文章编号:1004-0609(2010)03-0516-06

快淬速率对(Mg70.6Ni29.4)92La8贮氢合金的微结构及电化学性能的影响

黄林军1,唐建国1,周轶凡2,王 瑶1,刘继宪1,王 蕊1,黄 震1

(1. 青岛大学 化学化工与环境学院,青岛 266071;

2. 浙江大学 材料科学与工程学院,杭州 310027)

摘 要:采用熔体快淬法制备(Mg70.6Ni29.4)92La8贮氢合金带,研究快淬速率对合金的微观组织结构及其电化学性能的影响。结果表明:随着快淬速率的加快,合金由纳米晶向非晶过渡,合金的非晶化程度增强,合金带的最大放电容量增加。冷却辊线速度为21.8 m/s制备的合金的循环最大放电容量可达568.5 mA?h/g,经过20次循环后,其最高容量保持率达79.3%;合金样品充电完成后形成的氢化物主要是Mg2NiH4,同时还保留大量的非晶结构。循环伏安测试结果显示较明显的氧化峰和还原峰,且峰电位差较小,反映电极合金具有较好的吸放氢反应的可 逆性。

关键词:Mg-Ni-La系贮氢合金;微观结构;电化学性能;熔体快淬

中图分类号:TG 139.7 文献标识码:A

Effects of melt-spinning velocity on microstructure and electrochemical properties of (Mg70.6Ni29.4)92La8 alloys

HUANG Lin-jun1, TANG Jian-guo1, ZHOU Yi-fan2, WANG Yao1, LIU Ji-xian1, WANG Rui1, HUANG Zhen1

(1. College of Chemistry, Chemical and Environmental Engineering, Qingdao University, Qingdao 266071, China;

2. College of Materials Science and Engineering, Zhejiang University, Hangzhou 310027, China)

Abstract: Hydrogen-storage (Mg70.6Ni29.4)92La8 alloys were prepared by melt-spinning. The effects of velocities of cooling roll on the microstructures and electrochemical properties for the as-quenched ribbons were investigated. The results show that the microstructure is transformed from nanocrystallization to amorphous phase, the degree of short-range order and the discharge-capacity increases with increasing the velocity of cooling roll for (Mg70.6Ni29.4)92La8 alloys. The highest discharge capacity reaches 568.5 mA·h/g for (Mg70.6Ni29.4)92La8 sample at the velocity of 21.8 m/s. The capacity conservation rate of the alloy is 79.3% after 20 cycles. It is obvious that Mg2NiH4 phase is major product with many amorphous phases during the charging process. Cyclic voltammetry results indicate significant peaks responding to oxidation and reduction reactions, and the difference between peak potentials is small, which means good reversibility of the electrode during the charge/discharge reaction.

Key words: Mg-Ni-La hydrogen-storage alloy; microstructure; electrochemical property; melt-spinning

自1990年小型Ni/MH电池问世以来,Ni/MH已经得到迅速的发展,在激烈竞争的电池市场中占有重要的地位[1?2]。然而,由于锂离子电池具有更高的质量(或体积)能量密度,使Ni/MH电池的广泛应用受到限制。因此,研究具有更高容量的新型贮氢合金已迫在眉睫。到目前为止,合金非晶化已被证实是改善贮氢合金电化学性能的有效方法之一[3?4]。目前,国际上镁基非晶储氢合金的研究重点主要集中在:1) 如何进一步提高其放电容量;2) 改善其循环稳定性,提高电极循环寿命。KHORKOUNOV等[5]通过球磨方法制备Mg61Ni30Y9 非晶电极合金,其放电容量高达570 mA?h/g。XIAO等[6]采用球磨方法制备2Mg-Fe+150%Ni 非晶合金电极,其放电容量达到565.2 mA?h/g。在此,本文作者采用熔体快淬法制备(Mg70.6Ni29.4)92La8贮氢合金带,研究快淬速率对合金的微观组织结构及其电化学性能的影响。

1 实验

1.1 合金的制备

合金的成分为(Mg70.6Ni29.4)92La8。制备合金所用的La、Ni和Mg元素的纯度均高于99.8%。实验合金在真空中频感应电炉熔炼。为了防止Mg在冶炼过程中挥发,用氩气加正压(0.1 MPa)保护。熔炼后的合金 经铜模浇铸获得母合金锭,用真空快淬炉将母合金重熔后,进行单辊快淬处理,获得快淬态合金。淬速 以铜辊表面线速度表示,淬速为5.2、6.4、12.8和21.8 m/s。

