双辊铸轧铸嘴内部铝液流动的三维数值仿真

邓圭玲, 段吉安, 钟 掘

(中南大学 机电工程学院, 湖南 长沙,410083)

摘要: 针对在常规铸轧条件下结构型式完全不同的2种铸嘴,根据实际工况,分别应用层流模型和低雷诺数的k-ε湍流模型, 用商业软件CFX(version 4.2)对铝液在其内部的流动进行了三维数值仿真。研究结果表明:对于应用层流模型的铸嘴结构,其内部铝液流动的仿真结果与水模实验结果基本一致;对于应用低雷诺数的湍流模型的铸嘴结构,其内部铝液流动的仿真结果能较好地为铸嘴结构及参数的改进提供依据。尽管2种铸嘴结构的差异很大,铸嘴入口处的流动状态不同,分别处于层流和湍流的状态,但铸嘴出口处沿铸轧方向的流速分布规律在铸嘴宽度和高度方向非常相似。

关键词: 双辊铸轧; 铸嘴; 低雷诺数的湍流模型; 层流模型; 三维数值仿真

中图分类号: TF301; TG335.13; TG249.7 文献标识码:A 文章编号: 1672-7207(2005)04-0615-06

3-D numerical simulation of molten aluminum flow in feed tip nozzles of twin roll-casting

DENG Gui-ling, DUAN Ji-an, ZHONG Jue

(School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: 3-D numerical simulation of molten aluminum flow in feed tip nozzles of two completely different configuration feed tips used in conventional roll-casting condition was performed by using commercial, general purpose code CFX (version 4.2). For one feed tip, the laminar flow model should be applied and the simulation results are in agreement very well with the results of the water model of this feed tip. For the other feed tip, the low Reynolds number k-ε turbulence model should be applied and the numerical simulation results can provide foundation for improving the configuration and parameters of feed tips. Though the configurations of these two feed tips are greatly different and the flow fields at the entrance of them are completely different (one is laminar flow and the other is turbulence flow), the flow at the exit of them are very similar, especially for the distribution of velocity components parallel to the roll-casting direction both across the feed tip width and along the height.

Key words: twin roll-casting; feed tip nozzle; low Reynolds number turbulence model; laminar flow model; 3-D numerical simulation

在铝带坯双辊铸轧生产工艺中,铸嘴是输送铝液最关键的部件,其结构直接影响铝液能否均匀一致、平稳地流入铸轧区,进而影响铸轧板坯的质量甚[CM(22] 至板坯的稳定、正常生产。自20世纪90年代中期以来,国内外超薄快速铸轧技术的研究结果表明:超薄快速铸轧工艺要求从铸嘴出口流入铸轧区的铝液沿板宽方向的流量与温度均匀一致;在常规铸轧条件下正常生产用的铸嘴,不适用于快速铸轧[1-8]。美国铝业公司、Fata-Hunter公司和Pechiney公司的科研人员采用水模实验和二维数值仿真,对快速铸轧铸嘴结构参数设计和熔体在铸嘴内的流动规律进行研究[6-13]。H.Hu等[9,10]研究了以渐缩或渐扩的侧封块和机翼型分流块为特征的铸嘴结构的设计准则和铸嘴出口处的流速分布规律;D.M.Smith等[11-16]研制了用于快速铸轧和铝合金铸轧的多种类型的铸嘴;P.Y.Memet等[6]和M.Cortes[7]设计了用于快速铸轧的新型铸嘴结构。此外,土耳其ASSAN铝厂的科研人员运用商业软件FIDAP对铸嘴内熔体流动的速度场和温度场进行了二维数值仿真,并设计了用于快速铸轧的铸嘴[8]。值得指出的是,由于铸嘴上下板对铝液流动的约束作用非常重要,数值仿真采用忽略铸嘴上下板约束作用的二维流动模型很不合理;要使数值仿真能真实地反映流动实际,必须采用三维数值仿真。

