文章编号:1004-0609(2014)11-2892-08

氧化锌烟尘中铟的挥发富集

罗虹霖,刘 维,覃文庆,刘瑞增,郑永兴,杨 康,韩俊伟

(中南大学 资源加工与生物工程学院,长沙 410083)

摘 要:针对含多种有价金属的还原挥发氧化锌烟尘,对各元素的挥发特性进行热力学平衡计算、实验室回转窑挥发和中试试验,验证铟镉铅选择性挥发效果,获得高铟物料和脱除氟氯的高锌焙砂的工艺路线。在实验室回转窑中,铟和铅的挥发率分别为93.20%和95.12%,同时,得到含锌67.36%、含氟0.013%和氯0.407%的焙砂。在中试试验中,挥发产物中铟的平均含量超过700g/t,较原料富集比超过2倍,铅的平均挥发率达到98.94%,焙砂中平均锌含量为64.16%,锌焙砂中氟和氯的含量分别降到了0.013%和0.211%,这说明从氧化锌烟尘中分离铟并获得可以满足电解锌要求的焙砂的挥发效果非常显著。

关键词:烟尘;氧化锌;铟;挥发

中图分类号:TD953;TD982;TF111 文献标志码:A

Volatilization of indium from zinc oxide fly ash

LUO Hong-lin, LIU Wei, QIN Wen-qing, LIU Rui-zeng, ZHENG Yong-xing, YANG Kang, HAN Jun-wei

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: On the basis of zinc oxide fly ash bearing multiple valuable metals,thermodynamic equilibrium calculations, laboratory-scale rotary furnace volatilized experiments and pilot test concerning the volatilization of the metals Pb, Zn, In and Cd were carried out, which verified the processing route at the zinc oxide fly ash by selective volatilization of In, Cd and Pb to yield a high-In volatilized product and a high-Zn and removal fluorine and chlorine roasted product. In the laboratory-scale rotary furnace experiments, the volatilization rates of In and Pb are 93.20% and 95.12%, respectively, and the roasted product contains Zn 67.36%, F 0.013% and Cl 0.407%. In the pilot test, the volatilized product contains In more than 700 g/t, which enriches more than two times comparing with the fly ash, the volatilization rate of Pb is 98.94%, and the roasted product contains Zn 64.16%, F 0.013% and Cl 0.211%. The route have a prominent effect on separation In from zinc oxide fly ash, and the roasted product can completely meet the requirements of electrolytic zinc route.

Key words: fly ash; zinc oxide; indium; volatilization

我国是世界最大的铅生产国和消费国[1],同时也是世界最大的锌生产国和消费国[2]。在铅熔炼过程中,铟几乎平均分配于粗铅、炉渣和烟灰中。粗铅火法精炼熔析除铜时,粗铅中的铟大部分进入铜浮渣,用苏打-铁屑法在反射炉处理时,绝大部分铟挥发随烟气进入收尘系统。炉渣烟化处理时铟随锌进入烟尘中,因而铅冶炼过程绝大部分铟都最终富集于含铟氧化锌烟尘中。在湿法炼锌中,当锌精矿进行焙烧时,由于矿石中的铟被氧化成难挥发的氧化铟,故矿石中95%以上的铟留在焙砂中。而采用常规浸出时,80%~100%的铟留在浸出渣中。而采用回转窑挥发处理含铟渣时,有60%~70%的铟进入氧化锌烟尘中[3-4]。

从氧化锌中提取铟的过程污染非常严重[3-13]。一般采用硫酸浸出-P204萃取-盐酸反萃-锌置换流程从氧化锌中提取铟,该方法流程简单、操作容易,但由于氧化锌中铟含量往往很低,提铟过程需要溶解大量氧化锌,制备铟浓度不高的硫酸锌溶液,然后直接从溶液中萃取回收铟,该过程溶液处理量大、铟回收率低、萃取剂消耗大、最终生成成本很难有效控制。含铟萃余液为高氟氯硫酸锌溶液,还含有一定量的铜、镉等重金属离子,由于溶液中含有大量氟氯离子[14-18],硫酸锌溶液不能返回作为生产电解锌之用,最多只能用于结晶硫酸锌,产品市场和价值非常有限,不能大宗消耗次氧化锌;很多企业直接将萃余液中和沉淀后排放水,导致重金属污染非常严重。

