文章编号:1004-0609(2008)04-0577-06

O相合金Ti-22Al-25Nb固态扩散连接

邹贵生,白海林,谢二虎,吴树甲,吴爱萍,王 庆,任家烈

(清华大学 机械工程系 教育部先进成形制造重点实验室,北京 100084)

摘 要:用热-力学模拟试验机Gleeble 1500D进行O相合金Ti-22Al-25Nb的固态扩散连接。结果表明:当连接温度和连接压强分别不低于970 ℃和7 MPa以及保温时间不短于30 min时,能获得界面结合致密的接头;当连接温度高于1 000 ℃时,B2基体相明显粗化,且O相明显减少;当连接温度、压强和保温时间分别为1 020 ℃、7 MPa和30 min时,接头室温和650 ℃的拉伸强度分别为925 MPa和654 MPa;当连接温度不高于1 000 ℃的接头,拉伸断裂大部分发生在结合界面;当连接温度高于1 000 ℃时,则断裂主要发生在近界面母材中。

关键词:O相合金;扩散连接;界面结合;接头强度

中图分类号:TG 407 文献标识码:A

Solid diffusion bonding of Ti-22Al-25Nb O phase alloy

ZOU Gui-sheng, BAI Hai-lin, XIE Er-hu, WU Shu-jia, WU Ai-ping, WANG Qing, REN Jia-lie

(Department of Mechanical Engineering, Key Laboratory for Advanced Manufacturing by Materials Processing Technology, Ministry of Education of China, Tsinghua University, Beijing 100084, China)

Abstract: The solid diffusion bonding of Ti-22Al-25Nb O phase alloy was performed with a thermal-mechanical simulator Gleeble 1500D. The results show that a tight bonding interface is formed under conditions of the bonding temperature higher than 970 ℃, bonding pressure higher than 7 MPa and holding time longer than 30 min. When the bonding temperature is higher than 1 000 ℃, the interfacial matrix phase B2 is coarsened and increased, while the amount of O phase is decreased. The tensile strengths at room temperature and 650 ℃ of the joints under conditions of bonding temperature 1 020 ℃, bonding pressure 7 MPa and bonding time 30 min reach up 925 and 654 MPa, respectively. The tensile fracture of joints mostly occurs at the bonding interfaces when the bonding temperature is lower than 1 000 ℃, while the tensile fracture of joints mostly occur in base materials near the bonding interfaces when the bonding temperature is higher than 1 000 ℃.

Key words: O-phase alloy; diffusion bonding; interfacial bonding; joint strength

O相(Ti2AlNb)形成于亚稳的B2相或由有序密排六方α2相(Ti3Al相)发生小的扭转且Nb在某些点阵位置有序化得到,当Ti3Al基合金的显微结构中O相为主要组成相时,合金称为O相(或Ti2AlNb)合金[1-3]。O相合金的成分通常在Ti-(18%~30%)Al-(12.5%~30%)Nb (摩尔分数)范围并含少量V、Mo和Ta等合金元素。一般认为,当x(Nb)<25%时,在β/B2+O+α2三相区热处理得到的B2+O+α2三相合金为第一代O相合金;当x(Nb)≥25%时,在β/B2+O两相区热处理得到的B2+O双相合金为第二代O相合金。由于O相的强化作用 比α2相的明显,第二代O相合金具有更好的综合性能,特别是具有良好的室温塑性、断裂韧性、蠕变和抗氧化性能,能在600~800 ℃长时间使用、1 000 ℃以上短时间使用,是替代高温钛合金、镍基合金最具前景的轻质耐高温航空发动机材料之一[1, 3-7]。