无论常规铸轧还是快速铸轧,铸嘴结构的内腔尺寸特点相同:高度方向尺寸最小,出口处一般为6 mm左右,入口处一般小于20 mm;长度方向尺寸一般为360 mm左右;宽度方向尺寸最大,出口处通常为1000 mm以上。尽管铸嘴的结构型式多种多样,但根据铸嘴入口处的特征,可分为2种基本结构:包含多入口的宽入口铸嘴;单一窄入口铸嘴[3,8,9,11-14]。所有的铸嘴结构均为此2种铸嘴结构的变异,如分流块的形状、大小和位置不同,或位于铸嘴内侧的侧封块形状不同,或铸嘴的上板形状、下板形状不同等情形。熔体在此2种基本结构的铸嘴内流动有本质不同,为此,作者对熔体在铸嘴内流动速度场进行三维数值仿真。

1 铸嘴内熔体流动的工况参数、数学模型与边界条件

1.1 层流模型铸嘴的工况参数、数学模型与边界条件

1.1.1 宽入口铸嘴的工况参数

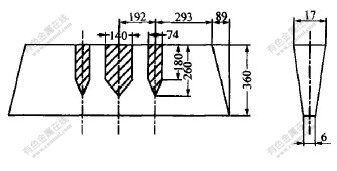

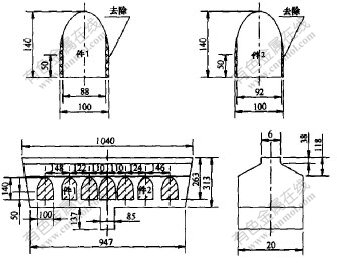

图1所示为一种实际生产使用的宽入口铸嘴,它包含多个入口。对于图1所示的铸嘴结构,其实际工况如下:

熔体入口温度tin=685 ℃,出口温度tout=670 ℃;铸轧板厚度H=7 mm,宽度b=1185 mm;铸轧速度 us=0.95 m/min;铸轧板密度ρs=2.70×103 kg/m3,铝熔体密度ρl=2.369×103 kg/m3;动力粘度μ=1.2248×10-3 Pa·s。运动粘度ν=5.17×10-7 m2/s。

图 1 宽入口铸嘴(铸嘴A)结构

Fig. 1 Configuration of feed tip with wide entrance (feed tip A)

当流体流动时,其流动状态可分为层流、湍流和过渡流。对于不同的流动状态,其数学模型不同。因此,必须进行流动状态判别。

流体的流动状态由雷诺数Re的大小决定[15]。

其中:um为主流方向流体的平均运动速度;ν为流体的运动粘度;R为水力半径,R=4A/L。A为过水面积,L为润湿周长。

当Re〈2300时,流体的流动状态为层流;当Re>2300时,流体的流动状态为湍流。而湍流又可进一步分为充分发展的湍流和未充分发展的湍流。

假设熔体在各入口铸轧方向的平均速度相同,另外2个方向的速度为零。由以上数据计算熔体在铸嘴内腔流动时的定性参数如下:

熔体在各入口铸轧方向的平均速度uin=1.364×10-2 m/s;中央入口处熔体的雷诺数Re=822.0;两侧入口处熔体的雷诺数Re=814.4;熔体沿铸嘴出口方向的流动,其雷诺数Re〈814.4。由此可判定,熔体在整个铸嘴内的流动处于层流态,因此,分析熔体在此铸嘴内的流动应采用层流模型。

1.1.2 铸嘴内熔体层流流动的数学模型与边界条件

根据实际情况,在对铸嘴流场进行仿真时,作如下假设:熔体为不可压缩流体,其密度ρ为常数;因流场温度变化小,动力粘度μ为常数;流场为定常流动。

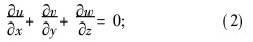

当流体的流动状态为层流时,流场的控制方程如下。

连续方程为:

