文章编号: 1004-0609(2006)05-0858-04

高温质子导体Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ的合成与性能

庞兆宝, 孟 波, 谭小耀

(山东理工大学 化工学院, 淄博 255049)

摘 要: 采用低温燃烧法合成掺Zr的新型高温质子导体Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ陶瓷粉体。 运用X射线衍射仪、 扫描电子显微镜以及激光粒度仪分别对粉体的晶型、 微观形貌和粒度分布进行分析。 通过控制柠檬酸用量与金属离子摩尔总量的比, 直接制备出具有斜方晶钙钛矿结构的纯Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ超细粉体, 且粉体粒度分布均匀, 平均粒径为5.55μm。 粉体烧结性能实验结果表明, 粉体在1200℃发生烧结, 在1300℃下烧结致密, 相对密度达到94.32%。

关键词: 高温质子导体;Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ陶瓷粉体; 低温燃烧; 钙钛矿 中图分类号: TQ174.758; O614.3

文献标识码: A

Synthesis and characteristics of

Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ high temperature proton conductor

PANG Zhao-bao, MENG Bo, TAN Xiao-yao

(College of Chemical Engineering and Technology,

Shandong University of Technology, Zibo 255049, China)

Abstract: The high temperature proton conductor Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ ceramic powders were synthesized by the low-temperature combustion method. The crystalline phase, microstructures and particle size distribution of the powders were investigated by XRD, SEM and laser grain analyzer, respectively. The experimental results indicate that the Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ micro-powders with single rhombic perovskite structure can be directly synthesized through controlling the ratio of citric acid to metal ions. The particle size of powders distributes evenly, and the average grain size is 5.55μm. The results of sintering properties of Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ show that the sintering starts at 1200℃ and the samples become dense at 1300℃, the relative density reaches up to 94.32%.

Key words: high temperature proton conductor; Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ ceramic powders; low-temperature combustion; perovskite

自从1988年Iwahare等[1]发现高温氢气氛下钙钛矿型氧化物BaCeO3基陶瓷具有优良的质子传导性以来, 此类电解质在中高温燃料电池、 氢传感器、 水蒸汽电解制氢、 氢的分离和提纯、 氢分子泵、 有机合成的催化加氢和脱氢等能源变换及各种电化学装置上的应用已经成为研究热点 [2-7]。 但BaCeO3基材料在低于800℃的含CO2气氛下不稳定, 容易分解, 这种现象降低了其在某些方面的实用价值。 Yajima等[8]和Bae等[9]在BaCeO3基材料中掺杂Zr取代部分Ce的固溶体, 在保证了较高的质子传导性的同时, 提高了其化学稳定性。

目前合成此类电解质粉体的方法有很多, 如固相反应法[10, 11], 化学共沉淀法[12], 自蔓延高温合成法[13]等。 然而这些方法普遍存在着物理混合不均匀, 合成温度高, 难以制备出组成均匀、 粒度分布范围窄的粉体等缺点。 低温燃烧合成法(low-temperature combustion synthesis, LCS)既具有溶胶-凝胶法的混合均匀, 又具有燃烧温度低、 反应时间短等优点[14-18]。 本文作者采用低温燃烧法合成掺杂的Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ(BCZY)粉体, 运用X射线衍射仪和扫描电子显微镜考察了粉体的晶型、 微观形貌以及粉体的粒度分布, 并对粉体的烧结性能进行了研究。

1 实验

1.1 样品的制备

按化学计量比称取分析纯的硝酸钡、 硝酸铈、 硝酸锆和硝酸钇, 将其溶于适量的蒸馏水中, 待完全溶解后, 加入计量的柠檬酸和乙二醇, 柠檬酸的加入量由其与金属离子总物质的量的比(r)确定, 乙二醇与柠檬酸等物质的量。 在70~80℃下加热浓缩, 使其充分络合, 用氨水和硝酸调节溶液的pH值至9~10, 以防止溶液出现沉淀, 反应5~6h后即得到一定粘度的溶胶。 然后将所得溶胶在电热板上加热至300℃左右, 凝胶迅速膨胀并发生燃烧, 得到毛绒状的粉体。 称取2g左右粉体在20MPa压力下干压成直径为25mm的片体, 分别在1000、 1100、 1200、 1300和1400℃的温度下于空气气氛中煅烧4h, 得到烧结体陶瓷片。

