DOI:10.19476/j.ysxb.1004.0609.2019.05.08

TA15钛合金模锻件低倍组织中局部粗晶的形成机理

陈 雷1,张启飞1,贾 伟1,莫安军2,邹宗园1,金 淼1

(1. 燕山大学 机械工程学院,秦皇岛 066004;

2. 中国第二重型机械集团 德阳万航模锻有限责任公司,德阳 618000)

摘 要:在TA15钛合金模锻件应以模糊晶为主的低倍组织中发现了局部粗大的清晰晶。利用金相拼接和逐点统计方法,结合微拉伸、SEM等手段,分析对比了粗大清晰晶区、模糊晶区的显微组织与力学性能,着重探讨了局部粗晶的形成机制。结果表明:各晶区内显微组织均呈典型双态组织,显示了两相区变形的基本特征。与模糊晶区相比,粗大清晰晶区内初生等轴α相(αp)含量略低,且存在粗大片层组织;存有大量的粗大原始β晶粒(连续的晶界α相包围的晶粒),平均尺寸可达124 μm,是模糊晶区平均尺寸(32 μm)的近4倍。这些异常粗大的β晶粒是导致低倍粗晶的最主要因素,同时也是导致合金的强度和塑性均下降的主要原因之一。热物理模拟结果表明,双相区变形后出现的粗大清晰晶对应变速率敏感。慢速率变形会增大形成低倍粗晶的倾向,这主要与变形过程中动态αp→β相变有关。对于模锻件而言,局部粗大清晰晶区火次应变小使其较模糊晶区应变速率慢,再经多火次小应变(慢速率)累积导致了β晶粒明显粗化。

关键词:钛合金;低倍组织;清晰晶;模糊晶;原始β晶粒

文章编号:1004-0609(2019)-05-0954-09 中图分类号:TG146.2 文献标志码:A

钛合金因其良好的综合性能,在航空领域得到广泛应用,常通过热模锻制成飞机的承力构件[1-2]。在我国当前航空工业对钛合金模锻件需要量迅猛增加的同时,对钛合金航空模锻件的宏微观组织和力学性能的要求也越来越苛刻。航空模锻件的低倍组织是锻件质量评估和产品判废的重要依据之一,对锻件的形变历程和热历史十分敏感。特别对于大型模锻件,由于锻件结构复杂以及模具的影响,使得锻件内温度和变形的不均匀性明显而导致的锻件局部低倍组织不达标的问题层出不穷[3-4]。有些锻件不得不将低倍组织缺陷切除,使得材料利用率大幅降低,有的低倍组织缺陷甚至直接导致锻件报废。钛合金低倍组织通常分为:清晰晶和模糊晶,其主要与β晶粒尺寸、晶粒的不等轴程度和衬度有关[5-6],显微组织之间并不存在明确的关联关系。TA15钛合金模锻件主要在α+β双相区多火次成形,其达标的低倍组织通常为模糊晶。本文在前期发现某TA15钛合金航空模锻件低倍组织中出现局部低倍粗大清晰晶的基础上,力图通过宏微观组织分析,明确低倍粗晶形成的微观主控因素及其对力学性能的影响,并探讨其与热加工工艺间的关联关系,从而揭示TA15钛合金模锻件局部低倍粗晶的形成机理。

1 实验

试验用材料为某TA15钛合金模锻件的局部解剖件,该锻件坯料来源于商用锻造原坯,锻造前经过严格的理化处理,其微观组织不存在成分偏析等缺陷。该锻件热加工流程为:坯料在两相区进行加热保温,之后出炉经多火次锻造成形后空冷至室温后,再进行完全退火处理。局部解剖件的最大外围轮廓尺寸为:85 mm×45 mm×23 mm,如图1所示。由图1可见,锻件的低倍组织主要为模糊晶,在靠近锻件表层部位出现了局部粗大的清晰晶(见图中白色虚线勾勒区域)。由局部放大的低倍组织(见图1(b))可见,由表层向内,低倍组织大致可分为三个区域:靠近表层的局部粗晶区(清晰晶区)、近心部的模糊晶区(锻件的目标低倍组织)以及二者之间的过渡晶区。其中,在局部粗晶区改变入射光线的角度会使得低倍试样表面出现亮暗交替的现象,这主要是由于该区域内显微组织晶体位向不同[7]。

