DOI: 10.11817/j.issn.1672-7207.2016.10.018

基于IPSO算法的回转窑煅烧带温度D-FNN预测控制

田中大1,高宪文2,李树江1,王艳红1

(1. 沈阳工业大学 信息科学与工程学院,辽宁 沈阳,110870;

2. 东北大学 信息科学与工程学院,辽宁 沈阳,110819)

摘要:为了提高石灰回转窑煅烧带温度的控制性能,提出一种基于改进的粒子群优化算法(IPSO)与动态模糊神经网络(D-FNN)的预测控制方法。该方法利用动态模糊神经网络建立石灰回转窑煅烧带温度的非线性预测模型,通过输出温度的预测值,引入输出反馈与偏差来校正预测误差,建立偏差与控制量的控制性能指标,通过改进的粒子群优化算法滚动优化得到系统最优控制量。对控制方法的稳定性进行分析。仿真实验结果表明动态模糊神经网络的温度预测误差在±10 ℃之内,具有较高的预测精度。提出的预测控制方法能使输出煅烧带温度快速稳定地跟踪设定值的变化,同时在系统输出有扰动的情况下也能较好地跟踪设定值。控制量的平均单步滚动优化需 0.31 s,可满足实际应用。

关键词:回转窑;煅烧带温度;粒子群优化算法;动态模糊神经网络;预测控制

中图分类号:TP273 文献标志码:A 文章编号:1672-7207(2016)10-3409-08

D-FNN predictive control for burning zone temperature in rotary kiln with IPSO algorithm

TIAN Zhongda1, GAO Xianwen2, LI Shujiang1, WANG Yanhong1

(1. College of Information Science and Engineering, Shenyang University of Technology, Shenyang 110870, China;

2. College of Information Science and Engineering, Northeastern University, Shenyang 110819, China)

Abstract: In order to improve the control performance of burning zone temperature in lime rotary kiln,a predictive control method based on an improved particle swarm optimization (IPSO) and dynamic fuzzy neural network (D-FNN) was proposed. This predictive control method utilizes dynamic fuzzy neural network to build a nonlinear predictive model for burning temperature in lime rotary kiln.Through predictive output temperature, performance indicators were established by deviation and control value to reduce the error in feedback output error and error correction. The optimal control value was obtained by rolling optimization of improved particle swarm optimization algorithm. The stability of the control method was analyzed. The simulation results show that the temperature prediction error of the dynamic fuzzy neural network is within ±10 ℃, and has high prediction accuracy. The proposed predictive control method can make the burning zone output temperature fast and stable track the change of the setting value. The system can also track the setting value well with the disturbance of the system output. The average single step rolling optimization of control value needs 0.31 s, which can meet the practical application.

Key words: rotary kiln; burning zone temperature; particle swarm optimization; dynamic fuzzy neural network; predictive control

石灰回转窑生产能力强,能适应多种工业过程,因而被广泛地应用于冶金、水泥、耐火材料、化工等行业。但石灰回转窑过程存在多变量、强耦合、非线性、关键工艺参数检测困难、难以实现自动控制和优化控制、在很大程度上仍然依赖于人工技巧和经验等问题。由此导致产品质量不稳定、设备运转率低和产能低等问题[1]。随着新兴智能建模及控制方法的出现,大量的智能建模方法用于建立回转窑的模型。LI等[2]提出了一种利用极限学习机进行回转窑燃烧状态识别的建模方法,取得了良好的现场运行效果。GEORGALLIS[3]阐述了1个包括物料流动与热传导的三维石灰回转窑模型。 等[4]针对回转窑建立了热回收的数学模型。人们对回转窑的煅烧温度模型进行了长期研究并取得了很多经验,但至今仍存在模型不准确、难以通用和受约束条件过多等问题。而针对回转窑控制理论的研究大多以智能控制为主,常见的有模糊控制[5]、神经网络[6-7]、专家系统[8-9]、混合智能控制策略[10-12]等。虽然目前人们对回转窑的控制取得了很大的进展,但是回转窑煅烧温度控制是一个复杂的控制系统,要实现其有效而精确的自动控制,仅仅采用单一的控制方法已远远不能达到预期的控制效果。为此,本文作者以回转窑煅烧带温度的控制为研究对象。由于动态模糊神经网络(D-FNN)具有通用逼近和学习能力、需要较少的先验知识、能够在线学习等特点,因此,据动态模糊神经网络建立窑煅烧带温度非线性预测模型。同时,由于系统建立的预测模型是非线性的,因此,制量的求解是一个非线性约束问题,本文提出一种改进的粒子群优化算法(IPSO)进行控制量的迭代优化,在每个采样时刻,D-FNN预测模型预测回转窑系统未来某时刻的煅烧带温度,利用输出反馈进行偏差校正得到控制量与偏差组成的目标函数,通过IPSO算法作为滚动优化策略以求解最优控制量。最后通过仿真验证本文控制方法的有效性。

