CVI-RMI法制备C/SiC复合材料的微观结构与弯曲性能

肖 鹏,谢建伟,熊 翔,闫志巧

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:以T700炭纤维准三维编织针刺整体毡为预制体,在炭纤维表面CVI预沉积热解炭涂层,利用化学气相渗透-反应熔体浸渗法(CVI-RMI)制备C/SiC复合材料,观察材料的微观形貌,并探讨界面对弯曲性能的影响。研究结果表明:利用CVI-RMI联合工艺制备的C/SiC复合材料致密度高,开孔率较小(10%),基体分布均匀;材料弯曲强度达133 MPa,呈逐层破坏机制,表现出良好的假塑性;热解炭涂层与CVI-SiC基体减少了RMI工艺过程对炭纤维的损伤,且热解炭涂层调节了炭纤维与基体之间的界面结合状况,有利于纤维的拔出。

关键词:C/SiC复合材料;微观结构;化学气相渗透法;反应熔体浸渗法;弯曲性能

中图分类号:TB332 文献标识码:A 文章编号:1672-7207(2007)03-0381-05

Microstructure and flexural properties of

C/SiC composites by CVI-RMI method

XIAO Peng, XIE Jian-wei, XIONG Xiang, YAN Zhi-qiao

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Pyrolytic carbon coating and successive SiC matrix were respectively prepared by chemical vapor infiltration (CVI) in T700 kind integer felt. The subsequent reactive melt infiltration (RMI) method was adopted to densify it further and C/SiC composites were successively prepared. The microstructure and effect of interface on flexural properties were thoroughly investigated. The results show that C/SiC composites fabricated by CVI-RMI methods have high density and low porosity(10%), in which CVI-SiC and RMI-SiC distribute uniformly. The flexural strength of the composites is 133 MPa. The composites are damaged layer by layer with good pseudo-plasticity. C fibers are damaged lightly because of pyrolytic carbon coating and CVI-SiC. Pyrolytic carbon coating moderates the interface strength between C fibers and SiC, which is beneficial to the pulling out of C fibers.

Key words: C/SiC composite materials; microstructure; chemical vapor infiltration; reactive melt infiltration; flexural properties

连续纤维增强陶瓷基复合材料(CMCs)具有密度小、比强度高、比模量高、高温热结构性能和抗热冲击性能好的特点,是未来航天科技发展的关键支撑材料之一[1-5]。其中比较突出的是炭纤维增强碳化硅基复合材料,作为超高温复合材料在航空航天热防护系统上具有十分广阔的应用前景。我国西北工业大学制备的液体火箭发动机全尺寸C/SiC喷管已通过高空台架试车。法国SEP公司利用化学气相渗透法制备了C/SiC复合材料,并已应用于液体火箭推力室[6-8]。化学气相渗透法(CVI)是目前诸多制备CMCs方法中惟一成功实现商业化的工艺,被认为是最具潜力的陶瓷基复合材料制备工艺之一,其主要优点[9]如下:a. 能在低压低温下进行制造基体,材料内部残余应力小,纤维几乎不受损伤;b. 能实现微观尺度上的成分设计;c. 能制备形状复杂、近净尺寸和纤维体积分数高的部件。但是,采用CVI法制备周期长,材料的致密度低,并存在密度梯度等缺点。采用反应熔体浸渗法(RMI)制备C/SiC复合材料具有工艺简单、周期短、成本低、最终产品致密度高等优点[10],但RMI过程中熔融Si易损伤炭纤维,导致材料强度降低。

化学气相渗透-反应熔体浸渗(CVI-RMI)联合工艺能兼顾2种工艺的优点,具有材料内部残余应力小、损伤纤维少、致密度高、周期短、成本低等特点,能有效克服CVI法制备周期长、致密度低等缺陷,快速制备C/SiC复合材料[11-12]。在此,本文作者采用CVI-RMI联合工艺制备C/SiC复合材料,进行了微观形貌和力学性能测试分析,并探究该材料的失效破坏机制。

