冷弯薄壁型钢自攻螺钉连接抗剪性能试验研究

卢林枫1, 2,张亚平1,方文琦3,杨东华4

(1. 长安大学 建筑工程学院,陕西 西安,710061;

2. 长安大学 交通行业重点实验室,陕西 西安,710061;

3. 新时代(西安)设计研究院有限公司,陕西 西安,710054;

4. 西部机场集团有限公司,陕西 西安,710075)

摘要:介绍单颗自攻螺钉连接件和多颗自攻螺钉连接件的试件制作、加载装置及它们抗剪承载力的试验全过程。根据试验过程和破坏现象,总结不同试件的荷载-变形曲线、抗剪承载力试验值及破坏模式。依据各国规范及相关文献,结合试验数据,验证中国规范GB 50018—2002及美国AISI规范对于计算单颗螺钉抗剪承载力的可行性及可靠性。通过探讨不同母材厚度、不同螺钉数目、不同螺钉排列方式及不同螺钉间距对自攻螺钉连接抗剪承载力的影响,总结得到自攻螺钉连接抗剪试验破坏的几个阶段、主要破坏模式和影响因素:(1) 螺钉数目及间距是影响自攻螺钉连接抗剪性能的最主要因素;(2) 螺钉排列方式对连接的抗剪性能影响较小;(3)在某些破坏模式下,母材厚度也是影响连接件抗剪性能的主要因素之一。通过对试验数据统计分析,发现自攻螺钉群的抗剪承载力具有“群体折减效应”,并给出能反映“群体折减效应”的螺钉群效率系数的分布范围,发现螺钉间距及数目也是影响效率系数的主要因素。

关键词:冷弯薄壁型钢;自攻螺钉;连接件;抗剪承载力;试验研究

中图分类号:TU391;TU317.1 文献标志码:A 文章编号:1672-7207(2013)07-2997-09

Experimental investigation on shear-bearing capacity for self-drilling screw connections of cold-formed thin-walled steel

LU Linfeng1, 2, ZHANG Yaping1, FANG Wenqi3, YANG Donghua4

(1. School of Civil Engineering, Chang’an University, Xi’an 710061, China;

2. Key Laboratory of Communications, Chang’an University, Xi’an 710061, China;

3. New Era (Xi’an) Design Engineering Co., LTD, Xi’an 710054, China;

4. China West Airport Group, Xi’an 710075, China)

Abstract: The production of specimens, loading equipment and the whole test process of both single and multiple self-drilling screw connections were introduced. According to the test and failure phenomenon, the load-deformation curves, shear-carrying capacity and failure modes were testified. The feasibility and reliability of the calculating methods in GB 50018—2002 and AISI were verified by the experiment data. Through considering the influence of different base materials, screws numbers, arrangements and screw spacing, the loading stages, main failure mode and influencing factors of the test are concluded: (1) Screw numbers and spacing are the main factors to the bearing capacity of self-drilling screws connections; (2) The screw arrangements have little effect on the shearing behavior of connections;(3) In certain situations, the thickness of base metal is also one of the main factors to the shearing behavior of connections. Based on the statistical analysis of the test data, it is found that the shear-carrying capacity of self-drilling screw connections has “group reduction effect”, and the range of efficiency coefficient for screws is provided as well. The screw numbers and spacing are also proved as main factors to efficiency coefficient by further analysis,

Key words: cold-formed thin-walled steel; self-drilling screw; connection; shear-bearing capacity; experimental investigation