从解剖件上选取典型区域后将其切下,一部分用以分析不同晶区的宏微观组织特点,另一部分用来评估不同晶区的力学性能。宏微观组织均采用硝酸和氢氟酸的混合水溶液浸蚀,其中,硝酸、氢氟酸及水之间的体积比为1:6:7,浸蚀时间为5~8 s。低倍组织利用单反相机微距功能拍摄,显微组织采用KEYENCE VHX-100型光学显微镜进行观察;力学性能试验在INSTRON-5948R Micro Tester微力材料试验机上进行。从图1中框①和②沿高度方向分别获取清晰晶区和模糊晶区的拉伸试样各5个,试样规格如图2所示。对各晶区的5个试样进行拉伸试验,以0.36 mm/min的恒速度进行拉伸至试样断裂,最后对各晶区试验结果进行均值处理。采用ZEISS SIGMA 500/VP扫描电镜观察断口形貌。

图1 TA15钛合金锻件局部解剖件

Fig. 1 Part decomposed specimen of TA15 titanium alloy forging and metallographic specimen

图2 微拉伸试样尺寸

Fig. 2 Dimension of specimen for micro tensile test (Unit: mm)

图3 TA15钛合金显微组织

Fig. 3 Microstructures of TA15 titanium alloy

在Gleeble3800热/力模拟试验机上进行高温压缩试验,试验用材为与出现局部粗晶锻件坯料同批次的TA15钛合金,其原始组织为钛合金典型的等轴组织,由60%等轴α相、40%片层α相及残余β相组成,且显微组织分布均匀,如图3(a)所示。热模拟用试样尺寸为d 10 mm×15 mm。试样以10 ℃/s的速度进行加热,温度升高到960 ℃后,保温10 min(变形前显微组织包含27%等轴α相,如图3(b)所示)进行等温变形,变形速率分别采用0.001 s-1、0.01 s-1及1 s-1,变形量为10%、30%及50%,变形后空冷至室温后,再进行完全退火处理。

2 结果分析与讨论

2.1 不同晶区的显微组织及力学性能分析

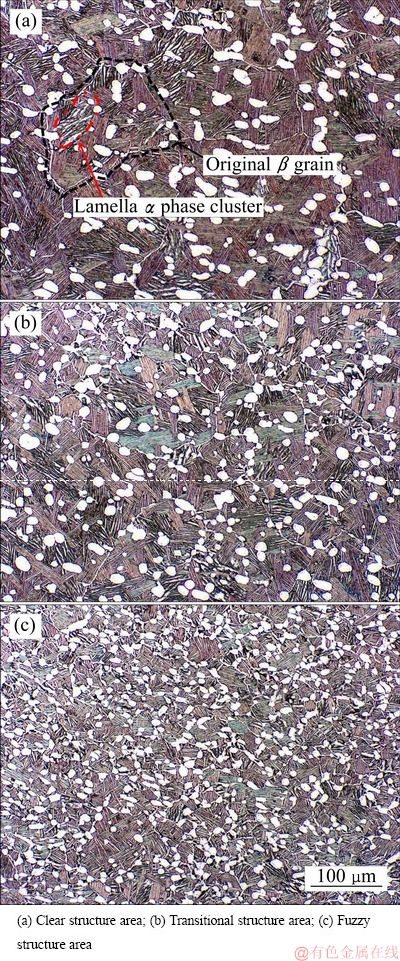

图4所示为不同晶区的显微组织。由图4可见,不同区域的显微组织均表现出钛合金典型的双态组织特征,但也存有差异,主要表现为:清晰晶区原始β晶粒(连续的晶界α相包围的晶粒)尺寸粗大[1],过渡晶区次之,模糊晶区的原始β晶粒最小;清晰晶区晶界α厚度也较厚。清晰晶区的存有较多的大尺寸初生α相(αp),彼此间距较大,且具有较为明显的方向性,过渡晶区仍存有部分粗大的αp,而模糊晶区域的αp尺寸较小且分布相对密集,等轴化程度高。在清晰晶区内一些原始β晶粒内存在厚且粗大的次生α团簇(见图4(a)中红点划线围成部分),近似于魏氏组织,较粗大的次生α团簇在过渡晶区仍可见少量,但模糊晶区片层α组织细而短且尺寸均匀。

