文章编号:1004-0609(2013)06-1507-09

挤压态7075铝合金再结晶经验模型及应用

郭海龙,孙志超,杨 合

(西北工业大学材料学院 凝固技术国家重点实验室,西安 710072)

摘 要:通过等温压缩试验和定量金相分析研究挤压态7075铝合金在变形温度为250~450℃、应变速率0.01~10 s-1下的变形行为和组织演化规律,得到不同变形条件下的真应力—应变曲线、平均晶粒尺寸、再结晶晶粒尺寸及再结晶分数。基于Yada模型通过统计回归建立挤压态7075铝合金动态再结晶经验模型并进行验证。结果表明:所建立的Yada再结晶模型误差平均值达到5%;通过二次开发实现了再结晶模型与Deform-3D软件的结合,并进行单向墩粗模拟验证,结果表明该模型预报精度较好。采用所建立的Yada再结晶模型研究7075铝合金三通件多向加载成形过程组织演化,获得加载路径对工件晶粒尺寸特征的影响规律。

关键词:7075铝合金;再结晶模型;数值模拟

中图分类号:TG302;TG146 文献标志码:A

Empirical recrystallization model and its application of as-extruded aluminum alloy 7075

GUO Hai-long, SUN Zhi-chao, YANG He

(State Key Laboratory of Solidification Processing, School of Materials Science and Engineering,

Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: Using isothermal compression test and quantitative metallographic analysis, the deformation behavior and microstructure evolution of as-extruded aluminum alloy 7075 were studied within a temperature range of 250-450 ℃ and a strain rate range of 0.01-10s-1. The true stress—strain curves, average grain size, recrystallized grain size, recrystallization volume fraction under different deformation conditions were obtained. Based on Yada recrystallization model, an empirical dynamic recrystallization model of the as-extruded aluminum alloy 7075 was established by means of statistical regression method. The results show that the average error of the model is less than 5%. Through secondary development, the established recrystallization model was implanted in the software Derform-3D, simulation validation shows that the prediction accuracy of the model can meet the requirements. Then, adopting the established model, the microstructure evolution in multi-way loading forging process of the as extruded 7075 triple valve workpiece was studied, and the grain size and distribution laws of the workpiece under the two loading paths were obtained.

Key words: 7075 aluminum alloy; recrystallization model; numerical simulation

7075铝合金是Al-Zn-Mg-Cu系可热处理强化的超硬铝合金,广泛用于航空航天、兵器、交通运输等领域高性能复杂构件的成形制造,如7075铝合金多腔阀体类和枝杈类零件[1-2]。相对于铸态合金,挤压态7075铝合金由于经过塑性变形,改善了材料的组织和原始铸造缺陷,并通过后续热成形更易于获得较高性能,因此成为制造上述构件的首选。但在7075铝合金热成形过程中材料发生一系列对变形条件十分敏感的组织演化,如回复和再结晶等,其中动态再结晶将变形晶粒彻底改组成等轴晶粒,是决定材料最终内部晶粒尺寸大小及分布的关键因素之一,从而在很大程度上决定了构件的显微组织和力学性能。因此,研究掌握动态再结晶及其影响因素对控制构件的性能十分重要。

随着计算机科学和热成形技术的不断发展,结合微观组织建模的有限元数值模拟已成为研究分析热成形过程微观组织演化的先进手段[3]。而热加工过程中材料组织演化复杂,影响因素多,如何建立精度高、可靠、简洁适用的组织模型是进行微观组织模拟分析的前提和关键。当前应用于热成形过程微观组织模拟的模型主要有经验模型、统计模型、内变量模型和直接模拟模型。上述几种建模方法,在创立之初就被限定在某一特定的空间尺寸范围内,在其特定的应用场合都能比较精确地体现微观组织特性[4]。经验模型形式相对简单,容易与有限元软件结合,求解效率高,在一定范围内有较高的精度。7075铝合金热成形温度范围狭窄,采用经验模型建模可得到较高的精度;且热加工工艺复杂,影响因素多,故综合考虑精度、效率和可靠性,本文作者拟采用经验模型中广泛应用的Yada模型建模。