1.2 显微结构的分析

采用Rjgaku D型X射线衍射仪(CuKα辐射,λ=0.154 06 nm,石墨单色器)对Mg-Ni-La快淬合金带进行物相分析,扫描范围为20?~80?,扫描速度为10(?)/min。采用Hitachi H?800型透射电子显微镜观察熔体快淬合金带的微观组织形貌,样品制备在Gatan691型离子减薄仪上进行。

1.3 实验电极的制备及电化学性能的测试

将合金带用研钵处理成贮氢合金粉,然后与导电剂镍粉按质量比为1?4的比例混和;粘合剂由2.5%的CMC水溶液和60%的聚四氟乙烯乳液按体积比为1?2的比例调制而成。将粘合剂与粉末按照约0.6 mL/g的比例进行混浆。将浆均匀地涂抹在泡沫镍圆面的两面上,在60 ℃下干燥8 h之后,将圆片在20 MPa下压制成型。电化学性能的测试采用Arbin BTW?2000电池测试仪。贮氢合金电极片作为试验电池的负极,正极为Ni(OH)2/NiOOH,电解液采用的是6 mol/L的KOH水溶液和17.5 g/L的LiOH水溶液的混合液。测试时的充放电制度为:100 mA/g恒电流密度充电6 h,间隔10 min后,以100 mA/g恒电流密度放电至0.80 V,测试环境温度保持在25 ℃。循环伏安测试采用三电极体系(测试电极、Ni(OH)2/NiOOH辅助电极、Hg/HgO参比电极)在Arbin BTW?2000电池测试仪上进行,测试电压范围是?0.95~?0.4 V(vs.Hg/HgO),扫描速度为0.5 mV/s。

2 结果与讨论

2.1 快淬速率对微结构的影响

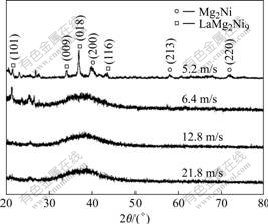

图1所示为不同冷却辊线速度制备的(Mg70.6Ni29.4)92La8贮氢合金带的XRD谱。

图1 不同冷却辊线速度下(Mg70.6Ni29.4)92La8贮氢合金带的XRD谱

Fig.1 XRD patterns of (Mg70.6Ni29.4)92La8 alloys prepared at different melt-spinning velocities

由图1可以看出,随着冷却辊线速度的加快,合金的微观组织由纳米晶向非晶转变。当冷却辊线速度为5.2 m/s时,制备的(Mg70.6Ni29.4)92La8贮氢合金带合金的衍射峰明显宽化,具有晶体结构,经过标定,其晶体相成分为为Mg2Ni和LaMg2Ni9;当冷却辊线速度为6.4 m/s时,制备的合金样品的衍射图谱中既有非晶的漫散射特征,也有晶体的衍射峰特征,表明其组织为非晶和纳米晶的混合,经过标定,其晶相中有少量的LaMg2Ni9相;当冷却辊线速度为12.8和21.8 m/s时,合金样品的衍射谱图中显现出平缓、分散的漫散射峰,表明制备的合金均为非晶。随着冷却辊线速度的加快,合金带的非晶漫散射峰逐渐变低、变平,而且非晶峰位逐渐向低角度偏移,这表明非晶的短程有序结构更加均匀,非晶化程度增强。

由图1也可以看出,随着冷却辊线速度的加快,合金带的短程有序范围减小,短程有序集团的混乱程度进一步增大。这表明,随着冷却辊线速度的加快,合金带的非晶化程度增强。

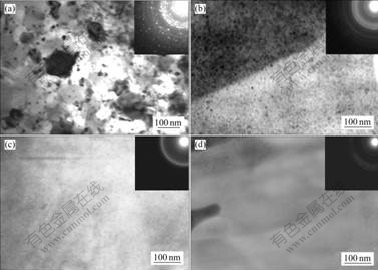

图2所示为冷却辊线速度分别为5.2、6.4、12.8和21.8 m/s时(Mg70.6Ni29.4)92La8贮氢合金带的TEM像及其电子衍射花样。

图2 不同冷却辊线速度下(Mg70.6Ni29.4)92La8贮氢合金带的TEM像及其电子衍射花样

Fig.2 TEM images and electron diffraction patterns of as-quenched (Mg70.6Ni29.4)92La8 alloys prepared at different melt-spinning velocities: (a) 5.2 m/s; (b) 6.4 m/s; (c) 12.8 m/s; (d) 21.8 m/s