等[4]针对回转窑建立了热回收的数学模型。人们对回转窑的煅烧温度模型进行了长期研究并取得了很多经验,但至今仍存在模型不准确、难以通用和受约束条件过多等问题。而针对回转窑控制理论的研究大多以智能控制为主,常见的有模糊控制[5]、神经网络[6-7]、专家系统[8-9]、混合智能控制策略[10-12]等。虽然目前人们对回转窑的控制取得了很大的进展,但是回转窑煅烧温度控制是一个复杂的控制系统,要实现其有效而精确的自动控制,仅仅采用单一的控制方法已远远不能达到预期的控制效果。为此,本文作者以回转窑煅烧带温度的控制为研究对象。由于动态模糊神经网络(D-FNN)具有通用逼近和学习能力、需要较少的先验知识、能够在线学习等特点,因此,据动态模糊神经网络建立窑煅烧带温度非线性预测模型。同时,由于系统建立的预测模型是非线性的,因此,制量的求解是一个非线性约束问题,本文提出一种改进的粒子群优化算法(IPSO)进行控制量的迭代优化,在每个采样时刻,D-FNN预测模型预测回转窑系统未来某时刻的煅烧带温度,利用输出反馈进行偏差校正得到控制量与偏差组成的目标函数,通过IPSO算法作为滚动优化策略以求解最优控制量。最后通过仿真验证本文控制方法的有效性。

1 回转窑煅烧过程描述

活性石灰回转窑系统主要分为物料系统和气流系统。物料系统为原料(石灰石)在原料仓下通过振动给料机、皮带秤、输送提升到筛分设备再经输送机进到竖式预热器,在竖式预热器内进行气物热交换后,通过推杆把物料均匀推入窑内。物料通过回转窑高温煅烧,产出的石灰进入竖式冷却器,经冷却器下部振动给料机排出到鳞板输送机上,再通过输送、筛分、提升设备进入成品仓。气流系统是二次风通过鼓风机进入竖式冷却器,与物料进行热交换后热风通过窑头罩进入回转窑,常温一次风经燃烧器后与燃料混合,一次风、二次风在回转窑参与燃烧后,从窑尾进入预热器。从竖式预热器出来的废气通过掺入冷空气来降低温度,降温后的废气通过除尘器、高温风机,再通过烟囱排入大气。整体工艺流程见图1[12]。

煅烧温度对反应效果起至关重要的作用。影响回转窑煅烧温度的因素很多,如燃料与助燃风的温度、压力、流量、窑体的转速、进料量以及各种随机干扰等。

在控制量选择问题上,首先,煅烧温度的变化是燃料燃烧的结果,涉及燃烧、传热和流动等过程,煤气流量是影响窑内温度的决定因素。其次,回转窑转速也是影响回转窑煅烧温度的重要因素。为此,将其他参数作为系统的工况,当系统工况不变时,以煤气流量和回转窑转速为输入,以煅烧带温度为输出,建立动态模糊神经网络模型。