国内外针对7075铝合金微观组织演化和建模已进行了大量研究,周建等[5]分析了锻造方式对7075铝合金锻件动态再结晶的影响;QUAN等[6]分析了流动应力、温度、应变与变形速率对7075铝合金动态软化的影响;ATKINSON等[7]分析了半固态7075铝合金的再结晶行为;WANG等[8]通过力学性能试验,X射线衍射和投射电子实验研究了低频电磁铸造7075铝合金的微观组织和力学性能;王煜等[9]研究了挤压态7075铝合金高温流变行为,建立了7075铝合金本构关系神经网络模型。权国政等[10]通过铸态7075铝合金的真应力—真应变曲线建立了温度、应变速率、应变量、动态再结晶体积分数之间的动态耦合关系模型;LEE等[11]研究了7075铝合金动态再结晶对温度与应变速率的依赖性,建立了本构方程;SALEHGHAFFARIDENG等[12]提出一种物理指导的数值拟合方法,提高了7075-T651铝合金BCJ塑性模型中材料参数拟合结果的准确性。但没有涉及加工过程中铝合金晶粒分布,目前,针对挤压态7075铝合金且可应用于热加工过程微观组织预报的再结晶模型的研究尚未见报道。

本文作者拟通过热模拟实验和金相分析,建立挤压态7075铝合金再结晶经验模型,将此模型与有限元软件结合,对多向加载成形7075铝合金三通件的微观组织进行模拟预测。为挤压态7075铝合金的热加工工艺优化和构件组织性能预测控制提供模型基础。

1 实验

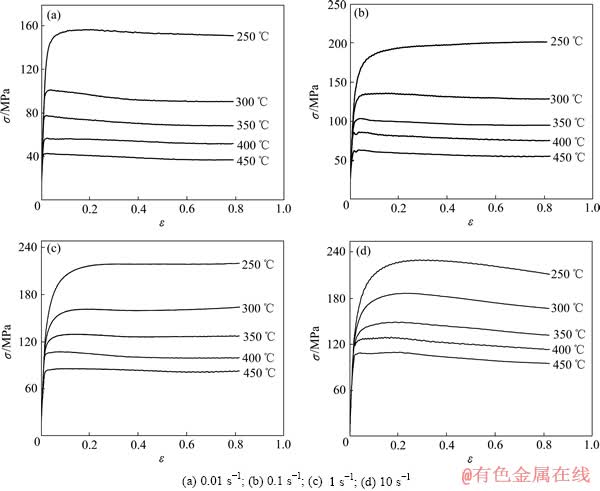

实验采用7075铝合金热挤压棒材,成分符合GB/T 3190—1996,其具体化学成分见表1[13]。

表1 7075铝合金化学成分

Table 1 Chemical composition of extruded 7075 aluminum alloy (mass fraction, %)

将原始棒料加工成d 10 mm×15 mm的压缩试样,压缩时在样品两端涂覆石墨加机油作为润滑剂,以减小样品与模具之间的摩擦,从而减小试样的不均匀变形,避免试样产生严重鼓形。具体试验方案如下:变形温度为250、300、350、400和450 ℃。应变速率为0.01、0.1、1和10 s-1。冷却方式为水冷。变形量为70%、50%和30%。

试样加热速度为10 ℃/s,加热到指定温度后保温1 min,在预定变形速率下进行压缩,变形结束后立即水淬以保留高温组织。

2 模型建立及验证

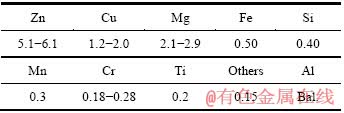

压缩试验获得的7075铝合金的真应力—应变曲线如图1所示[9]。

观察所得应力—应变曲线可知,当变形温度低于350 ℃时,7075铝合金的流变应力曲线呈动态回复 型;通过观察变形温度在350℃以上的曲线的细部特征,在应变速率为0.1 s-1、温度为400 ℃时,曲线明显降低,在高应变速率(10 s-1)条件下,流动应力出现峰值后持续下降,且没有趋于稳定,说明材料的软化程度大于加工硬化程度,即动态再结晶占据主动[13-14]。