近年来,冷弯薄壁型钢结构住宅体系在国内外得到广泛应用[1],自攻螺钉连接是其主要的连接方式之一。较其他形式(拉铆钉、焊接、螺栓)而言,自攻螺钉连接具有施工简便、连接刚度好、承载能力高等特点。自攻螺钉连接的抗剪性能是影响自攻螺钉连接承载力的主要因素之一,国内外学者对自攻螺钉连接的受力性能及受力机理进行研究。LaBoube等[2]认为自攻螺钉的排布方式、螺钉间距对连接构件均有影响,且自攻螺钉连接件具有“群体折减效应”;Babalola[3]对北美AISI规范[4]及Rogers等[5]提出的计算方法进行对比分析;Serrette等[6]对自攻螺钉连接件的抗剪性能进行一系列试验研究。潘景龙[7]在对自攻螺钉连接件抗剪性能进行试验研究的基础上,讨论影响自攻螺钉连接件抗剪性能的主要因素;石宇等[8]研究认为墙面板的材料特性对自攻螺钉的连接性能影响明显,试件的承载力主要由自攻螺钉孔边板的承载强度控制;刘楠[9]通过试验现象及对试验数据的回归分析,得到螺钉连接抗剪承载力的设计方法及构造要求;宋延勇[10]针对2 mm以下Q235冷弯薄壁型钢自攻螺钉连接的抗剪性能进行一系列研究;方文琦[11]对不同厚度的冷弯薄壁型钢自攻螺钉连接的抗剪性能进行试验研究。各国相关规范也已对冷弯薄壁型钢单颗自攻螺钉连接抗剪承载力给出明确的计算方法。但在实际中,构件之间的连接需要用多颗自攻螺钉组成螺钉群来承受外力。中国现行的GB 50018—2002(《冷弯薄壁型钢结构技术规范》)[12]未涉及自攻螺钉被剪断这一破坏模式,也没有考虑自攻螺钉的群体效应。事实上,剪断破坏模式偏属于脆性破坏,对结构极限承载能力有较大影响,而且已有研究表明自攻螺钉群连接存在明显的折减效应。为明确自攻螺钉抗剪连接的破坏机理、破坏模式和螺钉群连接的折减效应,本文作者在国内外已有相关研究的基础上[13],对单颗自攻螺钉连接和螺钉群连接的抗剪性能进行一系列试验研究。以2种不同厚度的冷成型钢材为母材,采用自攻螺钉连接,通过改变螺钉数目、间距及排列方式等,对自攻螺钉连接的抗剪性能进行分析。

1 试件设计

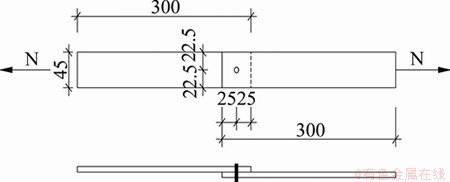

冷弯薄壁型钢自攻螺钉连接试件分别采用2种不同厚度的钢板(厚板长×宽×厚度为300 mm×45 mm×1.2 mm;薄板长×宽×厚度为300 mm×85 mm×0.72 mm)。自攻螺钉采ST4.2级圆头十字钻尾螺丝螺钉,公称直径为4.2 mm,长度为16 mm(见图1)。单颗螺钉连接试件按美国AISI TS4-02规范[14]推荐方法及尺寸进行制作,2颗及2颗以上螺钉连接试件除端距按AISI TS-4-02推荐的尺寸制作之外,螺钉间距按我国GB50018—2002规范规定的构造要求设计。

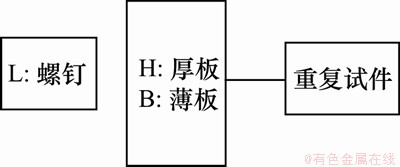

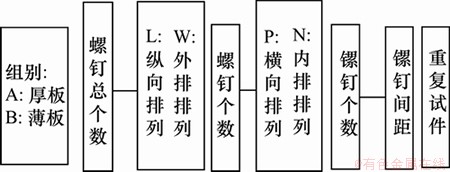

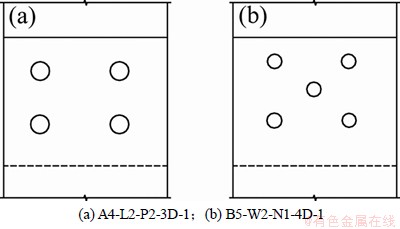

自攻螺钉连接试件主要分为单颗和多颗螺钉连接试件,单颗螺钉连接试件编号规定如图2所示,如试件LH-1表示厚板单颗螺钉连接系列试件中的第1个试件,其设计简图如图3所示。多颗螺钉连接试件编号规定见图4,如试件A4-L2-P2-3D-1表示A组厚板2列2排共4颗螺钉。以3倍螺钉直径连接的第1个试件,其设计简图如图5(a)所示;试件B5-W2-N1-4D-1表示B组薄板外排2颗内排1颗共5颗螺钉,以4倍螺钉直径为间距连接的第1个试件,设计简图如图5(b)所示。本次试验依据不同母材厚度和不同螺钉排列方式,按照图2和图4的编号规定对连接试件进行分组编号。

