文章编号:1004-0609(2014)10-2546-07

等离子喷涂粉煤灰复合涂层的制备及性能

孙方红1,马 壮2,刘应瑞2,董世知2,李智超2

(1. 辽宁工程技术大学 创新实践学院,阜新 123000;

2. 辽宁工程技术大学 材料科学与工程学院,阜新 123000)

摘 要: 利用煤炭固体废弃物,采用等离子喷涂技术,在工业纯铜表面制备粉煤灰复合涂层。利用SEM和XRD分析涂层的组织形貌和物相组成,通过热震实验、抗氧化性实验、磨粒磨损实验、冲蚀磨损实验分别测试涂层的热震性、抗氧化性、磨粒磨损性和冲蚀磨损性。结果表明:涂层表面致密,结合性良好,且有3Al2O3·2SiO2、AlB2和Al9Si等新相产生;涂层具有良好的热震性能,热震次数达到74次;涂层具有良好的抗氧化性和耐磨性,其抗氧化性、磨粒磨损性和冲蚀磨损性比基体分别提高了3.14倍、6.16倍和7.48倍。

关键词:等离子喷涂;粉煤灰复合涂层;纯铜;冲蚀磨损

中图分类号:TG174.44 文献标志码:A

Preparation and properties of fly ash composite coating on pure copper surface by plasma spray

SUN Fang-hong1, MA Zhuang2, LIU Ying-rui2, DONG Shi-zhi2, LI Zhi-chao2

(1. College of Innovation and Practive, Liaoning Technical University, Fuxin 123000, China;

2. College of Materials Science and Engineering, Liaoning Technical University, Fuxin123000, China)

Abstract: Using coal solid waste, the fly ash composite coating was prepared on the surface of pure copper by plasma spray. The morphologies were observed with SEM, and phase composition of the composite coating were analyzed with XRD. The properties of thermal shock,oxidation resistance,abrasive wear and erosion wear of the composite coating were investigated by thermal shock test,anti-oxidative test,abrasive wear test and erosion wear test. The results show that the coating is dense and has high bonding strength. New phases, such as 3Al2O3·2SiO2, AlB2 and Al9Si, are produced too. The coating has very excellent thermal shock property, and the times of thermal shock is 74. The coating has excellent oxidation resistance and wear resistance. Compared with the base of pure copper, the oxidation resistance, abrasive wear and erosion wear of the coating are improved by 3.14, 6.16 and 7.48 times, respectively.

Key words: plasma spray; fly ash composite coating; pure copper; erosion wear

在金属基体上制备表面防护层的方法很多,有热喷涂法、气相沉积法、溶胶-凝胶法、自蔓延高温合成技术、激光熔覆技术、等离子熔覆技术和热化学反应法等。其中,热喷涂技术能够赋予金属材料表面耐蚀、耐磨、耐高温、抗氧化以及其他的特殊性能,是表面工程领域内赋予材料表面新功能最有效的技术之一,因而被广泛地应用于机械制造、交通运输、电力能源、石油化工、航空航天、冶金矿山、轻工纺织等国民经济建设的各个领域,并发挥了日益巨大的作用[1]。热喷涂技术主要包括火焰喷涂、爆炸喷涂、等离子喷涂、激光喷涂、超音速喷涂等。其中,等离子喷涂技术是热喷涂技术常用的一种金属或陶瓷涂层制备方法,既能满足产品对实际工况的需求,又能提高社会经济效益、提高零部件的使用寿命,已在耐磨、减磨、耐蚀、抗高温氧化、热障涂层等方面得到广泛应用[2-3]。尤其是能够喷涂各种品质低劣的矿物质获得高附加值产品[4]。