图1 回转窑工艺流程

Fig. 1 Process flow of rotary kiln

2 回转窑煅烧带温度的D-FNN建模

模糊神经网络为知识的获取提供了行之有效的途径。但是,现有的模糊神经网络不能对模糊规则数进行辨识,无法判断哪条模糊规则最重要。而动态模糊神经网络能够在线、实时地处理时变、非线性甚至是病态的系统。其学习算法描述如下[13-14]。

2.1 规则产生准则

输出误差是确定新规则是否应该加入的重要依据。对于第i个观测数据(Xi,ti)(其中,Xi为输入向量,ti为期望的输出),若误差满足||ei||>ke,则需要增加1条新的规则。ke是根据D-FNN期望的精度选定的。

对于第i个观测数据(Xi,ti),计算输入值Xi和现有的RBF单元的中心Cj直接的距离di(j):

(1)

(1)

找出

(2)

(2)

若距离的最小值dmin>kd (其中,kd为可容纳边界的有效半径),则需要增加1条新的模糊规则,

2.2 分级学习思想

分级学习思想其算法思想是ke和ke不是常数,而由下列式子确定:

(3)

(3)

(4)

(4)

其中:emax为预先定义好的误差||ei||的最大误差;emin为期望的D-FNN精度;β(0<β<1),为收敛常数;dmax为输入空间的最大长度;dmin为关心的最小长度; γ(0<γ<1)为衰减常数。

2.3 前提参数分配

新产生的规则的初始参数按照如下方式分配:

(5)

(5)

(6)

(6)

其中:k(k>1)为重叠因子;σi为第i个高斯隶属函数的中心。只有当||ei||>ke,dmin>kd时,才需要增加1条模糊规则。不满足该条件的其他3种情况的算法 如下。

1) 第1种情况:||ei||≤ke,dmin≤kd。此时,D-FNN可以完全容纳观测数据(Xi,ti),此时不需要任何变动或只需更新结果参数。

2) 第2种情况:||ei||≤ke,dmin>kd。这种情况表明所建立的D-FNN具有较强的泛化能力,只要结果参数需要调整。

3) 第3种情况:||ei||>ke,dmin≤kd。这种情况表示覆盖Xi的RBF单元的泛化能力并不是很强。因此,该RBF节点以及结果参数会同时被更新。对于最接近Xi的第k个RBF单元按下式调整:

(7)

(7)

其中:kω(kω>1)为预定常数。

2.4 结果参数确定

假定n个观测数据产生了u个模糊规则,N个节点的输出写成矩阵形式:

(8)

(8)

系统的输出yj可表示为

(9)

(9)

其中:

寻找1个最优的系数向量:

(10)

(10)

最优的W*具有如下形式:

(11)

(11)

其中: 为

为 的转置;

的转置; ,为

,为 的广义逆。

的广义逆。

2.5 修剪技术

修剪技术对于动态时变非线性系统的辨识是非常必要的。若在学习进行时,检测到不活跃的模糊规则并加以剔除,则可获得更紧凑的D-FNN结构。定义误差下降率为

(12)

(12)

是由回归量qi所造成的期望输出方

是由回归量qi所造成的期望输出方

差的一部分,D=TT,为期望的输出。新得到的 重新排列为矩阵

重新排列为矩阵 ,

, 的第i列

的第i列 就是与第i个规则相关的(r+1)个误差下降率。进一步定义:

就是与第i个规则相关的(r+1)个误差下降率。进一步定义:

(13)

(13)

ηi反映第i个规则的重要性,ηi越大,表示第i个规则越重要。若

(14)

(14)

则第i个规则可剔除。其中,kerr为预设的阈值。

设回转窑煅烧系统的模型可由如下非线性方程来描述:

(15)

(15)

式中:y为煅烧带温度(℃);u1为煤气流量(m3/h);u2为窑转速(r/min);k为采样时刻。则基于动态模糊神经网络方法建立回转窑煅烧过程模型的框图如图2所示。

