Q G. Microstructural effects on the tensile and fracture behavior of aluminum casting alloys A356/357[J]. Metallurgical and Materials Transactions A, 2003, 34(12): 2887-2899.

[2] ZHAO H D, WANG F, LI Y Y, XIA W. Experimental and numerical analysis of gas entrapment defects in plate ADC12 die castings[J]. Journal of Materials Processing Technology, 2009, 209(9): 4537-4542.

[3] ZHAO Hai-Dong, BAI Yan-Fei, OUYANG Xiao-xian, DONG Pu-yun. Simulation of mold filling and prediction of gas entrapment on practical high pressure die castings[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(11): 2064-2070.

[4] WAN Li, HU Zu-qi, WU Shu-sun, LIU Xue-qiang. Mechanical properties and fatigue behavior of vacuum-assist die cast AlMgSiMn alloy[J]. Materials Science and Engineering A, 2013, 576: 252-258.

[5] DONG Xi-xi, ZHU Xiang-zhen, JI Shou-xun. Effect of super vacuum assisted high pressure die casting on the repeatability of mechanical properties of Al-Si-Mg-Mn die-cast alloys[J]. Journal of Materials Processing Technology, 2019, 266: 105-113.

[6] LIU Fei, ZHAO Hai-dong, YANG Run-sheng, SUN Feng-zhen. Microstructure and mechanical properties of high vacuum die-cast AlSiMgMn alloys at as-cast and T6-treated conditions[J]. Materials, 2019, 12(13): 2065.

[7] LI Sheng-yong, LI De-jiang, ZENG Xiao-qin, DING Wen-jiang. Microstructure and mechanical properties of Mg-6Gd-3Y-0.5Zr alloy processed by high-vacuum die-casting[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(12): 3769-3776.

[8] WANG Zhi-qin, ZHANG Bin, LI De-jiang, FRITZSCH R. Effect of heat treatment on microstructures and mechanical properties of high vacuum die casting Mg-8Gd-3Y-0.4Zr magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(12): 3762-3768.

[9] ZOVI A, CASAROTTO F. Silafont-36, the low iron ductile die casting alloy development and applications[J]. Metallurgia Italiana, 2007(6): 33-8.

[10] FRANKE R, DRAGULIN D, ZOVI A, CASAROTTO F. Progress in ductile aluminium high pressure die casting alloys for the automotive industry[J]. Metallurgia Italiana, 2007(5): 19-23.

[11] BOSCH D, POGATSCHER S, HUMMEL M, FRAGNER W, UGGOWITZER P J, GOKEN M, HOPPEL H W. Secondary Al-Si-Mg high-pressure die casting alloys with enhanced ductility[J]. Metallurgical and Materials Transactions A, 2015, 46(3): 1035-1045.

[12] TIMELLI G, LOHNE O, ARNBERG L, LAUKLI H I. Effect of solution heat treatments on the microstructure and mechanical properties of a die-cast AlSi7MgMn alloy[J]. Metallurgical and Materials Transactions A, 2008, 39(7): 1747-1758.

[13] SRIVASTAVA M C, LOHNE O. Effects of heat treatment on the microstructure and mechanical properties of ductile AlSi9MgMn die castings[J]. International Journal of Metalcasting, 2016, 10(4): 556-565.

[14] XU Jun-jie, PAN Ye, LU Tao, BO Bing. Synergistic effects of composition and heat treatment on microstructure and properties of vacuum die cast Al-Si-Mg-Mn alloys[J]. China Foundry, 2018, 15(2): 117-123.

[15] 张百在, 刘学强, 万 里, 汪学阳, 黄志垣, 徐飞跃. 型腔真空度及热处理对AlSiMgMn压铸件性能的影响[J]. 特种铸造及有色合金, 2016, 36(7): 673-676.

ZHANG Bai-zai, LIU Xue-qiang, WANG Li, WANG Xue-yang, HUANG Zhi-yuan, XU Fei-yue. Effects of cavity vacuum and heat treatment on mechanical properties of AlSiMgMn die castings[J]. Special Casting & Nonferrous Alloys, 2016, 36(7): 673-676

[16] 葛继龙. 压射速度对ADC12压铸件微观组织与力学性能的影响[D]. 广州: 华南理工大学, 2016.

GE Ji-long. Effect of injection speed on microstructure and mechanical properties of ADC12 die castings[D]. Guangzhou: South China University of Technology, 2016

[17] LI X, XIONG S M, GUO Z. On the porosity induced by externally solidified crystals in high-pressure die-cast of AM60B alloy and its effect on crack initiation and propagation[J]. Materials Science and Engineering A, 2015, 633: 35-41.