粉煤灰属于煤炭固体废弃物,主要成分为SiO2、Al2O3、CaO、MgO等,与氧化物陶瓷涂层的组成及比例大致相近,作为一种涂层材料用于工程零件和建筑材料方面具有巨大的潜力[5-6]。MISHRA等[7-8]、KRISHNA等[9]、SATAPATHY等[10]、YILMAZ等[11]、SIDHUA等[12]采用等离子喷涂或爆炸喷涂分别在低碳钢、不锈钢或铝板等金属材料表面制备了纯粉煤灰或者粉煤灰+Al粉防护层。结果表明:涂层中存在SiO2、A12O3、莫来石、CaO、K2O等相,涂层具有较好的结合强度,但耐磨性还有待于进一步提高。本文作者及课题组成员[13-19]采用热化学反应法在Q235钢表面制备了粉煤灰复合陶瓷涂层。结果表明:涂层中均有新相产生,涂层与基体结合良好,提高了基体的耐蚀性和耐磨性,但要在工业中推广应用,其性能还需进一步提高。

为了进一步提高粉煤灰复合涂层的性能,本文作者在前期采用热化学反应法制备粉煤灰复合涂层的基础上,以粉煤灰为主要骨料,添加一定量的Al粉、B2O3和CeO2,采用等离子喷涂在工业纯铜表面制备粉煤灰复合涂层,对其组织结构、物相组成、热震性、抗氧化性、耐磨性等进行了研究。

1 实验

1.1 实验材料

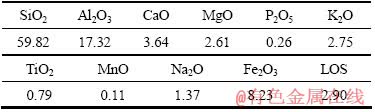

基体材料为工业纯铜,尺寸为20 mm×20 mm×3 mm。喷涂材料为90%粉煤灰复合粉末(粉煤灰占88%,B2O3占10%,CeO2占2%)+10%Al粉。粉煤灰的成分见表1。

表1 粉煤灰化学成分

Table 1 Chemical composition of fly ash (mass fraction, %)

添加B2O3有利于涂层中形成新相,优化涂层的组织结构,提高涂层的耐磨性等;添加CeO2有利于细化涂层晶粒,改善晶界状态,提高基体与涂层的结合强度,降低涂层中的孔隙率和空洞尺寸等;加入Al 粉,利用其熔点低(933 K)及熔化后通过毛细管作用扩散,向周围陶瓷粒表面铺展、粘结,提高陶瓷粒子的熔化率和半熔化率[20]。

1.2 涂层制备

喷涂设备为美国Praxair/TAFA公司生产的3710型等离子喷涂系统,喷枪型号为SG-100,具体工艺参数见表2。喷涂制备工艺大致如下:粉煤灰预处理(800 ℃保温2 h)→骨料球磨→造粒(选聚乙烯醇为粘接剂)→研磨→筛选→喷涂。为了提高纯铜与涂层的结合强度,减少基体与涂层两者间由于膨胀系数不同而产生的应力,在纯铜表面喷涂一层Ni-Al过渡层,厚度约为100 μm。

表2 等离子喷涂工艺参数

Table 2 Plasma spraying process parameters

1.3 涂层性能结构测试

使用日本理学D/MAX-RB型X射线衍射仪和日立SSX-550型扫描电镜(SEM)分析了涂层的物相组成和涂层的表面形貌以及界面结合情况。

热震试验采用急冷急热法测试涂层与基体的结合性能,即把试样加热到700 ℃,保温10 min。取出试样迅速放入水中,试样冷却后取出,观察涂层表面是否有裂纹或剥落现象,若没有上述现象,即为一次热震,依次循环,直至涂层的裂纹或剥落达到整体面积的1/3。实验以涂层非边角处大面积的平面涂层出现剥落的程度作为失效判据,力图克服边角的外界离散几何因素的影响, 提高实验结果的准确性[21]。

涂层的抗氧化性在箱式电阻炉中进行,把试样加热到700℃,分别保温2、4、6、8和10 h,采用增重法计算试样的单位面积氧化量p,p的计算公式如下:

式中:p为试样单位面积氧化量,g /m2; 为试样的质量损失,g;s为氧化的面积,m2。

为试样的质量损失,g;s为氧化的面积,m2。

磨粒磨损实验在ML-10型磨粒磨损实验机上进行,具体参数如下:实验载荷为20 N,对磨材料为金相砂纸,磨损时间分别为3、5、7、10 min。称量后,计算试样的单位面积的质量损失来反应涂层的抗磨粒磨损性。