本文作者提出在氧化锌烟尘中分离铟镉铅等有价资源,使其充分富集,并同时脱除氧化锌中的氟氯,使氧化锌焙砂达到电解锌要求,大大提高铟提取效率和降低溶液处理量进而减少排放,还可以将氧化锌烟尘中锌资源有效利用,提高其经济效益。

1 实验

1.1 原料及设备

1.1.1 试验原料

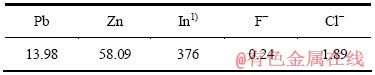

本试验所用原料为河南某厂铅冶炼渣回转窑挥发所得氧化锌烟尘,其主要成分如表1所列。从表1可以看出,锌烟灰成分复杂,氟和氯的含量很高,其主要物种为ZnO、PbO、In2O3、CdO、ZnX2、PbX2、InX3和CdX2(X为F和Cl)等。

1.1.2 试验设备

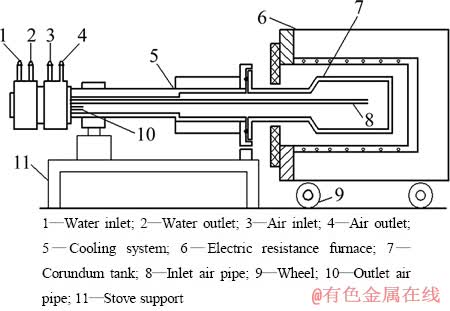

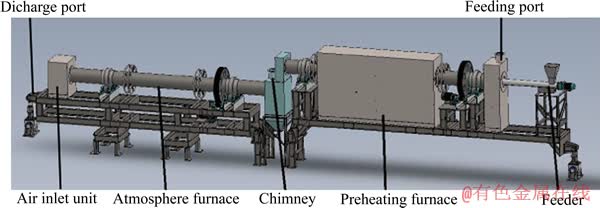

实验室挥发试验所用的设备为自制的密闭间断式回转窑(其示意图见图1),主要由电阻炉、刚玉罐、循环水冷系统、转动轮和进气管及出气管组成。焙烧样品在刚玉罐内进行反应,采用电阻炉加热,炉内温度通过热电偶测量,水冷系统的作用是控制非加热部分炉体的温度,转动轮配有调速装置,可以调节回转窑的转速。中试所用设备为自制焙烧炉设备(其示意图如图2所示),主要由两段组成,前段为电加热区,可以快速将物料加热至反应所需的温度;后段为煤气加热区,可以通过煤气燃烧来获得热量和反应所需的气氛。

表1 锌烟灰化学成分

Table 1 Chemical composition of zinc oxide fume dusts sample (mass fraction,%)

图1 密闭间断式回转窑示意图

Fig. 1 Schematic diagram of airtight intermittent rotary kiln

1.2 方法

1.2.1 热力学计算

图2 焙烧炉示意图

Fig. 2 Schematic diagram of roasted furnace

本研究中计算热力学平衡组分随温度变化规律[17-18],原料氧化物(单独计算氟氯化物的挥发性时用元素的氟氯化合物)含有金属元素锌、铅、铟和镉10 mol,氯化物(HCl、Cl2、CaCl2、MgCl2和NaCl)含有氯元素500 mol,反应气氛模拟空气(8 kmol N2和2 kmol O2),计算挥发物中金属元素摩尔量与原料中对应金属元素摩尔量比,即为该元素随温度变化的挥发率。

1.2.2 实验室挥发试验

称取一定量的氧化锌烟尘放入回转窑中,升温至设定温度后,通入气氛气体(CO、CO2或空气),恒温焙烧一定时间后,停止通入气氛气体,同时停止加热,在N2保护下冷却后取出样品,即得挥发产物,挥发产物通过化学分析各元素含量,计算挥发率。

1.2.3 挥发中试试验

在500 t/a的中试生产线上,按200 kg/h进料速度累计连续运行32 d,共处理料球104 t,将原料、烟道烟灰、布袋烟灰以及焙砂成分分别进行化学分析,计算各元素挥发率和分布。