图4 不同区域的显微组织

Fig. 4 Microstructural characteristics in different areas

表1列出了该TA15钛合金锻件不同晶区的力学性能。与模糊晶区相比,清晰晶区强度和塑性均有所降低,特别是强度,其中清晰晶区屈服强度比模糊晶区低近100 MPa。图5所示为不同晶区试样的拉伸断口形貌。不同区域对应的宏观断口存在明显的差异,模糊晶区对应的宏观断口表面较为均匀、细密,少见粗大的撕裂岭(见图5(a)),而清晰晶区对应的宏观断口表面存有明显的撕裂岭,且还可见少量较明显的二次裂纹(见图5(c))。

表1 不同低倍形貌的力学性能

Table 1 Mechanical properties of different macroscopic microstructures

对模糊晶区断口进行局部放大可见,断口表面韧窝多而深,韧窝细密而均匀,表现出明显的韧性断裂特征,如图5(b)所示。而清晰晶区局部放大断口表面形貌较为混乱,韧窝不均匀且存有明显的沿粗大原始β晶界的撕裂岭(见图5(d)中红色虚线所围部分),断口表面在此粗大β晶粒内既存有明显的韧窝区,也可见一些较为平坦的准解理小平台区[8-12]。这主要与粗大原始β晶粒内存有较粗大次生α团簇的近魏氏组织(见图3(a))有关。

图5 不同晶区的拉伸断口形貌

Fig. 5 Morphologies of tensile fracture surface in different areas

图6 不同晶区初生αp含量及尺寸特征

Fig. 6 Characteristics of αp in different areas

为进一步对比清晰晶区(局部粗晶区)与模糊晶区间的显微组织的差异,通过对各晶区较大面积(约为20 mm2)的金相拼接与统计,获得了各晶区显微特征的量化差异。图6所示为不同晶区初生α相含量及其尺寸特征。清晰晶区的αp含量最低,为13.3%,过渡晶区域和模糊晶区含量αp略高,分别为15.8%和19.8% (见图6(a))。清晰晶区的平均αp尺寸最大,为10 μm,主要集中在7~15 μm,占比约61.4%;过渡晶区的平均αp尺寸次之,为8.7 μm,分布在6~12 μm,占比约61.3%;而模糊晶区的平均αp尺寸最小,为8.2 μm,大多为5~10 μm,占比约为70.6%,如图6(b)所示。