由图2(a)可以看出,当冷却辊线速度为5.2 m/s时,制备的合金带的微观组织颗粒由几纳米到数十纳米,其电子衍射花样上显现出大量的衍射斑点和衍射环,表明该合金带具有多晶体结构,与X射线衍射结果相符,纳米晶的平均颗粒大小为80~100 nm。

由图2(b)可以看出,当冷却辊线速度为6.4 m/s制备的合金带微观组织比冷却辊线速度为5.2 m/s制备的合金带均匀,由少量的纳米晶颗粒镶嵌在大量的非晶组织中,纳米晶的平均颗粒大小为10~20 nm。

当冷却辊线速度为12.8(见图2(c))和21.8 m/s(见图2(d))时,制备的(Mg70.6Ni29.4)92La8合金带具有单一的非晶结构,且随着冷却辊线速度的加快,非晶结构更加细腻、均匀,这与图1所示的X射线衍射结果以及表1所列的计算结果相吻合。

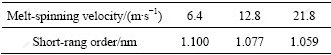

表1 不同冷却辊线速度制备的(Mg70.6Ni29.4)92La8非晶合金带的短程有序结果

Table 1 Short-range orders of amorphous alloys prepared at different melt-spinning velocities

2.2 快淬速率对电化学性能的影响

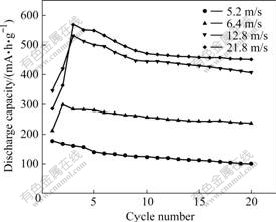

图3所示为不同冷却辊线速度下制备的(Mg70.6Ni29.4)92La8贮氢合金带的循环性能曲线。由图3可看出,冷却辊线速度为5.2 m/s制备的纳米晶合金带的循环性能最差,放电容量在第1次循环就达到最高值,为177.5 mA?h/g;经过20次循环后,放电容量降为100.6 mA?h/g。冷却辊线速度为6.4 m/s制备的半纳米晶半非晶合金带需要经过一个活化过程,在第2次循环时,放电容量达到最高值,为298.8 mA?h/g;经过20次循环以后,放电容量降为236.9 mA?h/g。冷却辊线速度为12.8和21.8 m/s制备的非晶合金带则具有较好的循环性能,但是需要2个活化过程才达到最高放电容量(分别为531.8 mA?h/g和568.5 mA?h/g)。快淬速率为21.8 m/s制备的合金样品具有更均匀的非晶结构,其循环性能最好,在经过20次循环后,其放电容量仍高于450 mA?h/g。

图3 不同冷却辊线速度下制备的(Mg70.6Ni29.4)92La8合金带的循环性能曲线

Fig.3 Cycle properties curves of (Mg70.6Ni29.4)92La8 samples prepared at different cooling roll velocities

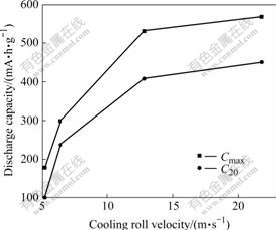

图4所示为不同冷却辊线速度制备的(Mg70.6Ni29.4)92La8贮氢合金带的循环最大放电容量Cmax以及经过20次循环后的放电容量C20随冷却辊线速度变化关系。由图4可见,随着快淬速率的加快,合金的最高放电容量和经过20次循环后,放电容量都呈现出明显增加的趋势。根据Cmax和C20可以计算出不同快淬速率制备的(Mg70.6Ni29.4)92La8贮氢合金经过20次循环后的容量保持率,分别为56.7%(5.2 m/s)、79.2%(6.4 m/s)、76.7%(12.8 m/s)和79.3%(21.8 m/s)。由此可以看出,微观组织结构含有非晶的贮氢合金其放电容量保持率都达到75%,而原始状态为纳米晶组织的放电容量保持率只有56.7%,这说明具有非晶结构的镁基贮氢合金其电极性能优于纳米晶结构的贮氢合金。文献[7?10]的研究结果也证明了这个观点。

图4 冷却辊线速度与(Mg70.6Ni29.4)92La8合金带的放电容量的关系

Fig.4 Relationship between discharge capacity and cooling roll velocity of (Mg70.6Ni29.4)92La8 samples