高质量的连接技术是O相合金作为结构材料的关键,但迄今为止,关于O合金的连接技术研究还未见公开报道[8-9]。而针对在合金元素组成、力学性能方面与O相合金有一定相似性的α2合金、超α2合金和γ- TiAl合金,已有较多的焊接方法及其工艺的研究[8-10],主要有熔化焊(包括激光焊、氩弧焊、电子束焊等)[11-13]、扩散连接[14-15]、钎焊[16]、过渡液相(Transient liquid phase, TLP)扩散连接[17-19]、摩擦焊、燃烧合成连接等[8-9]。熔化焊易出现脆性组织甚至出现裂纹,钎焊接头的高温性能一般较低,摩擦焊和燃烧合成连接的研究很少,从设备要求和接头性能角度来讲,TLP扩散连接是有前景的方法,但设计和制作中间层较困 难[8, 17-19]。相对其它连接方法,固态扩散连接在制作结构简单的构件时更易获得室温和高温强度更理想的接头,且当采用超塑性成形及扩散连接组合工艺时还可以制备结构较复杂的构件[8-9, 14-15]。本文作者研究Ti-22Al-25Nb合金不加中间层的直接固态扩散连接。

1 实验

母材名义成分为Ti-22Al-25Nb(摩尔分数,%),实测为Ti-11.3Al-41.7Nb(质量分数,%),其室温组织为:一定量的颗粒状O相分布于基体相B2中,母材熔点为1 700 ℃。母材沿轧制方向的室温和650 ℃的平均拉伸强度分别为1 096 MPa和809 MPa。沿轧制方向将待连接母材制作成圆片或圆棒,其中用于接头界面结合研究的母材尺寸为d8 mm×5 mm;用于接头拉伸强度测试的母材直径为8 mm,长度为32~35 mm。连接前对待焊表面依次用200#到2000#砂纸水磨,将磨好的试样放入丙酮中进行超声波清洗、烘干、保存备用。

固态扩散连接实验采用高性能动态-热力学模拟试验机Gleeble 1500D。在连接过程中,真空度可达到10-3 Pa量级;加热通过对试样直接通电流来实现,升温速率控制为4 ℃/s。试样保温结束后,停止加 热,试样在保温温度(θB)和700 ℃之间的自然冷却,速率从27 ℃/s开始基本以线性速度下降到7 ℃/s。

母材和接头拉伸强度测试采用直径为5 mm的标准试样,测试也在试验机Gleeble 1500D上进行,测试时,静载拉伸位移速率为1 mm/min,其中在650 ℃高温强度测试时,试样在650 ℃保温5 min后再加载。显微组织分析采用扫描电镜(SEM)及其配置的能谱仪(EDS)和X射线衍射(XRD)分析仪。