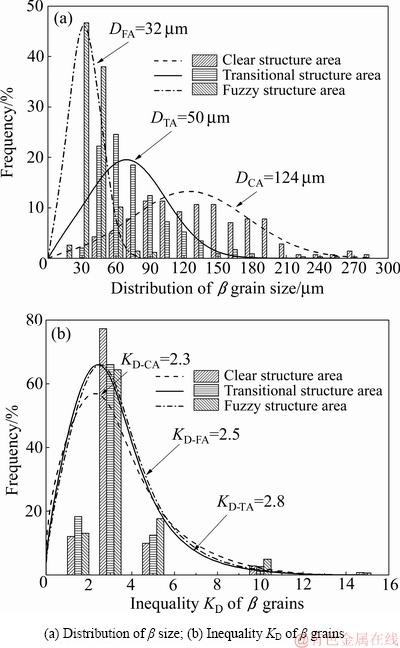

图7 不同晶区的β晶粒尺寸分析

Fig. 7 Analysis of β grain size in different regions

β晶粒尺寸作为判别钛合金低倍组织特征的关键因素之一,如前所述,清晰晶区内原始β晶粒尺寸较过渡晶区和模糊晶区明显粗大。图7所示为大面积统计的不同区域的原始β晶粒的特征。由图7(a)可知,模糊晶区原始β平均晶粒尺寸约为32 μm,过渡晶区约为50 μm,而清晰晶区的原始β晶粒尺寸最粗大,平均尺寸约为124 μm,是模糊晶区原始β晶粒尺寸的近4倍。而这些粗大的β晶粒也易使β→α相变后的次生α片层厚,片层团簇尺寸粗大(见图4(a)),进而使得细晶强化效应减弱,可见,粗大的原始β晶粒也是导致清晰晶区强度降低的主要原因之一。图7(b)给出了不同晶区的另一判定低倍组织参数:晶粒不等轴度KD(晶粒长轴与短轴之比[6])的特点。分析可知,各晶区的KD值分布均较集中,约在2~4之间。粗大清晰晶区原始β晶粒的KD平均值(2.3)略低于过渡晶区(2.8)和模糊晶区(2.5),即:清晰晶区原始β晶粒的等轴化程度略低,但整体而言,各晶区的不等轴度的差异不大。由此推断,粗大的原始β晶粒是导致TA15合金在双相区变形(对应双态组织)却出现局部粗大清晰晶的主要原因,而且,尽管各晶区均存有原始β晶粒,但其尺寸需超过某一临界值时才能表现出明显的低倍清晰晶。由图1(b)可见,过渡晶区的宏观组织特征与模糊晶区较为接近,但仍隐约可见少量亮暗相间的宏观晶粒,可认为其属于半模糊晶。因此,对于TA15钛合金而言,可将本实验用锻件过渡晶区对应的原始β晶粒平均尺寸50 μm作为其低倍组织呈现明显清晰晶的的临界条件。另一方面,钛合金清晰晶区中局部发亮或发暗的小区域通常被认作为一个宏观晶粒。图1(b)表明锻件粗大清晰晶区内宏观晶粒尺寸(约为0.5~1 mm)明显大于该区域内原始β晶粒平均尺寸,由此可知,锻件清晰晶区的宏观粗大晶粒由多个相邻的粗大原始β晶粒组成。这些相邻β晶粒及其后续的转变组织由于具有相近的晶体学位向,而在低倍组织中表现出相同或近似的图像衬度,进而被观察为一个宏观的清晰晶晶粒[6-7]。

2.2 低倍粗晶形成机理分析

局部粗晶区对应的显微组织粗大,特别是初生αp含量降低,这似乎暗示了该晶区变形时出现了温升使得部分αp溶解。然而,该晶区所处锻件的近表面区域,因此该区域变形时温度低于锻件心部温度,那么锻件心部的αp含量应该更低,这与实际不符(见图4),由此推断,低倍粗晶形成不是温升[13]造成的,而应与应变和应变速率有关。

图8所示为TA15钛合金热变形后的低倍与心部显微组织(由于热压缩变形后试样截面上各区域应变不同,心部组织应变量最接近设定值)。由图8可见,在960 ℃下变形、宏观变形量为30%条件下,较快速率(1 s-1)变形后,初生αp含量与变形前的(见图3(b))相当,部分αp被压扁,少见粗大的原始β晶粒,而试样各区域低倍组织均表现为模糊晶(见图8(a))。在慢速率(0.01 s-1)变形后初生αp含量明显减少且尺寸变小,可见粗大原始β晶粒,经统计试样心部原始β晶粒平均尺寸约为70 μm,大于前述出现低倍粗晶的临界尺寸50 μm,试样心部大应变区(见图8(b)虚线区域内)表现为粗大清晰晶。同样地,在应变速率更慢(0.001 s-1)的条件下变形,心部低倍仍呈现为清晰晶,初生αp含量进一步降低,原始β晶粒的尺寸更大,达到110 μm,如图8(c)所示。上述结果表明,低倍粗晶对应变速率敏感,相同变形量下(心部:30%),变形时间越长,即应变速率越慢,低倍粗晶倾向越大。换句话说,当变形温度和变形时间一定时,低倍组织出现粗大清晰晶的变形量需低于某一临界值,即ε≤ε1。但值得提出的是,慢速变形试样的难变形区和小应变区仍为模糊晶,这表明当变形温度和时间一定时,变形量还需高于一定值,即ε≥ε2时,试样才能表现出低倍清晰晶[14]。由图8(d)(0.01 s-1,变形量10%)可见,心部显微组织虽出现了较明显的原始β晶粒,但其平均尺寸约为33 μm,小于50 μm,心部低倍组织仍表现为模糊晶,进一步验证了前述推断(ε≥ε2)。对于双态组织而言,(α+β)双相区β晶粒的粗细取决于αp的数量与间距及其对再结晶β晶粒的影响。通常,再结晶的β在αp颗粒之间长大[5],也就是说αp颗粒间距(记为bβ)越大,β晶粒长的越粗大,而αp分布越密,β晶粒则不易长大。但图3(b)表明,钛合金在变形前bβ并不大。然而,最近的研究表明[15-17],在相对较慢的应变速率下,钛合金在变形过程中将发生动态相变,初生αp转变成β,这也是本实验中0.01 s-1及0.001 s-1速率下变形,即使不会产生明显的变形热,αp含量仍然明显降低的主要原因,如图8(b)和(c)所示。因此,慢应变速率下,β较小变形下就可能开始再结晶,伴随着变形过程中αp向β的转变,αp颗粒间距增大,β晶粒在逐渐拉开距离的αp颗粒间长大粗化。与图8(d)对比可知,慢速率下变形时间越长(即变形量越大,如图8(b)和(e)所示),动态αp→β相变越充分,αp颗粒间距越大,β粗化越显著,尺寸越容易超过出现粗大清晰晶的临界尺寸。甚至,随着变形量的进一步增加,变形时间足够长,变形前的初生αp则会全部溶解,完全转变为单相β组织。而单相区的β在高温下更容易迅速长大,导致最终材料目标组织不合格以及“β脆”[18]。此外,由于变形速率慢,相同变形量下变形时间长,即再结晶β晶粒在较高温度下停留时间长,这也可能会导致部分β晶粒发生聚集长大[5],形成更粗的β晶粒。