由上面的实验结果可以发现,镁基贮氢合金的电化学性能不仅依赖于其合金的成分,也受到其微观组织结构的影响,尤其是随着其非晶相的增多和非晶化程度的加强,其放电容量显著提高。由图1可以发现,随着快淬速率的加快,其衍射图谱的非晶漫散射峰也逐渐变低、变平,而且衍射峰的角度逐渐向左偏移,表明其原子间的混乱程度越来越大,即随着快淬速率的加快,贮氢合金的非晶组织更加均匀,非晶化程度逐渐增大。由于非晶态的结构是短程有序,氢在其中的扩散和溶解能力要优于结构为长程有序的晶态合金,非晶和纳米晶结构的产生使晶粒的晶界区域扩大、比表面积大幅度增加,并产生大量晶体缺陷。这样的微观组织结构既可以加速氢原子扩散到合金内部,产生的大量晶体缺陷又可作为氢化形核点,以加大贮氢容量。根据文献[9, 11]的研究结果,镁基合金的晶界区和非晶区是其主要的贮氢区域。因此,采用高快淬速率制备的贮氢合金就是由于具备均匀、统一的非晶结构才使其贮氢量得到大幅度提高。

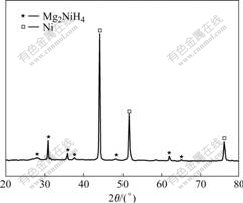

图5所示为快淬速率为21.8 m/s制备的(Mg70.6Ni29.4)92La8非晶样品在第3次循环充电6 h后的XRD谱。由图5可以看出,(Mg70.6Ni29.4)92La8非晶样品充电完成后形成的氢化物主要是Mg2NiH4,同时,还保留大量的非晶结构(这里由于导电剂Ni的强衍射峰影响而被掩盖)。这表明合金样品在具有最好的放电容量时其微观结构是以非晶为主。这也进一步验证了上面的研究结果。

图5 (Mg70.6Ni29.4)92La8非晶样品在第3次循环充电6 h后的XRD谱

Fig.5 XRD pattern of amorphous (Mg70.6Ni29.4)92La8 alloy after being charged for 6 h during the 3rd cycle

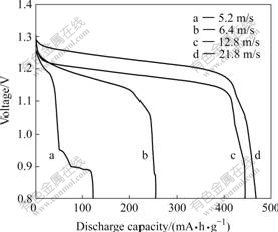

衡量贮氢合金电化学性能的另一个重要指标是放电电压平台的平坦性。因为一个好的放电平台是电极材料能够在实际中应用的保证。图6所示为不同冷却辊线速度制备的(Mg70.6Ni29.4)92La8贮氢合金带在第10次循环时的放电电压和放电容量的关系。

图6 (Mg70.6Ni29.4)92La8贮氢合金在第10次循环时的放电电压和放电容量的关系

Fig.6 Relationship between voltage and discharge capacities of (Mg70.6Ni29.4)92La8 alloys during the 10th cycle

由图6可见,随着放电容量的增加,都有一个明显的1.3~0.9 V的放电平台。这表明这种镁基合金在实际应用中的可能性。在1.3~1.0 V的放电平台,冷却辊线速度为12.8和21.8 m/s制备的非晶合金的放电容量都达到400 mA?h/g,而纳米晶(Mg70.6Ni29.4)92La8贮氢合金的放电容量只有123.2 mA?h/g。这进一步说明非晶态合金的微观组织结构对于提高镁基贮氢合金的电化学性能是一个主要因素。

图7所示为冷却辊线速度为12.8和21.8 m/s制备的(Mg70.6Ni29.4)92La8非晶合金电极在第10次充、放电循环时的循环伏安曲线。由图7可看出,2个样品都显示出较明显的氧化峰和还原峰,且峰电位差较小,说明合金的氧化还原反应的可逆性较好。此外,随着冷却辊线速度的加快,还原峰电位略向正方向移动(从?855 mV变为?831 mV),氧化峰电位略向负方向移动(从?680 mV变为?699 mV)。电位差变小且峰电流增大,说明加快冷却辊快淬速率使合金的可逆性能和放电容量上升,这与合金电极的充、放电性能测试结果相吻合(见图3)。LU等[12]认为氧化峰面积和电化学容量是相对应的,较大的氧化峰面积对应较大的电化学贮氢容量。从图7可以看出,采用21.8 m/s制备的电极合金的氧化峰面积明显高于采用12.8 m/s制备的电极合金的氧化峰面积,说明前者具有更高的电化学容量。这2种合金电极的放电容量测试也体现同样的结果(分别为568.5 mA?h/g和531.8 mA?h/g)。

图7 (Mg70.6Ni29.4)92La8贮氢合金在第10次循环时的循环伏安曲线

Fig.7 CV curves of (Mg70.6Ni29.4)92La8 alloys during the 10th cycle: (a) 12.8 m/s; (b) 21.8 m/s

3 结论

1) 熔体快淬法制备的(Mg70.6Ni29.4)92La8合金带的微观组织受到快淬速率的影响。当冷却辊线速度小于6.4 m/s时,制备的合金带具有纳米晶结构;当冷却辊线速度大于12.8 m/s时,制备的合金带具有非晶 结构,且随着冷却辊线速度的加快,合金的非晶化程度逐渐增强。