2 结果与讨论

2.1 连接工艺对接头界面结合与母材组织的影响

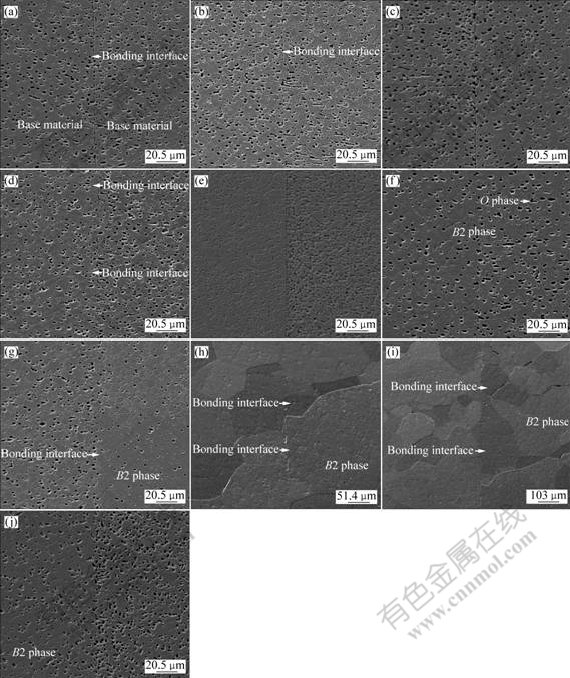

一般情况下,决定固态扩散连接质量的主要工艺参数为连接压强(pB)、连接温度(θB)和保温时间(tB)。金属固态扩散连接时,为确保两个待焊面能有足够的原子扩散通道进行互扩散、回复、再结晶从而形成冶金结合,必须施加足够的连接压强,促使待焊面的微观凸起处产生充分的塑性变形以实现大部分待焊面的微观接触。当pB偏低时,待焊面附近的塑性变形不足,一方面微观上实际接触面积偏少;另一方面晶格畸变、空位及位错等缺陷相对较少,界面激活不充分,不利于原子扩散以促进回复和再结晶。针对O相合金Ti-22Al-25Nb扩散连接,当θB=970 ℃,tB=30 min,在连接压强为2 MPa和5 MPa条件下,接头还保持了初始接触界面的痕迹(见图1(a)和(b));当连接压强达到7 MPa时,初始接触界面塑性变形充分,形成了基本无界面痕迹的接头(见图1(f))。同样,当θB偏低时,原子活性不高、扩散慢,或tB偏短时再结晶不能充分完成,这两种情况也不利于形成无初始接触界面痕迹的接头(见图1(c)、(d)和(e))。

图1 连接参数对接头界面结合及其组织的影响

Fig.1 Effects of bonding parameters on interfacial bonding and microstructures of joints: (a) 970 ℃, 30 min, 2 MPa; (b) 970 ℃, 30 min, 5 MPa; (c) 940 ℃, 30 min, 7 MPa; (d) 960 ℃, 30 min, 7 MPa; (e) 970 ℃, 15 min, 7 MPa; (f) 970 ℃, 30 min, 7 MPa; (g) 990 ℃, 30 min, 7 MPa; (h) 1 000 ℃, 30 min, 7 MPa; (i) 1 020 ℃, 30 min, 7 MPa; (j) 970 ℃, 90 min, 7 MPa

由图1(a)~(f)可知,当θB>970 ℃、pB>7 MPa以及tB>30 min时,合金Ti-22Al-25Nb能实现良好的界面冶金结合,即发生了穿越初始接触界面的晶粒生长(再结晶),初始界面基本消失,且母材组织无明显变化;但当θB达到990 ℃时,界面附近母材已出现部分基体相B2发生粗化和O相减少的迹象(见图1(g)右下部);当θB≥1 000 ℃时,母材基体B2相明显粗化、增多,而强化相O相明显减少并变小,且无初始界面痕迹(见图1(h)和(i))。上述接头组织特征的原因分析如下:根据Ti3Al-Nb伪二元相图[17],在平衡状态下,Ti-22Al-25Nb合金在θB=990 ℃时处于B2+O双相区且非常接近B2单相区,而当θB=1 000 ℃时处于B2单相区。因此,当待焊试样加热到连接温度990 ℃时,O相向B2相溶解,B2相逐渐增多,同时,因轧制而形成的B2相长条本身也会在连接温度下发生再结晶并逐步粗化。保温结束后,试样停止加热,冷却快,原子来不及充分扩散,B2相转变成O相的量相对于已溶解的O相要少。

另外,由于结合界面显微结构总是存在一定的不均匀性,畸变程度大的局部区域优先发生O相溶解和B2相粗化,在保温时间较短(如30 min)的情况下,只有部分结合界面区域的母材发生上述明显变化。而当连接温度进一步提高到1 000 ℃时,在保温条件下,原子扩散速度提高,更多的初始O相快速转变为高温B2相,同时B2相迅速长大,保温结束后,粗大的高温B2相在快速冷却条件下来不及发生平衡相变而保留到室温。与θB的影响对比,在本研究的连接参数范围内,tB的延长对母材组织尺寸的影响不明显(见图1(j))。