1.2 粉体晶型、 粒度及微观结构的表征

用X射线衍射仪(日本理学, D/max2200)检测粉体的晶型, 铜靶(λ=0.154178nm), 电压35kV, 扫描频率2.0(°)/min , 记录步长为0.02°, 范围(2θ)为10°~70°。 应用激光粒度分析仪(Winner2000)测定Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ粉体的粒度及粒度分布, 用扫描电镜(荷兰, FEI Sinrion 2000)观察粉体以及陶瓷片的微观结构, 用阿基米德法测定烧结体的密度。

2 结果与讨论

2.1 样品的X射线衍射分析

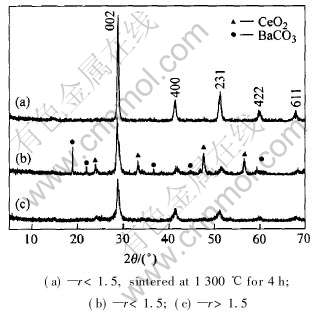

图1所示为不同柠檬酸用量时粉体以及烧结体的X射线衍射谱。 由图1可以看出, 由低温燃烧法直接制备的粉末(图1(c))和1300℃下烧结片的X射线衍射谱(图1(a))与检索到的JCPDS 22-0074的BaCeO3标准卡片基本一致, 说明两者已经形成斜方晶钙钛矿结构。 在柠檬酸不足的情况下(r〈1.5)(图1(b)), 得到的粉体谱中存在CeO2和BaCO3杂质相; 但是粉体经过1300℃煅烧4h处理后, X射线衍射谱中已经没有CeO2和BaCO3杂质相(图1(c)), 只有Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ的斜方晶钙钛矿相。 根据1300℃下烧结片的X射线衍射谱, 可以计算出其晶格参数为: a=0.8720nm, b=0.6174nm, c=0.6175nm, V=0.3324nm3。 这与JCPDS 22-0074给出的没有掺杂BaCeO3的晶格常数相比有所减小, 因而晶胞体积也缩小了0.0078nm3, 这主要是由于Zr和Y部分取代了离子半径比较大的Ce所致。 其理论密度为6.226g/cm3, 根据阿基米德法测得的实际密度为5.869g/cm3, 因此所得到的烧结样片的相对密度已达到94.32%。

图1 Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ的X射线衍射谱

Fig.1 XRD patterns of Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ powders

2.2 粉体的粒度分布以及微观结构

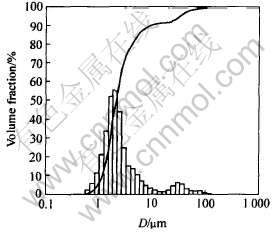

图2所示为Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ粉体的粒度分布。 由图2可看出, 低温燃烧后得到的没有经过研磨的Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ粉体的粒度分布比较集中, 50%(体积分数)粉体(D50)的粒度为2μm, 90%(体积分数)粉体(D90)的粒径为10μm, 粉体的平均粒径为5.55μm。 图3所示为Ba(Ce0.8-Zr0.2)0.9Y0.1O3-δ粉体的SEM像。 由图3可看出, 粉体呈现片状的网络结构, 无法分辨出单个的粉体颗粒, 这是由于燃烧时粉体团聚所致。 根据Scherrer方程 (其中Dhkl为对应hkl晶面的晶粒直径, nm; λ为所用的单色X射线波长, nm; β为半峰宽, (°); θ为入射束对某组晶面的折射角, 即布拉格角, (°)), 由图1(a)粉体X射线衍射谱中002晶面的半峰宽, 计算得到粉体的晶粒直径D002=17nm, 可见制备的粉体为纳米颗粒团聚物。