动量方程为:

其中:u,v和w为对应x,y和z方向的流动速度;x,y和z分别为铸嘴的长度、宽度和高度方向坐标;p为压力;g为重力加速度;μ和ρ分别为流体的动力粒度和宽度。

对于层流,其边界条件如下:

壁面处Γw为固壁的边界条件为: u=v=w=0;

铸嘴出口处Γout的边界条件为:

铸嘴入口处Γin的边界条件为:各入口处的平均速度为vin=0,win=0,uin=1.364×10-2 m/s。

1.2 低雷诺数的k-ε湍流模型铸嘴的工况参数、数学模型与边界条件

1.2.1 单一窄入口铸嘴的工况参数

图2所示为一种实际生产使用的单一窄入口铸嘴。对于图2所示的铸嘴结构,其实际工况如下:

图 2 单一窄入口铸嘴(铸嘴B)

Fig. 2 Configuration of feed tip with single narrow entrance (feed tip B)

熔体入口温度tin=685 ℃,出口温度tout=670 ℃;铸轧板厚度H=6.5 mm,板宽b=1080 mm;铸轧速度us=0.95 m/min,铸轧板密度ρs=2.70×103 kg/m3,铝熔体密度ρl=2.70×103 kg/m3;动力粘度μ=1.2248×10-3 Pa·s,运动粘度ν=5.17×10-7 m2/s。

假设入口处熔体沿铸轧方向的平均速度相同,另外2个方向的流动速度为零。由以上数据可以得出熔体在铸嘴内腔流动的定性参数如下。

铸嘴入口处:熔体在铸轧方向的平均速度uin=9.021×10-2 m/s,雷诺数Re=5648.4;

铸嘴出口处:雷诺数Re=564.6。

由上述数据可判定熔体在铸嘴内腔的流动状态:入口处处于未充分发展的湍流区,流经铸嘴后在铸嘴出口处逐步变为层流区。因此,分析熔体在此铸嘴内的流动既不能采用层流模型,也不能采用在工程上广泛应用、反映充分发展、各向同性、高雷诺数湍流流动的k-ε湍流模型。计算结果也证实这一点,当采用层流模型计算熔体在此铸嘴内的流动时,计算无法取得收敛的结果;当采用k-ε湍流模型计算时,计算结果与实际情况明显不符。这是因为k-ε湍流模型对于近壁区、湍流各向异性、低雷诺数ReT的区域不适用。ReT指局部区域的湍流Re数,即ReT=ρk2/(εμ)。事实上,铸嘴内铝熔体流动的最大特点是近壁且各向异性,因此,不宜采用k-ε湍流模型。目前,低雷诺数k-ε湍流模型能较好地反映近壁区各向异性、低雷诺数ReT湍流流动[16],并且CFX4.2也支持该模型,为此,作者采用该模型进行计算。

1.2.2 铸嘴内熔体低雷诺数湍流流动的数学模型与边界条件

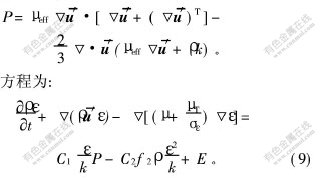

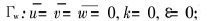

对于低雷诺数的k-ε湍流模型,其数学方程如下。

连续方程为:

动量方程为:

其中:有效粘度μeff=μ+μT;μT=Cμfμρ[SX(]k2[]ε[SX)];B为体积力矢量;[AKu-D]′为时均速度矢量(在x,y,z3个方向分别量为[AKu-D],[AKv-D],[AKw-D]);p′为时均压力。

k方程为:

其中:P为产出项,且

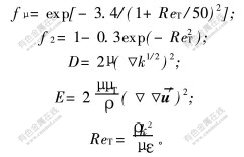

其中,函数fμ,f2,D和E的定义如下:

