文章编号:1004-0609(2011)07-1535-06

NH4F溶液化学处理对γ-TiAl抗高温氧化性能的影响

唐光泽1, 2, 孙科文3, 马欣新2, 刘文静3

(1. 哈尔滨工业大学 金属精密热加工国防科技重点实验室, 哈尔滨 150001;

2. 哈尔滨工业大学 现代焊接生产技术国家重点实验室,哈尔滨 150001;

3. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:采用NH4F溶液对γ-TiAl合金进行表面氟化处理,以提高TiAl合金的抗高温氧化性能。分别研究经过氟化处理和未处理试样在850和900 ℃时的高温氧化行为及NH4F溶液浓度对合金氧化层组织结构的影响。结果表明,经过NH4F溶液处理TiAl合金高温氧化层的组织比未处理合金更加致密,高温氧化抗力高于未处理合金的。850 ℃氧化时,TiAl合金氧化抗力随NH4F溶液浓度的增高而增加;900 ℃氧化时,TiAl合金氧化后的质量增量不随NH4F溶液浓度增加而改变。

关键词:γ-TiAl合金;高温氧化;氟化处理;组织结构

中图分类号:TG146.2 文献标志码:A

Effects of NH4F solution dipping treatment on

high temperature oxidation behaviors of γ-TiAl alloy

TANG Guan-ze1, 2, SUN Ke-wen3, MA Xin-xin2, LIU Wen-jing3

(1. National Key Laboratory for Precision Hot Processing of Metals,

Harbin Institute of Technology, Harbin 150001, China;

2. School of Material Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

3. State Key Laboratory of Advanced Welding and Joining,

Harbin Institute of Technology, Harbin 150001, China)

Abstract:The surface of γ-TiAl alloy was treated by dipping into NH4F solution to improve the high temperature oxidation resistance of this alloy. The high-temperature oxidation behaviors and the effect of solution concentration on the microstructure of oxide layer were investigated at 850 and 900 ℃, respectively. The results show that the high-temperature oxidation layer of the treated alloy is more compact than that of the untreated alloy, and a higher oxidation resistance of the treated alloy is obtained. The oxidation resistance of the treated alloy increases with the increase of NH4F solution concentration at 850 ℃, while the mass gain of the alloy after oxidation is independent of the NH4F solution concentration at 900 ℃.

Key words:γ-TiAl alloy; high-temperature oxidation; fluorinated treatment; microstructure

γ-TiAl合金的密度低、比强度和比刚度高,在高温下兼具陶瓷的强度和金属韧性,是航空航天的理想高温结构材料。但是,当γ-TiAl合金服役温度超过850 ℃后,合金会发生严重氧化而失效,制约了γ-TiAl合金在高温领域的应用。目前,改善γ-TiAl合金抗高温氧化能力的方法主要是表面涂层和合金化两种[1-3],这两种技术都能有效地提高γ-TiAl合金的高温氧化抗力,但是都存在一定的不足。表面涂层法的主要技术难点在于涂层与基体热膨胀系数不匹配,在长时间使用后涂层和基体会发生剥落和高温下元素互扩散,形成界面硬脆的析出相和Kirkedall孔洞,导致工件疲劳失效;而合金化往往在提高抗氧化性的同时导致其他性能(如密度和强度等)下降,使γ-TiAl合金的综合性能不能兼顾。

