热轧低碳钢卷取后冷却过程中三次氧化铁皮结构转变行为

曹光明,何永全,刘小江,刘振宇

(东北大学 轧制技术及连轧自动化国家重点实验室,辽宁 沈阳,110819)

摘要:采用SEM和热模拟试验机研究在卷取后连续冷却条件下、不同的卷取温度和不同冷却速度条件下低碳钢三次氧化铁皮结构转变行为。研究结果表明:在连续冷却转变过程中,FeO层的转变均遵循“C”曲线规律,400~500 ℃为FeO共析反应的“鼻温”范围,在这个温度区间内,以较小的冷速冷却到室温可以得到以共析组织Fe3O4和单质Fe为主的氧化铁皮结构,较快冷速则会抑制共析反应的发生;当冷速达到25 ℃/min时,FeO共析转变进程被抑制,氧化铁皮结构以先共析Fe3O4为主。结合连续冷却结构转变曲线,通过控制卷取温度和冷却速率,可以控制FeO的共析反应进程,从而达到精确控制氧化铁皮结构目的。

关键词:氧化铁皮;共析转变;连续冷却;卷取温度;冷却速率

中图分类号: TG335.1 文献标志码:A 文章编号:1672-7207(2014)06-1790-07

Tertiary oxide scale structure transition of low carbon steel during continuous cooling after coiling process

CAO Guangming, HE Yongquan, LIU Xiaojiang, LIU Zhenyu

(The State Key Laboratory of Rolling & Automation, Northeastern University, Shenyang 110819, China)

Abstract: The nonisothermal structure transition behavior of low carbon steels was studied by using SEM and thermal-simulator at different oxidation temperatures and cooling rate during continue cooling process after coiling process. The results show that the transformation curves for the FeO layer of them are found to be in a “C” shape and the “nose” temperature for FeO eutectoid transformation zone in the continuous cooling curve is 400-500 ℃, in the range of which the eutectoid structure (Fe3O4+Fe) is obtained at slow cooling rate. High cooling speed will inhibit the eutectoid transformation in the scale, and when the cooling rate reaches 25 ℃/min, the eutectoid transformation of the wustite layer is inhibited, and the structure of the scale in the room temperature is mainly pro-eutectoid Fe3O4. Based on the nonisothermal time-temperature-transformation curve,the eutectic reaction kinetics from FeO can be controlled by changing coiling temperature and cooling rate, and also the oxide structures are controlled.

Key words: oxide scales; eutectoid transformation; continuous cooling ;coiling temperature; cooling rate

热轧钢材表面氧化铁皮结构一般由3层铁的氧化物组成:最外层为致密柱状结晶构造的Fe2O3,呈红色;中间层是致密的Fe3O4,呈黑色;最内层靠近基体的部分是疏松多孔、易被破坏的FeO,呈蓝灰色,这些氧化物的氧含量是由外到内逐渐减小,并且外层致密,内层疏松多孔[1-3]。在热轧条件下,氧化铁皮相中的FeO具有一定的塑性,而Fe3O4和Fe2O3没有塑性。一般FeO的破坏应力约为0.4 MPa,Fe3O4的破坏应力约为40 MPa,Fe2O3的破坏应力约为10 MPa[4-5]。不同的氧化铁皮结构决定了最终产品的表面质量和表面氧化铁皮的使用性能[6-7],因此,如何通过化学成分和热轧新工艺的设计实现热轧产品表面氧化铁皮结构控制,从而满足后续加工和用户的使用要求是本文的研究目的。在热轧生产流程过程中,根据热轧过程不同的阶段将氧化铁皮分为一次、二次、三次和四次氧化铁皮[8-9]。一次和二次氧化铁皮由于生成温度较高,一般在1 000~1 250 ℃,氧化铁皮厚度较厚,在出加热炉和粗轧阶段的除鳞过程中被除去;三次氧化铁皮一般在精轧除鳞后的过程后产生,氧化铁皮厚度一般为10 μm,考虑到三次氧化铁皮生成的温度为800~1 100 ℃,结合Fe-O相图可知:其氧化铁皮结构比较简单,通常仅由最外层Fe3O4和内层大量的FeO构成。570 ℃是平衡状态下共析反应发生的温度,在570 ℃以上时,FeO/Fe平衡成分随温度变化不大,这一成分更接近于FeO共析成分;在570 ℃以上,Fe的过饱和度有限,Fe在FeO中的先共析反应不明显。相反,FeO/Fe3O4的平衡浓度随温度变化很大,1 424 ℃时摩尔分数为54.57%,570 ℃时为51.38%。随着温度降低,在FeO层会不断地析出先共析的Fe3O4[10],同时,Paidassi[11]的研究结果也表明,连续冷却过程中,在FeO层中的先共析Fe3O4的出现几乎是无法阻止的。考虑到相关温度对应于热轧卷取过程,Chen等[12]对热轧带钢卷取后氧化铁皮的结构及分布和它的形成机制进行了详细的研究,他们指出中部区域的氧化铁皮厚度与终轧温度相关,而边部区域则与卷取温度相关,并且厚度与温度均成正比。在氧元素贫乏的条件下,依靠Fe2+和Fe3+离子的扩散改变氧化层的结构,逐渐消耗Fe2O3和Fe3O4高价氧化物,最后氧化铁皮的结构一般为外层Fe3O4和内层共析组织(Fe3O4+Fe)与部分残余的Fe1-yO混合物。并将不同冷却开始温度和冷却速率下碳钢表面生成的氧化铁皮结构进行分类[13]。从生产实践来看,板带热轧过程中其三次氧化铁皮结构较为单一,基本结构以FeO为主,在后续卷取过程中,FeO在卷取过程中发生先共析或共析反应转变成α-Fe和Fe3O4的混合物形成不同结构的“四次氧化铁皮”。 因此、合理制定卷取温度及卷取后冷却速度是控制三次氧化铁皮的结构转变、获得最优表面质量的关键。到目前为止,关于带钢在卷取后冷却过程中形成的FeO在不同温度和冷却速率条件下的转变行为还缺乏系统的研究,因此,本文作者通过热模拟实验手段研究卷取温度和冷却速率对三次氧化铁皮结构演变的影响,并应用于现场实践,以便为建立合理的卷取工艺以控制氧化铁皮结构提供依据。

