文章编号:1004-0609(2011)11-2838-08

SiC涂层对C/C复合材料高温氧乙炔焰烧蚀性能影响

苏哲安, 杨 鑫, 黄启忠, 黄伯云, 李建立, 张明瑜, 谢志勇

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用化学气相反应法在C/C复合材料表面制备抗氧化SiC涂层,借助X射线衍射仪、扫描电镜及能谱等分析手段,研究涂层的结构;通过氧乙炔焰烧蚀试验考察SiC涂层对C/C复合材料高温耐烧蚀性能影响。结果表明:SiC涂层可明显提高C/C复合材料的高温短时耐烧蚀性能,经过20 s的高温氧乙炔焰烧蚀后,C/C复合材料试样的线烧蚀率和质量烧蚀率分别为13 μm/s和6.6 mg/s,SiC涂层试样的线烧蚀率和质量烧蚀率分别为22 μm/s和0.5 mg/s;在烧蚀中心区,涂层试样的烧蚀以升华分解为主,同时还伴有氧化烧蚀和微区机械剥蚀;在烧蚀过渡区,涂层的烧蚀机制以热氧化和燃气冲刷为主;而在烧蚀边缘区,涂层的烧蚀则主要表现为弱氧化烧蚀。

关键词:C/C复合材料;抗氧化涂层;SiC;氧乙炔焰烧蚀

中图分类号:TB332 文献标志码:A

Effect of SiC coating on ablation resistance of C/C composites under oxyacetylene torch flame

SU Zhe-an, YANG Xin, HUANG Qi-zhong, HUANG Bai-Yun, LI Jian-li, ZHANG Ming-yu, XIE Zhi-yong

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The anti-oxidation SiC coatings were prepared on C/C composites by the chemical vapor reaction (CVR) method. The structure of the coatings was studied by XRD, SEM and EDS analysis, and the effect of SiC coatings on ablation resistance of C/C composites was investigated by oxyacetylene torch flame test. The results show that the prepared SiC coatings can effectively improve the ablation resistance of C/C composites in short time ablation. After 20s ablation by oxyacetylene flame, the linear ablation rate and mass ablation rate of C/C composites are 13 μm/s and 6.6 mg/s, respectively while those of SiC coated C/C composites are 22 μm/s and 0.5 mg/s, respectively. In the ablation center, the ablation mechanism of the coated sample is sublimation and decomposition, combined with thermo-oxidation and mechanical denudation. In the transitional field, the ablation mechanism of the coating is controlled by thermo-oxidation and scouring. And in the ablation rim, the coating exhibits slight oxidation behavior.

Key words: C/C composites; anti-oxidation coating; SiC; oxyacetylene torch flame ablation

C/C复合材料具有良好的导电导热性、抗腐蚀性和热稳定性以及一系列优异的高温性能。它是目前最具竞争力的高温结构材料,具有广阔的应用领域。C/C复合材料优异的耐热性和耐烧蚀性,使其能在极其苛刻的高温条件下工作,如可以承受高于3 000 ℃的高温、耐热冲刷,目前它已被成功用于火箭发动机喷管、喉衬、燃烧室等构件,并显示出极大的优越性[1-4]。C/C复合材料虽然具有良好的高温耐烧蚀性能,然而极端环境中的应用需求(如高冲质比的固体火箭发动机喉衬材料、导弹鼻锥、新一代飞行器前缘部位材料等[5-7]),对C/C复合材料的抗氧化、耐烧蚀能力提出了更高的要求[8-9]。因此,为满足新一代高性能航空航天器的发展需要,必须进一步提高C/C复合材料的高温抗氧化和耐烧蚀性能。抗氧化涂层技术是提高C/C复合材料高温抗氧化、耐烧蚀性能的有效方法之一。本文作者采用化学气相反应法在C/C复合材料表面制备SiC抗氧化涂层,对制备的SiC涂层进行了微观结构分析,并研究涂层的高温氧乙炔焰烧蚀性能。