[18] LIU Fang, YU Fu-xiao, ZHAO Da-zhi, ZUO Liang. Transmission electron microscopy study of precipitates in an artificially aged Al-12.7Si-0.7Mg alloy[J]. Materials Characterization, 2015, 107: 211-219.

[19] CHEN Rui, XU Qing-yan, GUO Hui-ting, XIA Zhi-yuan, WU Qin-fang, LIU Bai-cheng. Correlation of solidification microstructure refining scale, Mg composition and heat treatment conditions with mechanical properties in Al-7Si-Mg cast aluminum alloys[J]. Materials Science and Engineering A, 2017, 685: 391-402.

[20] WENG Yao-yao, JIA Zhi-hong, DING Li-peng, PAN Yan-feng, LIU Ying-ying, LIU Qing. Effect of Ag and Cu additions on natural aging and precipitation hardening behavior in Al-Mg-Si alloys[J]. Journal of Alloys and Compounds, 2017, 695: 2444-2452.

[21] CHEN Rui, XU Qing-yan, GUO Hui-ting, XIA Zhi-yuan, WU Qin-fang, LIU Bai-cheng. Modeling the precipitation kinetics and tensile properties in Al-7Si-Mg cast aluminum alloys[J]. Materials Science and Engineering A, 2017, 685: 403-416.

[22] CHROMINSKI W, LEWANDOWSKA M. Precipitation phenomena in ultrafine grained Al-Mg-Si alloy with heterogeneous microstructure[J]. Acta Materialia, 2016, 103: 547-557.

[23] RAVI C, WOLVERTON C. First-principles study of crystal structure and stability of Al-Mg-Si-(Cu) precipitates[J]. Acta Materialia, 2004, 52(14): 4213-4227.

[24] RINDERER B, COUPER M, XIONG X Y, GAO S, NIE J F. Precipitation sequence in an Al-Si-Mg foundry alloy[J]. Materials Science Forum, 2010, 654/656: 590-595.

[25] 朱 刚, 赵海东, 陈振明, 陈飞帆, 胡启耀. 6061和SiCp/6061合金时效析出动力学[J]. 中国有色金属学报, 2017, 27(10): 1996-2004.

ZHU Gang, ZHAO Hai-dong, CHEN Zhen-ming, CHEN Fei-fan, HU Qi-yao. Kinetics of precipitation during aging of 6061 and SiCp/6061 alloys[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(10): 1996-2004.

[26] DING Li-peng, HE Yang, WEN Zhang, ZHAO Pi-zhi, JIA Zhi-hong, LIU Qing. Optimization of the pre-aging treatment for an AA6022 alloy at various temperatures and holding times[J]. Journal of Alloys and Compounds, 2015, 647: 238-244.

[27] GHOSH K S, GAO N. Determination of kinetic parameters from calorimetric study of solid state reactions in 7150 Al-Zn-Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(6): 1199-1209.

Effect of Mg on age hardening of high vacuum die casting AlSi10MgMn alloys

HU Chen, ZHAO Hai-dong, WANG Xue-ling, ZHENG Ling-bo

(National Engineering Research Center of Near-Net-Shape Forming for Metallic Materials, South China University of Technology, Guangzhou 510640, China)

Abstract: High vacuum die casting experiment of AlSiMgMn alloys with different Mg contents was carried out. The microstructure of alloys was analyzed by scanning electron microscopy and transmission electron microscopy. The density of β′′ precipitates of the alloys was obtained, and their effects on mechanical properties were discussed. The differential scanning calorimetry (DSC) was used to determine the effect of Mg content on precipitation kinetics of alloys, and the precipitation kinetic parameters of precipitates were calculated by the Arami-Johnson-Mehl equation. The results show that the effect of age strengthening is not obvious when the content of Mg is low, and with the increase of Mg content, the effect of age hardening is gradually improved; the increase of Mg content significantly increases the number density of β″ precipitate in the alloys, and β″ precipitates are the main influencing factors of aging hardening; as the content of Mg increases, the time needed for reaching peak aging becomes longer, and the β″ precipitate activation energy increases.

Key words: AlSi10MgMn alloy; high vacuum die casting; age hardening; precipitation kinetics

Foundation item: Project(TC160A310-10-01) supported by the Industry Base Enhanced Project and Ministry of Industry and Information Technology, China; Project (201802030012) supported by the Science and Technology Program of Guangdong Province, China

Received date: 2019-07-19; Accepted date: 2019-10-08

Corresponding author: ZHAO Hai-dong; Tel: +86-20-87112948-302; E-mail: hdzhao@scut.edu.cn

(编辑 王 超)

基金项目:工信部工业强基工程项目(TC160A310-10-01);广州市科技项目(201802030012)

收稿日期:2019-07-19;修订日期:2019-10-08

通信作者:赵海东,教授,博士;电话:020-87112948-302;E-mail:hdzhao@scut.edu.cn