2 结果与分析

2.1 挥发热力学平衡计算

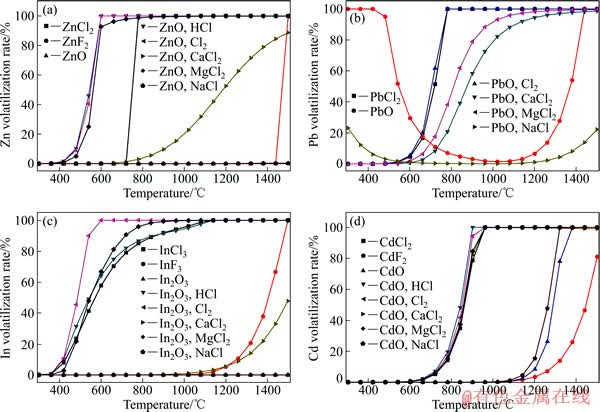

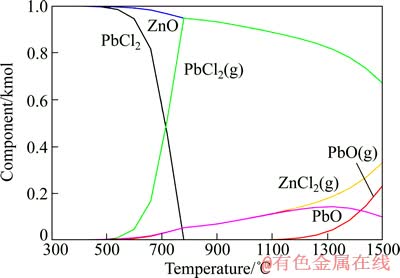

锌铅铟镉氟氯化物及其氧化物与氯化物在空气中的挥发热力学计算如图3所示。ZnO在空气中加热几乎不发生挥发。ZnO与HCl、Cl2以及MgCl2在400 ℃时发生反应,生成ZnCl2并开始挥发;到600 ℃时,挥发完全,而ZnCl2单独在空气中700 ℃时才开始挥发,到800 ℃时可以挥发完全。ZnO加入CaCl2后在空气中600 ℃左右时开始反应生成ZnCl2并挥发,到1500 ℃时可挥发锌85%。ZnF2在空气条件下要在1400 ℃以上才能挥发,到1500 ℃可以实现完全挥发,以NaCl形式加入氯化剂在空气中不能使ZnO发生氯化反应。

PbO在低温条件下可以实现完全挥发,主要是低温条件下PbO在空气中会转化为Pb2O3发生挥发,到1000 ℃时无Pb2O3存在,以PbO形式发生挥发,在低温条件下加入NaCl后发生铅的挥发也是由Pb2O3的生成而引起的,但在1200 ℃时PbO能与NaCl发生氯化反应生成PbCl2进行挥发。Cl2、CaCl2和MgCl2氯化剂的加入,均能在500 ℃前与PbO发生氯化反应,生成PbCl2并进行挥发,Cl2条件下可在720℃时实现铅的全部挥发。

InCl3具有较强的挥发性,在360℃时开始挥发,600℃时超过80%的铟发生挥发。In2O3与CaCl2约在1000 ℃时才能开始挥发,1500 ℃时,50%的铟发生挥发。In2O3在空气中不能发生挥发,加入NaCl也不能使In2O3发生氯化而进行挥发。

图3 不同条件锌铅铟镉元素挥发热力学平衡计算结果

Fig. 3 Zn, Pb, In and Cd volatilization thermodynamic equilibrium calculation results under different conditions

CdCl2具有较强的挥发性,CdCl2或加入CaCl2和MgCl2的CdO在900 ℃时能实现镉完全挥发,而CdO要在1100 ℃时才能开始挥发,在1380 ℃时可实现完全挥发。CdO能与NaCl在1100 ℃时发生氯化反应开始挥发镉,在1300 ℃时可实现镉的完全挥发。

ZnCl2与PbO在空气中的热力学组分平衡如图4所示(以1 kmol ZnCl2和1 kmol PbO为原始条件计算体系的热力学组分平衡)。由图4可知,低温时,体系中的氯化物为PbCl2;500 ℃时,PbCl2开始挥发,而ZnCl2仅有少量挥发,因此,当PbO与ZnCl2在同一体系中时,PbO会与ZnCl2发生氯化反应生成PbCl2而发生挥发,而锌的挥发量很少。

上述热力学计算表明,ZnO和PbO以及In2O3和CdO在空气中的挥发性存在显著差异,同时它们在CaCl2和MgCl2条件下的挥发也存在显著差异,且当体系中同时存在ZnCl2和PbO时,系统会生成PbCl2并挥发,实现铅与锌的分离。因此,可以实现ZnO烟尘中铟、镉和铅等有价资源的分离,使其充分富集,并同时脱除氧化锌中的氟和氯,使ZnO焙砂达到电解锌要求,同时将ZnO烟尘中锌资源有效利用,提高其经济效益。