研究发现,通过在γ-TiAl合金表面涂覆一层氯化物或者进行表面氯化处理,可以在高温氧化时诱发,优先形成一层连续的氧化铝层,极大地提高γ-TiAl合金的高温氧化抗力[4-6]。但是,进一步研究发现,由氯化处理形成的氧化铝阻挡层与γ-TiAl合金基体的结合力较弱,氧化层和基体界面处存在孔洞和裂纹等缺陷,在经历一段时间高、低温氧化循环后会发生剥落失效,失去保护作用[7-8],这就限制了氯化处理技术在γ-TiAl合金上的应用。近几年来,德国的一些研究小组发现,表面经过氟化处理的γ-TiAl合金在高温氧化时同样也能生成一层连续、致密、具有很强氧化抗力的氧化铝保护层[9-10],而且该氧化铝层与γ-TiAl合金基体之间具有极强的结合力,可以经受1 a的循环氧化不剥 落[11]。上述结果表明,表面氟化处理是一种极具潜力的γ-TiAl合金表面处理技术。目前,研究得较多的γ-TiAl合金表面氟化处理工艺是离子注入和HF表面处 理[9-10,12-14]。离子注入处理需要复杂的设备,且处理的工件尺寸和数量受真空室限制;而HF溶液处理虽然工艺简单,但是HF溶液腐蚀性较强,对环境和人体都有潜在的危害。因此,开发一种新型具有工业大规模应用潜力的氟化处理工艺是目前γ-TiAl合金氟化处理技术研究的重点。NH4F具有价格便宜、腐蚀性小、对人体无害等优点,是一种理想的γ-TiAl合金氟化处理试剂。本文作者主要研究经不同浓度NH4F溶液处理的γ-TiAl合金在850和900 ℃的氧化动力学过程和对应氧化层的微观组织。

1 实验

实验材料选用工业用γ-TiAl合金,试样加工成15 mm ×15 mm×2 mm的片状样品,表面经砂纸打磨后的机械抛光。抛光后的试样用丙酮清洗3次。试样分别用不同浓度NH4F稀溶液浸泡,NH4F溶液浓度为0.01、0.05和0.1 mol/L,浸泡时间为20 s,然后,用蒸馏水清洗试样,去除表面残留的盐,最后用热风吹干。氧化温度分别为850和900 ℃,氧化时间为10~100 h,冷却方式为空冷, 用精度为1 mg天平称量氧化前、后试样的质量,试样的质量增量除以总面积获得单位面积的质量增量。

用X射线光电子谱仪分析氟化层的元素浓度深度分布和化学态演化;用日本Hitachi公司生产的附带能谱的S-570型扫描电镜对试样氧化层表面和截面的形貌及元素分布进行分析。

2 结果与讨论

2.1 经NH4F溶液浸泡后试样的成分及化学态分析

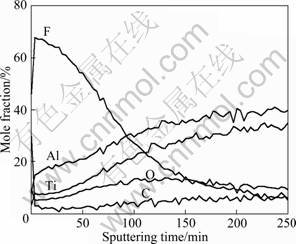

图1所示为经0.01 mol/L NH4F溶液浸泡后γ-TiAl合金氟化层成分深度分布。合金表面氟元素的摩尔分数达到67 %,溅射时间达250 min后仍然有10 %F(摩尔分数)存在,表明在γ-TiAl合金表面已经形成一层氟化物层。

图1 经NH4F溶液处理后γ-TiAl合金成分深度分布

Fig.1 Element depth profiles of TiAl alloy treated by NH4F solution

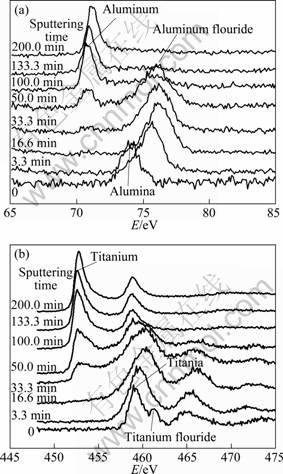

图2(a)和(b)所示为经0.01 mol/L NH4F溶液浸泡后γ-TiAl合金中铝和钛元素的化学态组成及其在深度方向的变化规律。由图2可知,对于铝元素,除了最表层是氧化铝以外,其化学态以氟化铝为主;而对于钛元素,其化学态为氧化钛和氟化钛的混合形式。