各方程的基本常数为:Cμ=0.09;σk=1.0;C1=1.44;C2=1.92;σε=1.3。

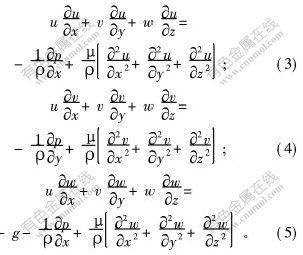

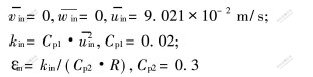

边界条件如下:

壁面处Γw:

铸嘴出口处Γout:  (充分发展);

(充分发展);

铸嘴入口处Γin:p′=0, 入口处的平均速度及k和ε值为:

,R为水力半径。

,R为水力半径。

2 2种铸嘴内熔体流动的数值仿真结果及分析

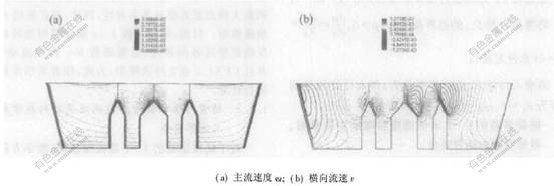

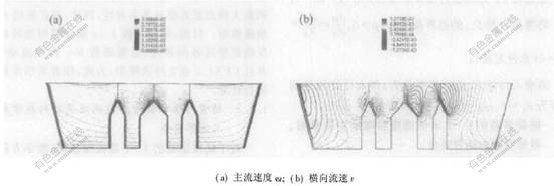

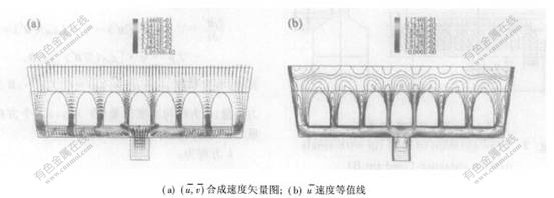

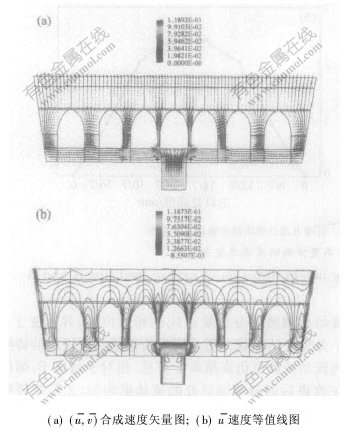

图3~5所示为熔体在铸嘴A与铸嘴B内流动的部分数值仿真结果。由图3和图4可以看出:铝熔体在2种铸嘴内的整个流动情况明显不同,但两者在铸嘴出口处的主流速度(u和[AKu-D])都比较均匀,在铸嘴边部两者都有较大的向外流动的横向速度(v和[AKv-D])。两者在铸嘴出口处对应于分流块的部位主流速度相对较低;对应分流块之间的通道或分流块与边[CM(22] 部挡块之间通道的主流速度相对较大。两者在分流

图 3 熔体在铸嘴A高度方向中剖面主流速度u和横向流速v的速度等值线图

Fig. 3 u and v velocity isoline charts of molten in symmetrical plane of feed tip A in height direction

图 4 熔体在铸嘴B高度方向中剖面的 合成速度矢量图与

合成速度矢量图与 速度等值线图

速度等值线图

Fig. 4 Vector graph of resultant velocity of ([AKu-D], [AKv-D])and [AKu-D] velocity isolinechart of molten in symmetrical plane of feed tip B in height direction

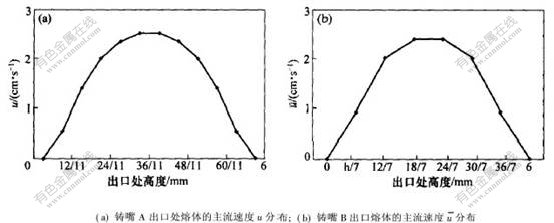

图 5 熔体在2种不同铸嘴出口处沿高度方向的主流速度分布图

Fig. 5 u and  velocity distribution of molten along height direction of exit of feed tips A and B

velocity distribution of molten along height direction of exit of feed tips A and B