1 实验

1.1 材料的制备

C/C复合材料的预制体为宜兴天鸟高新技术有限公司生产的针刺叠层炭毡,该预制体由单层0°无纬布、网胎、90°无纬布、网胎依次循环叠加,采用带倒钩刺的针对无纬布和网胎进行针刺,针的回位使挂住的纤维以垂直于无纬布方向留在坯体内,使网胎和无纬布结合成整体,从而形成准三维的预制体结构。C/C复合材料的增密工艺主要采用化学气相沉积和树脂浸 渍-炭化工艺。化学气相沉积增密工艺以丙烯为碳源气体,氮气为载气,沉积温度为850~1 050 ℃。C/C复合材料的后期采用树脂加压浸渍-炭化增密工艺,树脂浸渍以呋喃树脂为原料,浸渍温度为180 ℃,压力为1.6 MPa;炭化温度为1 000 ℃,保温2 h。经多次浸渍-炭化增密后,最终制得的C/C复合材料密度为1.83 g/cm3。

将C/C复合材料加工成氧乙炔焰烧蚀试样尺寸,表面用600号砂纸打磨,以利于涂层的生成和增加结合强度。超声波清洗15 min后,放入干燥箱烘干待用。将Si块和SiO2粗粉置于真空感应石墨化炉中高温保温以生成Si、SiO2及SiO混合蒸气,并将其引入反应室与C/C复合材料试样反应以生成SiC涂层。具体制备工艺见文献[10]。

1.2 氧乙炔烧蚀性能测试

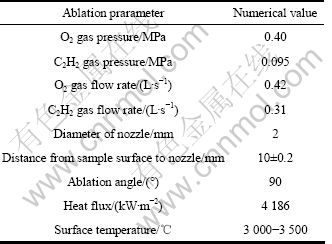

材料的烧蚀性能测试在西安航天复合材料研究所完成。氧乙炔焰烧蚀试验方法依据国家军用标准GJB323A—96进行,其测试的基本原理是:以氧乙炔焰流为热源(火焰温度最高达3 500 ℃左右),将该焰流以90?角冲刷圆形试样表面,对材料进行烧蚀。烧蚀前先点燃氧乙炔焰,并调整好烧蚀工艺参数,待氧乙炔焰稳定后,将烧蚀试样放入试样台固定夹紧。设置好烧蚀时间后,按下开始按钮,火焰喷嘴便移动到试样表面中心位置对试样进行烧蚀,烧蚀时间由系统秒表自动控制,到达设定的烧蚀时间后,火焰喷嘴便自动弹离试样表面。试验结束后,测量烧蚀前后试样厚度和质量的变化,并计算出试样的线烧蚀率和质量烧蚀率。测试试样的尺寸为d 30 mm×10 mm。氧乙炔焰烧蚀试验方法严格按照军用测试标准执行,其烧蚀试验的详细工艺参数见表1所列。

表1 氧乙炔焰烧蚀测试工艺参数

Table 1 Ablation prarameters of oxyacetylene flame test

采用X射线衍射仪分析涂层表面的相组成,利用扫描电镜(SEM)观察涂层的形貌及结构,同时采用扫描电镜配套能谱分析仪(EDS)进行微区成分分析。

2 结果与分析

2.1 SiC涂层对C/C复合材料烧蚀性能影响

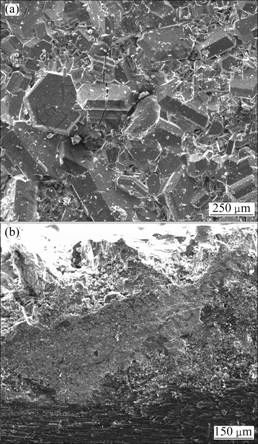

图1所示为采用化学气相反应法制备的C/C复合材料表面SiC涂层的表面及截面SEM像。由图1(a)可知,制备的涂层表面主要由颗粒较大的SiC晶粒相互紧密堆积组成,这些形状规则的SiC晶粒相互连成整体并形成了连续的SiC涂层,涂层表面虽然出现少量微裂纹但未发现明显的孔洞缺陷,说明涂层表面具有较高的致密度。另外,从图中还可以看出,采用化学气相反应法制备的SiC涂层表面SiC晶粒比较粗大,平均尺寸达到了100 μm以上,少数SiC晶粒甚至达到了400 μm。相关研究表明,高取向度的SiC大晶粒更有利于SiC涂层高温抗烧蚀性能的提高[11]。图1(b)所示为制备的SiC涂层的截面形貌图。由图1(b)可知,制备的涂层整体分布比较连续均匀,具有较大的厚度(>400 μm)。