图1所示的浓度分布曲线表明,当溅射100 min后,氟的摩尔分数约为30%。而由图2可知,当溅射时间达60 min后,钛和铝元素只有单质元素对应的峰,没有氟化物峰存在,表明此时溅射已经达到γ-TiAl合金基体。产生此现象的原因在于测试样品表面存在高低起伏,在离子枪溅射剥蚀过程中,突起部分溅射速率快,且对凹陷部分溅射产生屏蔽作用,因此,突起部分溅射速率远大于凹陷部分的,两部分溅射速率的差异导致当突起部分氟化层被溅射后,凹陷部分氟化层仍存在。溅射60 min后,XPS检测到的氟信号来源于凹陷部分的氟化层。由图1可知,氟化层表面氟浓度远大于钛和铝元素的浓度,因此,凹陷部分产生的钛和铝信号强度相对于突起部分钛和铝元素信号强度弱很多,被噪声信号所掩盖,因此,在图2中没有出现相应的氟化物峰。

图2 经0.01 mol/L NH4F溶液处理后γ-TiAl合金中铝和钛元素化学态及其深度演化规律

Fig.2 Chemical states and their evolution with depth of Al and Ti elements in TiAl alloy after dipping into 0.01 mol/L NH4F solution: (a) Al 2p; (b)Ti 2p

2.2 经NH4F溶液浸泡后试样的氧化动力学过程分析

图3(a)所示为原始γ-TiAl合金和经不同浓度NH4F溶液浸泡后γ-TiAl合金在850 ℃氧化时的动力学曲线。由图3(a)可知,在850℃氧化时,NH4F溶液浓度对γ-TiAl合金氧化抗力的增强有很大影响,随着NH4F溶液浓度的增加,γ-TiAl合金氧化抗力提高:当NH4F溶液为0.01 mol/L时,γ-TiAl合金氧化100 h后的质量增量为3.5 mg/cm2,表现出与未处理试样的一致;当NH4F溶液浓度提高到0.10 mol/L时,γ-TiAl合金氧化100 h后的质量增量仅为0.5 mg/cm2,远低于未处理试样的,高温氧化抗力得到明显提高,当氧化时间超过20 h后,合金的质量增量趋于平缓,氧化质量增量速率降低。

图3 经NH4F溶液浸泡后γ-TiAl合金在850和900 ℃氧化时的动力学曲线

Fig.3 Oxidation kinetics curves of TiAl alloy treated by NH4F solution at 850 (a) and 900 ℃(b)

γ-TiAl合金经NH4F溶液浸泡后,在900 ℃氧化时的动力学曲线如图3(b)所示。原始试样的氧化速率远高于浸泡处理后试样的,与850 ℃时的氧化动力学曲线相比,NH4F溶液浓度的差别对合金抗氧化性的影响已经不明显。当氧化时间超过10 h后,经NH4F溶液浸泡处理后,试样的氧化质量增加速率趋于平缓。氧化100 h后,质量增量仅为1.4 mg/cm2,与其他氟化处理技术防护效果一致[5]。

经过表面氟化处理的γ-TiAl合金氧化抗力的提高源自连续氧化铝层的形成,氟化处理γ-TiAl合金氧化铝的形成源自表面挥发出来的氟化铝的氧化,只有当氟化铝的挥发速率超过一个临界值后,表面才能生成连续的氧化铝层。当连续氧化铝层生成之后,合金氧

化的控制过程为氧在氧化铝阻挡层中的扩散,氧扩散速度决定了氧化后质量增加的速度。由于氧在氧化铝层中的扩散速度极慢,因此,形成连续氧化铝层后,合金氧化质量增量趋于平缓,氧化速率急剧降低[5-6]。