图2 基于动态模糊神经网络的回转窑煅烧过程建模

Fig. 2 Rotary kiln burning process modeling based on D-FNN

3 改进的粒子群优化算法

PSO算法是由EBERHART等[15]提出的一种演化计算技术,算法概念简单、容易实现,目前已广泛应用于函数优化[16]、神经网络训练[17]、模糊系统控制[18]等应用领域。但标准PSO算法仅仅是对自然生物群集智能的一种简单模拟,即粒子向种群最优和个体最优2个点趋近,而忽略了存在于种群中的大量有用信息,因此,算法在进化过程中容易失去种群多样性,最终导致早熟收敛。本文尝试对这些潜在于粒子中的有用信息进行挖掘,提出1种改进的粒子群算法。

3.1 精英集的建立与更新

由于粒子在每一维上都向种群最优位置和个体最优位置的方向靠近,在适应度整体提高的同时,会发生某些分维上的退化现象。适应度整体提高很难体现出这种退化,但影响到进化后期的精度。考虑到具有较高适应度的精英粒子往往包含部分优秀分维信息,因此,将一定规模的精英粒子集结成1个精英集,并通过该集影响种群内部粒子的寻优来提高优化精度。

精英集是1个非空集合,元素为种群中适应度较高的精英粒子。在初始化精英集时,将种群中适应度最大的K(K为精英集规模)个粒子入选精英集。更新精英集时,入选精英集的粒子需要具备2个条件:一是高适应度;二是与精英集中已有的粒子形态差异大。

定义1:粒子距离。粒子距离d是指2个粒子间各维上的欧式距离和,即

(16)

(16)

定义2:粒子与精英集的距离。粒子与精英集的距离指某一特定粒子与精英集中所有粒子间的距离的平均值。

(17)

(17)

其中:D为优化问题维数;K为精英集规模,即精英集包含的粒子个数。

定义3:精英集中心。精英集中心即精英集中心点位置,它是由精英集中各粒子的位置平均值计算而得。

(18)

(18)

定义精英集中心与集的距离为

(19)

(19)

由上述定义,若某一粒子的适应度大于精英集中适应度最低的粒子,且该粒子与精英集的距离大于精英集中心点与该集的距离,则该粒子替换原集中适应度最低的粒子,反之丢弃此粒子,保持精英集不变。

3.2 粒子速度更新方式

在通常的PSO算法中,粒子的每一维均向种群最优点与个体最优点2个位置的合力方向直线飞行,而在本文的IPSO中,粒子各维的飞行方向并不一致。为了试图获得更优的分维信息组合, 本文采用2种粒子寻优飞行方式:一种是朝着基本PSO普遍采用的种群最优点与个体最优点的合力方向飞行;另一种则是朝着从精英集中随机抽取1个粒子的方向飞行。即

(20)

(20)

这样有利于粒子各维进行的独立性和多样性的保持。其中:r为[0,1]内均匀分布的随机数;m为[1,K]内均匀分布的随机整数;w为权重系数;c1和c2为加速常数;pi,j为个体极值;gj为全局极值;vt为粒子速度。 IPSO中的粒子由于在进化中不以概率1向全局最优点靠近,在种群进化前期会减慢收敛速度,但这将明显提高进化后期精度。IPSO算法具体流程如图3所示。

图3 IPSO算法流程图

Fig. 3 Flow diagram of IPSO algorithm

4 回转窑煅烧带温度预测控制

4.1 预测控制算法

假设利用D-FNN对回转窑煅烧带温度系统建立了如式(15)所示的非线性模型,输入控制量为

时,系统的输出量为y(k),通过系统过去的输入/输出和当前输入u(k),由D-FNN预测模型得到系统的输出估计值为

时,系统的输出量为y(k),通过系统过去的输入/输出和当前输入u(k),由D-FNN预测模型得到系统的输出估计值为 。由待优化的输入控制量u(k+1)与过去输入输出得到系统的输出预估值