(其中Dhkl为对应hkl晶面的晶粒直径, nm; λ为所用的单色X射线波长, nm; β为半峰宽, (°); θ为入射束对某组晶面的折射角, 即布拉格角, (°)), 由图1(a)粉体X射线衍射谱中002晶面的半峰宽, 计算得到粉体的晶粒直径D002=17nm, 可见制备的粉体为纳米颗粒团聚物。

图2 Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ粉体的粒度分布

Fig.2 Distribution of grain size of Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ powders

图3 Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ粉体的SEM像

Fig.3 SEM image of Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ powders

2.3 粉体的烧结性能

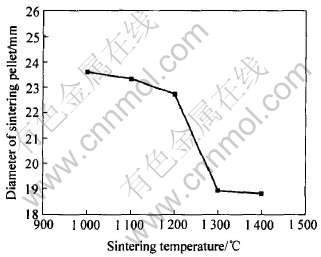

图4所示为烧结温度对烧结体直径的影响。 由图4可看出, 随着烧结温度的增加, 烧结体的直径逐渐减小, 当温度为1200~1300℃时, 烧结体的直径骤然减小; 而此后继续升高温度, 烧结体的直径变化却不大, 说明在1200~1300℃时发生了烧结, 径向收缩率在1300℃达24.32 %。 图5所示为1300℃时烧结样片的SEM像。 由图5可看出, 1300℃温度下烧结得到的烧结体的表面已经相当致密, 截面虽然有部分孔, 但大多数是由于烧结过程中气体放出留下的封闭孔, 表明由燃烧法制备的粉体具有很好的烧结性能, 比由固相法合成的粉体烧结温度低400℃左右[11]。

图4 烧结温度对烧结体直径的影响

Fig.4 Effect of sintering temperature on

diameter of sintering pellet

图5 1300℃时烧结样片的SEM像

Fig.5 SEM images of sintered pellet at 1300℃

3 结论

1) 当柠檬酸与金属离子的摩尔比大于1.5时, 由低温燃烧法直接制备出了具有单一斜方晶钙钛矿结构的Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ粉体, 粉体的粒度分布范围窄, 团聚体的平均粒径为5.55μm。

2) Ba(Ce0.8Zr0.2)0.9Y0.1O3-δ粉体在1200~1300℃发生烧结, 在1300℃烧结致密, 相对密度达到94.32 %, 径向收缩率为24.32 %。

REFERENCES

[1]Iwahara H, Unhida H, Ono K, et al. Proton conduction in sintered oxides based on BaCeO3[J]. Journal of the Electrochemical Society, 1988, 135(2): 530-533.

[2]Iwahara H, Uchide H, Morimoto K. High-temperature C1-gas fuel cells using proton-conducting solid electrolytes[J]. Journal of Applied Electrochemistry, 1989, 19(3): 448-452.

[3]Hamakawa S, Hibino T, Iwahara H. Electrochemical hydrogen permeation in a proton-hole mixed conductor and its application to a membrane reactor[J]. Journal of the Electrochemical Society, 1994,141(7): 1720-1725.

[4]Iwahara H, Hibino T, Sunano T. Electrochemical steam pump using a proton conducting ceramic[J]. Journal of Applied Electrochemistry, 1996, 26(8): 829-832.

[5]Hibino T, Iwahara H. Detection of D2O in water isotopes using a high-temperature protonic conductor[J]. Journal of the Electrochemical Society, 1994, 141(9): 125-126.

[6]Iwahara H, Asakura Y, Katahira K, et al. Prospect of hydrogen technology using proton-conducting cera-mics[J]. Solid State Ionics, 2004, 168: 299-310.

[7]Stover D, Buchkremer H P, Uhlenbruck S. Processing and properties of the ceramic conductive multilayer device solid oxide fuel cell[J]. Ceramics International, 2004, 30(7): 1107-1113.

[8]Yajima T, Kageoka H, Iwahara H, et al. Proton conduction in sintered oxides based on CaZrO3[J]. Solid State Ionics, 1991, 47(3-4): 271-275.