1 实 验

1.1 原料及工艺参数

本实验中所用的纤维为日本东丽(Toray)公司生产的PAN基T700炭纤维,采用无纬布网胎叠层,接力针刺方法将网胎中的纤维垂直刺入无纬布成准三维结构(也称2.5维)纤维预制体,其纤维体积分数约为32%。

CVI沉积热解炭(PyC)采用丙烯为反应气体,N2为稀释气体,沉积温度为850 ℃,压力小于3 kPa。CVI沉积SiC的先驱体采用三氯甲基硅烷(MTS)为先驱体,H2为载气,通过鼓泡的方式将MTS带入反应室中,以Ar作稀释气体,沉积温度为1 100 ℃,压力小于1 kPa。浸渍树脂采用具有较高残炭率(63%)的呋喃树脂(Furan Resin,FR),液态粘度为(40~150)×10-3 Pa?s(25 ℃),含水率<1%,灰分<3%。浸渍固化炭化过程在1.5 MPa和160 ℃浸渍固化,950 ℃炭化。RMI过程所采用的硅粉纯度为99.3%,粒径为40~50 ?m,渗硅温度为1 700 ℃ 。

1.2 工艺过程

首先,利用CVI法在炭纤维表面制备厚度约 0.3 ?m的热解炭涂层;然后,沉积SiC使材料增密至1.3 g/cm3;继续在预制体内浸渍呋喃树脂,经固化炭化后在预制体内生成树脂C;最后,利用RMI法通过熔融Si与树脂C发生反应,生成SiC基体,最终得到C/SiC复合材料。C/SiC复合材料的制备工艺流程如 图1所示。

图1 CVI-RMI 制备C/SiC复合材料工艺流程图

Fig.1 Process flow of C/SiC composites by CVI-RMI

1.3 结构与性能表征

利用排水法测试材料的密度和开孔率。利用Jeol-6360LV型扫描电子显微镜(SEM)进行组织结构和断口观察。沿平行无纬布方向截取试样,采用三点弯曲法测量C/SiC复合材料的弯曲强度,试样尺寸为40 mm×5 mm×3 mm,跨距为30 mm,加载速率为0.5 mm/min,同时记录荷载-位移曲线。弯曲性能测试设备为机械工业部长春试验机研究所生产的CSS-44100电子万能试验机。

2 结果与讨论

2.1 C/SiC复合材料的微观结构

按孔隙尺寸可将炭纤维预制体内的孔隙分为两 类[13]:一类是纤维束内纤维之间尺寸较小的小孔隙 (<10 ?m),另一类是纤维束之间的尺寸较大的大孔隙(几十到几百微米)。在CVI过程中,反应气体在尺寸较小的小孔隙主要依靠Kundsen扩散传质,但随着CVI过程的进行,孔隙的尺寸不断减少,导致气体扩散阻力不断增大,在有限的生产周期内很难将这类间隙完全填充。而对纤维束之间的大孔隙,很难采用CVI法完全填充而产生较大的残留孔隙。

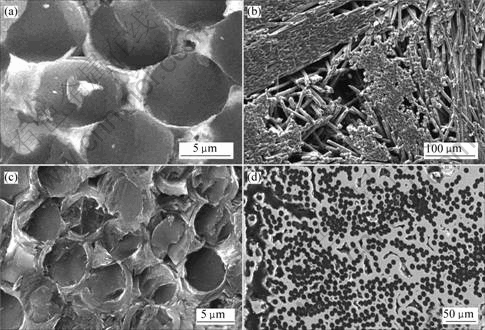

本实验在炭纤维表面预沉积一层约0.3 ?m厚的热解炭涂层后,利用CVI法沉积SiC将预制体增密至1.3 g/cm3。从图2可知,CVI-SiC基体优先沉积在纤维束内部纤维表面,填充于纤维束内纤维之间的小孔隙。图2(a)所示的基体致密,但仍有少量小孔隙存在;同时,纤维束间沉积SiC少,仍存在较大的孔隙(见图2(b))。在炭纤维预制体内浸渍呋喃树脂,经固化炭化,最后,利用RMI法制备SiC进一步增密,制得C/SiC复合材料。在RMI过程中,在毛细管力的作用下,依靠熔融Si的流动充分填充了纤维束内纤维之间尺寸较小的小孔隙(见图2(c)),以及纤维束之间尺寸较大的大孔隙(见图2(d))。从图2(c)和2(d)可以看出,CVI过程后留下的纤维束内纤维之间残留小孔隙和纤维束之间的残留大孔隙被RMI-SiC基体充分填充,因此,复合材料的致密化速度和效率显著提高。