图1 7075铝合金在不同应变速率下热压缩真应力—应变曲线

Fig. 1 True stress—strain curves of 7075 aluminum alloy under hot compression at different strain rates

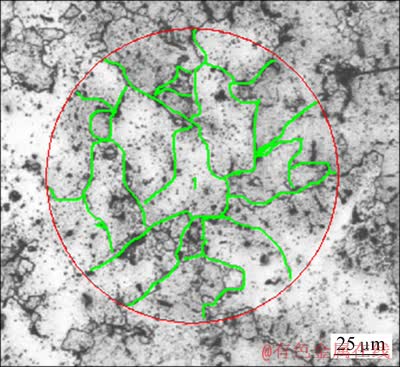

将变形后的试样沿纵截面剖开,进行金相观察和定量分析。本文作者采用面积法测定晶粒尺寸、平均晶粒尺寸、再结晶晶粒尺寸、再结晶分数。如图2所示,将已知面积的圆形测量网格置于晶粒图形上,然后计算完全落在测量网格内的晶粒数N1和被网格所切割的晶粒数N2,于是,该面积范围内的晶粒数N为

(1)

(1)

通过测量网格内晶粒数N和晶界面积A,可以计算出实际试样面上的平均晶粒直径d:

(2)

(2)

式中:N为面积范围内的晶粒数;A为使用的测量网格面积。为保证数据的准确合理,在每幅金相图不同部位测量6组数据,取平均值作为最终测量结果。表2所列为部分测量数据。

Yada模型中,材料是否发生再结晶取决于当前应变与临界应变之间的关系[15]。Yada模型表达式如下[16]:

(3)

(3)

(4)

(4)

(5)

(5)

式中: 为临界应变;

为临界应变; 为应变;

为应变; 为应变速率;T为绝对温度;R为摩尔气体常数;Xdyn为再结晶分数;

为应变速率;T为绝对温度;R为摩尔气体常数;Xdyn为再结晶分数; 为再结晶分数为50%时的应变;drex为再结晶晶粒大小;d0为原始晶粒尺寸;

为再结晶分数为50%时的应变;drex为再结晶晶粒大小;d0为原始晶粒尺寸; 为激活能;m和n为材料常数。

为激活能;m和n为材料常数。

图2 面积法晶粒尺寸测量示意图

Fig. 2 Diagram showing grain size measured by area method

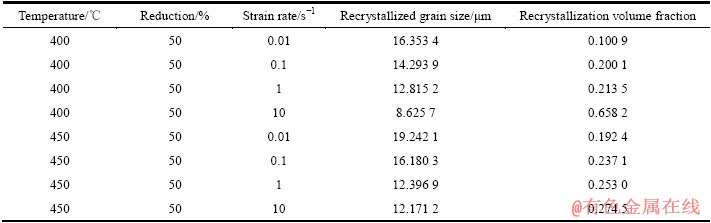

表2 400及450 ℃变形时再结晶晶粒尺寸与结晶分数测量结果

Table 2 Recrystallized grain size and recrystallization volume fraction deformed at 400 and 450 ℃

从宏观流变曲线来看,动态再结晶发生在流变应力达到峰值之前,与峰值应力对应的峰值应变是描述材料热变形过程的重要参数。以上模型中临界应变由激活能及温度决定,不同应变速率及不同温度下金属材料的 是不同的,它不仅与温度和应变速率有关,还与原始晶粒尺寸和激活能有关。在其他条件相同的情况下,金属的原始晶粒越小,则变形抗力越大,变形后储存的畸变能越高,再结晶驱动力增大,再结晶温度降低。此外,金属的原始晶粒越细小,晶界越多,变形后能提供的再结晶形核点越多,有利于再结晶。临界应变值

是不同的,它不仅与温度和应变速率有关,还与原始晶粒尺寸和激活能有关。在其他条件相同的情况下,金属的原始晶粒越小,则变形抗力越大,变形后储存的畸变能越高,再结晶驱动力增大,再结晶温度降低。此外,金属的原始晶粒越细小,晶界越多,变形后能提供的再结晶形核点越多,有利于再结晶。临界应变值 ,其中