图8 TA15钛合金热变形后的低倍组织和心部显微组织

Fig. 8 Macroscopic and center microstructures of TA15 titanium alloy after hot deformation

对于本研究中的模锻件而言,如前所述,尽管近表面区域温度低但仍表现出了粗大清晰晶且αp数量少。由上述β晶粒粗化机制分析可推断,锻件中低倍粗大清晰晶主要与该区域变形量较小有关,因为每一火次各晶区的变形时间相同,小应变区则对应较慢的应变速率,使得此区域变形时β晶粒发生粗化。此外,钛合金火次间显微组织通常具有遗传性[19-20],模锻件多火次成形过程中的小应变(慢应变速率)区,前一火次的粗化组织将作为后一火次的初始组织再经慢应变速率变形,即火次间小应变累积,将会使得该区域的β晶粒进一步粗化,在某一火次β平均晶粒尺寸超过 50 μm,且多个位向相近的粗大β晶粒集聚而最终表现为低倍粗大清晰晶。

3 结论

1) 低倍组织中粗大清晰晶区与模糊晶区的显微组织均为典型双态组织,但低倍粗晶区的强度和塑性均低于模糊晶区。与模糊晶区相比,粗大清晰晶区内αp含量略低且存有粗大次生α片层组织;特别是该区域原始β晶粒明显粗大,其平均尺寸达124 μm,是模糊晶区(32 μm)的近4倍。

2) 粗大的原始β晶粒是导致模锻件出现局部粗大清晰晶的主要原因,但其形成不是变形热导致的温升造成的。当原始β晶粒尺寸超过50 μm时,低倍组织表现为粗大清晰晶。

3) 低倍粗大清晰晶对应变速率敏感。应变速率越慢,低倍组织呈现粗大清晰晶的倾向越大,而变形过程中的动态αp→β相变是主要原因。慢速率下变形时间越长(即变形量越大),动态相变越充分,αp颗粒间距越大,β晶粒粗化越显著。

4) 与锻件模糊晶区相比,粗大清晰晶区单火次成形的应变速率始终较慢,增大了β晶粒粗化倾向,经多火次小应变(慢应变速率)累积,β晶粒进一步粗化,而最终形成低倍粗大清晰晶。

REFERENCES

[1] 赵永庆, 辛社伟, 陈永楠, 毛小南. 中国战略性新兴产业-新材料-新型合金材料—钛合金[M]. 北京: 中国铁道出版社, 2017.

ZHAO Yong-qing, XIN She-wei, CHEN Yong-nan, MAO Xiao-nan. China's strategic emerging industries-new materials, new alloy materials—Titanium alloys[M]. Beijing: China Railway Publishing House, 2017.

[2] 金和喜, 魏克湘, 李建明, 周建宇, 彭文静. 航空用钛合金研究进展[J]. 中国有色金属学报, 2015, 25(2): 280-292.

JIN He- xi, WEI Ke- xiang, LI Jian- ming, ZHOU Jian- yu, PENG Wen- jing. Research development of titanium alloy in aerospace industry[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 280-292.

[3] 陈 强, 王庆娟, 王鼎春, 刘继雄, 李 强, 周 晓, 梁 博. 锻件组织不均匀性对新型近β钛合金组织与力学性能的影响[J]. 中国有色金属学报, 2018, 28(1): 87-96.