图4 PbO与ZnCl2的平衡组分随温度的变化

Fig. 4 Change of equilibrium amounts of PbO and ZnCl2 with temperature

2.2 回转窑试验

2.2.1 挥发气氛的影响

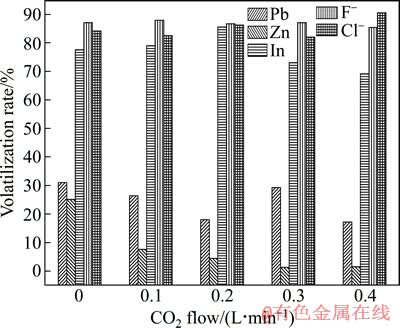

称取氧化锌烟尘60 g,在温度900 ℃条件下,挥发2 h,按各次条件调节CO与CO2流量比,通入窑内总气体流量为0.6 L/min,研究还原气氛对挥发效果的影响,结果如图5所示。

由图5可以看出,在各条件下氟、氯和铟的挥发率均超过70%,铅和锌的挥发率却不高,且随着还原性气氛的增强,锌的挥发率提高,即锌挥发加剧,而铅铟等的挥发率提高有限,因而认为还原气氛对氧化锌烟尘选择性分离铅锌影响不大。而在纯CO2的条件下,铅与锌的挥发率也未存在显著差异,不能实现铅锌分离。在还原气氛下,氧化物还原为金属,铅与锌的卤化物的蒸气压远高于其金属元素的,因此,卤化物发生挥发而对应的金属挥发量小。惰性条件下,依上述热力学计算可知ZnO与PbO在900 ℃时挥发量均很小,除了烟尘中原有的卤化铅、锌发生挥发外,其他铅、锌物质不发生挥发。因此,挥发气氛对本试验的影响不大,同时考虑到生产过程经济性和工程实现的方便性,不考虑在还原气氛或惰性气氛下进行,后续试验直接采用通入空气进行挥发。

图5 不同气氛条件下各元素的挥发率

Fig. 5 Volatilization rate of different elements in different atmospheres

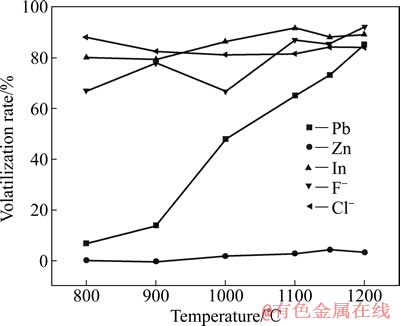

2.2.2 挥发温度的影响

称取氧化锌烟尘60 g,挥发时间2 h,通入空气流量0.6 L/min,考察不同挥发温度对各元素挥发的影响,各元素挥发率如图6所示。

由图6可以看出,锌的挥发率几乎维持为0,即氧化锌烟尘中锌在空气条件下温度对锌的挥发没有影响。随着温度的升高,铅、铟挥发率显著提高,在1200 ℃条件下,挥发率均超过80%,并且氟氯的挥发率也均超过80%。在挥发热力学计算中,PbO随着温度的升高,其挥发量增大,在理论上PbO可在1300 ℃时达到完全挥发,同时,烟尘中ZnCl2会与PbO发生反应而生成PbCl2,这样更加抑制了锌的挥发而加剧铅的挥发。这样可以实现,挥发富集铅,铟和脱除氧化锌中氟氯的目的,因而,操作温度可选取在大于1150 ℃。