,其中 为峰值应变(材料变形过程中峰值应力对应的应变),在一般有限元预报模型中,

为峰值应变(材料变形过程中峰值应力对应的应变),在一般有限元预报模型中, 取值为0.8,

取值为0.8, 通过下式[17]获得:

通过下式[17]获得:

(6)

(6)

再结晶晶粒大小与原始晶粒大小、变形程度、应变速率及温度相关。在本模拟中,再结晶晶粒大小(drex)通过下式[17]确定:

(7)

(7)

式中:Q1和Q2为试验拟合常数。

在热变形过程中,材料的不同部位发生加工硬化和软化程度不同,发生再结晶的程度不尽相同且会发生变动,因此,变形材料的微观组织是动态再结晶晶粒与未发生再结晶的原始晶粒共存的混晶结构。在本计算中,采用平均晶粒尺寸来反映混晶尺寸的大小,平均晶粒尺寸定义为

(8)

(8)

基于式(3)~(8),针对实验数据采用统计回归方法确定各项参数,得到的挤压态7075铝合金经验模型如下:

(9)

(9)

(10)

(10)

(11)

(11)

(12)

(12)

(13)

(13)

(14)

(14)

式中: 为峰值应变;d为平均晶粒尺寸。

为峰值应变;d为平均晶粒尺寸。

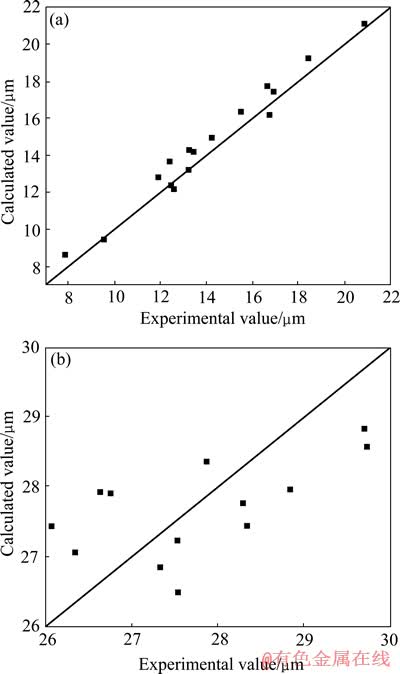

对模型自身误差进行分析,图3(a)所示为挤压态7075铝合金再结晶晶粒尺寸实测值与计算值对比结果,计算值与实测值最大误差为8.42%,最小误差为0.58%,误差平均值为4.53%。平均晶粒尺寸实测值与计算值对比如图3(b)所示,计算值与实测值最大误差为4.96%,最小误差为1. 10%,误差平均值为3.10%。

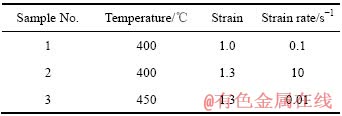

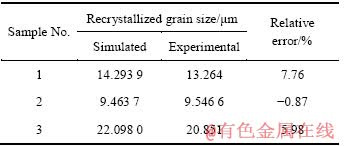

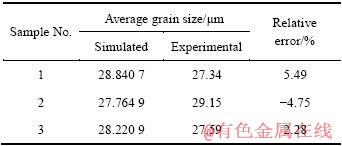

表3所列为检验样本变形条件,表4显示了检验样本再结晶晶粒尺寸预测值与实测值之间误差的情况,表5显示了检验样本平均晶粒尺寸预测值与实测值之间的误差。从表3~5中可以看出,模型自身误差与检验样本误差平均值在5%以内,此模型精度满足要求。

图3 再结晶晶粒尺寸和平均晶粒尺寸实测值与计算值对比

Fig. 3 Comparison of experimental and calculated values of recrystallized grain size(a) and average grain size(b)

表3 检验样本的变形条件

Table 3 Deformation condition of test samples

表4 检验样本再结晶晶粒尺寸模拟值与实验值对比

Table 4 Comparison of experimental and calculated values of recrystallized grain size of test samples