2.2 工艺参数对接头强度及其断裂特征的性能

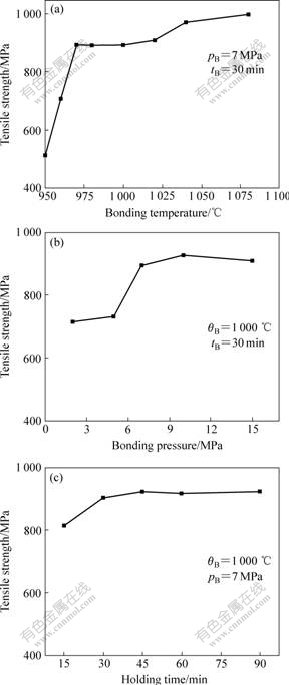

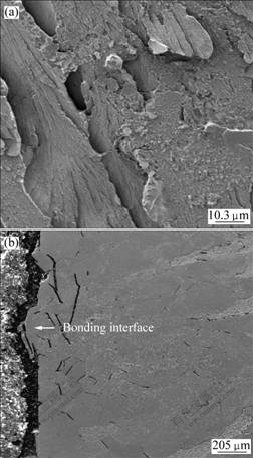

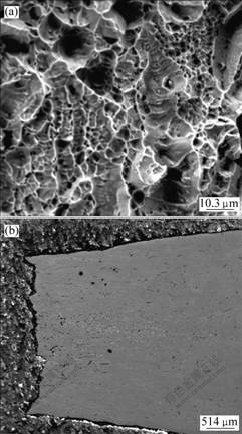

连接温度、压强和保温时间对接头室温拉伸强度的影响如图2所示。由图2(a)可知,其它参数不变,当连接温度在940~970 ℃范围时,接头强度随连接温度的升高迅速增加;而当连接温度高于970 ℃时,接头强度有一定程度地提高,但不明显。虽然连接温度高于1 000 ℃时,B2相明显粗化和增多,而O相明显减少,但接头强度并未下降。分析认为,B2相基体本身具有良好的室温强度和塑性,因此,连接温度的提高导致其尺寸增大的结果并不能明显影响其力学性能,相应地,反而会提高接头的界面冶金结合,从而一定程度地提高了接头强度。SEM分析发现,当pB= 7 MPa,tB=30 min时,连接温度不高于1 000 ℃的接头拉伸断裂主要发生在结合界面上并有少量发生在与结合界面相距几个晶粒大小的母材中(见图3),且随着连接温度的升高,断裂在界面上的概率逐渐减少,这与上述强度特征相一致。当连接温度进一步升高 时,结合界面的强度也会提高,甚至高于经过同样热循环的母材,断裂主要发生在离结合界面有一定距离的母材(近界面母材)中。同时还发现,接头在拉伸时发生了明显的塑性变形,其塑性特性比断于结合界面附近的接头更显著(见图4)。SEM和XRD分析发 现,与1 000 ℃条件下的连接相比,在1 040 ℃连接时,接头室温组织的B2相基体更大,O相甚至消失,表现出更好的塑性,且断口有明显的韧窝,这与B2相的室温良好塑性一致。针对Ti-22Al-25Nb合金的固态扩散连接,当pB=7 MPa,tB=30 min时,连接温度θB为1 020和1 080 ℃时对应的接头室温拉伸强度分别为925和1 000 MPa,分别达到原始母材强度的84%和91%,其中1 020 ℃连接温度下的接头在650 ℃高温强度为654 MPa,达到原始母材强度的81%。

图2 连接参数对接头拉伸强度的影响

Fig.2 Effects of bonding parameters on tensile strengths of joints

图3 结合界面处断裂的典型断口及断裂接头纵截面形貌

Fig.3 Typical fractograghs and longitudinal section graph of joints fracturing at bonding interfaces under condition of pB=7 MPa, θB=1 000 ℃, tB=30 min: (a) Fractograph of joint; (b) Longitudinal section micrograph of fractured joint

图4 近界面母材处断裂的典型断口及断裂接头纵截面显微形貌

Fig.4 Typical fractogragh and longitudinal section graph of joints fracturing in base material near bonding interfaces under conditions of pB=7 MPa, θB=1 040 ℃, tB=30 min: (a) Fractograph of joint; (b) Longitudinal section micrograph of fractured joint

连接条件下加压有利于界面紧密接触和界面冶金结合的形成,因此,在低连接压强范围内,接头强度偏低,拉伸断裂发生在结合界面;随着连接压力的提高,接头强度不断提高。但当压强提高到一定值后,对界面结合的促进作用不再明显增加,因此,接头的强度变化不大(见图2(b))。同样,短保温时间不利于界面的冶金结合,接头强度偏低,拉伸断裂发生在结合界面,且随着保温时间的延长,接头强度提高;但当连接温度偏高(如1 000 ℃)时,保温时间的延长对接头强度的影响不大(见图2(c))。