冲蚀磨损是在MSH型腐蚀磨损试验机上进行,冲蚀液为石油介质+建筑用砂,石油介质成分见表3[22],建筑用砂粒度为0.2~0.5 mm,冲蚀角为90°,转速为400 r/min。每30 min称量一次,并计算单位面积氧化量。

表3 溶液中各溶质的含量

Table 3 Solute amount of substance in solution (mmol/L)

2 结果与分析

2.1 涂层形貌

图1所示为粉煤灰复合涂层的界面和表面形貌。从图1(a)涂层的界面形貌可以看出,Ni-Al过渡层与基体结合面呈不同程度的咬合,界面以机械结合为主。由于Ni-Al复合粉末具有“自粘结”效应,Ni和Al在喷涂的过程中反应产生大量的热,提高了过渡层与基体之间的结合力。而涂层与Ni-Al层之间没有明显的界限,出现明显的互相凸凹现象,表现出宏观的不均匀性和微观连续性的分布特征[23],呈现出一定的冶金结合和化学结合,有利于提高过渡层与涂层之间的结合强度。由图1(b)涂层表面形貌可知,涂层表面致密,具有典型的层片状结构,同时还有一些球状的小颗粒和微米级孔洞。这说明在喷涂过程中,粉煤灰涂层中的Al2O3和SiO2等充分熔化,其颜色较深,少量的CaO和MgO等物质未熔化,其颜色较浅。熔化的粒子在喷涂的过程中铺展性好,形成层片状结构,未熔化的粒子无法充分展开、平铺而凝固形成球状的小颗粒。空洞一般出现在球状的小颗粒周围,可能是由于凝固冷却时发生收缩而产生。由于在涂层中添加了Al粉和CeO2,提高涂层的熔化率和减少了涂层的孔隙率等,使涂层的致密度和结合强度有所提高。

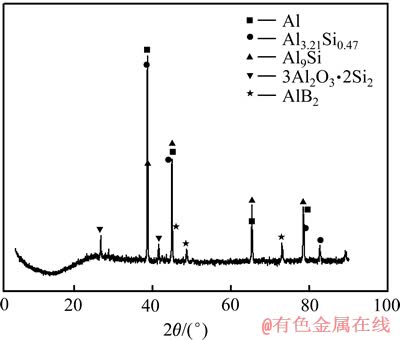

2.2 涂层物相分析

图2所示为等离子喷涂粉煤灰复合涂层的XRD谱。从图2可以看出,过渡层中的Ni和Al元素没有形成化合物,以均匀的单质形式存在,涂层中有3Al2O3·2SiO2、AlB2、Al9Si和Al3.21Si0.47等新相产生,说明涂层中的Al2O3、SiO2、Al粉和B2O3等之间发生了某些化学反应,不仅提高了涂层的结合强度和致密性,而且有利于增加涂层的耐磨性和抗氧化性。这是因为在等离子喷涂过程中,Al元素产生大量的热,等离子喷涂温度高,加入的稀土氧化物CeO2能显著提高陶瓷化烧结涂层的表面硬度,并有效降低涂层的烧结温度,使骨料在喷涂过程中产生原位合成反应,有利于提高涂层的结合强度和涂层中陶瓷粒子间的聚合强度[24-26]。