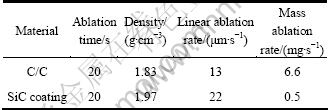

表2所列为C/C复合材料及SiC涂层试样的烧蚀性能测试结果。与C/C复合材料相比,涂层试样的密度明显提高,经过20s的氧乙炔焰烧蚀后,涂层试样的线烧蚀率稍有增大,但质量烧蚀率显著降低,与无涂层的C/C复合材料试样相比,涂层试样的质量烧蚀率降低了一个数量级,说明制备的SiC涂层具有较好的短时抗烧蚀性能。本实验制得的SiC涂层C/C复合材料氧乙炔焰烧蚀性能明显优于采用CVD工艺制备的SiC涂层C/ZrB2-SiC[12]复合材料,SiC-ZrC-SiC复合涂层C/ZrB2-SiC[12]复合材料及采用化学气相渗透法制备的三维针刺C/SiC复合材料烧蚀性能[13]。

图1 化学气相反应法制备SiC涂层表面及截面形貌

Fig.1 SEM images of surface (a) and cross-section (b) of SiC coating prepared with CVR

表2 C/C复合材料试样及SiC涂层试样的烧蚀性能

Table 2 Ablation properties of C/C composites and C/C composites with SiC coating

2.2 C/C复合材料烧蚀后的结构与形貌

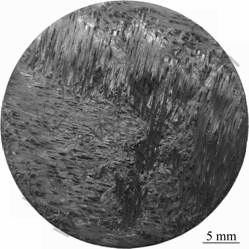

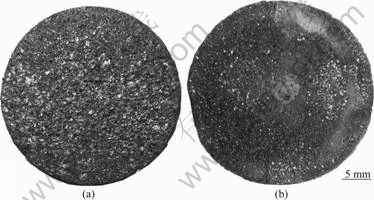

图2所示为C/C复合材料试样烧蚀后的宏观形貌。由图2可以看出,烧蚀后试样表面较粗糙,烧蚀中心区形成了明显的烧蚀凹坑,且凹坑周围存在烧蚀平台。

图2 C/C复合材料试样烧蚀后的宏观形貌

Fig.2 Macro-ablation morphology of C/C composites after oxyacetylene test

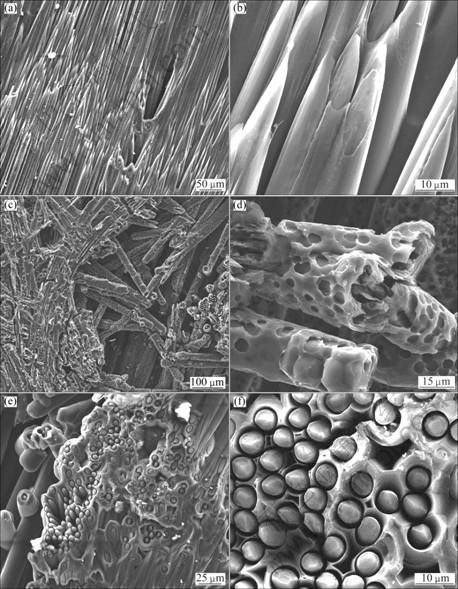

图3所示为C/C复合材料试样烧蚀中心区不同部位微观形貌。图3(a)对应为无纬布区纤维束烧蚀形貌图,从图3(a)可以明显看出,在烧蚀中心部位,无纬布中的纤维束被整齐地烧断。烧断的纤维端部呈现针尖状的结构形貌(见图3(b))。由于烧蚀过程中氧乙炔焰火焰温度未达到碳的升华温度(碳的升华温度大于 3 700 ℃),因此,烧蚀过程中C/C复合材料的烧蚀表现为高温气流氧化引起的热化学烧蚀、高速气流冲刷引起的材料剥蚀以及热应力破坏。图3(c)所示为烧蚀中心网胎区的烧蚀形貌。与无纬布区相比,网胎区结构显的较疏松,纤维之间形成了较大的烧蚀坑,这是因为,网胎区短纤维排列较乱,孔隙大,基体炭填充较多,但纤维与基体的结合力相对较弱,因此,该处力学性能薄弱,在气流剪切力和涡旋力的作用下容易发生剥蚀现象。图3(d)所示为纤维表面热解炭的氧化形貌。与炭纤维烧蚀后形成的光滑形貌不同的是,热解炭烧蚀后表面比较粗糙,存在大量的蜂窝状孔洞及层状缝隙,说明热解炭的烧蚀主要起始于热解炭层及层间存在的杂质、缺陷、界面等活性位。图3(e)所示为垂直火焰方向纤维截面的烧蚀形貌。由图3(e)可知,纤维与基体的界面结合处往往优先发生烧蚀,且在烧蚀过程中热解炭在纤维周围形成了环形的“包鞘”结构,对纤维起到了一定的保护作用。另外,从图3(e)和3(f)中还可以看出,烧蚀过程中截面处纤维头部形成了针尖及钝头状两种形貌。