块尾部附近区域都有明显的横向流动速度。熔体在铸嘴A的出口处流动特征为:中央区域的主流速度u较小,两边部通道的主流速度较大;横向流动的速度v在对应分流块位置的部位和边部都比较大。熔体在铸嘴B出口处的流动特征为:对应于中央部位的分流块之间的4个通道的主流速度u较大,其对应的横向速度v较小。

熔体在2种铸嘴宽度方向对称中心出口处沿高度方向的主流速度分布如图5所示。仿真结果表明:熔体在2个铸嘴的不同出口位置的流动沿高度方向的主流速度的分布非常相似,即层流分布和近似层流分布。由于横向速度与主流速度所受铸嘴上、下板的约束类似,所以,铸嘴出口处横向速度沿铸嘴高度方向分布也是层流分布和近似层流分布,这已由仿真结果所证实。

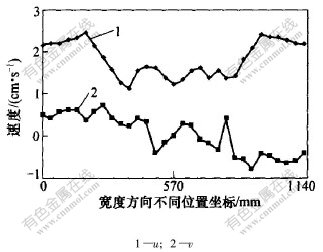

为验证数值仿真结果的正确性,按照雷诺准则设计实验铸嘴并进行水模型实验。水模型用实验铸嘴的结构参数与铸嘴A的结构参数相同,实验采用氢气泡法测量流动速度。在铸嘴内产生的氢气泡离铸嘴出口有一定距离,由于铸嘴高度较低,为便于观察,水的流量不能太大。实验中水的流量分别为36,60和78 L/min。图6所示为水的流量为78 L/min时熔体在铸嘴A中剖面上离出口25 mm处的u和v速度分布。可见,其规律与图3所示 的数值仿真结果相吻合。然而,水模型实验不可能确切地模拟铸轧时铝熔体流动的真实情况,因此,上述结果也只有定性的意义。

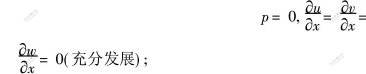

应用结果表明:采用铸嘴B进行铸轧生产时,板坯出现较明显的M型板型,板型的下凹部位正好位于铸嘴中央部位的分流块之间的4个通道处。对比仿真结果可知,4个通道处熔体主流速度过快。为了改善板型,对该铸嘴的结构进行改进。改进后的铸嘴结构如图7所示。由图7可知,改进后的铸嘴结构调整了分流块之间的相对位置,并改变了2个分流块的形状。图8所示为熔体在改进后的铸嘴内流动的数值仿真结果。可见,相对于铸嘴B,熔体在改进后的铸嘴出口处的流动更均匀,尤其是铸嘴

图 6 水模实验在铸嘴A靠近出口处的实测速度分布

Fig. 6 Velocity distribution of molten near exit obtained by water model test in symmetrical

图7 铸嘴B改进结构

Fig. 7 Configuration of reformed feed tip B

图 8 熔体在改进后的铸嘴B流动时沿高度方向中剖面 合成速度矢量图与

合成速度矢量图与 速度等值线图

速度等值线图

Fig. 8 Vector graph of resultant velocity  and

and  velocity isoline chart of molten insymmetrical plane of reformed feed tip B in height direction

velocity isoline chart of molten insymmetrical plane of reformed feed tip B in height direction