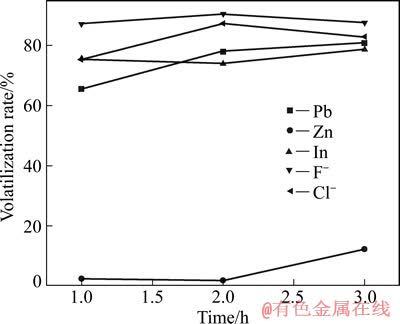

2.2.3 挥发时间的影响

称取氧化锌烟尘60 g,挥发温度1150 ℃,通入空气流量0.6 L/min,考察不同挥发时间对各元素挥发的影响,各元素挥发率如图7所示。

图6 不同温度条件下各元素的挥发率

Fig. 6 Volatilization rate of different elements at different temperatures

由图7可以看出,铅铟氟氯的挥发效率高,挥发1 h后,挥发率均超过70%;挥发2 h后,挥发率均变化不大,而锌在挥发2 h后,挥发率有所上升。这表明延长挥发时间在一定程度上可以促进铅铟的挥发和氟氯的脱除,对锌挥发的影响不大,但是在高于2 h的挥发时间后,锌的挥发率变大,其它元素挥发影响不大,考虑到生产过程经济性和处理量,选取操作挥发时间为2 h,实现铅铟的挥发和锌焙砂中氟氯的脱除。

图7 不同挥发时间各元素的挥发率

Fig. 7 Volatilization rate of different elements in different volatilization time

2.2.4 制粒对挥发的影响

考虑到氧化锌烟灰密度小、水分含量低,在生产实际中非常容易被风吹入道烟道中,从而导致烟尘率大,而铅铟镉等与锌分离效果不佳,为此,在入炉前需要将烟灰进行制粒,在实验室试验中考查不同制粒大小对各元素挥发的影响。

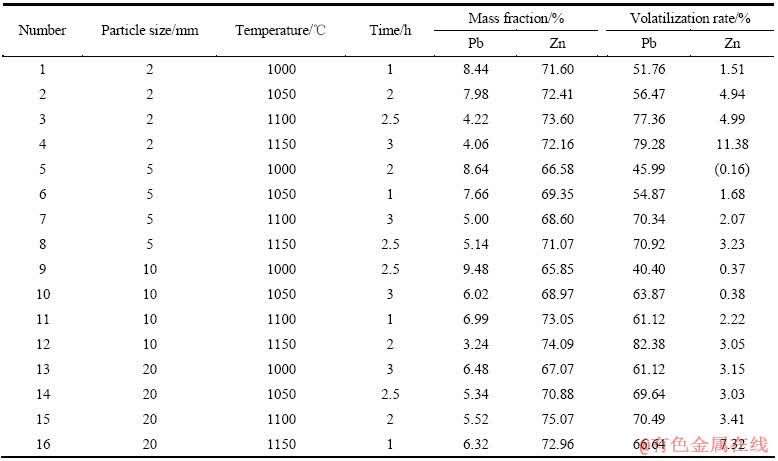

由表2可以看出,随着制球粒度的增大,相同挥发条件下铅锌的挥发率有所下降,这主要是由动力学上的反应效率所确定。在1150 ℃的空气气氛中挥发10 mm球团粒2 h,铅挥发率达到了82.28%,而锌挥发率控制在3.05%,焙砂中含铅3.24%、锌74.09%,说明通过挥发作业能够达到铅锌分离的目的,制粒后挥发影响不大。