表5 检验样本平均晶粒尺寸模拟值与实验值对比

Table 5 Comparison of experimental and calculated values of average grain size of test samples

通过Fortran语言将挤压态7075铝合金动态再结晶经验数值模型通过对用户定义单元变量模块的二次开发嵌入到Deform-3D软件中,并通过单向热压缩试验对模型的可靠性进行验证。

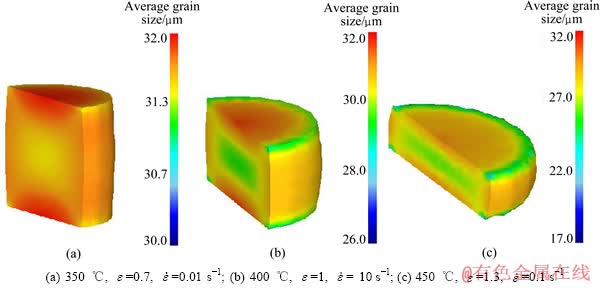

模拟选用圆柱形坯料,原始尺寸为d 10 mm×15 mm,材料为7075铝合金,上下模选用H-13热模具钢,恒温恒应变速率压缩。本文作者选取如下不同温度及应变速率下的3组工艺方案对模型进行了验证:1) 变形温度350 ℃,应变0.7,应变速率0.01 s-1;2) 变形温度400 ℃,应变1.0,应变速率10 s-1;3) 变形温度450 ℃,应变1.3,应变速率0.1 s-1。

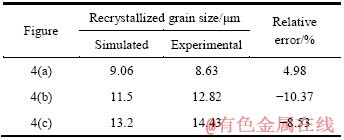

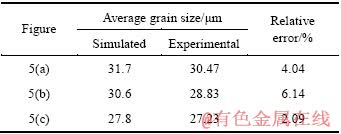

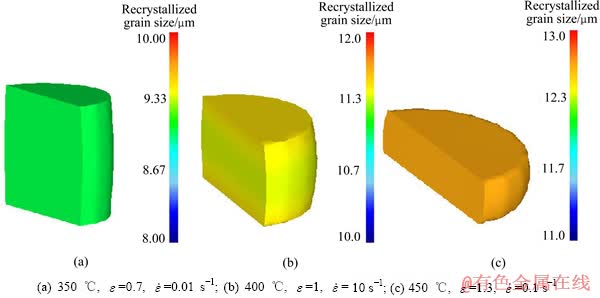

3组工艺条件下的再结晶晶粒尺寸模拟结果如图4所示,等温压缩条件下坯料应变速率相同,而且不同部位的应变非常接近,致使变形体再结晶晶粒尺寸几乎相同,与实测值比较误差见表6。平均晶粒尺寸模拟结果如图5所示,与实测值的比较误差见表7。Yada 模型与有限元软件结合后误差略有增加,可能是模拟变形环境与实验条件有一定差别所致,但能满足预测要求。

表6 图4中再结晶晶粒尺寸误差分析

Table 6 Error analysis of recrystallized grain size in Fig. 4

表7 图5中平均晶粒尺寸模拟结果误差分析

Table 7 Error analysis of average grain size in Fig. 5

图4 压缩试验再结晶晶粒尺寸模拟结果

Fig. 4 Simulation results of recrystallized grain size in compression

图5 压缩试验平均晶粒尺寸模拟结果

Fig. 5 simulation results of average grain size of simulation compress

3 再结晶模型在三通件多向加载成形中的应用

高性能7075铝合金多腔阀体类零件,如三通阀体类零件,由于易于实现装备的轻量化和高可靠性而对其需求愈来愈广泛。同时作为关键承力构件,以及其恶劣的服役环境,从而对该类构件的组织和力学性能提出了更高的要求。7075铝合金三通件成形是一个多因素耦合作用下的宏观变形和微观组织演变交互影响的复杂成形过程。该过程对变形条件十分敏感,若组织控制不当,出现粗晶等组织缺陷,将导致零件的性能极大下降,在恶劣环境中服役十分危险。因此,在前面所做工作基础上,将所建立的挤压态7075铝合金再结晶模型应用于7075铝合金三通件多向加载过程中。