。由待优化的输入控制量u(k+1)与过去输入输出得到系统的输出预估值 。但由于噪声或模型失配等,预测值

。但由于噪声或模型失配等,预测值 与系统实际输出y(k)存在误差。设k时刻的预测误差为

与系统实际输出y(k)存在误差。设k时刻的预测误差为

(21)

(21)

利用误差修正 得到修正量:

得到修正量:

(22)

(22)

对于本文的回转窑煅烧带温度的控制,需通过IPSO算法得到确定的目标函数的最小值。对于本文的控制系统,输出为1个控制量,输入为2个控制量,是1个两输入一输出的非线性系统,本文确定控制量u的目标函数为

(23)

(23)

其中:yr(k+1)为k+1时刻的参考轨迹;yp(k+1)为k+1时刻输出量经反馈校正的预测输出;q与λj为加权系数。利用IPSO算法优化的回转窑煅烧带温度预测控制系统框图如图4所示。

图4 基于IPSO算法的煅烧带温度D-FNN预测控制结构

Fig. 4 D-FNN predictive control structure for burning zone temperature in rotary kiln with IPSO algorithm

本文基于IPSO算法的回转窑煅烧带温度D-FNN预测控制方法步骤可描述如下。

Step 1:设置IPSO算法与D-FNN模型参数。

Step 2:对石灰回转窑煅烧过程非线性系统采样得到输入/输出数据构成样本集,使用动态模糊神经网络对训练样本进行训练,离线建立回转窑煅烧带温度的D-FNN预测模型。

Step 3:在第k个时刻,对于确定的控制量序列u(k),系统的输出y(k),通过上面建立的D-FNN预测模型得到k个时刻的预测输出 ,利用待优化的下一时刻控制量u(k+1)计算k+1个时刻的预测输出

,利用待优化的下一时刻控制量u(k+1)计算k+1个时刻的预测输出 ,计算目标函数的适应度。

,计算目标函数的适应度。

Step 4:将待优化的下一时刻的控制量u(k+1)作为IPSO算法的优化对象,利用目标函数,滚动优化得到k+1个时刻的最优控制量u(k+1)。

Step 5:将最优控制量u(k+1)作用于石灰回转窑系统进行控制,令k=k+1,转入Step 3,直到控制结束为止。

4.2 算法稳定性分析

Jk代表第k次目标函数值,由式(22)可知Jk≥0,若满足k→∞时有Jk=J∞=0,则该系统稳定。因为当J∞=0时,由式(22)可得 ,即系统输出等于期望的输出,这时系统是渐进稳定的。下面只需证明当k→∞时有J∞=0成立。

,即系统输出等于期望的输出,这时系统是渐进稳定的。下面只需证明当k→∞时有J∞=0成立。

利用反证法,假设k→∞时J∞≠0,由IPSO算法可知Jk是单调递减函数,在时刻k则有

其中:J0为初始时刻的目标性能函数值,为常数。Jk显然为有界闭集,则由Weierstrass定理可知ΔJk存在最大值。设最大值为ΔJmax,因为J∞≠0以及目标函数非负,所以,ΔJmax≠0,将Jk变换为

因为-ΔJmax<0,所以,上式表明k→∞时J∞→∞,这显然与目标函数非负相矛盾,因此,有J∞=0。

由该证明可知本文的控制系统是渐进稳定的。

5 仿真验证

5.1 IPSO算法验证

为了验证本文IPSO算法的性能,选用下式的Sphere函数[19]进行测试:

(24)

(24)