(a) 采用CVI方法沉积SiC后纤维束内形貌;(b) 采用CVI方法沉积SiC后纤维束间形貌;

(c) 采用CVI-RMI方法后纤维束内形貌;(d) 采用CVI-RMI方法后纤维束间形貌

图2 采用CVI-RMI法和RMI法制备的C/SiC复合材料的微观形貌

Fig.2 SEM micrographs of C/SiC composites by CVI-RMI and RMI

纤维束间的大孔隙很难被CVI法完全填充而产生较大的残留孔隙,复合材料的致密度低。RMI工艺周期短,能充分填充纤维预制体内残留孔隙,材料致密度高,开孔率较小(10%)。

2.2 C/SiC复合材料弯曲性能及断裂机制

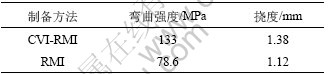

表1所列为采用2种方法制备的C/SiC复合材料的弯曲性能,RMI方法制备C/SiC复合材料的过程如下:首先,采用CVI法沉积热解炭将预制体增密至 1.1 g/cm3;然后,采用RMI-SiC法增密,使复合材料的最终密度和CVI-RMI方法制备的相同。从表1可以看出,通过CVI-RMI方法制备的材料弯曲强度较高,平均值达到133 MPa;而采用RMI法制备的C/SiC复合材料的弯曲强度仅为78.6 MPa;CVI-RMI方法制备的材料弯曲强度接近RMI法制备的材料弯曲强度的2倍。

表1 C/SiC复合材料的弯曲性能

Table 1 Flexural properties of C/SiC composites

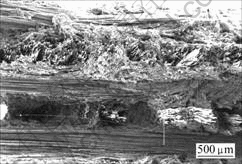

C/SiC复合材料的断裂特征主要取决于炭纤维与热解炭的界面的厚度、结合状态,材料的密度以及材料的内部缺陷等[14]。由于预制体采用的是准三维编织结构,两层排列有序的无纬布垂直叠层,中间夹层是无序网胎层,z向的针刺分布较少且只起固定作用,材料是一种层状复合材料(见图3)。

图3 C/SiC复合材料层状形貌

Fig.3 SEM photograph of C/SiC composites

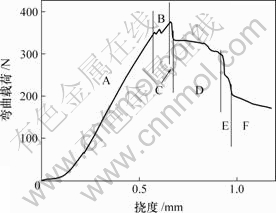

图4所示为C/SiC复合材料的弯曲载荷与挠度的关系曲线,可将曲线分为6个阶段:A阶段为弹性阶段;B阶段类似于金属材料的屈服阶段,裂纹从试样表面基体层开始扩展,遇到质软的热解炭涂层发生偏转,热解炭与纤维脱粘,消耗了大量的能量;C阶段应力在纤维周边集中,随着挠度的增加,第1层无纬布层整体断裂,载荷下降;而D阶段材料强度缓慢下降,由于裂纹进入第2层无纬布层,随着裂纹的进一步扩展,纤维脱粘拔出,载荷-挠度曲线出现一个平台;E阶段为无纬布层断裂,导致载荷急剧下降;F阶段中裂纹在第3层无纬布内热解炭涂层发生偏转,随着实验的进行,纤维发生脱粘拔出,出现一个平台;如此循环下去,直到最后一层无纬布发生断裂后,整个材料才发生整体断裂(见图5)。正是由于热解炭涂层的脱粘、纤维脱粘和拔出,整个材料呈逐层断裂破坏模式,且表现出很高的抗破坏能力和良好的假塑性。