图1 ST4.2×16自攻螺钉

Fig.1 ST4.2×16 self-drilling screw

图2 单颗螺钉连接件编号说明

Fig.2 Single self-drilling screw connection number description

图3 单颗螺钉连接试件简图(单位:mm)

Fig.3 Single self-drilling screw connection diagram

图4 多颗螺钉连接试件编号说明

Fig.4 Self-drilling screws connection number description

图5 多颗螺钉连接试件简图

Fig.5 Self-drilling screws connections diagram

2 试验装置及加载制度

本次试验采用CSS-WAW300DL型电液伺服万能试验机进行加载,依据美国AISI TS-4-02规范中对自攻螺钉连接试验加载速度的相关要求,本次试验加载速度为2.5 mm/min,其变形由YJY-41型电子应变引伸计进行量测。试验时,按预先设定好的加载制度由计算机控制加载;试验数据由计算机自动采集、记录,并绘制出试验试件的荷载-变形曲线。

3 试验现象

3.1 厚板系列试件的试验现象

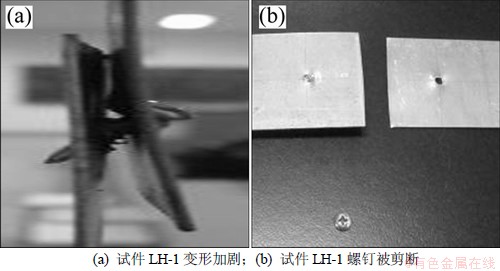

3.1.1 厚板单颗螺钉系列试件的试验现象

厚板单颗螺钉试件(LH系列)。加载初期,试件螺钉发生倾斜;随着荷载的增加,螺钉倾斜程度越来越大,在母材板件钉孔处出现较大塑性变形(如图6(a)所示);最终加载至荷载下降,试件破坏。其中:LH-1试件破坏模式为螺钉帽脱落,螺钉被剪断(如图6(b)所示);LH-2试件和LH-3试件螺钉孔处母材板件变形较大,破坏时螺钉倾斜严重。

图6 厚板单颗螺钉试件的试验现象

Fig.6 Slab single self-drilling connections testing phenomenon

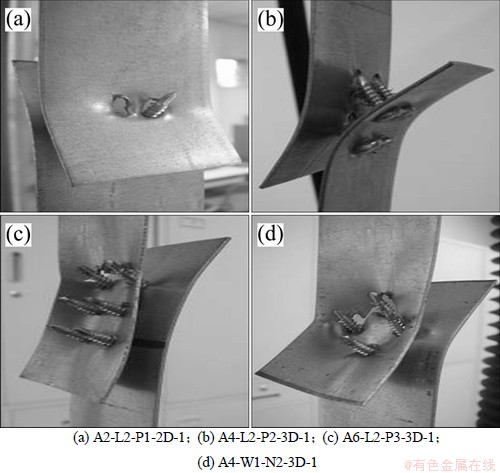

3.1.2 厚板多颗螺钉系列试件的试验现象

对于厚板多颗螺钉系列试件的试验现象和破坏模式,根据不同螺钉数目和不同排列方式选取以下典型试件进行描述。

(1) 试件A2-L2-P1-2D-1和试件A4-L2-P2-3D-1:加载初期,2试件的连接螺钉出现倾斜和板件翘起;随着荷载的增加,加剧连接螺钉倾斜程度和连接区段板件翘起变形;最终,试件破坏时,连接板件螺钉孔被拉长,连接区段板件翘起严重;试件A2-L2-P1-2D-1连接螺钉被剪断,并脱离连接板件(如图7(a)所示);试件A4-L2-P2-3D-1连接螺钉逐渐从螺钉孔中被拔出,并脱离钉尖一侧连接板件(如图7(b)所示)。

(2) 试件A6-L2-P3-3D-1和试件A4-W1-N2-3D-1:加载初期,与上述2试件发生的现象完全一样;最终试件破坏时,试件A6-L2-P3-3D-1连接区段板件变形严重,在螺钉连接处有被撕裂的趋势,而螺钉未被剪断(如图7(c)所示);试件A4-L1-P2-3D-1连接区段中间2颗螺钉位置的板件出现撕裂现象,螺钉孔被拉长,并迅速与连接区段端部螺钉孔贯通,螺钉连接区段板件沿螺钉群外边缘撕裂,板件翘起变形严重(如图7(d)所示)。