[9]Bae J S, Choo W K, Lee C H. The crystal structure of Ba(Ce0.8Zr0.2)O3[J]. J Euro Ceram Soc, 2001, 21(10-11): 1779-1782.

[10]Reichel U, Arons R R, Schilling W. Investigation of n-type electronic defects in the protonic conductor SrCe1-xYxO3-δ[J]. Solid State Ionics, 1996, 86-88(ptl): 639-645.

[11]邵玮, 张宏力, 万建慧, 等. SrCe0.95Y0.05O3-α的直接固相法制备及导电性能[J]. 中国有色金属学报, 2004, 14(1): 42-46.

SHAO Wei, ZHANG Hong-li, WAN Jian-hui, et al. Preparation of direct solid state reaction and conductivity of SrCe0.95Y0.05O3-α protonic conductor[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 42-46.

[12]薛丽红, 张一玲, 李强, 等. 共沉淀法制备复合钙钛矿PLZST的研究[J]. 无机材料学报, 2004, 19(3): 566-570.

XUE Li-hong, ZHANG Yi-ling, LI Qiang, et al. Preparation of PLZST with complex perovskite structure by coprecipitation[J]. J Inorganic Materials, 2004, 19(3): 566-570.

[13]祝宝军, 贡涛, 唐元洪, 等. 自蔓延高温合成SOFC阴极材料La0.7Sr0.3MnO3[J]. 湖南大学学报, 2005, 32(2): 90-94.

ZHU Bao-jun, GONG Tao, TANG Yuan-hong, et al. Self-propagating high-temperature synthesis of La0.7Sr0.3MnO3[J]. Journal of Hunan University, 2005, 32(2): 90-94.

[14]杨乃涛, 孟波, 谭小耀. 溶胶-凝胶法合成超细Ce1-xGdxO2-x/2电解质粉体[J]. 材料科学与工程学报, 2004, 22(4): 572-575.

YANG Nai-tao, MENG Bo, TAN Xiao-yao. Synthesis of ultra-fine Ce1-xGdxO2-x/2 electrolyte powders with sol-gel method[J]. J Materials Science & Engineering, 2004, 22(4): 572-575.

[15]孟波, 谭小耀, 张宝砚, 等. 新的燃烧工艺合成BaCe0.95Y0.05O3-δ纳米粉[J]. 中国稀土学报, 2004, 22(6): 795-799.

MENG Bo, TAN Xiao-yao, ZHANG Bao-yan, et al. A new combustion process for nanosized BaCe0.95-Y0.05O3-δ powders[J]. J Chinese Rare Earth Society, 2004, 22(6): 795-799.

[16]黄祥卉, 陈振华. NiFe2O4/SiO2纳米复合体的制备及其磁性能[J]. 中国有色金属学报, 2004, 14(11): 1901-1905.

HUANG Xiang-hui, CHEN Zhen-hua. Synthesis and magnetic properties of nickel ferrite on silica nanocomposites[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(11): 1901-1905.

[17]John A M, Jose R, Koshy J. Synthesis and rapid densification of nanoparticles of barium praseodymium hafnium oxide: a new complex perovskite[J]. J Nanoparticle Research, 2001, 51(3): 413-417.

[18]崔梅生, 李明来, 张顺利, 等. 钙钛矿催化材料La1-xCexCoO3+δ的制备、 表征及甲烷燃烧催化性质[J]. 中国有色金属学报, 2004, 14(9): 1580-1584.

CUI Mei-sheng, LI Ming-lai, ZHANG Shun-li, et al. Preparation and physicochemical characterization of La1-xCexCoO3+δ perovskite catalyst and its methane catalytic combustion[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(9): 1580-1584.

基金项目: 山东省自然科学基金资助项目(2003zx09)

收稿日期: 2005-09-05; 修订日期: 2005-12-12

通讯作者: 孟 波, 副教授, 博士; 电话: 0533-2786292; E-mail: mb1963@126.com

(编辑李艳红)