CHEN Qiang, WANG Qing-juan, WANG Ding-chun, LIU Ji-xiong, LI Qiang, ZHOU Xiao, LIANG Bo. Effect of microstructure in homogeneity of forgings on microstructure and mechanical properties of new near β titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(1): 87-96.

[4] 张旺峰, 王玉会, 颜孟奇, 张庆玲. 锻造方法对TA15钛合金组织和性能的影响[J]. 中国有色金属学报, 2013, 23(s1): 15-19.

ZHANG Wang-feng, WANG Yu-hui, YAN Meng-qi, ZHANG Qing-ling. Effect of forging method on microstructure and mechanical properties of TA15 titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(s1): 15-19.

[5] 马济民, 贺金宇, 庞克昌. 钛铸锭和锻造[M]. 北京: 冶金工业出版社, 2012.

MA Ji-min, HE Jin-yu, PANG Ke-chang. Titanium ingot and forging[M]. Beijing: Metallurgical Industry Press, 2012.

[6] 中国锻压协会. 特种合金及其锻造[M]. 北京: 国防工业出版社, 2009.

Confederation of Chinese Metal Forming Industry. Special alloys and their forging[M]. Beijing: National Defense Industry Press, 2009.

[7] 曹京霞, 黄 旭, 孙贵东, 方 波. 一种Ti-6Al-2Zr-1Mo-1V合金锻件的宏观与微观组织特征分析[J]. 钛工业进展, 2004, 21(2): 23-26.

CAO Jing-xia, HUANG Xu, SUN Gui-dong, FANG Bo. Macro-and microstructure feature analysis of Ti-6AI-2Zr- lMo-lV titanium alloy forging[J]. Titanium Industry Progress, 2004, 21(2): 23-26.

[8] LIN Yong-cheng, JIANG Xing-you, SHUAI Ci-jun, ZHAO Chun-yang, HE Dao-guang, CHEN Ming-song, CHEN Chao. Effects of initial microstructures on hot tensile deformation behaviors and fracture characteristics of Ti-6Al-4V alloy[J]. Materials Science and Engineering A, 2018, 711: 293-302.

[9] NIINOMI M, KOBAYASHI T, SASAKI N. Toughness and microstructural factors of Ti-6Al-4V alloy[J]. Materials Science and Engineering, 1988, 100(4): 45-55.

[10] 李 萍, 薛克敏, 姚彭彭, 李成铭. 热变形TA15钛合金的显微组织和室温力学性能[J]. 稀有金属材料与工程, 2016, 45(6): 1495-1499.

LI Ping, XUE Ke-min, YAO Peng-peng, LI Cheng-ming. Microstructure and mechanical properties of hot deformed TA15 titanium alloy at room temperature[J]. Rare Metal Materials and Engineering, 2016, 45(6): 1495-1499.

[11] LIU Rui, HUI Song-xiao, YE Wen-jun, XIONG Bai-qing, YOU Zhen-ping. Effects of annealing temperature on dynamic fracture toughness for TC4 titanium alloy[J]. Rare Metal Materials and Engineering, 2011, 40(10): 1799-1803.

[12] OBASI G C, FONSECA J Q D, RUGG D, PREUSS M. The effect of β grain coarsening on variant selection and texture evolution in a near-β Ti alloy[J]. Materials Science & Engineering A, 2013, 576(9): 272-279.

[13] 王 杨, 曾卫东, 马 雄, 周建华, 王晓英, 王 腾. BT25钛合金在两相区变形过程中的显微组织定量分析[J]. 中国有色金属学报, 2013, 23(7): 1861-1865.

WANG Yang, ZENG Wei-dong, MA Xiong, ZHOU Jian-hua, WANG Xiao-ying, WANG Teng. Quantitative metallography analysis of microstructure of BT25 titanium alloy deformed in two-phase field[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1861-1865.

[14] ABBASI S M, MOMENI A, LIN Yong-cheng, JAFARIAN H R. Dynamic softening mechanism in Ti-13V-11Cr-3Al beta Ti alloy during hot compressive deformation[J]. Materials Science and Engineering A, 2016, 665: 154-160.

[15] FAN Xiao-guang, YANG He, GAO Peng-fei, ZUO Rui, LEI Peng-hui, JI Zhe. Morphology transformation of primary strip α phase in hot working of two-phase titanium alloy[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(6): 1294-1305.