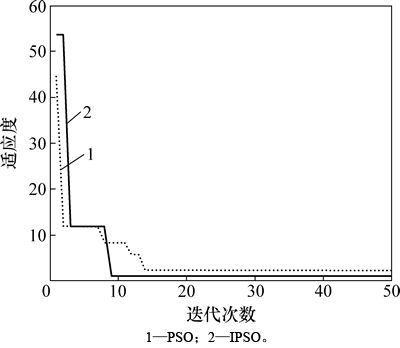

其中:Sphere函数的xi取值范围为[-50,50],变量数n=4,PSO与IPSO算法选择相同的基本参数:迭代次数为50,加速常数c1为1.5,c2为1.7,种群数量为20,权重w为0.9。利用2种算法对Sphere函数进行寻优,优化后PSO的最佳适应度为2.521 5,IPSO算法的最佳适应度为1.063 1。图5所示为2种算法的适应度曲线。从图5可看出:本文的IPSO算法较PSO算法在收敛精度、收敛速度以及寻优结果上都有一定提高,更适合预测控制算法中最优控制量的计算。

图5 Sphere函数适应度曲线

Fig. 5 Fitness curves of sphere function

5.2 D-FNN建模仿真

在工况不变时,以煤气流量和窑转速作为输入量,以煅烧带温度作为输出量建立D-FNN预测模型,本文数据来源于天铁集团石灰回转窑。首先用现场采集到的350组样本数据来构建回转窑煅烧带温度的动态模型,并采用另外50组数据进行检验。D-FNN仿真参数如下:输出延迟步长na=5,输入控制量延迟步长nb=3,预定义最大误差emax=1,期望精度emin=0.02,输入空间的最大长度dmax=4,空间最小长度dmin=0.2,收敛常数β=0.9,衰减常数γ=0.92,重叠因子k=1.1,预设阈值kerr=0.002。测试集的建模预测效果如图6所示,为了对比建模效果,与文献[7]中的BP神经网络建模进行对比,BP神经网络参数如下:输入层为7层,隐层为20层,输出层为1层,学习速率为0.1,期望误差最小值为0.000 04,训练的最大次数为1 000。图7所示为D-FNN与BP建模的误差曲线。

图6 测试样本预测效果对比

Fig. 6 Comparison of prediction effect of testing sample

图7 预测误差曲线对比

Fig. 7 Comparison of prediction error curves

从图7可以看到:基于动态模糊神经网络的实际值与模型输出值之间的误差在-10 ℃到10 ℃之间,而采用BP网络建立的模型的实际值与模型输出值之间的误差在-30 ℃到30 ℃之间,说明采用动态模糊神经网络建立的模型更接近回转窑煅烧过程的实际模型。仿真结果表明该方法能够满足系统建模要求。

5.3 回转窑煅烧带温度的预测控制

利用前面提出的预测控制方法来实现回转窑煅烧温度的控制,并通过仿真来验证本文提出方法的有效性。本文选择文献[20]中提出的子空间建立状态模型的方法。同时,为了说明本文方法的有效性,与文献[11]中的回转窑预测控制方法进行比较。

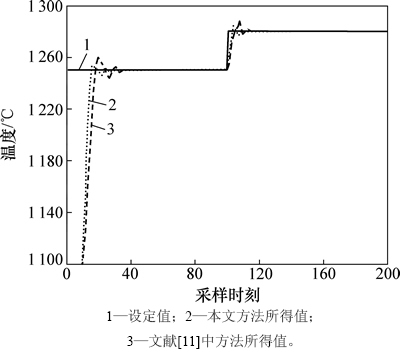

仿真参数如下:IPSO算法的种群数 N=20,最大的迭代次数 Gmax=80,加速常数c1=1.5,c2=1.7,惯性权重为 1, 窑转速变化范围设为[0.7,1.0],煤气流量范围为[8 500,9 500],输出最大值ymax=1 300,输出最小值ymin=1 100;加权系数q=1,λ=0.2;输入参考轨迹为幅值为1 250 ℃的阶跃信号,煅烧带温度初始值设置为1100 ℃。图8所示为系统对于幅值为1 250阶跃信号的输出响应。