1 连续冷却过程氧化铁皮转变实验

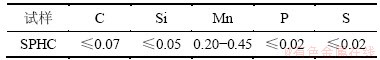

对低碳钢SPHC采用的现场三次氧化铁皮热取样,其化学成分如表1所示。将卷取后的钢卷立即开卷取样,取样后淬火至室温,保留原始的三次氧化铁皮结构,将试样切制成2 mm×10 mm×15 mm(长×宽×高),加工过程中要保持表面氧化铁皮完整,避免因机械操作造成对氧化铁皮的损伤和破坏。利用超声波清洗仪对试样表面进行清洗,然后用酒精清洗、吹干以备实验使用。钢板表面氧化铁皮的断面形貌如图1所示。从图1可见:典型的三次氧化铁皮结构保留完整,最外侧是较薄的原始Fe3O4层,内层为比较完整的FeO层,内部有极少量的先共析Fe3O4,这与文献[6]描述的一致。

表1 实验材料的化学成分 (质量分数)

Table 1 Composition of experimental steels %

图1 试验用钢的氧化铁皮结构

Fig. 1 Oxide scale structure of experimental steels

图2 模拟卷取温度和冷却速率对氧化铁皮的影响

Fig. 2 Simulated test for cooling temperature and cooling rate

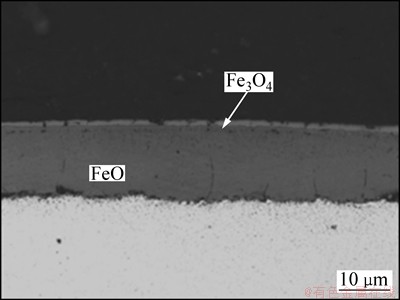

利用高温热重分析仪(TGA)研究模拟卷取温度和冷却冷率对氧化铁皮组织转变的影响。考虑到实际卷取过程后钢板处于贫氧区,因此,在整个模拟实验过程中通入氩气保护以防止三次氧化铁皮进一步氧化对共析反应造成影响。具体操作过程如下:首先,将试样悬吊于热重分析仪的加热炉内,对加热炉内腔抽真空,使试样处于真空的环境中,然后充入氩气,开始以升温速率25 ℃/min加热到1 000 ℃,使得试样中先共析Fe3O4发生逆共析反应得到原始的FeO,保证原始三次氧化铁皮和结构,然后以25 ℃/min冷却到设定的目标卷取温度。试样在设定的温度下保温5 min,使得试样表面的温度均匀,然后分别以1,5,10和25 ℃/min的冷却速率冷却至室温。实验工艺如图2所示,实验参数如表2所示。