图1 涂层的界面及表面形貌

Fig. 1 SEM images of interface(a) and surface(b) of coatings

2.3 涂层的抗热震性

图2 等离子喷涂粉煤灰复合涂层的XRD谱

Fig. 2 XRD pattern of fly ash composite coatings by plasma spray

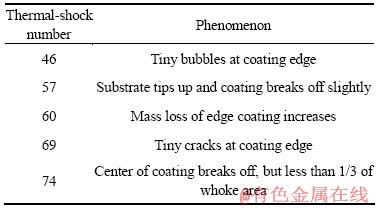

一般认为热应力是影响涂层热震性能的关键因素,涂层与基体的热物理性能匹配(热膨胀系数、弹性模量和断裂强度等)也非常重要[27-28]。涂层的热震性能实验结果见表4。从表4可以看出,涂层热震到第46次时,试样边缘开始出现微小气泡;热震第57次时,试样边缘翘角且开始出现微小脱落;热震第60次时,涂层边缘脱落开始增加,涂层中心完好;热震第69次时,涂层表面出现细微裂纹,但未延至涂层心部;热震第74次时,涂层中心局部出现脱落,但涂层脱落面积不到试样总表面的1/3,可见涂层具有良好的抗热震性。主要原因一方面是在涂层与基体之间喷涂Ni-Al过渡层和添加Al粉消除了涂层与基体不易结合的情况,减小了涂层与基体的热膨胀系数差异,降低了热循环过程中产生的热应力,提高了涂层的结合强度,并使涂层具备一定的弹性模量和断裂强度,有利于提高涂层的抗热震性;另一方面,从涂层的界面、表面形貌和物相分析结果可知,涂层表面致密,界面结合良好,且涂层中有新相的产生,有利于提高涂层的结合强度,使其抗热震性提高。最后,有关文献[29]中指出:增加涂层空隙会松弛热震过程所造成的应力集中,从而提高涂层的热震性。从图1可以看出,涂层表面存在一定的微孔洞,当过渡层氧化不严重时,可以通过微孔洞释放热应力,随着过渡层氧化严重,氧化物在涂层微孔洞处生长,阻碍了热应力的释放,故当涂层热震到74次时,导致局部涂层脱落。

表4 700 ℃时涂层的热震实验结果

Table 4 Thermal-shock experiment results of coating at 700 ℃

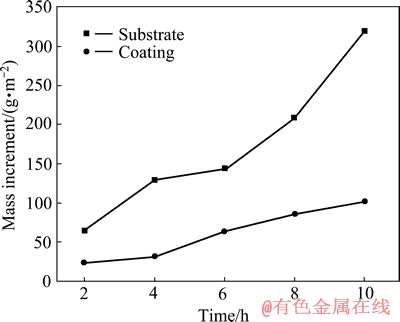

2.4 涂层的抗氧化性

图3所示为在700 ℃时经过不同时间保温涂层的氧化质量增加曲线。从图3可以看出,随着时间的延长,基体的氧化质量增加呈指数增加,涂层的氧化质量增加呈近似直线增加,粉煤灰复合涂层有效地提高了基体抗氧化性,大约是基体抗氧化性的3.14倍。由于纯铜和空气中的氧发生化学反应,纯铜表面发黑,且随着时间的延长,氧化愈严重,氧化增量增加。彭其凤等[30]指出当氧与涂层接触时,通过涂层的微孔向内部扩散,并于位于界面的金属元素发生反应,生成氧化物,体积膨胀形成界面压力,导致涂层的凸起或开裂。由于粉煤灰复合涂层表面致密,涂层与界面结合强度高,氧气难以扩散到基体界面,当涂层表面保温10 h后,涂层表面仍完好无缺损,因而表现出较好的抗氧化性。

图3 涂层的氧化质量增加曲线

Fig. 3 Oxidation mass increment curves of coatings

2.5 涂层的磨粒磨损性能

涂层的抗磨粒磨损性主要与涂层的结合强度、致密性和组织中硬质相的硬度、数量等有关。粉煤灰复合涂层的磨粒磨损实验数据如图4所示。从图4可以看出,磨损初期,基体的磨损曲线较陡,磨损率较大,随着磨损时间的延长,基体的磨损率逐渐趋于平缓,而涂层的磨损率从磨损开始到结束,磨损质量损失率较少,表明该复合涂层相对基体的耐磨性提高了6.16倍。主要原因一方面是涂层有3Al2O3·2SiO2、AlB2、Al9Si和Al3.21Si0.47等新相及未溶的硬质氧化物产生,提高了涂层的表面硬度和耐磨性。另一方面,涂层中添加Al粉和稀土氧化物,增加了涂层的致密性和结合强度,也有利于涂层耐磨性的提高。涂层磨粒磨损失效常见的两种失效方式[31]:1) 涂层中的陶瓷颗粒在应力的作用下,因疲劳而脱落;2) 从涂层中脱落下来的硬质粉末,又使涂层产生微磨粒磨损。由图1可以看出,涂层表面存在一定的球状小颗粒,随着磨粒磨损时间的延长,部分小颗粒随之脱落,又对涂层产生微磨粒磨损,使涂层磨损质量损失增加,因此,粉煤灰复合涂层主要以第二种失效方式为主要的失效过程。