2.3 SiC涂层C/C复合材料烧蚀后的结构与形貌

图4所示为C/C复合材料SiC涂层试样烧蚀前后的表面宏观形貌。由图4(a)可以看出,涂层处理后,试样表面生成了一层连续的SiC晶粒覆盖层。图4(b)所示为烧蚀后涂层试样的表面宏观形貌。从图4(b)可以看出,与C/C复合材料试样一样,烧蚀后,涂层试样中心区也形成了明显的凹坑,但凹坑的直径明显减小。而在凹坑周围,试样表面的涂层仍然完好,烧蚀过程中未发生明显的脱落、剥离痕迹,说明采用化学气相反应法制备的SiC涂层具有良好的结合性能及高温抗热震性能。按烧蚀后试样表面结构形貌特点,涂层表面可分为3个区域,即烧蚀中心区(凹坑处)、烧蚀边缘区及烧蚀中心与边缘之间的过渡区。

图3 C/C复合材料烧蚀中心区不同部位微观形貌

Fig.3 Surface morphologies of different positions of ablation center for C/C composites: (a) Nonwoven cloth; (b) Needle-shape carbon fiber heads; (c) Short-cut web; (d) Pyrolytic carbon on carbon fibers; (d) Cross-section of ablated carbon fibers; (e) Blunt carbon fiber heads

图4 C/C复合材料SiC涂层试样烧蚀前后表面宏观形貌

Fig.4 Macro-photographs of SiC coated C/C composites before and after oxyacetylene test: (a) Before ablation; (b) After ablation

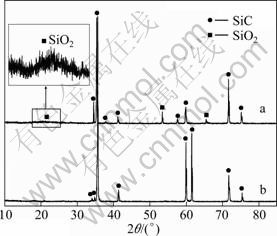

图5所示为C/C复合材料SiC涂层试样烧蚀前后的XRD谱。由烧蚀前的谱线a可知,谱线中只出现了SiC的衍射峰,未发现其他物质的衍射峰,说明制备的涂层主要由SiC相组成。与烧蚀前的谱线相比,烧蚀后的谱线b中出现了微弱的SiO2衍射峰,试样表面SiO2的生成主要与烧蚀过程中SiC涂层的氧化有关。

图5 C/C复合材料SiC涂层试样烧蚀前后的XRD谱

Fig.5 XRD patterns of SiC coated C/C composites before and after ablation: (a) Before ablation; (b) After ablation

图6所示为C/C复合材料SiC涂层试样烧蚀中心区的SEM像。在烧蚀中心(对应图4(b)中的中心凹坑处),可以发现大量的炭纤维和热解炭裸露在材料表面,试样表面原有的SiC涂层已被完全烧蚀冲刷掉,这是由于烧蚀中心对应于火焰中心,材料表面温度最高(火焰温度>3 000 ℃),而SiC的熔点为2 380 ℃,升华温度为2 700 ℃,因此,在烧蚀中心,SiC涂层处于完全升华分解状态[14];同时,在烧蚀中心,材料表面的压力最大,受到的燃气冲刷也最为严重。另外,在高温、高速的燃气流作用下,SiC涂层还会与气流中的氧化性气体发生反应(氧气与乙炔的流量比为1.35:1,火焰为氧化焰)生成大量的SiO气体或SiO2,而在高速气流的冲刷作用下,涂层表面生成的SiO2熔体很快被冲刷掉,SiC涂层直接暴露在氧化性的燃气流中,这就加速了SiC涂层的氧化损耗。由于以上因素的共同作用,在以升华分解为主的高温下,SiC的线烧蚀速率远大于炭基体,因此,在烧蚀中心区,SiC涂层的烧蚀以升华分解为主,同时还伴有氧化烧蚀和微区机械剥蚀。