表2 温度参数

Table 2 Parameters of temperature

2 实验结果及分析

2.1 实验结果

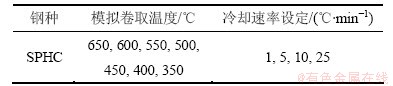

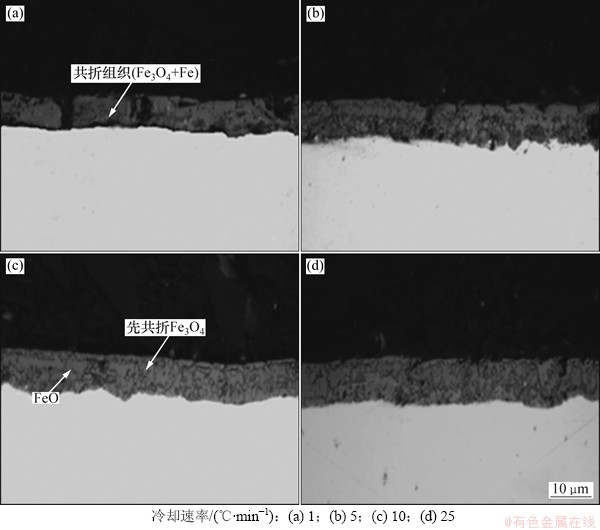

图3所示为模拟卷取温度在350 ℃时不同冷却速率的氧化铁皮的断面形貌。从图3可见:在不同的冷却速率下,生成的氧化铁皮的结构均为残留的FeO和少量先共析的Fe3O4,在这个卷取温度下,均没有共析组织生成。其主要原因是较低的温度导致离子的扩散能力减弱,Fe离子很难从过饱和的FeO析出,从而抑制了共析反应的进行,冷却到室温的组织中残留了较多的FeO。

模拟卷取温度400 ℃时不同冷却速率氧化铁皮的断面形貌如图4所示。从图4可见:当冷却速率为1,5和10 ℃/min时,钢板表面的氧化铁皮均发生了不同程度的共析转变,生成Fe3O4和Fe的共析组织。但在这个温度下,共析转变发生的并不完全,在每个冷却速率条件下,都有大量的FeO残留,并且在FeO层还同时存在先共析Fe3O4;在冷却速率为25 ℃/min时,氧化铁皮的组织只含有大量的FeO和先共析的Fe3O4。

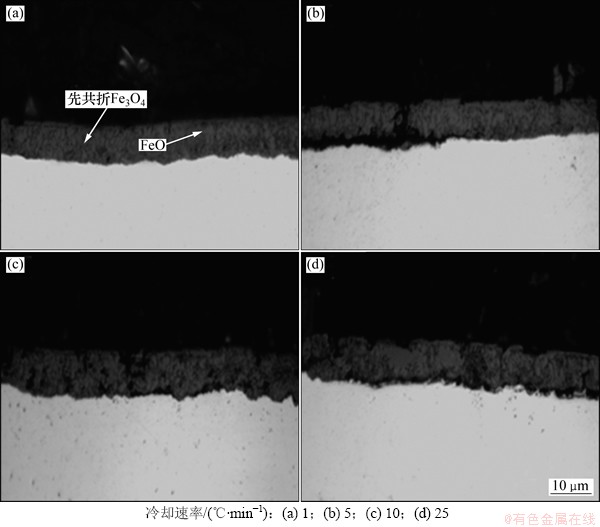

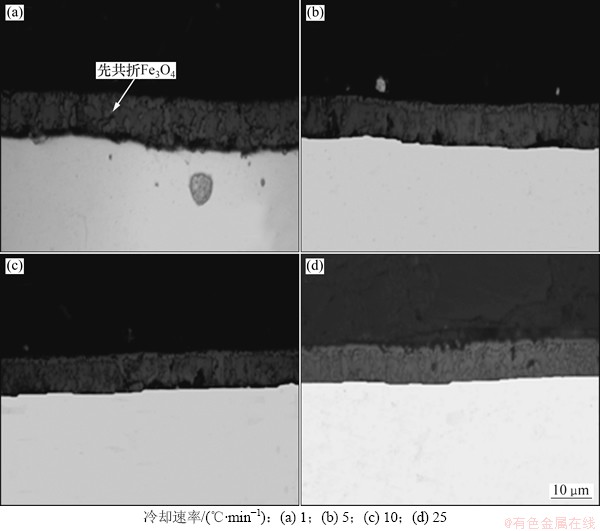

图5所示为模拟卷取温度550 ℃时不同冷却速率条件下氧化铁皮的断面形貌。从图5可见:当冷却速率为1 ℃/min时,在氧化铁皮层中出现了大量的先共析和共析组织。冷速为5 ℃/min时,只有在FeO层中的极少数位置出现了共析组织的形核点,存在大量FeO的残留;而当冷速为10和25 ℃/min时,FeO层并没有出现共析组织,只有大量的先共析的Fe3O4出现。