图7 厚板多颗螺钉系列试件最终破坏模式

Fig.7 Slab self-drilling connections ultimate failure mode

综上所述,无论是厚板单颗螺钉试件还是多颗螺钉试件,其试验破坏模式主要有以下3种:连接螺钉被剪断、连接螺钉倾斜被拔出以及连接区段板件撕裂。

3.2 薄板系列试件的试验现象

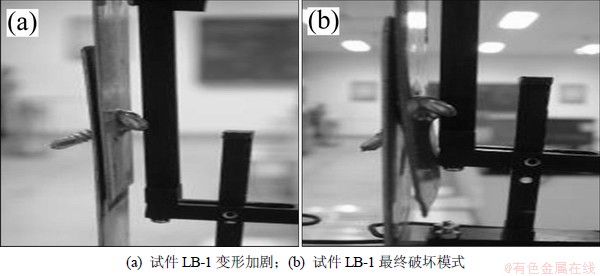

3.2.1 薄板单颗螺钉系列试件的试验现象

薄板单颗螺钉试件(LB系列)。加载初期,试件螺钉发生倾斜、板端部发生翘起现象;随着荷载的增加,螺钉倾斜及板端部翘起变形加剧,母材板件钉孔处发生较大塑性变形(如图8(a)所示);最终加载至荷载下降,试件破坏。LB系列试件在破坏时螺钉倾斜严重,板端部翘起及钉孔处板件塑性变形较大(如图8(b)所示)。

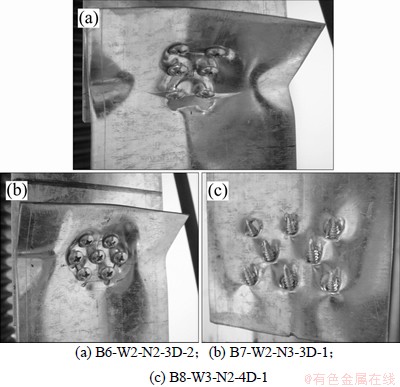

3.2.2 薄板多颗螺钉系列试件的试验现象

对于薄板多颗螺钉系列试件的试验现象和破坏模式,根据不同螺钉数目和不同排列方式选取以下典型试件试件B6-W2-N2-3D-2,B7-W2-N3-3D-1和B8-W3-N2-4D-1进行描述:加载初期,3试件螺钉发生轻微倾斜,钉帽侧连接板件端部发生微小翘起变形;随着加载的增加,连接螺钉倾斜现象明显,连接区段板件翘起变形逐渐加剧;最终,试件B6-W2-N2-3D-2和试件B7-W2-N3-3D-1突然发出“咔”的响声,钉帽侧连接板件在邻近夹持端一边的最外排螺钉处被撕裂,板件破坏严重(如图9(a)和(b)所示),此时认为已达到其极限荷载力(出现不能继续承载的较大变形),而试件B8-W3-N2-4D-1钉尖侧连接板件螺钉孔出现拉长扩大,螺钉倾斜严重,并逐渐脱丝,有被拔出的趋势,最终破坏模式(如图9(c)所示)。