图4 涂层的磨粒磨损曲线

Fig. 4 Wear resistance curves of coatings

2.6 涂层的冲蚀磨损性能

冲蚀磨损是腐蚀与冲蚀磨损共同作用的材料损耗过程,即腐蚀加速材料磨损,而磨损又促进材料腐蚀,是腐蚀-磨损介质工况工作的机械零部件(如泥浆泵、石油管道和化工设备等) 面临的失效问题[32]。涂层冲蚀磨损失效一般与腐蚀的介质、试样的转速、涂层的结合强度和致密性等有关。实验以石油介质+建筑用砂为介质,转速为400 r/min定量地测试涂层的耐腐蚀冲蚀磨损性能。

图5所示为粉煤灰涂层的腐蚀冲蚀磨损曲线和腐蚀冲蚀磨损表面形貌。从图5(a)可以看出,基体在腐蚀磨损下,质量损失较快,而涂层的质量损失增加缓慢,涂层的耐腐蚀磨损性能比基体的提高了约7.48倍。由于粉煤灰复合涂层结构为层状结构,且存在一些近似球状的小颗粒,存在未结合或弱结合现象。从图5(b)可以看出,在腐蚀冲蚀磨损过程中,在建筑用砂+石油介质的腐蚀冲蚀下,球状的小颗粒剥落都会造成材料损失,导致涂层质量损失率的增加。涂层中的颗粒不断脱落,涂层表面的粗糙度也开始增加,且使颗粒下方的空隙裸露,在涂层表面形成很多的蜂窝状蚀坑,随后,蜂窝状蚀坑逐渐加深,使基体裸露,导致涂层失效。另外,腐蚀与磨损的交互作用使粉煤灰复合涂层诱发了大量的裂纹,降低了涂层之间的结合力,导致涂层质量损失增加。但在腐蚀磨损过程中,腐蚀产物覆盖在裂纹的表面,不仅降低了腐蚀速率,而且减缓了涂层的磨损,因此,粉煤灰复合涂层质量损失呈缓慢增加趋势。粉煤灰涂层腐蚀冲蚀磨损失效可能是由于腐蚀和冲蚀引起粒子逐渐脱落累积而导致。可见,粉煤灰复合涂层的冲蚀磨损主要表现出冲蚀疲劳磨损,并伴随一定的腐蚀磨损。

图5 涂层的腐蚀冲蚀磨损曲线和表面形貌

Fig. 5 Corrosion-erosion wear curves(a) and surface morphology(b) of coatings

3 结论

1) 采用等离子喷涂,选用90%粉煤灰复合粉末(粉煤灰占88%,B2O3占10%,CeO2占2%)+10%Al粉配方,在工业纯铜表面制备粉煤灰复合涂层,涂层表面致密,同时存在一些球状的小颗粒和微米级孔洞,并产生3Al2O3·2SiO2、AlB2、Al9Si和Al3.21Si0.47等新相,提高了涂层的结合强度。

2) 热震实验和抗氧化实验表明:涂层具有良好的抗热震性和抗氧化性,在700 ℃时,涂层的热震次数达到74次,大部分涂层表面仍然完好,涂层的抗氧化性约为基体的3.14倍。

3) 磨粒磨损实验和腐蚀冲蚀磨损实验表明:涂层的磨粒磨损性能比基体的提高了6.16倍,涂层的腐蚀冲蚀磨损性能比基体的提高了约7.48倍。涂层的冲蚀磨损主要表现出冲蚀疲劳磨损,并伴随一定的腐蚀磨损。

REFERENCES

[1] 吴子健. 热喷涂技术与应用[M]. 北京: 机械工业出版社, 2006: 15.