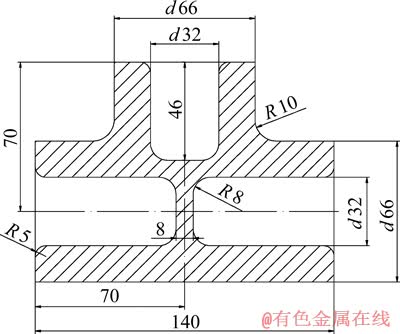

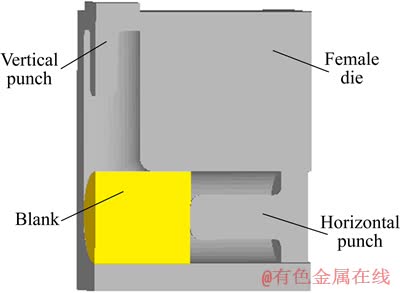

在本模拟中,所研究的等径三通件形状及尺寸如图6所示,模拟计算中材料本构模型采用文献[18]所建本构模型,坯料预热至400 ℃,模具预热至350 ℃,凸模加载速度为5 mm/s。三通件多向加载宏观有限元几何模型如图7所示。

根据文献[19]在两种加载路径下进行三通件成形模拟。

加载路径Ⅰ:分步加载,水平凸模运动至连皮位置,完毕后保持。垂直凸模向下运动,到达连皮位置后终止。

加载路径Ⅱ:同步加载,调整垂直凸模位置,使之与连皮之间距离与水平凸模与连皮距离相等。加载时,水平凸模和垂直凸模同时同速运动。开始阶段只有水平凸模加载,垂直凸模空载;随着垂直型腔里向上流动的金属与下行的垂直凸模相遇,水平凸模和垂直凸模开始共同加载,共同运动到连皮位置,加载结束。

图6 所成形三通件示意图

Fig. 6 Schematic diagram of triple valve to form (Unit: mm)

图7 三通件多向加载成形几何模型

Fig. 7 Geometric model of triple valve forming by multi-way loading

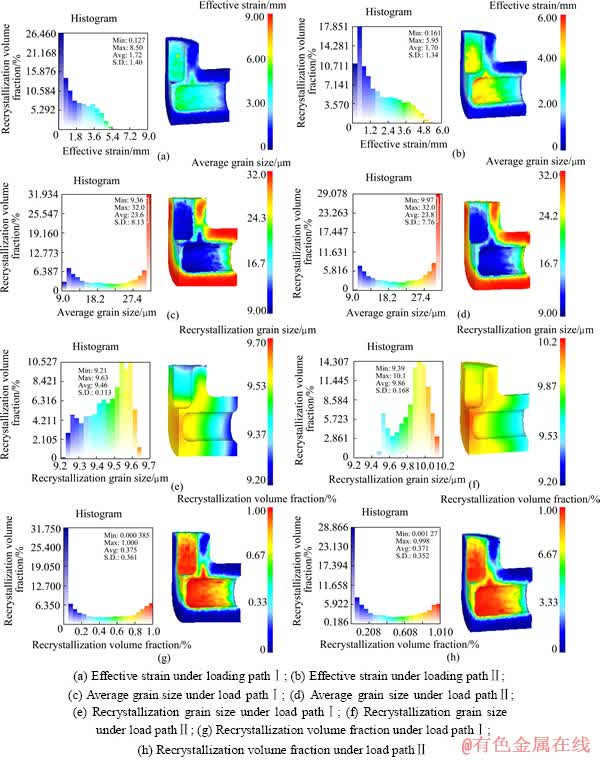

图8 两种加载路径下等效应变、平均晶粒尺寸、再结晶晶粒尺寸及再结晶体积分数模拟结果

Fig. 8 Simulation results of effective strain, average grain size, recrystallized grain size and recrystallization volume fraction under two loading paths