图8 薄板单颗螺钉试件的试验现象

Fig.8 Sheet single self-drilling connections testing phenomenon

图9 薄板多颗螺钉系列试件最终破坏模式

Fig.9 Sheet self-drilling connections ultimate failure mode

综上所述,无论是薄板单颗螺钉试件还是多颗螺钉试件,其试验破坏模式主要有以下2种:连接螺钉被拔出以及连接区段板件撕裂。

4 试验结果及分析

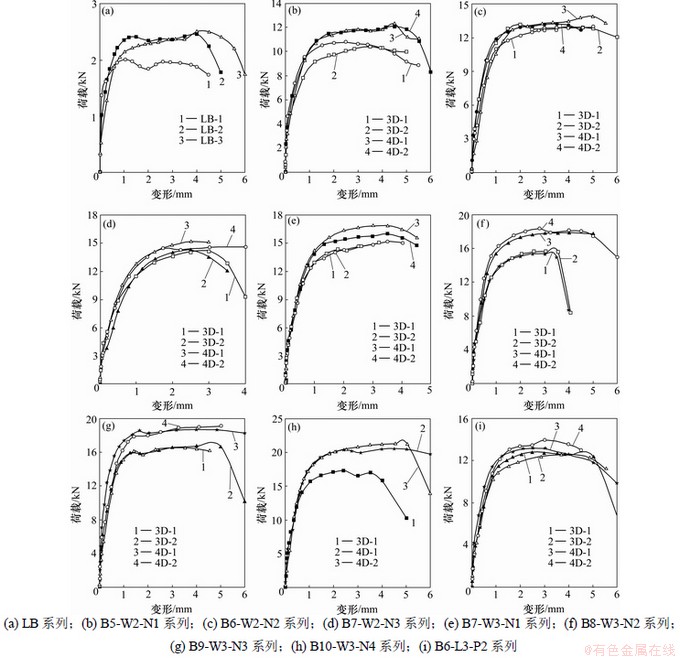

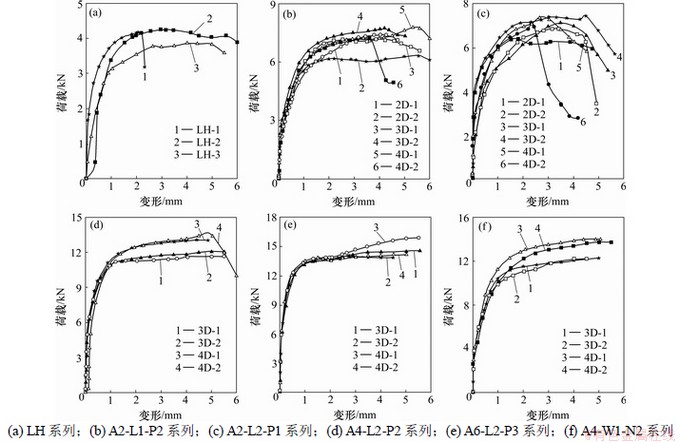

4.1 试验荷载-变形曲线

荷载-变形曲线是由计算机自动绘制的,如图10和图11所示。由图10和图11可见:试验试件连接抗剪的破坏过程有一定的共性:加载初期,荷载-变形曲线呈线性;随着加载的进行,由线性逐渐变为非线性,曲线斜率下降;加载继续进行,荷载涨幅不大但变形不断发展,曲线趋于平缓,除螺钉被剪断的试件有明显下降外,大部分试件曲线无明显的下降,各个试件连接区段有较大的变形,呈现出较好的塑性;同时,同一系列试件的荷载-变形曲线比较接近,但并不完全重合。这主要是各试件在加工制作过程中存在连接板件平整程度不同及螺钉的拧紧程度不同等初始缺陷造成的。

图10 薄板试件荷载-变形曲线

Fig.10 Sheet tests load-deformation curves

结合试件的荷载-变形曲线,可以将本次冷弯薄壁型钢自攻螺钉连接抗剪试验的破坏过程分为以下几个阶段。

(1) 弹性阶段:试件荷载-变形曲线呈线性关系增长,荷载主要由连接试件螺钉杆与孔壁承压及螺钉杆抗剪传递。

图11 厚板试件荷载-变形曲线

Fig.11 Slab tests load-deformation curve

(2) 弹塑性阶段。荷载-变形曲线的斜率逐渐减小,呈非线性增长,曲线变缓。此阶段螺杆发生倾斜,螺钉孔壁出现塑性变形,连接区段板端翘起。

(3) 塑性阶段。荷载-变形曲线趋于平缓,试件连接区段变形加剧,但荷载增加幅度不大,部分连接区段板件进入塑性阶段。

(4) 破坏阶段。对于螺钉被剪断的连接,其破坏阶段主要表现在荷载-变形曲线突然下降段,而对于螺钉倾斜被拔出及连接区段板件撕裂的试件,其荷载-变形曲线没有明显的下降段。

综上所述:当试件因连接区段板端翘起、螺钉过度倾斜而失效时,自攻螺钉连接处的变形量很大,试件体现出较好的塑性,属于延性破坏;当试件出现螺钉被剪断时,螺钉连接处的变形量较小,破坏较突然,属脆性破坏。