表2 制粒挥发正交试验结果

Table 2 Experimental results of pelletized volatilization

2.2.5 氯含量的影响

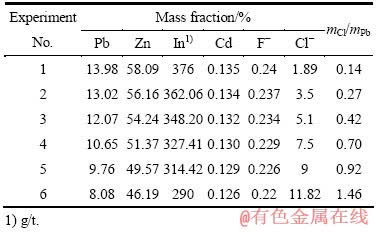

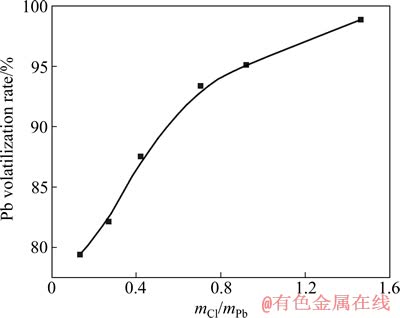

通过上述挥发热力学计算研究可以看出,由于在1150 ℃左右时PbO挥发率不大,但PbCl2的挥发率远大于PbO的挥发率,而当烟灰中氟氯含量较高时,PbO会优先与氟氯结合生成氯化铅挥发,最终可以实现铟、镉、铅的氯化挥发,而留下ZnO在焙砂中富集,为此,烟灰中的氟氯含量就成了选择性挥发的敏感条件。烟灰中氟氯含量可以通过加入氯化剂的方式来调节,但在上述热力学计算中知道,加入HCl、Cl2、CaCl2和MgCl2对铟镉铅在氧化锌的选择性氯化不强, 不利于铟、镉和铅的挥发分离,而NaCl的反应温度过高且不与In2O3发生反应,加入氯化剂也会加大氧化锌烟尘脱除氯的压力,会使氧化锌焙砂的氯升高,不利于后续锌电解。另外一种方式是可以通过不同氟氯含量的烟灰通过配料的方式来调节烟灰中氯含量,烟尘中原有ZnCl2会与PbO发生氯化反应促进铅挥发而抑制锌挥发(见图4),这样即实现了铟、镉和铅在氧化锌烟尘中的分离,也提高了铅的挥发速率。通过配料得到氯含量分别为1.89%、3.5%、5.1%、7.5%、9%和11%(质量分数)的样品6个,其主要成分如表3所列。

表3 不同氯含量试样成分

Table 3 Chemical composition of fume dust samples in different chlorine fractions

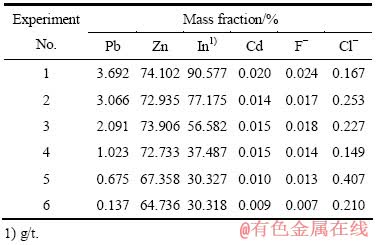

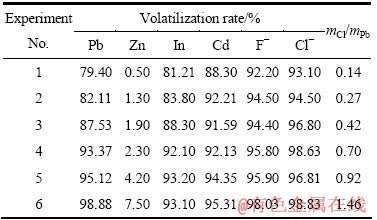

取上述成分物料各200 g,加入8%左右的水制成10 mm左右的球团,在1150 ℃下空气气氛中挥发2 h,得到挥发后的焙砂成分如表4所示,各主要成分挥发率如表5所列(mCl/mPb为氯铅质量比)。由表3~5可以看出,试样中氯含量对各元素尤其是铅的挥发率的具有非常显著影响,当氯含量升高时,各元素的挥发都显著增加,但锌的挥发率并不大,焙砂中锌得到富集,其他元素得到有效的分离。为了考察氯含量对铅挥发的影响,用试样中的氯与铅含量的比值对铅挥发率作图8。要想控制铅挥发率在95%以上,需要控制试样中氯与铅的质量比大于0.9,但氯含量也不宜过高,此时锌的挥发率会显著增大,最终会增大烟尘率,降低烟尘中铟、铅等有价金属的含量,减少焙砂中锌的回收率。

表4 不同氯含量试样挥发后焙砂成分

Table 4 Chemical composition of roasted products with different chlorine fractions

表5 不同氯含量试样中主要成分挥发率

Table 5 Volatilization rates of elements in different chlorine fractions

图8 试样中氯铅质量比对铅挥发率的影响

Fig. 8 Effect of volatilization rate of lead on mass ratios of chlorine to lead in samples

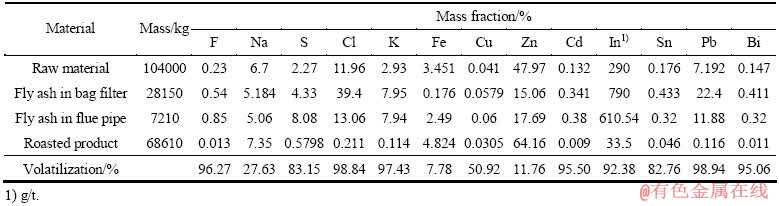

表6 中试环节各物料质量及平均成分

Table 6 Average chemical compositions and mass of pilot test products

2.3 挥发中试试验

根据实验室试验的条件要求,在中试生产线上按200 kg/h进料速度累计连续运行了32 d,共处理料球104 t,原料、烟道烟灰、布袋烟灰以及焙砂成分分别如表6所列。由表6可以看出,挥发过程平均烟尘率为34%,由于原料中氟氯含量累计超过12%,由于原料中氯与铅的质量比达到1.66,氯含量很高,氧化锌烟尘中各有价金属挥发率都很高,铟、镉、铅、锡和铋的挥发率分别达到92.38%、95.5%、98.94%、82.76%和95.06%,氟氯脱除效率也非常理想,分别达到96.27%和98.84%,锌挥发率为11.76%,但也在可以接受的范围,烟尘中铟、镉和铅等有价金属富集明显,平均铟含量超过700 g/t,富集超过2倍,为进一步回收创造了条件。挥发焙砂中F和Cl含量分别降到0.013%和0.211%,Zn含量达到了64.16%,完全可以满足电解锌的要求。