WU Zi-jian. Thermal spraying technology and application[M]. Beijing: China Machine Press, 2006: 15.

[2] 陈 燕, 芦 笙, 陈 静, 段珍珍. AZ91D镁合金等离子喷涂Ni-Al/陶瓷涂层的组织和性能[J]. 中国有色金属学报, 2012, 22(4): 1094-1095.

CHEN Yan, LU Sheng, CHEN Jing, DUAN Zhen-zhen. Microstructure and properties of Ni/Al/ceramic coatings plasma-sprayed on AZ91D magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(4): 1094-1095.

[3] 安家财, 杜三明, 肖宏滨, 张永振. 等离子喷涂ZrO2/Al2O3陶瓷涂层及其摩擦磨损性能研究[J]. 中国表面工程, 2011, 24(1): 20-24.

AN Jia-cai, DU San-ming, XIAO Hong-bin, ZHANG Yong-zhen. Tribological properties of plasma sprayed ZrO2/Al2O3 ceramic coatings[J]. China Surface Engineering, 2011, 24(1): 20-24.

[4] SATAPATHY A, SAHU S P, MISHRA D. Development of protective coatings using fly ash premixed with metal powder on aluminium substrates[J]. Waste Management & Research, 2010, 28(7): 660-666.

[5] 马 壮, 陶 莹, 李智超. 热化学反应法制备粉煤灰陶瓷涂层展望[J]. 硅酸盐通报, 2012, 31(6): 1514-1517.

MA Zhuang, TAO Ying, LI Zhi-chao. Forecast on fly ash ceramic coatings by thermal chemical reaction[J]. Bulletin of the Chinese Ceramic Society, 2012, 31(6): 1514-1517.

[6] KRISHNA L R, SEN D, RAOAND D S, SUNDARARAJAN G. Coatability and characterization of fly ash deposited on mild steel by detonation spraying[J]. Journal of Thermal Spray Technology, 2003, 12(1): 77-79.

[7] MISHRA S C, MISHRA P C, ROUTB K C. Fly ash as a coating material for plasma spray coatings[J]. National Institute of Technology, 1999, 24: 131-135.

[8] MISHRA S C, ROUTB K C, AADMANABHANC P V. Plasma spray coating of fly ash pre-mixed with luminium powder deposited on metal substrates[J]. Journal of Materials Processing Technology, 2000, 102: 9-13.

[9] KRISHNA L R, SEN D, RAOAND D S. Coatability and characterization of fly ash deposited on mild steel by detonation spraying[J]. Journal of Thermal Spray Technology, 2003, 12(1): 77-79.

[10] SATAPATHY A, SAHU S P, MISHRA D. Plasma spray deposition of fly ash+aluminum coatings on steel substrates[J]. National Institute of Technology, 2009, 24: 52-56.

[11] YILMAZ S, OKUMUS S C, DEMIRKIRAN A S. Fly ash based plasma spray coating[J]. Key Engineering Materials, 2004, 264/268: 533-536.

[12] SIDHUA B S, SINGHB H, PURIB D, PRAKASH S. Wear and oxidation behaviour of shrouded plasma sprayed fly ash coatings[J]. Tribology International, 2007, 40(5): 800-808.

[13] 马 壮, 陶 莹, 闫翠娟, 李智超. 粉煤灰复合涂层腐蚀磨损性能研究[J]. 材料导报, 2013, 27(8): 127-130.

MA Zhuang, TAO Ying, YAN Cui-juan, LI Zhi-chao. Effects on corrosive wear of composite coatings derived from fly ash[J]. Materials Review, 2013, 27(8): 127-130.

[14] 马 壮, 闫翠娟, 孙方红, 李智超. Al2O3对硅酸盐矿物涂层耐蚀性能的影响[J]. 热加工工艺, 2012, 41(22): 169-171.