图4 C/SiC复合材料的弯曲载荷-挠度曲线

Fig.4 Load-displacement curves for C/SiC composites

图5 试样断裂宏观形貌

Fig.5 Fracture macrograph of sample

热解炭涂层与炭纤维的结合强度对复合材料的力学性能有极大的影响[15],界面结合强度高,不能产生界面脱粘,表现为明显的脆性断裂,易发生灾难性断裂。采用RMI法时在1 700 ℃进行,也相当于对复合材料进行了热处理,由于热解炭涂层、碳化硅基体与炭纤维三者热膨胀系数的差异,高温热处理削弱了纤维/基体之间的界面结合,有利于纤维的拔出,复合材料的弯曲断裂曲线呈现明显的假塑性(见图4)。图6所示为C/SiC复合材料的断口形貌,可以看出纤维束被大量拔出和纤维束内部纤维被拔出。

(a) C/SiC复合材料纤维束被拔出;

(b) C/SiC复合材料纤维被拔出

图6 复合材料的断口形貌

Fig.6 SEM photographs of fracture surfaces of C/SiC composites

2.3 界面对弯曲性能的影响

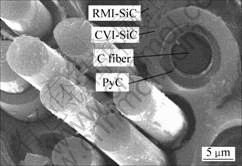

C/SiC复合材料断裂后的界面结合如图7所示,C/SiC复合材料中炭纤维呈单根被热解炭涂层均匀致密包覆,周围是CVI-SiC基体细密无缺陷,RMI-SiC基体分布在最外层。材料包含3类界面:炭纤维与热解炭涂层之间的界面,热解炭涂层与CVI-SiC基体之间的界面,CVI-SiC基体与RMI-SiC基体之间的界面。热解炭涂层的存在降低了CVI-SiC体与炭纤维之间的结合强度。在材料破坏过程中,裂纹在热解炭涂层发生偏转,大大缓解了炭纤维与CVI-SiC基体之间的应力集中,热解炭层与炭纤维发生脱粘,随着载荷的增加,纤维被拔出。

图7 C/SiC复合材料断裂后的界面结合

Fig.7 Interface bonding of C/SiC composites after fracture

从图7可以看出,材料断裂后炭纤维被明显拔出,拔出的纤维表面比较光滑,纤维较完整,说明热解炭涂层和CVI-SiC能极大地保护纤维不受RMI工艺的损伤。

3 结 论

a. 采用CVI-RMI方法成功制备了致密度高,开孔率为10%的C/SiC复合材料,采用该方法可以快速有效地制备C/SiC复合材料。

b. 采用CVI-RMI方法制备的材料弯曲强度为133 MPa,接近RMI方法制备的同类复合材料强度的2倍,材料呈逐层断裂破坏机制,表现出良好的假塑性。

c. 热解炭涂层调节了纤维与基体之间的界面结合状况,有利于纤维的拔出,且在RMI工艺过程中,热解炭涂层与CVI-SiC基体减少了对纤维的损伤。

参考文献:

[1] 刘荣军,周新贵,张长瑞,等. CVD法制备SiC先进陶瓷材料研究进展[J]. 材料工程, 2002(7): 46-49.

LIU Rong-jun, ZHOU Xin-gui, ZHANG Chang-rui. Development of SiC advanced ceramics by CVD[J]. Materials Engineering, 2002(7): 46-49.

[2] Grathwohl G, Hahnel A, Meier B, et al. Fiber-reinforced SiC-matrix composites: Microstructure, interfaces and mechanical properties[J]. Journal of the European Ceramic, 1992, 10(1): 1-12.

[3] Naslain R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview[J]. Composites Science and Technology, 2004, 64(2): 155-170.

[4] Delhaes P. Chemical vapor deposition and infiltration processes of carbon materials[J]. Carbon, 2002, 40(5): 641-657.

[5] Qian J, Wang J, Hou G, et al. Preparation and characterization of biomorphic SiC hollow fibers from wood by chemical vapor infiltration[J]. Scripta Materialia, 2005, 53(12): 1363-1368.