另外,当pB、θB以及tB值增大时,接头的变形量逐渐增加,例如当pB=7 MPa,tB=30 min时,连接温度为940、970、990、1 020和1 040 ℃对应的接头变形程度分别为1.3%、1.6%、2.2%、3.0%和3.2%;当θB=970 ℃,tB=30 min时,连接压强分别为2、5、7和10 MPa对应的接头变形程度分别为0.7%、1.5%、1.6%和3.2%;当pB=7 MPa,θB =970 ℃时,连接时间为15、30、45、60和90 min的接头变形程度分别为1.0%、1.6%、1.9%、2.5%和3.1%,因此,连接参数增大不利于实际结构件精度的控制,为此,在满足接头强度要求的情况下,应尽量减小连接参数值。

3 结论

1) 增大连接压强、提高连接温度以及延长保温时间有利于界面冶金结合,但也会增大接头的变形量。同时,当连接温度等于或高于1 000 ℃时会增大B2相基体的尺寸和减少第二相O相的数量;当连接温度和连接压强分别不低于970 ℃和7 MPa以及保温时间不短于30 min时,能获得结合致密的界面。

2) 当pB=7 MPa,tB=30 min,连接温度为940~ 970 ℃时,接头强度随连接温度的升高显著增加;而当连接温度为970~1 080 ℃时,接头强度随连接温度的升高增加不明显;连接温度为1 020和1 080 ℃对应的接头室温拉伸强度分别为925和1 000 MPa,分别达到原始母材强度的84%和91%,其中1 020 ℃连接温度下的接头650 ℃高温强度为654 MPa,达到原始母材强度的81%。

3) 连接温度不高于1 000 ℃的接头拉伸断裂发生在结合界面及离界面只有一至几个晶粒尺寸的母材中;当连接温度高于1 000 ℃时,则断裂发生在离结合界面一定距离的母材中。

REFERENCES

[1] 司玉锋, 孟丽华, 陈玉勇. Ti2AlNb合金的研究进展[J]. 宇航材料工艺, 2006, 36(3): 10-25.

SI Yu-feng, MENG Li-hua, CHEN Yu-yong. Research development of Ti2AlNb-based alloy[J]. Aerospace Materials and Technology, 2006, 36(3): 10-25.

[2] LI Shi-qiong, MAO Yong, ZHANG Jian-wei. Effect of microstructure on tensile properties and fracture behavior of Intermetallic Ti2AlNb alloys[J]. Trans Nonferrous Met Soc China, 2002, 12(4): 582-586.

[3] CHENG Yun-jun, LI Shi-qiong, LIANG Xiao-bo, ZHANG Jian-wei. Effect of deformed microstructure on mechanical properties of Ti-22Al-25Nb[J]. Trans Nonferrous Met Soc China, 2006, 12(4): s2058-2061.

[4] WYNICK G L, BOEHLERT C J. Electron backscattered diffraction characterization technique for analysis of a Ti2AlNb intermetallic alloy[J]. Journal of Microscopy, 2005, 219(3): 115-121.

[5] 彭继华, 李世琼, 毛 勇, 孙训方. Ta对Ti2AlNb基合金微观组织和高温性能的影响[J]. 中国有色金属学报, 2000, 10(S1): 50-54.

PENG Ji-hua, LI Shi-qiong, MAO Yong, SUN Xun-fang. Effect of Ta on microstructures and high temperature tensile properties for Ti2AlNb alloys[J]. The Chinese Journal of Nonferrous Metals Society, 2000, 10(S1): 50-54.

[6] DJANARTHANY S, VIALA J C, BOUIX J. An overview of monolithic titanium aluminide based on Ti3Al and TiAl[J]. Materials Chemistry and Physics, 2001, 72(3): 301-319.

[7] BOEHLERT C J. The effects of forging and rolling on microstructure in O+BCC Ti-Al-Nb alloys[J]. Mater Sci Eng A, 2000, 279(1/2): 118-129.