图6所示为模拟卷取温度为600 ℃不同冷速条件下氧化铁皮形貌。从图6可见:在4个的冷却速率下,氧化铁皮铁皮层中都没有出现共析组织Fe3O4和Fe,但在每个冷却速率下均有大量的先共析Fe3O4出现,同时650 ℃的实验结果与600 ℃时的相似。模拟卷取温度设定在共析反应温度(570 ℃)以上,在进入共析反应区间之前,FeO处于先共析区间,且随着冷却速度减小,在先共析区间停留时间延长,先共析反应越充分,当冷却速率1 ℃/min时,氧化铁皮基本以先共析Fe3O4为主。

图3 350 ℃时在不同的冷却速率下氧化铁皮的断面形貌

Fig. 3 Cross-sectional images of oxide scale at different cooling rates at 350 ℃

图4 400 ℃时在不同的冷却速率下氧化铁皮的断面形貌

Fig. 4 Cross-sectional images of oxide scale at different cooling rates at 400 ℃

图5 550 ℃时在不同的冷却速率下氧化铁皮的断面形貌

Fig. 5 Cross-sectional images of oxide scale at different cooling rates at 550 ℃

图6 600 ℃时在不同的冷却速率下氧化铁皮的断面形貌

Fig. 6 Cross-sectional images of oxide scale at different cooling rates and 600 ℃

2.2 结果分析

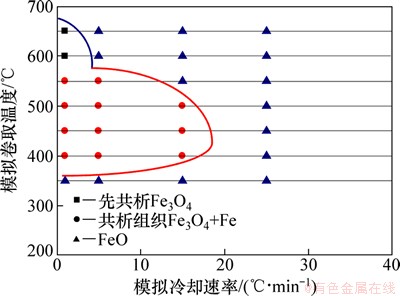

图8所示为低碳钢FeO层的等温转变“C”曲线,整个等温转变分为2个阶段,即析出先共析Fe3O4的第1阶段和后续发生的共析反应(FeO Fe+Fe3O4)阶段,450~550 ℃为FeO分解反应的“鼻尖”温度范围。相对等温转变,图7所示为SPHC钢的氧化铁皮在不同的卷取温度下,以不同的冷却速率冷到室温的连续冷却转变曲线。考虑到氧化铁皮结构转变其本质还是由离子扩散决定的,因此,其随着温度和时间的变化规律类似于等温转变的“C”曲线的规律,在连续冷却转变曲线中400~500 ℃为FeO的“鼻温”范围,将等温转变的“鼻尖”温度降低50 ℃,在这个温度段内,以较小的冷却速率冷到室温后就可以得到共析组织Fe3O4和Fe,而在较高的卷取温度如650 ℃以上,以较大的冷却速率冷却到室温可以获得先共析Fe3O4和残余FeO的组织,无共析组织产生。连续冷却的过程可以看成是无数个微小的等温过程。连续冷却转变就是在这些微小的等温过程中孕育和长大的。因此,连续冷却转变既具有等温转变的特点,但又有其自身的特点。在连续冷却转变过程中,FeO层的转变和等温转变相同,FeO的转变速率也与形核率和生长速率有关,而形核率和生长速率又取决于过冷度。随着过冷度增大,转变温度降低,Fe3O4和FeO自由能差增大,转变速率应当加快。但FeO的分解是一个扩散的过程[14],随着过冷度的增大,温度降低,FeO层中离子扩散速度显著减小,形核率和生长速率减小,所以,过冷度增大又会使转变速度减慢。因此,这2个因素综合作用的结果,导致在“鼻温”以上随着过冷度增大,转变速度增大,转变过程受新、旧两相相变自由能差所控制;在“鼻温”以下,随着过冷度增大,转变速度减慢,转变要受低温下离子扩散速度所控制,所以,在“鼻温”附近,转变速度达到1个极大值。