氟化铝的挥发速度与表面氟浓度和氧化温度有关。在850 ℃氧化时,经0.01 mol/L NH4F溶液处理后γ-TiAl合金的氟化铝挥发少,不足以生成连续氧化铝层,因此,不能有效提高γ-TiAl合金的氧化抗力。随着NH4F溶液浓度的增加,γ-TiAl合金表面氟浓度增加,氟化铝的挥发速率增加,有利于氧化铝的生成,因此,随着NH4F溶液浓度的增加,γ-TiAl合金的氧化抗力增加。当NH4F溶液浓度增加到0.1 mol/L且氧化时间超过20 h后,氧化速率急剧下降,氧化后质量增加趋于平缓,表明连续氧化铝层已经生成;当氧化温度达900 ℃时,氟化铝的挥发速率大幅增加,氧化铝层生成速度加快,即使经0.01 mol/L NH4F溶液处理的试样,挥发出来的氟化铝也足够生成连续的氧化铝层,氧化控制过程为氧在氧化铝层中的扩散,因此,经不同浓度NH4F溶液处理的γ-TiAl合金在该温度下氧化后的质量增加曲线基本一致,与浓度无关。

2.3 氧化层组织分析

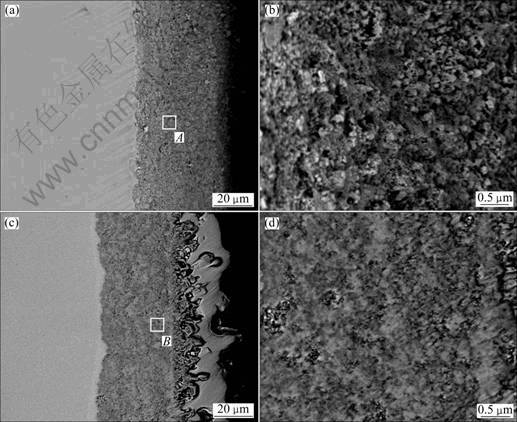

图4(a)和(b)所示分别为未经处理的γ-TiAl合金在850和900 ℃氧化100 h后氧化层横截面的SEM像,图4(c)和(d)分别为对应A和B处的局部放大SEM像。由图4可知,未经处理的γ-TiAl合金在850和900 ℃氧化100 h后的氧化层厚度分别约为30和60 μm,氧化层呈疏松多孔结构,对氧扩散阻力较低,因此,γ-TiAl合金的高温氧化抗力较差。

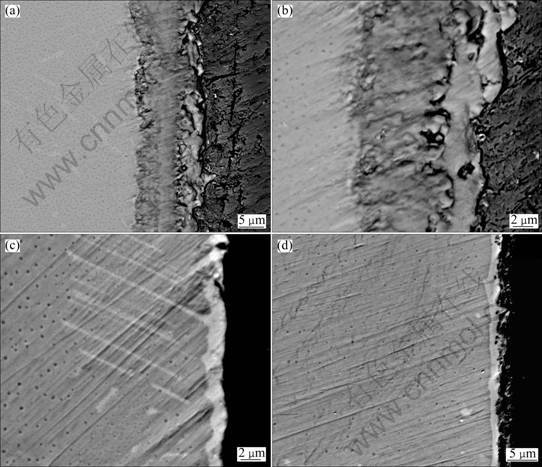

图5(a)~(c)所示分别为经浓度为0.01、0.05和0.10 mol/L NH4F溶液处理后γ-TiAl合金试样在850 ℃氧化100 h后横截面组织的SEM像。可知,随着NH4F溶液浓度增加,经过处理的γ-TiAl合金氧化层厚度逐减小,氧化层致密性增加,阻挡氧向基体扩散的能力增强,γ-TiAl合金氧化抗力增加。图3所示合金氧化动力学曲线表明,NH4F溶液浓度为0.01 mol/L时,合金氧化后的质量增量与未处理试样的相当;但是,由图5(a)可知,经0.01 mol/L NH4F溶液处理后,合金的氧化层厚度小于未处理试样的,说明其氧化抗力大于未处理试样的。产生该矛盾的原因是在氧化过程中未处理试样的氧化层发生了局部脱落(在氧化动力学曲线上20~60 h时的质量增加平台也证实了该推断),因此,测得的氧化质量增量比实际的小,而从SEM像观察到的是未发生脱落的氧化层,该厚度反映的是真实氧化程度,因此,经0.01 mol/L NH4F溶液处理后γ-TiAl合金的实际氧化抗力大于未处理合金的。图5(d)所示为经浓度为0.05 mol/L NH4F溶液处理后γ-TiAl合金试样在900 ℃氧化100 h后横截面组织的SEM像,该氧化层致密性很高,有利于提高γ-TiAl合金的氧化抗力。