加载结束后,两种路径下所成形三通件等效应变、平均晶粒尺寸尺寸、再结晶晶粒尺寸、再结晶分数分布云图如图8所示。从图8可以看出,两种路径下等效应变、平均晶粒尺寸、再结晶晶粒尺寸及再结晶分数分布规律大致相同。坯料与凸模前端及圆角部位接触部分变形剧烈,等效应变较大,极易超过临界应变 ,因而大部分发生了动态再结晶,晶粒尺寸较小;工件芯部动态再结晶发生较完全,再结晶体积分数几乎为1;坯料外层区域变形较小,未发生动态再结晶。

,因而大部分发生了动态再结晶,晶粒尺寸较小;工件芯部动态再结晶发生较完全,再结晶体积分数几乎为1;坯料外层区域变形较小,未发生动态再结晶。

在同步加载路径下,坯料向垂直型腔的快速流动受到下行的垂直凸模的限制,与分步加载路径下的坯料相比应变较小。故在分步加载路径下,等效应变平均值比同步加载路径下的大,更易达到再结晶临界条件,再结晶体积分数高于同步加载路径下的再结晶分数,而晶粒尺寸平均值比同步加载路径下晶粒尺寸平均值小,采用分步加载能够成形晶粒较为细小的构件。

4 结论

1) 通过挤压态7075铝合金热压缩试验及后续金相观察获得真应力应变数据及各变形条件下晶粒尺寸、再结晶晶粒尺寸、再结晶分数等数据,建立挤压态7075铝合金再结晶经验数值模型,并将该模型嵌入到Deform-3D软件中,通过模拟热压缩试验验证了模型的可靠性。

2) 在2种加载工艺路径下对7075铝合金三通件多向加载过程进行数值模拟,结果表明成形件与凸模前端及圆角部位接触部分等效应变变形量超过临界应变,因而大部分发生了动态再结晶,晶粒尺寸较小;构件芯部动态再结晶发生较完全,再结晶分数接近于1;坯料外层区域变形较小,未发生动态再结晶;对比两种路径下模拟结果得出,分步加载路径下晶粒较为细小。

REFERENCES

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 1版. 长沙: 中南大学出版社, 1989.

WANG Zhu-tang, TIAN Rong-zhang. Aluminum alloy and its processing manual[M]. 1st ed. Changsha: Central South University of Technology Press, 1989.

[2] 张 珏. 铝合金在航空航天中的应用[J]. 铝加工, 2009(3): 50-53.

ZHANG Jue. Application of aluminum alloy to aerospace industry[J]. Aluminium Fabrication, 2009(3): 50-53.

[3] 李 峰, 林俊峰, 初冠南. 铝合金锻件成形及三维有限元分析[J]. 中国有色金属学报, 2009, 19(7): 1197-1202.

LI Feng, LIN Jun-feng, CHU Guan-nan. 3D finite element analysis and forging process of aluminum alloy forging parts[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(7): 1197-1202.

[4] 罗 姣, 李淼泉, 李 宏. 塑性变形时的微观组织模拟[J]. 材料导报, 2008, 22(3): 102-106.

LUO Jiao, LI Miao-quan, LI Hong. Microstructural simulation during plastic deformation[J]. Materials Review, 2008, 22(3): 102-106.

[5] 周 建, 赵廷杰, 张小明, 马光来, 田 锋, 周 廉. 锻造方式对7075铝合金锻件动态再结晶的影响[J]. 稀有金属材料与工程, 2004, 33(8): 827-830.

ZHOU Jian, ZHAO Ting-jie, ZHANG Xiao-ming, MA Guang-lai, TIAN Feng, ZHOU Lian. The influence of force mode on dynamic recrystallization for 7075 aluminum forging[J]. Rare Metal Materials and Engineering, 2004, 33(8): 827-830.

[6] QUAN G Z, LIU K W, ZHOU J. Dynamic softing behaviors of 7075 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(S3): s537-s541.

[7] ATKINSON H V, BURKE K, WANEETVELD G. Recrystallisation in the semi-solid state in 7075 aluminum alloy[J]. Material Science and Engineering A, 2008, 490: 266-276.