Fe+Fe3O4)阶段,450~550 ℃为FeO分解反应的“鼻尖”温度范围。相对等温转变,图7所示为SPHC钢的氧化铁皮在不同的卷取温度下,以不同的冷却速率冷到室温的连续冷却转变曲线。考虑到氧化铁皮结构转变其本质还是由离子扩散决定的,因此,其随着温度和时间的变化规律类似于等温转变的“C”曲线的规律,在连续冷却转变曲线中400~500 ℃为FeO的“鼻温”范围,将等温转变的“鼻尖”温度降低50 ℃,在这个温度段内,以较小的冷却速率冷到室温后就可以得到共析组织Fe3O4和Fe,而在较高的卷取温度如650 ℃以上,以较大的冷却速率冷却到室温可以获得先共析Fe3O4和残余FeO的组织,无共析组织产生。连续冷却的过程可以看成是无数个微小的等温过程。连续冷却转变就是在这些微小的等温过程中孕育和长大的。因此,连续冷却转变既具有等温转变的特点,但又有其自身的特点。在连续冷却转变过程中,FeO层的转变和等温转变相同,FeO的转变速率也与形核率和生长速率有关,而形核率和生长速率又取决于过冷度。随着过冷度增大,转变温度降低,Fe3O4和FeO自由能差增大,转变速率应当加快。但FeO的分解是一个扩散的过程[14],随着过冷度的增大,温度降低,FeO层中离子扩散速度显著减小,形核率和生长速率减小,所以,过冷度增大又会使转变速度减慢。因此,这2个因素综合作用的结果,导致在“鼻温”以上随着过冷度增大,转变速度增大,转变过程受新、旧两相相变自由能差所控制;在“鼻温”以下,随着过冷度增大,转变速度减慢,转变要受低温下离子扩散速度所控制,所以,在“鼻温”附近,转变速度达到1个极大值。

图7 FeO层的变温转变曲线

Fig. 7 Nonisothermal transformation curves for FeO

图8 FeO层的等温转变曲线[15]

Fig. 8 Isothermal transformation curves for FeO[15]

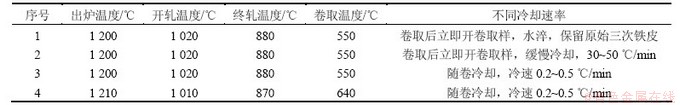

3 现场实验验证

对国内某钢厂热连轧生产线SPHC进行试轧实验,通过降低开轧温度,提高轧制速度来降低氧化铁皮厚度,结合现场实际情况,考虑到热连轧后卷重较大,很难获得较快冷速,通过设定不同卷取温度和卷取后立即开卷取样设定不同的冷却方式实现钢板表面氧化铁皮结构的控制以验证前部实验结果,具体轧制工艺参数及轧后不同冷却方式如表3所示。

结合图7和8进行不同卷取温度和冷却速度现场实验验证,调整工艺后氧化铁皮厚度分布均匀,基本控制在10 μm以下。图9所示为不同工艺条件下氧化皮的断面形貌,最外侧是较薄的原始Fe3O4层,内层为比较完整的FeO层,在FeO内部有少量的块状先共析Fe3O4,这与文献[6]中的结果完全一致。随着冷却速率的降低,块状先共析Fe3O4数量有增多的趋势(图9(b)),但考虑到工艺2冷却速率仍然超过共析组织产生的临界速率,因此,没有出现明显的共析组织。当带钢随卷冷却后,卷取温度控制在共析反应鼻温区附近,同时冷却速度极小,冷却速率为0.2~0.5 ℃/min,有利于氧化铁皮中共析反应的发生,氧化铁皮结构以共析组织Fe3O4+Fe为主。在工艺4条件下,虽然冷却速率较低,但卷取温度较高,富氧的FexO向富铁的FeyO转变(x<y),即FeO的缺陷浓度降低,这束缚了Fe离子的扩散,导致共析反应延迟,此时,氧化铁皮结构以大量的先共析Fe3O4为主。从本次现场实验也进一步验证了热轧低碳钢卷取后冷却过程中三次氧化铁皮结构转变规律。

表3 现场热轧工艺参数

Table 3 Processing parameter of hot rolling

图9 氧化铁皮的断面形貌

Fig. 9 Cross-sectional images of oxide scale

4 结论

(1) 在连续冷却条件下,冷却速度越小越利于氧化铁皮中共析反应的发生。当冷却速度为1 ℃/min,模拟卷取温度在650~350 ℃之间时,室温下氧化铁皮结构中都出现了共析组织。350 ℃卷取时,由于温度过低,离子扩散能力有限,共析反应被抵制,最后室温氧化铁皮结构中无共析物出现。