MA Zhuang, YAN Cui-juan, SUN Fang-hong, LI Zhi-chao. Effect of Al2O3 on corrosion resistance of silicate mineral ceramic coating[J]. Hot Working Technology, 2012, 41(22): 169-171.

[15] 马 壮, 陶 莹, 闫翠娟, 李智超. Al-TiO2-B2O3系粉煤灰复合涂层冲蚀磨损性能研究[J]. 硅酸盐通报, 2013, 32(9): 1746-1749.

MA Zhuang, TAO Ying, YAN Cui-juan, LI Zhi-chao. Study on erosion wear of composite coatings from fly ash with Al-TiO2-B2O3 system[J]. Bulletin of the Chinese Ceramic Society, 2013, 32(9): 1746-1749.

[16] 马 壮, 李 剑, 闫翠娟, 李智超. 粉煤灰玻璃/陶瓷复合涂层冲蚀磨损性能研究[J]. 硅酸盐通报, 2013, 32(8): 1684-1687.

MA Zhuang, LI Jian, YAN Cui-juan, LI Zhi-chao. Erosion wear of glass-ceramic composite coating from fly ash[J]. Bulletin of the Chinese Ceramic Society, 2013, 32(8): 1684-1687.

[17] 马 壮, 李 剑, 闫翠娟, 李智超. 粉煤灰玻璃/陶瓷复合涂层制备工艺及性能研究[J]. 硅酸盐通报, 2013, 32(4): 699-702.

MA Zhuang, LI Jian, YAN Cui-juan, LI Zhi-chao. Preparation and properties of glass-ceramic composite coating from fly ash[J]. Bulletin of the Chinese Ceramic Society, 2013, 32(4): 699-702.

[18] 马 壮, 陶 莹, 闫翠娟, 李智超. 粉煤灰复合涂层腐蚀磨损性能研究[J]. 材料导报, 2013, 27(8): 127-130.

MA Zhuang, TAO Ying, YAN Cui-juan, LI Zhi-chao. Effects on corrosive wear of composite coating derived from fly ash[J]. Materials Review, 2013, 27(8): 127-130.

[19] 马 壮, 杨 杰, 韩子钰, 羊 娟, 孙方红. 热反应法制备粉煤灰陶瓷涂层中的CeO2对涂层耐磨性能的影响[J]. 材料保护, 2013, 46(9): 54-57.

MA Zhuang, YANG Jie, HAN Zi-yu, YANG Juan, SUN Fang-hong. Effect of cerium dioxide on wear resistance of thermal reaction fly ash ceramic coatings of steel substrate[J]. Materials Protection, 2013, 46(9): 54-57.

[20] 马 壮, 曲文超, 李智超, 袁晓光. 热化学反应喷涂Al2O3基复合陶瓷涂层的制备及其性能[J]. 中国有色金属学报, 2009, 19(6): 1093-1098.

MA Zhuang, QU Wen-chao, LI Zhi-chao, YUAN Xiao-guang. Preparation and properties of Al2O3 based composite ceramic coating on pure copper surface by thermo-chemical reaction spraying[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(6): 1093-1098.

[21] 马 壮, 林 鹏, 董世知, 李智超. 在AZ91D表面SHS反应热喷涂Al-CuO系Al2O3基复相陶瓷涂层[J]. 中国有色金属学报, 2009, 19(8): 1379-1382.

MA Zhuang, LIN Peng, DONG Shi-zhi, LI Zhi-chao. Al2O3-based multiphase ceramic coating of Al-CuO system prepared by SHS reaction thermal spraying on AZ91D[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(8): 1379-1382.

[22] 马 壮, 陶 莹, 闫翠娟, 李智超. 粉煤灰复合涂层腐蚀磨损性能研究[J]. 材料导报, 2013, 27(8): 127-130.

MA Zhuang, TAO Ying, YAN Cui-juan, LI Zhi-chao. Effects on corrosive wear of composite coatings derived from fly ash[J]. Materials Review, 2013, 27(8): 127-130.