图4 未经处理的γ-TiAl合金在不同温度氧化100 h后氧化层横截面的SEM像

Fig.4 SEM images of cross-section of untreated TiAl alloy oxide layer after oxidation at different temperatures for 100 h: (a) 850℃; (b) 900 ℃: (c) Enlargement of zone A in (a); (d) Enlargement of zone B in (b)

图5 经不同浓度NH4F溶液处理后γ-TiAl合金在不同温度氧化100 h氧化层截面的SEM像

Fig.5 SEM images of oxide layer cross-section of NH4F solution treated TiAl alloy after oxidized at different temperatures for 100 h: (a) 0.01 mol/L, 850 ℃; (b) 0.05 mol/L, 850 ℃; (c) 0.10 mol/L, 850 ℃; (d) 0.05 mol/L, 900 ℃

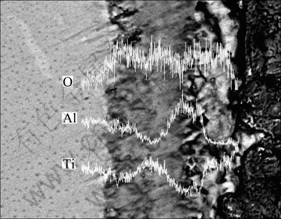

图6所示为经0.01 mol/L NH4F溶液处理后试样在850 ℃氧化100 h氧化层成分线扫描结果。由图6可知,氧化层由外向内依次是氧化钛层、氧化铝层及氧化钛和氧化铝的混合层。该结果证实,经NH4F溶液处理后γ-TiAl合金在高温氧化过程中会生成连续的氧化铝层。

图6 经NH4F溶液处理后γ-TiAl合金高温氧化层元素沿深度方向的分布

Fig.6 Element depth profile of high temperature oxide layer of TiAl alloy treated by NH4F solution

3 结论

1) 经NH4F溶液处理后,γ-TiAl合金表面生成氟化物层,在氟化物层中铝元素以氟化铝形式存在,而钛元素则是以氧化钛和氟化钛的混合物形式存在。

2) 经过NH4F溶液处理的合金在850和900 ℃下的高温氧化抗力得到了提高:在850 ℃氧化时,随着NH4F溶液浓度增加,合金抗氧化性能提高,当溶液浓度为0.1 mol/L时,氧化100 h后,合金的质量增量为0.5 mg/cm2,为原始合金的1/7;在900 ℃氧化时,合金的氧化抗力与NH4F溶液浓度无关,氧化100 h后合金的质量增量为1.4 mg/cm2,为原始合金的1/3。随着氧化时间的增加,氧化质量增加速度急剧降低。

3) 经NH4F溶液处理后,合金氧化层比未处理合金氧化层更加致密,并且生成了连续的氧化铝层,上述两个因素是经过NH4F溶液处理γ-TiAl合金高温氧化抗力提高的原因。

REFERENCES

[1] 贺志勇, 刘小萍, 王振霞, 徐 重. γ-TiAl金属间化合物表面改性技术研究现状[J]. 材料导报, 2007, 21(2): 83-86.

HE Zhi-yong, LIU Xiao-ping, WANG Zhen-xia, XU Zhong. Current status of surface modification on? γ-TiAl intermetallics[J]. Materials Review, 2007, 21(2): 83-86.

[2] 陈志勇, 黄因慧, 田宗军, 刘志东, 王东生. γ-TiAl合金表面高温抗氧化性工艺技术研究现状[J]. 热处理技术与装备, 2008, 29(1): 1-5.

CHEN Zhi-yong, HUANG Yin-hui, TIAN Zong-jun, LIU Zhi-dong, WANG Dong-sheng. Research states of high temperature oxidation resistance technology[J]. Heat Treatment Technology and Equipment, 2008, 29(1): 1-5.