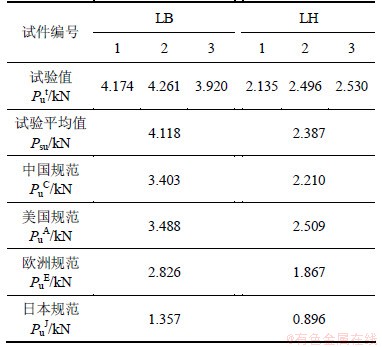

4.2 单颗螺钉连接抗剪承载力计算值的比较

依据各国规范[4, 12, 15-17]中单颗自攻螺钉连接件抗剪承载力的计算方法,计算得到本次试验LH和LB系列试件的抗剪承载力设计值,并与试验结果进行对比(如表1所示)。

表1 单颗螺钉连接件抗剪承载力对比

Table 1 Comparison of single screw connection shear capacity

由表1可知:采用我国规范GB50018—2002和美国AISI规范的计算方法计算单颗冷弯薄壁型钢自攻螺钉连接件抗剪承载力和试验结果比较接近,且还具有一定的安全储备;而采用欧洲EC3规范及日本规范计算得到的单钉承载力则过于保守。

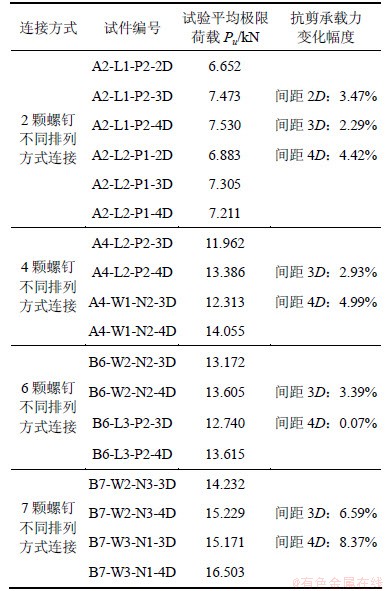

4.3 多颗螺钉连接抗剪承载力试验值的比较

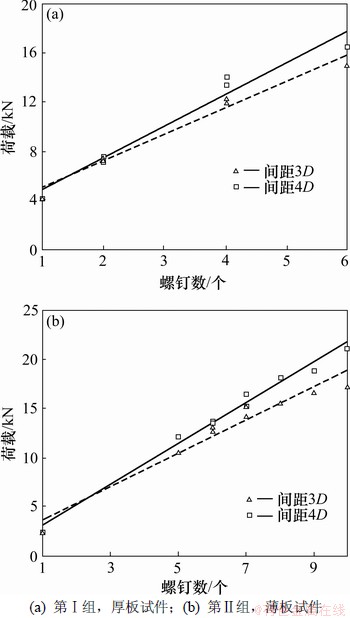

统计出螺钉排列方式对试件的试验平均极限抗剪承载力的影响如表2所示;螺钉数目及间距对试验试件抗剪承载力的影响见图12。

综合图10~12和表2结果,可得以下结论:

(1) 所有试件的破坏过程都有弹性阶段、弹塑性阶段、塑性阶段和破坏阶段4个阶段;同一系列试件的破坏模式较统一,试验平均极限荷载相差不大;

(2) 当螺钉数目和间距固定时,不同排列方式的连接件的抗剪承载力相差不大(差别在10%以内);

(3) 不同螺钉间距的同一系列试件的抗剪承载力随螺钉间距的增大而提高(如图12所示),但其荷载-变形曲线弹性阶段初始斜率基本相同,即它们具有基本相同的初始刚度(如图10~11所示);

表2 螺钉排列方式对连接件抗剪承载力的影响

Table 2 Screw arrangement affect the connection shear capacity

图12 螺钉数目及间距对连接件抗剪承载力的影响

Fig.12 Screw number and space affect connection shear capacity

(4) 冷弯薄壁型钢自攻自钻螺钉连接件抗剪承载力具有“群体折减效应”,即其抗剪承载力随螺钉数目的增加而呈非线性比例增长(如图12所示);