图6 C/C复合材料SiC涂层试样烧蚀中心区SEM像

Fig.6 SEM images of ablation center for SiC coated C/C composites: (a) Cross-section of ablation carbon fibers; (b) Ablation carbon fibers and pyrolytic carbon

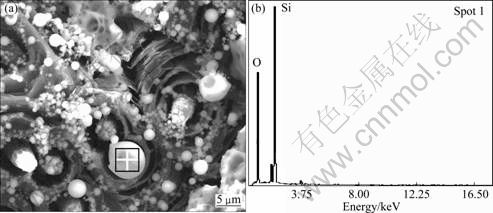

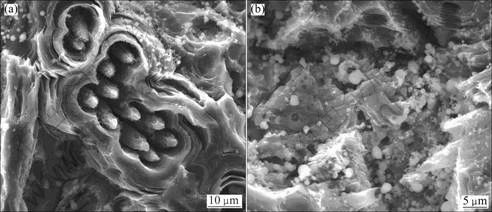

与此同时,涂层试样的中心烧蚀区还存在大量的颗粒状附着物,这些附着物应该是烧蚀过程中,SiC涂层烧蚀后所形成的残留物。图7所示为SiC涂层试样烧蚀中心区形成的颗粒状附着物形貌及能谱分析结果。从图7(a)中可以看出,这些颗粒状附着物呈规则的圆球状粘附在材料表面,且直径分布范围较广,绝大部分球体的直径在几个微米左右。由图7(b)能谱分析结果可知,白色球体主要含有Si、O两种元素,说明在烧蚀过程中,SiC发生了一定程度的氧化烧蚀,白色圆球状附着物应该为SiC氧化后形成的SiO2。烧蚀过程中,SiO2球状颗粒的形成过程大致为:在较高的烧蚀温度下,部分SiC涂层氧化生成的熔融态SiO2在气流冲刷作用下脱离涂层并粘附在试样表面,由于液态SiO2与炭纤维及基体的润湿性较差,因此在烧蚀后的冷却降温过程中,液态SiO2在表面张力及热应力的作用下便收缩为球状颗粒[15]。

图8所示为C/C复合材料SiC涂层试样烧蚀中心区不同部位粘附的SiO2球形貌。由图8可知,SiO2球除了大量粘附于热解炭表面外(见图7(a)),还粘附在纤维表面(见图8(a)),并填充在裂纹及烧蚀形成的孔洞处(见图8(b))。由于SiO2的熔化及蒸发能吸收大量的热量,因此,粘附、填充在基体和孔洞处的SiO2球在烧蚀过程中对纤维及基体能起到一定的热烧蚀阻挡保护作用[16]。

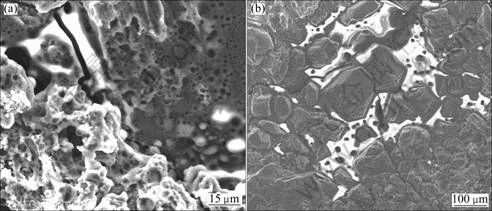

图9所示为SiC涂层试样烧蚀过渡区的SEM像。图9(a)所示为烧蚀中心区附近SiC涂层的高温烧蚀SEM像。由图9(a)可见,在靠近烧蚀中心的过渡区内,SiC涂层表面存在大量烧蚀形成的孔洞。图9(b)所示为远离烧蚀中心的过渡区涂层烧蚀SEM像。从图9(b)可以看出,在远离烧蚀中心的过渡区域内,涂层表面的SiC晶粒发生了明显的氧化现象,且在燃气流的冲刷作用下,SiC晶粒之间填充了大量的SiO2玻璃。与烧蚀中心区相比,由于到达烧蚀过渡区的火焰温度和压强都有所降低,因此涂层的烧蚀程度相对减轻。在此区域内,涂层的烧蚀机制也由烧蚀中心区的升华分解烧蚀转变为以热氧化和燃气冲刷为主。