为了验证本文预测控制方法的抗干扰性,在输出加入幅值为10 ℃的白噪声随机信号。图9所示为输出干扰情况下的系统输出响应。为了验证本文方法的跟随性,在仿真第100个采样时刻时将设定值改为 1 280 ℃,图10所示为改变设定值时系统的输出响应。

从图8~10可以看出:本文的预测控制方法能使输出煅烧带温度快速稳定地跟踪设定值的变化,同时在系统输出有扰动的情况下也能较好地跟踪设定值。这说明本文的IPSO算法优化的回转窑煅烧带温度的D-FNN预测控制具有较好的自适应能力和鲁棒性。同时对本文控制向量滚动优化策略进行时间测试,200采样周期的仿真过程耗时60.85 s,控制量的一步滚动优化平均需要0.31 s,可见,本文的预测控制方法可应用到实际控制之中。

图8 控制系统的阶跃响应曲线

Fig. 8 Step response of control system

图9 输出扰动情况下的控制系统响应曲线

Fig. 9 Step response of control system with disturbances

图10 设定值改变时的系统响应曲线

Fig. 10 Step response of control system with setting value changed

6 结论

1) 以石灰回转窑的煅烧带温度为控制目标,提出一种基于IPSO算法优化的回转窑煅烧带温度D-FNN预测控制方法,利用现场采集的输入输出数据通过D-FNN建立煅烧带温度的非线性预测模型。通过输出温度的预测值,引入输出反馈与偏差来校正预测误差,建立偏差与控制量的控制性能指标,通过IPSO算法滚动优化得到系统最优控制量,对控制算法的稳定性进行了分析。

2) D-FNN具有较高的预测精度。提出的预测控制方法能使输出煅烧带温度快速稳定地跟踪设定值的变化,同时在系统输出有扰动的情况下也能较好地跟踪设定值,具有一定的自适应性与鲁棒性。本文的控制算法是有效的。

3) 由于条件所限,控制方法的有效性通过仿真实验进行验证。下一步工作是将提出的控制方法应用于实践,并对方法的参数进行优化与调整。

参考文献:

[1] SAIDUR R, HOSSAIN M S, ISLAM M R, et al. A review on kiln system modeling[J]. Renewable and Sustainable Energy Reviews, 2011, 15(5): 2487-2500.

[2] LI Weitao, WANG Dianhui, CHAI Tianyou. Burning state recognition of rotary kiln using ELMs with heterogeneous features[J]. Neurocomputing, 2013, 102(2): 144-153.

[3] GEORGALLIS M. Mathematical modelling of lime kilns[J]. Pulp and Paper Canada, 2002, 103(8): 44-47.

[4]  Z, OKTAY Z,

Z, OKTAY Z,  H. Mathematical modeling of heat recovery from a rotary kiln[J]. Applied Thermal Engineering, 2010, 30(8): 817-825.

H. Mathematical modeling of heat recovery from a rotary kiln[J]. Applied Thermal Engineering, 2010, 30(8): 817-825.

[5] GUO Feng, LIU Bin, HAO Xiaochen, et al. Research on the fuzzy predictive control for calcining temperature of the rotary cement kiln[C]//10th International Conference on Signal Processing Proceedings. Piscataway, United States: IEEE, 2010: 2568-2571.

[6] YANG Baosheng, MA Xiushui. Temperature prediction and analysis based on BP and Elman neural network for cement rotary kiln[C]//Fourth International Seminar on Modern Cutting and Measuring Engineering. International Society for Optics and Photonics. Bellingham, United States: SPIE, 2010: 79972I.

[7] XUE Zengtao, LI Zheng. Application of fuzzy neural network controller for cement rotary kiln control system[C]//2011 International Conference on Advanced Materials and Engineering Materials. Clausthal-Zellerfeld, Germany: Trans Tech Publications, 2012, 457: 531-535.

[8] 王孝红, 房喜明, 于宏亮. 基于专家系统的回转窑窑头工况识别[J]. 控制工程, 2010, 17(3): 309-312.