中央部位分流块之间的4个通道熔体的主流速度 明显减少,铸轧板不再出现M型板型,且板型良好。

明显减少,铸轧板不再出现M型板型,且板型良好。

3 结 论

a. 分别采用层流模型或低雷诺数的k-ε湍流模型对铝熔体在结构不同的2种铸嘴内腔的流动进行数值仿真。

b. 尽管所研究的2种铸嘴结构不同,但铝熔体在铸嘴出口处的流动特征类似:沿宽度方向流量比较均匀, 沿高度方向流动状态为层流或近似层流。

c. 层流模型的数值仿真结果与水模实验比较吻合;采用低雷诺数k-ε湍流模型数值仿真结果能较好地分析铸嘴结构参数对熔体在铸嘴出口处流动特性、铸轧板型的影响;通过改变分流块形状和调整分流块位置能明显改善铸轧板坯板型。

参考文献:

[1]Frischknecht B, Thun G. Strip casting technologies: state of the art and trends[J]. Aluminum, 2001, 77(10): 746-751.

[2]Hamer S, Smith D M, Yildizbayarak G, et al. Twin roll casting of aluminum at 2.5 mm gauge: production and process improvement[A]. Light Metals 1999[C]. Warren Dale: TMS, 1999: 931-937.

[3]Beals R, Duvuri R, Hamer S, et al. Recent innovations in advanced casting technology[A]. Light Metals 1998[C]. Warren Dale: TMS, 1998: 1161-1167.

[4]Menet P Y, Hoffinmana J L, Maiwald K. Development of sheet for canstock and other applications on pechiney neuf-brisac 3CMTM caster[A]. Light Metals 1998[C]. Warren Dale: TMS, 1998:1153-1160.

[5]Daland O, Espedal A B, Nedreberg M L, et al. Thin gauge twin-roll casting process capabilities and quality[A]. Light Metals 1997[C]. Warren Dale: TMS, 1997:745-752.

[6]Menet P Y, Cayol R, Moriceau J, et al. PECHINEY JUMBO 3CMTM start-up of the NEUF-BRISACH thin strip caster[A]. Light Metals 1997[C]. Warren Dale: TMS, 1997:753-756.

[7]Cortes M. PECHINEY JUMBO 3CMTM: the new demands of thin strip casting[A]. Light Metals 1995[C]. Warren Dale: TMS, 1995:1161-1164.

[8]Sarioglu K, Yildizbayrak G, Dundar M. Computer simulation of metal feeding used in twin roll casting[A]. Light Metals 2000[C]. Warren Dale: TMS, 2000:663-666.

[9]Yu H, Ai D K. Roll caster apparatus having converging tip assembly[P]. US4526223. 1985-06-02.

[10]Yu H, Ai D K. A fluid mechanics consideration of the rolling caster tip design criteria[A]. Light Metals 1986[C]. Warren Dale: TMS, 1986:897-908.

[11]Smith D M. New system enables sheet width changes during casting[J]. Light Metal Ages, 2000, 57(8), 130-133.

[12]Smith D M. Adjustable molten metal feed system[P]. US6095383. 2000-08-01.

[13]Flowers J E, Rromannowiski C A, Smith D M. Continuous casting aluminum[P]. US 4751958. 1988-06-21.

[14]李向宇.铝铸轧机常用铸嘴结构和材质[J].轻合金加工技术,1998,26(10):17-19.

LI Xiang-yu. Design and material of feed tip of sheet caster[J]. Light Metals Processing Technology, 1998, 26(10):17-19.

[15]吴持恭. 水力学(下册)[M].北京:高等教育出版社,1983.

WU Chi-gong. Hydraulics (Vol.2)[M]. Beijing: Higher Education Press, 1983.

[16]Patel V C, Rodi W, Scheuerer G. Turbulence model for near-wall reynolds number flows: a review[J]. AIAA Journal, 1984, 123(9): 1308-1319.

收稿日期:2005-03-29

基金项目:国家重点基础发展规划项目(G1999064906)

作者简介:邓圭玲(1964-),男,湖南双峰人,副教授,从事微电子封装工艺与装备、材料制备研究

论文联系人: 邓圭玲,男,副教授;电话:0731-8836499(O); E-mail:gldeng@mail.csu.edu.cn