(2) 不同的冷却速度和卷取温度条件下得到的氧化铁皮类型,随着温度和时间的变化规律类似于“C”曲线的规律,其中,鼻尖温度出现在450 ℃左右。在同样的冷却速度下,450 ℃模拟卷取后,室温组织的共析反应最充分,共析组织含量最大。

(3) 当模拟卷取温度在共析反应温度以上时,由于在进入共析反应区间之前,FeO长时间停留在共析区间上方,先共析反应完成比较充分,且随着冷却速度的减小,先共析反应越充分;当冷却速率1 ℃/min时,氧化铁皮基本以先共析Fe3O4为主;随着冷却速率的增加,离子扩散速率减缓,共析反应进程减缓,当冷却速率达到或超过25 ℃/min时,共析反应基本被抑制。

参考文献:

[1] Birks N, Meier G H. Introduction to high temperature oxidation of metals[M]. London: Edward Arnold, 1983: 51-59.

[2] Vourlias G, Pistofidis N, Chrissafis K. High temperature oxidation of precipitation hardening steel[J]. Thermochimica Acta, 2008, 478(9): 28-33.

[3] Bryan A, Seetharaman S. The Effect of silicon on the high temperature oxidation behavior of low-carbon steels containing the residual elements copper and nickel[J]. ISIJ international, 2007, 47(9): 1245-1254.

[4] Bhattacharya R, Jha G, Kundu S, et al. Influence of cooling rate on the structure and formation of oxide scale in low carbon steel wire rods during hot rolling[J]. Surface and Coatings Technology, 2006, 201(1): 526-532.

[5] Lucia S, Yvan H, Xavier V E, et al, High temperature deformation of oxide scale[J]. Corrosion Science, 2009, 51(2): 309-315.

[6] Kiyoshi K, Ryoko W, Tomoharu I. High-temperature oxidation behavior and scale morphology of Si-containing steel[J]. Iron and Steel Institute of Japan (International), 2007, 47(9): 1329-1334.

[7] YANG Yuling, CHENG Hengyang, LIN Suning, et al. Effects of Si and its content on the scale formation on hot-rolled steel strips[J]. Materials Chemistry and Physics, 2008, 112(4): 566-571.

[8] Lee V H J, Gleeson B, Young D J, Scaling of carbon steel in simulated reheat furnace atmospheres[J]. Oxidation of Metals, 2007, 63(1): 15-31.

[9] Kiyoshi K, Ryoko W, Tomoharu I. High-temperature oxidation behavior and scale morphology of Si-containing steel[J]. Iron and Steel Institute of Japan (International), 2007, 47(9): 1329-1334.

[10] Chandra A S, Ieamsupapong S, Thanateponake V, et al. Effect of coiling temperature on the formation and pickling behavior of tertiary scale on hot-rolled carbon steel strip[J]. Key Engineering Materials, 2009, 410(7), 669-676.

[11] Paidassi J. The precipitation of Fe3O4 in scales formed by oxidation of iron at elevated temperature[J]. Acta Metallurgica, 1955, 3(4): 447-451.

[12] Chen R Y, Yuen W Y D. Review of the high-temperature oxidation of iron and carbon steels in air or oxygen[J]. Oxidation of Metals, 2003, 59(5/6): 433-468.

[13] Chen R Y, Yuen W Y D. A study of the scale structure of hot-rolled steel strip by simulated coiling and cooling[J]. Oxidation of Metals, 1999, 53(5/6): 539-560.

[14] Ilschner B, Mitzke E. The kinetics of precipitation in wustite[J]. Acta Metallurgica, 1965, 13(1): 855-867.

[15] 孙彬, 刘振宇, 邱以清, 等. 低碳钢表面FeO层空气条件下等温转变行为的研究[J]. 钢铁研究学报, 2010, 22(2): 34-40.

SUN Bin, LIU Zhenyu, Qiu Yiqing, et al. Isothermal eutectic decompositionof FeO formed on a low carbon steel in air[J]. Journal of Iron and Steel Research, 2010, 22(2): 34-40.

(编辑 陈爱华)

收稿日期:2013-08-15;修回日期:2013-11-06

基金项目:国家自然科学基金资助项目(51204047);“十二五”国家科技支撑计划项目(2011BAE13B04);中央高校基本科研业务费项目(N130407004)

通信作者:曹光明(1982-),男,四川绵阳人,讲师,博士,从事氧化铁皮控制技术研究;电话:13504187137 E-mail:caogm@ral.neu.edu.cn