(5) 厚板和薄板系列试件抗剪承载力相差幅度较大,但它们是按相同尺寸标准加工,且2种母材的材性比较接近[11],由此说明在其它因素不变时,母材厚度是影响冷弯薄壁型钢自攻螺钉连接件抗剪承载力的主要因素之一。但当母材厚度增大到一定程度时,连接件破坏模式将只是螺钉剪断破坏的单一模式。

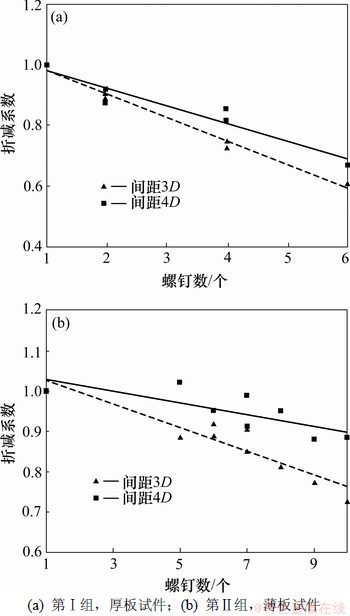

4.4 试验试件螺钉群连接的群体折减效应

文献[2]指出:螺钉群的抗剪承载力小于n倍单钉连接件抗剪承载力,即螺钉群连接件具有“群体折减效应”。本文提出用螺钉群的效率系数来考虑“群体折减效应”。依据本次试验结果,按下式计算本次试验试件螺钉群的效率系数:

R=Pu /(n.Psu) (1)

其中:R为螺钉群的效率系数;Pu为螺钉群连接件的试验平均极限荷载(如图10和图11所示);Psu为单颗螺钉连接件的试验平均极限荷载(如表1所示);n为试件自攻螺钉的颗数。

经统计计算,本次试验螺钉群连接试件的效率系数如下:厚板系列为0.60~0.90,薄板系列为0.70~1.00。

螺钉数目及间距对螺钉群效率系数的影响如图13所示,图中的直线是效率系数的线性回归直线。由图13可见:同系列螺钉连接件的R随螺钉间距的增大而增大,即适当增大螺钉间距可以使螺钉群中每个螺钉的使用效率提高;在螺钉排列方式相同时,R随螺钉个数的增加而减小;最后,当排列方式不同而螺钉个数和间距相同时,R差异较小。

图13 螺钉数目及间距对R的影响

Fig.13 Effect of screw number and spacing on R

5 结论

(1) 冷弯薄壁型钢自攻螺钉抗剪连接件的破坏模式主要有螺钉被剪断、螺钉倾斜拔出以及板件区段撕裂等;完整的破坏过程主要有弹性阶段、弹塑性阶段、塑性阶段和破坏阶段等4个阶段。

(2) 采用我国规范和北美规范规定的设计方法计算单颗冷弯薄壁型钢自攻螺钉连接件抗剪承载力和试验结果比较接近,具有一定的安全储备;采用欧洲规范及日本规范计算得到的单钉承载力则过于保守。

(3) 当螺钉数目及间距固定时,螺钉排列方式对冷弯薄壁型钢自攻螺钉连接件的抗剪承载力影响较小。

(4) 当螺钉数目及排列方式相同时,冷弯薄壁型钢自攻螺钉连接件的抗剪承载力随螺钉间距的增大而提高。

(5) 冷弯薄壁型钢自攻螺钉连接件的抗剪承载力随螺钉个数的增加而呈非线性增长。

(6) 其它因素不变时,在一定范围内,母材厚度也是影响冷弯薄壁型钢自攻螺钉连接件抗剪承载力的主要因素之一。

(7) 提出的螺钉群效率系数能较好地反映自攻螺钉群的“群体折减效应”。当螺钉排列方式及螺钉个数固定时,其螺钉群效率系数随螺钉间距的增大而增大;当螺钉排列方式及排列规则相同时,其螺钉群效率系数随螺钉个数的增加而减小;当螺钉个数和间距相同而排列方式不同时,其螺钉群效率系数差异较小。

参考文献:

[1] 弓晓芸, 严虹. 浅谈轻钢结构低层住宅[J]. 钢结构, 2001, 16(6): 27-29.

GONG Xiaoyun, YAN Hong. Talk about the light-steel low-rise residential[J]. Steel Structure, 2001, 16(6): 27-29.