WANG Xiaohong, FANG Ximing, YU Hongliang. Recognition of working condition for rotary kiln hood based on expert system[J]. Control Engineering of China, 2010, 17(3): 309-312.

[9] FAN Xiaohui, WANG Yi, CHEN Xuling. Mathematical models and expert system for grate-kiln process of iron ore oxide pellet production. Part II: Rotary kiln process control[J]. Journal of Central South University, 2012, 19(6): 1724-1727.

[10] ZHANG Li, GAO Xianwen. Approach of synthesizing model predictive control and its applications for rotary kiln calcination process[J]. Journal of Iron and Steel Research International, 2013, 20(8): 14-19.

[11] ZHANG Li, WANG Song, SU Guojun. Intelligence predictive control study on lime rotary kiln temperature[C]//2013 International Conference on Mechanical and Electronics Engineering. Zurich-Durnten, Switzerland: Trans Tech Publications Ltd, 2013, 385: 848-851.

[12] STADLER KONRAD S, POLAND J, GALLESTEY E. Model predictive control of a rotary cement kiln[J]. Control Engineering Practice, 2011, 19(1): 1-9.

[13] PAN Yongping, ER M J, LI Xiang, et al. Machine health condition prediction via online dynamic fuzzy neural networks[J]. Engineering Applications of Artificial Intelligence, 2014, 35(10): 105-113.

[14] 黄健康, 张刚, 樊丁, 等. 基于动态模糊神经网络的铝合金脉冲MIG焊接过程解耦控制分析[J]. 焊接学报, 2013, 34(9): 43-47.

HUANG Jiankang, ZHANG Gang, FAN Ding, et al. Decoupling control analysis of aluminum alloy pulse MIG welding process based on dynamic fuzzy neural networks[J]. Transactions of the China Welding Institution, 2013, 34(9): 43-47.

[15] EBERHART R C, KENNEDY J. A new optimizer using particle swarm theory[C]//Proceedings of the Sixth International Symposium on Micro Machine and Human Science. Piscataway, United States: IEEE, 1995: 39-43.

[16] REGIS R G. Particle swarm with radial basis function surrogates for expensive black-box optimization[J]. Journal of Computational Science, 2014, 5(1): 12-23.

[17] DONG Zengshou, ZHANG Xiaoyu, ZENG Jianchao. Hydraulic system fault diagnosis based on EMD and improved PSO-Elman Ann[J]. Transactions of the Canadian Society for Mechanical Engineering, 2013, 37(4): 1189-1197.

[18] LETTING L K, MUNDA J L, HAMAM Y. Optimization of a fuzzy logic controller for PV grid inverter control using S-function based PSO[J]. Solar Energy, 2012, 86(6): 1689-1700.

[19] 刘志雄, 梁华. 粒子群算法中随机数参数的设置与实验分析[J]. 控制理论与应用, 2010, 27(11): 1489-1496.

LIU Zhixiong, LIANG Hua. Parameter setting and experimental analysis of the random number in particle swarm optimization algorithm[J]. Control Theory & Applications, 2010, 27(11): 1489-1496.

[20] 张立. 预测控制综合方法及其在回转窑煅烧过程中的应用研究[D]. 沈阳: 东北大学信息科学与工程学院, 2011: 98-103.

ZHANG Li. Study on synthesis approach of model predictive control and its applications for rotary kiln calcinations process[D]. Shenyang: Northeastern University. College of Information Science and Engineering, 2011: 98-103.

(编辑 陈灿华)

收稿日期:2015-11-12;修回日期:2016-01-22

基金项目(Foundation item):国家自然科学基金资助项目(61034005);辽宁省博士启动基金资助项目(20141070)(Project(61034005) supported by the National Natural Science Foundation of China; Project(20141070) supported by the Doctor Startup Foundation of Liaoning Province)

通信作者:田中大,博士,讲师,从事复杂工业过程预测控制研究;E-mail:tianzhongda@126.com