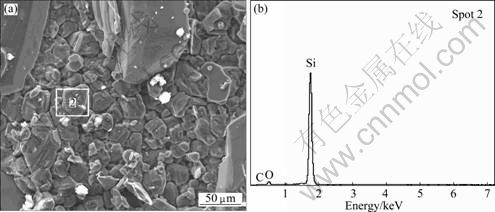

图10所示为SiC涂层试样烧蚀边缘区涂层的表面形貌及能谱分析结果。从图10(a)可以看出,在远离烧蚀中心的烧蚀边缘部位,由于火焰温度进一步降低,此区域内几乎未发生烧蚀现象,而且冲刷痕迹也不明显,虽然涂层表面形状规则的SiC晶粒尖锐的棱角部位发生了一定程度的钝化现象,但烧蚀后涂层整体形貌变化不大。能谱分析结果显示(见图10(b)),烧蚀后涂层表面的SiC晶粒含有微量的O元素,说明烧蚀过程中,烧蚀边缘区的涂层只发生了轻微的氧化现象,因此,在烧蚀边缘区域,涂层主要表现为弱氧化烧蚀。

图7 C/C复合材料SiC涂层试样烧蚀中心区形成的SiO2球形貌及能谱分析结果

Fig.7 SEM image (a) and EDS analyses (b) of SiO2 spheres formed at ablation center for SiC coated C/C composites

图8 C/C复合材料SiC涂层试样烧蚀中心区不同部位粘附的SiO2球SEM像

Fig.8 SEM images of SiO2 spheres adhered on different regions at ablation center for SiC coated C/C composites: (a) SiO2 spheres adhered on ablated carbon fibers; (b) Ablation holes filled with SiO2 spheres

图9 C/C复合材料SiC涂层试样烧蚀过渡区SEM像

Fig.9 SEM images of ablation transitional field for SiC coated C/C composites: (a) Transitional field near ablation center; (b) Transitional field far away from ablation center

图10 SiC涂层试样烧蚀边缘区涂层的表面形貌及能谱分析结果

Fig.10 SEM image (a) and EDS analysis (b) of ablation rim for SiC coated C/C composites

3 结论

1) 采用化学气相反应法在C/C复合材料表面制得了SiC涂层,涂层后C/C复合材料的高温短时耐烧蚀性能得到明显提高。经过20 s的高温氧乙炔焰烧蚀后,C/C复合材料试样的线烧蚀率和质量烧蚀率分别为13 μm/s和6.6 mg/s,SiC涂层试样的线烧蚀率和质量烧蚀率分别为22 μm/s和0.5 mg/s。

2) 受氧乙炔焰温度场及气体流场分布影响,烧蚀后,涂层试样表面按结构形貌特点可分为3个区域,即烧蚀中心区、烧蚀过渡区及烧蚀边缘区。对于烧蚀中心区,由于此区域的火焰温度最高(>3 000 ℃),因此,烧蚀过程中,涂层试样的烧蚀以升华分解烧蚀为主,同时还伴有氧化烧蚀和微区机械剥蚀;在烧蚀过渡区,随着火焰温度和压强的降低,涂层的烧蚀机制也由烧蚀中心区的升华分解烧蚀转变为以热氧化和燃气冲刷为主;在烧蚀边缘区,涂层的烧蚀则主要表现为弱氧化烧蚀。

REFERENCES

[1] VIGNOLES G L, LACHAUD J, ASPA Y, GOYH?N?CHE J M. Ablation of carbon-based materials: Multiscale roughness modeling[J]. Composites Science and Technology, 2009, 69(9): 1470-1477.

[2] SMEACETTO F, SALVO M, FERRARIS M. Oxidation protective multilayer coatings for carbon-carbon composites[J]. Carbon, 2002, 40(4): 583-587.

[3] 杨 鑫, 邹艳红, 黄启忠, 苏哲安, 王秀飞, 张明瑜. C/C复合材料MoSi2-Mo5Si3/SiC涂层的制备及组织结构[J]. 无机材料学报, 2008, 23(4): 779-783.

YANG Xin, ZOU Yan-hong, HUANG Qi-zhong, SU Zhe-an, WANG Xiu-fei, ZHANG Ming-yu. Preparation and structure of MoSi2-Mo5Si3/SiC multi-coating for carbon/carbon composites [J]. Journal of Inorganic Materials, 2008, 23(4): 779-783.

[4] YANG X, ZOU Y H, HUANG Q Z, SU Z A, ZHANG M Y, CHANG X, XIE Z Y. Influence of preparation technology on the structure and phase composition of MoSi2-Mo5Si3/SiC multi-coating for carbon/carbon composites[J]. J Mater Sci Technol, 2010, 26(2): 106-112.