[16] GUO Bao-qi, SEMIATIN S L, LIANG Jiang-tao, SUN Bin-han, JONAS J J. Opposing and driving forces associated with the dynamic transformation of Ti-6Al-4V[J]. Metallurgical and Materials Transactions A, 2018, 49(5): 1450-1454.

[17] JONAS J J, JR C A, FALL A, JAHAZI M. Transformation softening in three titanium alloys[J]. Materials & Design, 2017, 113: 305-310.

[18] ABBASI S M, MOMENI A. Effect of hot working and post-deformation heat treatment on microstructure and tensile properties of Ti-6Al-4V alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(8): 1728-1734.

[19] 石卫民, 魏寿庸, 王鼎春, 李渭清, 王青江, 刘建荣. Ti60钛合金大棒材的显微组织及力学性能[J]. 中国有色金属学报, 2010, 20(S1): s75-s78.

SHI Wei-min, WEI Shou-yong, WANG Ding-chun, LI Wei-qing, WANG Qing-jiang, LIU Jian-rong. Microstructures and mechanical properties of Ti60 Ti alloy large-section bars[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s75-s78.

[20] 张 津, 刘贞阳, 郭海明. Ti8LC钛合金热处理工艺对硬度和组织的影响[J]. 稀有金属, 2011, 35(1): 17-21.

ZHANG Jin, LIU Zhen-yang, GUO Hai-ming. Effect of heat treatment on hardness and microstructure of Ti8 LC alloy[J]. Chinese Journal of Rare Metals, 2011, 35(1): 17-21.

Formation mechanism for local coarse-grained macrostructure in TA15 titanium alloy die forging

CHEN Lei1, ZHANG Qi-fei1, JIA Wei1, MO An-jun2, ZOU Zong-yuan1, JIN Miao1

(1. School of Mechanical Engineering, Yanshan University, Qinhuangdao 066004, China;

2. Deyang Wanhang Die Forging Co., Ltd., China National Erzhong Group, Deyang 618000, China)

Abstract: A local coarse-grained macrostructure which was identified as the clear structure, was found in the TA15 titanium alloy die forging. Usually, the macrostructure of TA15 titanium alloy forging was required to display a fuzzy structure with fine microstructures. The microstructure and mechanical properties in the coarse-grained areas were investigated by means of optical microscope (OM), scanning electron microscope (SEM) as well as micro-tension tests. The formation mechanism for the local coarse-grained macrostructure was discussed. The results show that the microstructures in various areas of forging display a duplex microstructure of titanium alloy which typically shows the microstructural characteristics of titanium alloy during hot deformation in the (α+β) region. Compared with the fuzzy structure area, the fraction of primary equiaxed α (αP) in the clear structure area is slightly lower, and a coarse lamellar microstructure is found. Especially, a large number of coarse original β grains which are surrounded by α phase on grain boundaries are found in the clear structure area, and their average grain size reaches 124 μm, which is nearly 4 times of that (32 μm) in the fuzzy structure area. The abnormal coarse β grains are considered to be a critical factor for the formation of local coarse-grained macrostructure, and meanwhile, they can cause a decrease in strength and plasticity. Furthermore, the results of thermal-mechanical tests show that the coarse-grained macrostructure is sensitive to the strain rate. Lower strain rate causes an increase in the probability of such coarse-grained macrostructure. This is mainly related to the occurrence of αp→β dynamic transformation during deformation. For the forging with the clear structure, the lower strain rate in each forging step, which is caused by the small strain within the same deformation time as compared to the fuzzy structure area, as well as the further cumulative effect of small strain in subsequent forging steps results in a significant coarsen of original β grains.

Key words: titanium alloy; macrostructure; clear structure area; fuzzy structure area; original β grain

Foundation item: Project(51675467) supported by the National Science Foundation of China; Project(E2016203284) supported by the Natural Science Foundation of Hebei Province, China; Projects(2016M600194, 2017T100712) supported by the China Post Doctoral Science Foundation

Received date: 2018-04-28; Accepted date: 2018-07-26

Corresponding author: ZOU Zong-yuan; Tel: +86-15369701769; E-mail: zzy@ysu.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51675467);河北省自然科学基金资助项目(E2016203284);中国博士后科学基金资助项目(2016M600194, 2017T100712)

收稿日期:2018-04-28;修订日期:2018-07-26

通信作者:邹宗园,讲师,博士;电话:15369701769;E-mail:zzy@ysu.edu.cn