2) 电化学性能测试表明,随着冷却辊线速度的加快,合金带的最大放电容量随之增加。冷却辊线速度为21.8 m/s制备的合金的循环最大放电容量可达568.5 mA?h/g,经过20次循环后其最高容量保持率达到79.3%。合金样品充电完成后形成的氢化物主要是Mg2NiH4,同时,还保留大量的非晶结构,证明非晶态合金的微观组织结构对于提高镁基贮氢合金的电化学性能是一个主要因素。

3) 合金样品经过10次充、放电循环以后,伴随其放电容量的增加,都有一个明显的1.3~0.9 V的放电平台,并且放电电压平台的长度随快淬速率的增快而增加。快淬速率为12.8和21.8 m/s制备的非晶合金的放电容量都达到400 mA?h/g以上。

4) 循环伏安测试表明,快淬速率为12.8和21.8 m/s制备的非晶合金的吸放、氢反应的可逆性较好;快淬速率的加快使合金充、放电反应的可逆性能和放电容量上升,这与合金电极充、放电测试结果相一致。

REFERENCES

[1] UEHARA I, SAKAI T, ISHIKAWA H. The state of research and development for applications of metal hydrides in Japan[J]. Journal of Alloys and Compounds, 1997, 253/254: 635?639.

[2] WANG Q D, CHEN C P, LEI Y Q. The recent research, development and industrial applications of metal hydrides in the People’s Republic of China[J]. Journal of Alloys and Compounds, 1997, 253/254: 629?634.

[3] OKONSKA I, IWASIECZKOB W, JARZEBSKIA M, NOWAK M, JURCZYK M. Hydrogenation properties of amorphous 2Mg+Fe/x wt%Ni materials prepared by mechanical alloying (x=0, 100, 200)[J]. International Journal of Hydrogen Energy, 2007, 32: 4186?4192.

[4] WU Y, HAN W, ZHOU S X, LOTOTSKY M V, SOLBERG J K, YARTYS V A. Microstructure and hydrogenation behavior of ball-milled and melt-spun Mg-10Ni-2Mn alloys[J]. Journal of Alloys and Compounds, 2008, 466: 176?181.

[5] KHORKOUNOV B, GEBERT A, MICKEL C, SCHULTZ L. Improving the performance of hydrogen storage electrodes based on mechanically alloyed Mg61Ni30Y9[J]. Journal of Alloys and Compounds, 2008, 458: 479?483.

[6] XIAO Xue-zhang, WANG Xin-hua, GAO Lin-hui, WANG Li, CHEN Chang-pin. Electrochemical properties of amorphous Mg-Fe alloys mixed with Ni prepared by ball-milling[J]. Journal of Alloys and Compounds, 2006, 413: 312?317.

[7] LEI Zheng-long, LIU Zu-yan, CHEN Yan-bin. Cyclic hydrogen storage properties of Mg milled with nickel nano-powders and NiO[J]. Journal of Alloys and Compounds, 2009, 470: 472?477.

[8] CUI N, LUAN B, LIU H K. Discharge behavior of Mg2Ni-type hydrogen-storage alloy electrodes in 6 M KOH solution by electrochemical impedance spectroscopy[J]. J Power Sources, 1996, 63(2): 209?213.

[9] ORIMOI S, FUJII H. Materials science of Mg-Ni based new hydrides[J]. Appl Phys A, 2001, 72: 167?171.

[10] SPASSOV T, RANGELOVA V, NEYKOV N. Nanocrystallization and hydrogen storage in rapidly solidified Mg-Ni-RE alloys[J]. Journal of Alloys and Compounds, 2002, 334: 219?224.

[11] INOUE A. Stabilization of metallic supercooled liquid and bulk amorphous alloys[J]. Acta Mater, 2000, 48: 278?282.

[12] LU Z W, SUN S, LI G R, YAN T Y, QU J Q, GAO X P. Electrochemical hydrogen storage of ball-milled Mg-rich Mg-Nd alloy with Ni powders[J]. Journal of Alloys and Compounds, 2007, 433: 269?273.

基金项目:山东省优秀中青年科学实科研奖励基金资助项目(BS2009CL039);青岛大学青年科研基金资助项目(0814)

收稿日期:2009-04-16;修订日期:2009-08-13

通信作者:黄林军,副教授,博士;电话:0532-85951961;E-mail: newboy66@126.com

(编辑 杨 华)