[8] 邹贵生, 白海林, 谢二虎, 宁立芹, 梁德彬. Ti3Al基合金及其与异种材料的连接研究现状[J]. 宇航材料工艺,2007, 37(1):1-5, 67.

ZOU Gui-sheng, BAI Hai-lin, XIE Er-hu, NING Li-qin, LIANG De-bin. Research development of Ti3Al-based alloys and joining them to dissimilar materials[J]. Aerospace Materials and Technology, 2007, 37(1): 1-5, 67.

[9] 刘 博, 崔约贤, 钱宗德, 杨德庄. Ti3A1-Nb基合金的焊接性研究进展[J]. 宇航材料工艺, 1997, 27(5): 1-6.

LIU Bo, CUI Yue-xian, QIAN Zong-de, YANG De-zhuang. Advances in the weldability study of Ti3Al-Nb based aluminides alloys[J]. Aerospace Materials and Technology, 1997, 27(5): 1-6.

[10] 何 鹏, 冯吉才, 韩杰才, 钱乙余. TiAl 金属间化合物及其连接技术的研究进展[J]. 焊接学报, 2002, 23(5): 91-96.

HE Peng, FENG Ji-cai, HAN Jie-cai, QIAN Yi-yu. Advances in TiAl intermetallics and its joining technology[J]. Transactions of the China Welding Institution, 2002, 23(5): 91-96.

[11] DAVID S A, HORTON J A, GOODWIN G M, PHILLIPS D H, REED R W. Weldability and microstructure of a titanium aluminide[J]. Welding Journal, 1990, 69(4): s133-s140.

[12] MARTIN G S, ALBRIGT C E, JONES T A. An evaluation of CO2 laser beam welding on a Ti3Al-Nb alloy[J]. Welding Journal, 1995, 74(2): s77-s82.

[13] WU Ai-ping, ZOU Gui-sheng, REN Jia-lie, ZHANG Hong-jun, WANG Guo-qing, LIU Xin, XIE Mei-rong. Microstructures and mechanical properties of Ti-24Al-17Nb(at%) laser beam welding joints[J]. Intermetallics, 2002, 10(7): 467-452.

[14] YI Guo, ZHU Jin-man, HE Zhi-jing, LIAN Pi-fen, WU Qing. Diffusion bonding of Ti3Al base alloy[J]. J Mater Sci Technol, 1996, 12(6): 467-469.

[15] 贺跃辉, 黄伯云, 王 彬, 刘 咏, 王健农. TiAl基合金固态焊接[J]. 金属学报, 1998, 34(11): 1167-1172.

HE Yue-hui, HUANG Bai-yun, WANG Bin, LIU Yong, WANG Jian-nong. Solid-state joining of TiAl based alloys[J]. Acta Metallurgica Sinica, 1998, 34(11): 1167-1172.

[16] HE Peng, FENG Ji-cai, ZHOU He. Microstructure and strength of brazed joints of Ti3Al-base alloy with NiCrSiB[J]. Materials Characterization, 2004, 52(4/5): 309-318.

[17] CADDEN C H, YANG N Y C, HEADLEY T H. Microstructural evolution and mechanical properties of brazed joints in Ti-13.4Al-21.2Nb[J]. Welding Journal, Welding Research Supplement, 1997, 76(8): 316s-325s.

[18] WALLIS I C, UBHI H S, BACOS M P JOSSO P, LINDQVIST J, LUNDSTROM D, WISBEY A. Brazed joints in γ TiAl sheet: microstructure and properties[J]. Intermetallics, 2004, 12(3): 303-316.

[19] LEE S J, WU S K. Infrared joining strength and interfacial microstructures of Ti-48Al-2Nb-2Cr intermetallics using Ti-15Cu-15Ni foil[J]. Intermetallics, 1999, 7(1): 11-21.

基金项目:清华大学基础研究基金资助项目(Jcqn2005011)

收稿日期:2007-08-25;修订日期:2007-11-20

通讯作者:邹贵生,教授,博士;电话:010-62794670;E-mail:zougsh@tsinghua.edu.cn

(编辑 李艳红)