3 结论

1) 通过热力学计算,ZnO与PbO以及In2O3和CdO在空气中的挥发性存在显著差异,同时,它们在CaCl2和MgCl2条件下的挥发也存在显著差异,并且当体系中同时存在ZnCl2和PbO时,体系会首先生成PbCl2并挥发,实现铅与锌的分离。因此,氧化锌烟尘可以通过挥发,实现铟镉铅等有价资源分离,同时脱除氧化锌中氟氯元素。

2) 在实验室回转窑中,氧化锌烟尘氯铅质量比为0.92,制粒直径10 mm,挥发温度1150 ℃,空气流量0.6 L/min,挥发2 h后铟和铅的挥发率分别为93.20%和95.12%,同时得到含锌67.36%、含氟0.013%、含氯0.407%的焙砂,烟尘中的铟铅得到有效富集,焙砂中氧化锌中氟氯可得到有效脱除。

3) 在中试试验中,共处理104 t氧化锌烟尘,挥发产物中铟的平均含量超过700 g/t,较原料富集比超过2倍,铅的平均挥发率达到98.94%,焙砂中平均锌含量为64.16%,锌焙砂中的氟和氯的含量分别降到了0.013%和0.211%,效果非常显著,完全可以满足电解锌的要求。

REFERENCES

[1] 胡宇杰, 唐朝波, 唐谟堂, 杨建广, 陈永明, 杨声海, 何 静. 一种再生铅低温清洁冶金的绿色工艺[J]. 有色金属: 冶炼部分, 2013(8): 1-4.

HU Yu-jie, TANG Chao-bo, TANG Mo-tang, YANG Jian-guang, CHEN Yong-ming, YANG Sheng-hai, HE Jing. A clean and green process of low-temperature for smelting of secondary lead[J]. Nonferrous Metals: Extractive Metallurgy, 2013(8): 1-4.

[2] 廉彩会, 姜仕发, 董 凯, 赵 波. 锌浮渣处理的研究与实践[J]. 中国有色冶金, 2013(6): 23-24.

LIAN Cai-hui, JIANG Shi-fa, DONG Kai, ZHAO Bo. Research and practice of zinc dross processing[J]. China Nonferrous Metallurgy, 2013(6): 23-24.

[3] LI Xuan-hai, ZHANG Yan-juan, QIN Quan-lun, YANG Jian, WEI Yan-song. Indium recovery from zinc oxide flue dust by oxidative pressure leaching[J]. Transactions of the Nonferrous Metals Society of China, 2010, 20(S1): s141-s145.

[4] ALFANTAZI, A M, MOSKALYK, R R. Processing of indium: A review[J]. Minerals Engineering, 2003, 16(8): 687-694.

[5] ZHANG Yan-juan, LI Xuan-hai, PAN Liu-ping, WEI Yan-song. Effect of mechanical activation on extracting indium from neutral leach residue of zinc calcine[J]. Advanced Materials Research, 2011, 201/203: 1810-1815.

[6] LI Shi-qing, TANG Mo-tang, HE Jing, YANG Sheng-hai, TANG Chao-bo, CHEN Yan-ming. Extraction of indium from indium-zinc concentrates[J]. Transactions of the Nonferrous Metals Society of China, 2006, 16(6): 1448-1454.

[7] KOLEINI, S M J, MEHRPOUYA, H, SABERYAN, K, ABDOLAHI, M. Extraction of indium from zinc plant residues[J]. Minerals Engineering, 2010, 23(1): 51-53.

[8] KAZANBAEV, L A, GIRSHENGORN, A P, KOZLOV, P A, ZAGREBIN, S A, KOLESNIKOV, A V. Improvement of the processes of indium extraction from zinc solutions[J]. Tsvetnye Metally, 2005(5/6): 58-60.