[23] 董晓强, 罗 超, 李德元, 段思华. 可控气氛下梯度涂层组织与结合性能分析[J]. 焊接学报, 2011, 32(2): 57-60.

DONG Xiao-qiang, LUO Chao, LI De-yuan, DUAN Si-hua. Analysis of microstructure and binding ability of gradient coatings in controlled atmosphere[J]. Transactions of the China Welding Institution, 2011, 32(2): 57-60.

[24] 谢华生, 李 玲, 李汉锟. 稀土氧化物对铸造用纳米氧化铝陶瓷化涂层显微组织及性能的影响[J]. 铸造, 2010, 59(3): 247-250.

XIE Hua-sheng, LI Ling, LI Han-kun. Influence of rare earth oxides on microstructure and properties of nanometer Al2O3 ceramic coating[J]. Foundry, 2010, 59(3): 247-250.

[25] 刘长松, 殷 声. 反应热喷涂的发展[J]. 材料保护, 2000, 33(1): 83-85.

LIU Chang-song, YIN Sheng. Advance of reactive thermal spraying[J]. Materials Protection, 2000, 33(1): 83-85.

[26] 刘慧渊, 黄继华, 张建纲. 反应火焰喷涂的TiC/Fe金属陶瓷复合涂层[J]. 中国有色金属学报, 2004, 14(8): 1389-1393.

LIU Hui-yuan, HUANG Ji-hua, ZHANG Jian-gang. TiC/Fe metal ceramic composite coating by reactive flame spray[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1389-1393.

[27] 罗立新, 倪惠琼. 无机高温耐磨粘涂剂的研究和应用[J]. 材料保护, 2001, 34(4): 38-40.

LUO Li-xin, NI Hui-qiong. High temperature inorganic wear resistant coating[J]. Materials Protection, 2001, 34(4): 38-40.

[28] 张清纯. 陶瓷材料力学性能[M]. 北京: 科学出版社, 1987: 280.

ZHANG Qing-chun. Mechanical properties of ceramic materials[M]. Beijing: Science Press, 1987: 280.

[29] 孙方红. 热化学反应法Al2O3基纳米复合陶瓷涂层的制备及性能研究[D]. 阜新: 辽宁工程技术大学, 2006: 41-42.

SUN Fang-hong. Study on the preparation and properties of the nano-scale composite ceramic coating of the aluminum matrix by thermochemical reaction method[D]. Fuxin: Liaoning Technical University, 2006: 41-42.

[30] 彭其凤, 朱晓冬, 莫之民, 耿贵立, 郭小燕. 激光熔敷陶瓷涂层的抗氧化性[J]. 中国机械工程, 1996, 7(1): 96-98.

PENG Qi-feng, ZHU Xiao-dong, MO Zhi-min, GENG Gui-li, GUO Xiao-yan. Oxidation resistance of laser-melted oxide ceramic coating[J]. China Mechanical Engineering, 1996, 7(1): 96-98.

[31] 李国英. 表面工程手册[M]. 北京: 机械工业出版社, 1998: 257.

LI Guo-ying. Surface engineering manual[M]. Beijing: China Machine Press, 1998: 257.

[32] 王洪涛, 纪岗昌, 陈清宇, 白小波, 富 伟, 陈 枭. 超音速火焰喷涂Cr3C2-NiCr涂层腐蚀冲蚀磨损特性[J]. 材料科学与工艺, 2011, 19(6): 80-82.

WANG Hong-tao, JI Gang-chang, CHEN Qing-yu, BAI Xiao-bo, FU Wei, CHEN Xiao. Corrosion and erosion wear characteristics of HVOF sprayed Cr3C2-NiCr coating[J]. Materials Science & Technology, 2011, 19(6): 80-82.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(U1261123/E0422);中国煤炭工业协会科学技术研究指导性计划项目(MTKJ2012-296);校生产技术问题基金立项课题(14-T-008)

收稿日期:2014-03-14;修订日期:2014-08-14

通信作者:马 壮,教授,博士;电话:0418-3351727;E-mail: mazh123@263.net