[6] 邹 武, 张康助, 张立同. 陶瓷基复合材料在火箭发动机上的应用[J]. 固体火箭技术, 2000, 23(2): 60-64.

ZOU Wu, ZHANG Kang-zhu, ZHANG Li-tong. Application of ceramic matrix composite to rocket motor[J]. Journal of Solid Rocked Technology, 2000, 23(2): 60-64.

[7] 张立同, 成来飞, 徐永东. 新型碳化硅陶瓷基复合材料的研究进展[J]. 航空制造技术, 2003(1): 23-32.

ZHANG Li-tong, CHENG Lai-fei, XU Yong-dong. Progress in research work of new CMC-SiC[J]. Aeronautical Manufacturing Technology, 2003(1): 23-32.

[8] Reuge N, Vignoles G L. Modeling of isobaric-isothermal chemical vapor infiltration: effects of reactor control parameters on a densification[J]. Journal of Materials Processing Technology, 2005, 166(1): 15-29.

[9] 肖 鹏, 徐永东, 张立同. 高温陶瓷基复合材料制备工艺的研究[J]. 材料工程, 2000(2): 41-44.

XIAO Peng, XU Yong-dong, ZHANG Li-tong. Study of processing of high temperature ceramic matrix composite[J]. Materials Engineering, 2000(2): 41-44.

[10] 万玉慧, 徐永东, 潘文革, 等. 反应熔体浸渗法制备C/SiC复合材料的结构与力学性能[J]. 玻璃钢/复合材料, 2005(5): 20-24.

WANG Yu-hui, XU Yong-dong, PAN Wen-ge, et al. Structure and mechanical properties of C/SiC composites by reactive melt infiltration[J]. Fiber Reinforced Plastics Composites, 2005(5): 20-24.

[11] Xu Y, Cheng L, Zhang L. Carbon/silicon carbide composites prepared by chemical vapor infiltration combined with silicon melt infiltration[J]. Carbon, 1999, 37(8): 1179-1187.

[12] 尹洪峰, 徐永东, 成来飞, 等. 界面相对碳纤维增韧碳化硅复合材料性能的影响[J]. 硅酸盐学报, 2000, 28(1): 1-5.

YIN Hong-feng, XU Yong-dong, CHENG Lai-fei, et al. Effect of interphases on the properties of 3-D Cf/SiCm composites[J]. Journal of the Chinese Ceramic Society, 2000, 28(1): 1-5.

[13] Xu Y, Zhang L, Cheng L, et al. Microstructure and mechanical properties of three-dimensional carbon/silicon carbide composites fabricated by chemical vapor infiltration[J]. Carbon, 1998, 36(7/8): 1051-1056.

[14] 徐永东, 张立同, 成来飞, 等. CVI法制备三维碳纤维增韧碳化硅复合材料[J]. 硅酸盐学报, 1996, 24(5): 485-490.

XU Yong-dong, ZHANG Li-tong, CHENG Lai-fei, et al. Three dimensional carbon fiber reinforced silicon carbide composites prepared by chemical vapor infiltration[J]. Journal of the Chinese Ceramic Society, 1996, 24(5): 485-490.

[15] 尹洪峰, 徐永东, 成来飞, 等. 连续碳纤维增韧SiC复合材料的制备与性能研究[J]. 硅酸盐学报, 2000, 28(5): 437-440.

YIN Hong-feng, XU Yong-dong, CHENG Lai-fei, et al. Study on preparation and properties of continuous carbon fiber-reinforced silicon carbide composites[J]. Journal of the Chinese Ceramic Society, 2000, 28(5): 437-440.

收稿日期:2006-09-28

基金项目:湖南省杰出青年科学基金资助项目(06JJ10007); 国家高技术研究发展计划资助项目(2006AA03Z560)

作者简介:肖 鹏(1971-),男,湖南涟源人,博士,从事高性能陶瓷基复合材料制备及应用研究

通讯作者:肖 鹏,教授;电话:0731-8830131;E-mail:xiaopeng@mail.csu.edu.cn