[2] LaBoube R A, Sokol M A. Behavior of screw connections in residential construction[J]. Journal of Structural Engineering, 2002, 128(1): 115-118.

[3] Babalola M R, LaBoube R A. Strength of screw connections subject to shear force[R]. Department of Civil Engineering, Wei-Wen Yu Center for Cold-Formed Steel Structures, University of Missouri-Rolla, Rolla, Missouri, 2004.

[4] American Iron and Steel Institute, AISI. North American specification for the design of cold-formed steel structural members[S]. Washington, DC: American Iron and Steel Institute, 2001.

[5] Rogers C A, Hancock G J. Screwed connection tests of thin G550 and G300 sheet steels[J]. Journal of Structural Engineering, 1999, 125(2): 128-136.

[6] Serrette R, Peyton D. Strength of screw connections in cold-formed steel construction[J]. Journal of Structural Engineering, 2009, 135(8): 951-958.

[7] 潘景龙. 自攻螺钉连接的抗剪性能研究[J]. 哈尔滨建筑大学学报, 1995, 28(6): 41-47.

PAN Jinglong. Research on self-drilling screws connection shear capacity[J]. Journal of Harbin University of Architecture, 1995, 28(6): 41-47.

[8] 石宇, 周绪红, 聂少峰, 等. 冷弯薄壁型钢结构住宅螺钉连接的抗剪性能试验研究[J]. 建筑结构学报, 2010(增刊1): 184-188.

SHI Yu, ZHOU Xuhong, NIE Shaofeng, et al. Experimental investigation on shear behavior of screw connections in cold-formed steel residential building[J]. Journal of Building Structures, 2010(S1): 184-188.

[9] 刘楠. 自攻螺钉连接抗剪性能及其设计方法的研究[D]. 哈尔滨: 哈尔滨工业大学土木工程学院, 2007: 51-70.

LIU Nan. Research on the self-drilling screw connection shear capacity and design methods[D]. Harbin: Harbin Institute of Technology. School of Civil Engineering, 2007: 51-70.

[10] 宋延勇. 冷弯薄壁型钢偏压构件及自攻螺钉连接承载力试验研究[D]. 上海: 同济大学土木工程学院, 2008: 110-134.

SONG Yanyong. Experimental study of cold-formed steel pot pressure components and self-drilling screw connection capacity[D]. Shanghai: Tongji University. School of Civil Engineering, 2008: 110-134.

[11] 方文琦. 冷弯薄壁型钢自攻自钻螺钉连接抗剪承载力性能研究[D]. 西安: 长安大学建筑工程学院, 2010: 12-38.

FANG Wenqi. Research on shear bearing capacity of cold-formed steel self-drilling screw connection[D]. Xi’an: Chang’ an University. School of Civil Engineering, 2010: 12-38.

[12] GB 50018—2002, 冷弯薄壁型钢结构技术规范[S].

GB 50018—2002, Technical code of cold-formed thin-wall structures[S].

[13] 李元齐, 潘斯勇. 自攻螺钉连接承载力研究现状[J]. 结构工程师, 2008, 24(6): 154-158.

LI Yuanqi, PAN Siyong. Research progress on the bearing shear capacity of self-drilling screw connection[J]. Structural Engineer, 2008, 24(6): 154-158.

[14] AISI TS-4-02, Standard test methods for determining the tensile and shear strength of screws[S].

[15] European recommendations for connections in thin-walled structural steel elements[S].

[16] Euro code 3, Design of steel structures[S].

[17] 日本铁钢联盟编.薄板轻量型钢造建筑物设计の手册引ま[M]. 日本: 技报堂出版, 2002.

Iron and Steel Union Code in Japan. Light sheet steel design manual[M]. Japan: Church Publishing Science and Technology News, 2002.

(编辑 邓履翔)

收稿日期:2012-08-18;修回日期:2012-10-17

基金项目:陕西省自然科学基金资助项目(2007E225);中央高校基本科研专项基金项目(CHD2009JC008,CHD2012TD012);长安大学基础研究支持计划专项基金项目(2009);长安大学交通行业重点实验室开放基金项目(2009)

通信作者:卢林枫(1972-),男,黑龙江龙江人,博士,副教授,从事新型钢结构体系结构分析与设计研究;电话:029-82337821;E-mail: 54LLF@163.com