[8] WANG Gao-song, ZHAO Zhi-hao, CUI Jian-zhong, GUO Qiang. Microstructure and mechanical properties of low frequency electromagnetic casting 7075 aluminum alloy[J]. Acta Metallurgica Sinica, 2010, 25(2): 160-168.

[9] 王 煜, 孙志超, 李志颖, 杨 合. 挤压态7075铝合金高温流变行为及神经网络本构模型[J]. 中国有色金属学报, 2011, 21(11): 2880-2887.

WANG Yu, SUN Zhi-chao, LI Zhi-ying, YANG He. High temperature flow stress behavior of as-extruded 7075 aluminum alloy and neural network constitutive model[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2880-2887.

[10] 权国政, 张艳伟, 王凤标, 周一俊, 周 杰. 7075铝合金热塑性变形动态再结晶动力学模型[J]. 机械工程材料, 2011, 35(12): 97-101.

QUAB Guo-zheng, ZHANG Yan-wei, WANG Feng-biao, ZHOU Yi-jun, ZHOU Jie. Kinetics model for dynamic recrystallization of 7075 aluminum alloy in thermoplastic deformation[J]. Materials for Mechanical Engineering, 2011, 35(12): 97-101.

[11] LEE W S, SUE W C, LIN C F, WU C J. The strain rate and temperature dependence of dynamic impact properties of 7075 aluminum alloy[J]. Journal of Materials Processing Technology, 2000, 100: 116-122.

[12] SALEHGHAFFARIDENG S, RAIS-ROHANI M, MARIN E B, BAMMANN D J. A new approach for determination of material constants of internal state[J]. Computational Materials Science, 2012, 55: 237-244.

[13] 王 煜. 挤压态7075铝合金热变形及微观组织神经网络模型[D]. 西安: 西北工业大学, 2011.

WANG Yu. Hot deformation behavior of as-extruded 7075 aluminum alloy and neural network model of microstructure evolution[D]. Xi’an: Northwest Polytechnical University, 2011.

[14] 王 健. 基于流变曲线的热塑性变形过程微观组织模拟建模研究[D]. 秦皇岛: 燕山大学, 2009.

WANG Jian. Modeling research on microstructure simulation during hot plastic forming based on flow curve[D]. Qinhuangdao: Yanshan University, 2009.

[15] 吾志岗, 李德富, 郭胜利, 郭青苗, 彭海健, 胡 捷. GH625温合金动态再结晶模型研究[J]. 稀有金属材料与工程, 2012, 41(2): 235-240.

WU Zhi-gang, LI De-fu, GUO Sheng-li, GUO Qing-miao, PENG Hai-jian, HU Jie. Dynamic recrystallization models of GH625 Ni-based superalloy[J]. Rare Metal Materials and Engineering, 2012, 41(2): 235-240.

[16] YADA H. Proceedings of international symposium accelerated cooling of rolled steel[C]// Conference of Metallurgists. Canada, 1987.

[17] 崔金栋. 7050铝合金大锻件锻造工艺仿真与再结晶组织模拟[D]. 长沙: 中南大学, 2006.

CUI Jin-dong. Numerical simulation of process and recrystallization for large-sized aluminum alloy 7050 forging[D]. Changsha: Central South University, 2006.

[18] 李志颖. 7075铝合金三通阀多向加载成形开裂研究[D]. 西安: 西北工业大学, 2010.

LI Zhi-ying. Research on fracture in multi-way loading forming process of 7075 aluminum alloy tee-valve body[D]. Xi’an: Northwest Polytechnical University, 2010.

[19] 王江辉. 7075铝合金三通件多向加载成形路径研究[D]. 西安: 西北工业大学, 2012.

WANG Jiang-hui. Research on loading path in multi-way loading forming process of 7075 aluminum alloy triple valve[D]. Xi’an: Northwest Polytechnical University, 2012.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50905145,51275560);国家重点基础研究发展计划资助项目(2010CB731701);凝固技术国家重点实验室课题(59-TP-2010)

收稿日期:2012-09-24;修订日期:2012-01-14

通信作者:孙志超,教授;电话:029-88460212-802;E-mail: zcsun@nwpu.edu.cn