[9] ZHANG, Y, LI, X, PAN, L, LIANG, X, LI, X. Studies on the kinetics of zinc and indium extraction from indium-bearing zinc ferrite[J]. Hydrometallurgy, 2010, 100(3/4): 172-176.

[10] 高照国, 曹耀华, 刘红召, 王 威. 从含铟氧化锌烟尘中回收铟[J]. 有色金属: 冶炼部分, 2012(11): 41-43.

GAO Zhao-guo, CAO Yao-hua, LIU Hong-zhao, WANG Wei. Indium recovery from indium-bearing zinc oxide dust[J]. Nonferrous Metals: Extractive Metallurgy, 2012(11): 41-43.

[11] 谢美求. 从还原挥发氧化锌烟尘中提锌、铟工艺研究[J]. 矿冶工程, 2008(2): 63-65.

XIE Mei-qiu. Study on Technique for Extracting Zinc and indium from reduction and volatilization zinc oxide dust[J]. Mining and Metallurgical Engineering, 2008(2): 63-65.

[12] 沈丽娟, 吴克明, 袁芳沁, 高耀文. 锌冶炼过程中铟的富集与回收技术研究进展[J]. 矿产综合利用, 2012(4): 3-6.

SHEN Li-juan, WU Ke-ming, YUAN Fang-qin, GAO Yao-wen. Research progress of technologies for indium recovery and pre-concentration in zinc smelting[J]. Multipurpose Utilization of Mineral Resources, 2012(4): 3-6.

[13] 伍赠玲. 铟的资源、应用与分离回收技术研究进展[J]. 铜业工程, 2011(1): 25-30.

WU Zeng-ling. Indium resources application and the studying progress of separation and recovery technology[J]. Copper Engineering, 2011(1): 25-30.

[14] 范兴祥, 汪云华, 吴跃东, 赵家春, 董海刚. 还原挥发氧化锌烟尘中有价金属分离工艺研究[J]. 无机盐工业, 2011(11): 49-50.

FAN Xing-xiang, WANG Yun-hua, WU Yue-dong, ZHAO Jia-chun, DONG Hai-gang. Research on process of separating valuable metals from zinc oxide fly ash[J]. Inorganic Chemicals Industry, 2011(11): 49-50.

[15] 李义兵, 杨 超, 王小军, 龙露珍. 氧化锌碱法脱氯工艺研究及应用[J]. 矿冶工程, 2012(5): 98-100.

LI Yi-bing, YANG Chao, WANG Xiao-jun, LONG Lu-zhen. Study and its application of zinc oxide dechlorination by alkaline process[J]. Mining and Metallurgical Engineering, 2012(5): 98-100.

[16] 王亚健, 张利波, 彭金辉, 孙成余, 罗永光, 陈 菓, 巨少华. 氧化锌烟尘脱氯技术研究进展[J]. 矿冶, 2013(2): 78-82.

WANG Ya-jian, ZHANG Li-bo, PENG Jin-hui, SUN Cheng-yu, LUO Yong-guang, CHEN Guo, JU Shao-hua. Advances in dechlorination technology of zinc oxide dust[J]. Mining and Metallurgy, 2013(2): 78-82.

[17] NOWAK, B, FRIAS ROCHA, S, ASCHENBRENNER, P, RECHBERGER, H, WINTER, F. Heavy metal removal from MSW fly ash by means of chlorination and thermal treatment: Influence of the chloride type[J]. Chemical Engineering Journal, 2012, 179: 178-185.

[18] NOWAK, B, PESSL, A, ASCHENBRENNER, P, SZENTANNAI, P, MATTENBERGER, H, RECHBERGER, H, HERMANN, L, WINTER, F. Heavy metal removal from municipal solid waste fly ash by chlorination and thermal treatment[J]. Journal of Hazardous Materials, 2010, 179(1/3): 323-331.

(编辑 龙怀中)

基金项目:国家“十二五”科技支撑计划项目(2012BAC12B04);国家自然科学基金资助项目(50830301);国家高技术研究发展计划资助项目(2011AA061001)

收稿日期:2014-04-08;修订日期:2014-09-09

通信作者:刘 维,讲师,博士;电话:13787007421;E mail:ase.6520@163.com