[5] YANG X, HUANG Q Z, ZOU Y H, CHANG X, SU Z A, ZHANG M Y, XIE Z Y. Anti-oxidation behavior of chemical vapor reaction SiC coatings on different carbon materials at high temperatures[J]. Trans Nonferrous Met Soc China, 2009, 19(5): 1044-1050.

[6] OPEKA M M, TALMY I G, ZAYKOSKI J A. Oxidation-based materials selection for 2 000 ℃ + hypersonic aerosurfaces: Theoretical considerations and historical experience[J]. Journal of Materials Science, 2004, 39(19): 5887-5904.

[7] TONG Q F, SHI J L, SONG Y Z, GUO Q G, LIU L. Resistance to ablation of pitch-derived ZrC/C composites[J]. Carbon, 2004, 42(12/13): 2495-2500.

[8] TANG S F, DENG J Y, WANG S J, LIU W C. Comparison of thermal and ablation behaviors of C/SiC composites and C/ZrB2-SiC composites[J]. Corrosion Science, 2009, 51(1): 54-61.

[9] YIN J, ZHANG H B, XIONG X, HUANG B Y, ZOU J L. Ablation properties of carbon/carbon composites with tungsten carbide[J]. Applied Surface Science, 2009, 255(9): 5036-5040.

[10] 刘兴昉, 黄启忠, 苏哲安, 蒋建献. 化学气相反应法制备SiC涂层[J]. 硅酸盐学报, 2004, 32(7): 906-910.

LIU Xing-fang, HUANG Qi-zhong, SU Zhe-an, JIANG Jian-xian. Preparation of SiC coating by chemical vapor reaction[J]. Journal of the Chinese Ceramic Society, 2004, 32(7): 906-910.

[11] LEE Y J, JOO H J. Ablation characteristics of carbon fiber reinforced carbon (CFRC) composites in the presence of silicon carbide (SiC) coating[J]. Surface & Coatings Technology, 2004, 180/181(3): 286-289.

[12] LI H B, ZHANG L T, CHENG L F, WANG Y G. Ablation resistance of different coating structures for C/ZrB2-SiC composites under oxyacetylene torch flame[J]. Int J Appl Ceram Technol, 2009, 6(2): 145-150.

[13] 聂景江, 徐永东, 张立同, 成来飞, 马军强. 化学气相渗透法制备三维针刺C/SiC复合材料的烧蚀性能[J]. 硅酸盐学报, 2006, 34(10): 1238-1242.

NIE Jing-jiang, XU Yong-dong, ZHANG Li-tong, CHENG Lai-fei, MA Jun-qiang. Ablation properties of three dimensional needled C/SiC composites by the chemical vapor infiltration[J]. Journal of the Chinese Ceramic Society, 2006, 34(10): 1238-1242.

[14] NIE J J, XU Y D, ZHANG L T, FAN S W, XU F, CHENG L F, MA J Q, YIN X W. Microstructure, thermophysical and ablative performances of a 3D needled C/C-SiC composite[J]. Int J Appl Ceram Technol, 2010, 7(2): 197-206.

[15] 潘育松, 徐永东, 陈照峰, 成来飞, 张立同, 熊党生. 2D C/SiC复合材料烧蚀性能分析[J]. 兵器材料科学与工程, 2006, 29(1): 17-21.

PAN Yu-song, XU Yong-dong, CHEN Zhao-feng, CHENG Lai-fei, ZHANG Li-tong, XIONG Dang-sheng. Ablation properties analysis of 2D C/SiC composites[J]. Ordnance Material Science and Engineering, 2006, 29(1): 17-21.

[16] JIANG Y G, ZHANG C R, CAO F, WANG S Q, CAO Y B. Ablation property and mechanism of nitride-based ceramic composites reinforced by braided silica fibers[J]. Advanced Engineering Materials, 2007, 9(10): 921-924.

(编辑 何学锋)

基金项目:国家重点基础研究发展计划资助项目(2011CB605801);国家自然科学基金资助项目(50802115)

收稿日期:2011-01-04;修订日期:2011-03-10

通信作者:杨 鑫,博士;电话:0731-88877671;E-mail: popxin@yahoo.cn