[3] 席艳君, 王志新, 卢金斌. TiAl基合金的高温氧化及其保护[J]. 材料导报, 2006, 20(5): 82-85.

XI Yan-jun, WANG Zhi-xin, LU Jin-bin. High temperature oxidation and protection of TiAl alloy[J]. Materials Review, 2006, 20(5): 82-85.

[4] 辛 丽, 李铁藩, 李美栓, 周龙江. 氯对TiAl基合金高温氧化行为影响[J]. 腐蚀科学与防护技术, 1999, 11(3): 129-134.

XIN Li, LI Tie-fan, LI Mei-shuan, ZHOU Long-jiang. Effect of chlorine on oxidation of TiAl-based alloy[J]. Corrosion Science and Protection Technology, 1999, 11(3): 129-134.

[5] SCH?TZE. M, SCHUMACHER G, DETTENWANGER F, HORNAUER U, RICHTER E, WIESER E, M?LLER W. The halogen effect in the oxidation of intermetallic titanium aluminides[J]. Corrosion Science, 2002, 44: 303-318.

[6] DONCHEV A, GLEESON B, SCH?TZE M. Thermodynamic considerations of the beneficial effect of halogens on the oxidation resistance of TiAl-based alloys[J]. Intermetallics, 2003, 11: 387-398.

[7] XIN L, SHAO G, WANG F, TSAKIROPOULOS P, LI T. Improving high-temperature oxidation resistance of TiAl-based alloys by MnCl2 surface treatment[J]. Intermetallics, 2003, 11: 651-660.

[8] DONCHEV A, RICHTER E, SCH?TZE M, YANKOV R. Improvement of the oxidation behaviour of TiAl-alloys by treatment with halogens[J]. Intermetallics, 2006, 14: 1168-1174.

[9] ZHU Y C, LI X Y, FUJITA K, IWAMOTO N, MATSUNAGA Y, NAKAGAWA K, TANIGUCHI S. The improvement of the oxidation resistance of TiAl alloys by fluorine plasma-based ion implantation[J]. Surface and Coatings Technology, 2002, 158/159: 503-507.

[10] ZSCHAU H E, SCH?TZE M, BAUMANN H, BETHGE K. Application of ion beam analysis for the control of the improvement of the oxidation resistance of TiAl at 900 ℃ in air by fluorine ion implantation and HF-treatment[J]. Nuclear Instruments and Methods in Physics Research B, 2005, 240: 137-141.

[11] DONCHEV A, RICHTER E, SCH?TZE M, YANKOV R. Improving the oxidation resistance of TiAl-alloys with fluorine[J]. Journal of Alloys and Compounds, 2008, 452: 7-10.

[12] FUJITA K. Research and development of oxidation, wear and corrosion resistant materials at high temperature by surface modification using ion processing[J]. Surface and Coatings Technology, 2005, 196: 139-144.

[13] ZSCHAU H E, SCH?TZE M, BAUMANN H, BETHGE K. The time behaviour of surface applied fluorine inducing the formation of an alumina scale on gamma-TiAl during oxidation at 900 ℃ in air[J]. Intermetallics, 2006, 14: 1136-1142.

[14] 唐光泽, 孙科文. 氟离子注入对TiAlNb合金高温氧化性能的影响[J]. 金属热处理, 2009, 34(7): 17-19.

TANG Guang-ze, SUN Ke-wen. Effect of fluorine ions implantation on high temperature oxidation resistance of TiAlNb alloy[J]. Heat Treatment of Metals, 2009, 34(7): 17-19.

(编辑 陈卫萍)

基金项目:哈尔滨工业大学优秀青年教师培养计划项目(HITQNJS.2008.017);中央高校基本科研业务专项资金资助项目(HIT.NSRIF.2009030)

收稿日期:2010-08-25;修订日期:2010-11-22

通信作者:唐光泽,讲师,博士;电话:0451-86402860;E-mail:oaktang@hit.edu.cn