DOI: 10.11817/j.issn.1672-7207.2018.04.006

基于正交试验的7085铝合金双级时效制度

龙涛1,邓运来1, 2,范世通1,张研1

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 高性能与复杂制造国家重点实验室,湖南 长沙,410083)

摘要:采用正交试验,研究7085铝合金双级时效的预时效时间、二级时效温度和时间3个因素对硬度和电导率的影响,运用方差分析法研究3个影响因素的显著性,采用室温拉伸、慢应变速率拉伸和透射电镜观察等方法研究二级时效温度和时间对7085铝合金组织性能的影响。研究结果表明:3个因素的显著性从大到小为二级时效温度、二级时效时间、预时效时间。二级时效温度的提高和时间的延长使晶内η′相转变为η相、晶界相粗化且不连续,导致合金强度降低、抗应力腐蚀性能大幅提高,其中温度的影响作用更为显著,与正交试验结果相符。该合金最佳的T76双级时效工艺为:121 ℃/5 h+163 ℃/12 h,其抗拉强度和屈服强度分别为530 MPa和483 MPa,伸长率为14.2%,电导率为22.9 MS/m。

关键词:7085铝合金;正交试验;双级时效;拉伸性能;应力腐蚀

中图分类号:TG146.2+1 文献标志码:A 文章编号:1672-7207(2018)04-0809-08

Two-step aging treatment of 7085 alloy with orthogonal experiment

LONG Tao1, DENG Yunlai1, 2, FAN Shitong1, ZHANG Yan1

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. State Key Laboratory of High Performance and Complex Manufacturing,

Central South University, Changsha 410083, China)

Abstract: The effect of pre-aging time, secondary aging temperature and time of two-step aging on hardness and conductivity of 7085 aluminum alloy was investigated by orthogonal experiment. The significant regularity was studied by variance analysis, and the influence of secondary aging temperature and time on microstructure and properties of 7085 aluminum alloy was investigated by means of tensile test, slow strain rate test (SSRT) and transmission electron microscopy (TEM). The results show that the significant regularity (from big to small) of three factors is secondary aging temperature, secondary aging time, pre-aging time η′ phase transforms to η phase gradually, grain boundary precipitates become coarse and tend to be discontinuous with the increase of the secondary aging temperature and time. Thus, the strength of alloys decreases while the stress corrosion cracking (SCC) resistance increases. The influence of secondary aging temperature is more significant. During the optimal two-step aging treatment of 121 ℃/5 h+163 ℃/12 h, the tensile strength, yield strength, elongation and conductivity of the alloy are 530 MPa, 483 MPa, 12.6%, 22.9 MS/m, respectively.

Key words: 7085 alloy; orthogonal experiment; two-step aging; tensile properties; stress corrosion

Al-Zn-Mg-Cu合金具有高比强度、较好的抗腐蚀性能和断裂韧性,广泛应用于飞行器的主承力结构件[1-3]。20世纪60年代之前,Al-Zn-Mg-Cu合金主要采用T6峰值时效以获得较高的强度,但断裂韧性和抗腐蚀性能较差[4]。为了提高合金的抗腐蚀性能,美国Alcoa公司开发了T7x过时效工艺,而这使强度降低了10%~15%[5-7]。回归再时效(RRA)处理则可使合金在保持高强度的同时提高合金抗腐蚀性能。然而,由于RRA处理的回归处理阶段时间较短而难以应用于厚板生产[8-9],因此,在实际工业生产中,T7×热处理制度仍然是首选。众多学者对Al-Zn-Mg-Cu合金的双级时效制度进行了大量的研究[10-11],通过低温时效在较短时间内形成GP区,然后釆用高温二级时效促使GP区向η′相转变;选择合适的二级时效温度和时间细化晶内η′相并使之弥散分布,抑制η′相转变成粗大的η相提高合金的强度,同时促进晶界η相断续分布并使之发生粗化,从而达到提高合金的抗腐蚀性能目的[12-13]。以往的研究主要集中于针对特定的合金研究几种特定的双级时效制度,并从中选出最优制度,然而分别对预时效时间,二级时效温度和时间与合金组织、性能的关联规律研究较少,尤其是对3个因素影响力的大小即显著性缺乏有效、量化的评价。本文作者以7085铝合金板材为例,采用正交试验研究双级时效制度对其硬度和电导率的影响,通过方差分析和F检验给出3个影响因素显著性的量化指标,同时给出3个因素的影响规律和最优双级时效工艺;并通过室温拉伸和慢应变速率拉伸实验对正交试验结果进行验证。本研究的目的不仅是提供7085铝合金的最优双级时效制度,还期望为时效强化型铝合金工程化双级时效制度的开发提供一种普适性研究方法。

1 实验材料与方法

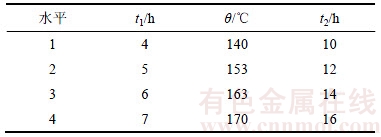

实验材料为经辊底式喷淋淬火处理的180 mm厚7085铝合金淬火态板材,其化学成分(质量分数,%)为:Al-7.5Zn-1.6Mg-1.7Cu-0.11Zr,w(Fe)<0.08,w(Si)<0.06。从板材中心层处切取2 mm厚的试样,进行不同双级时效处理。双级时效的预时效温度为121 ℃,对其他3个工艺参数(预时效时间t1,二级时效温度θ和时间t2)进行L16(43)正交实验,因素水平设计如表1所示。

硬度测试在HV-10B型维氏硬度计上进行,加载载荷为29.4 N,加载时间为 15 s,每个样品测量至少5个数据后取平均值。电导率测试在7501涡流导电仪上进行。室温拉伸性能测试在CSS-44100万能试验机上进行,拉伸试样按GB/6497—14规定取轧制方向的3个平行样,拉伸速率为2 mm/min。采用光滑试样的慢应变速率拉伸(slow strain rate tension,SSRT)方法评定应力腐蚀敏感性,拉伸速率为2×10-6 s-1,断口分析在EVO-MA10扫描电子显微镜上进行。透射电镜(TEM)分析在Tecnai G2 20电镜上进行,加速电压为200 kV,样品采用电解双喷方法制备,电解液为20%HNO3+80%CH3OH(体积分数),温度控制在-30~ -20 ℃之间。

表1 双级时效因素水平表

Table 1 Factors and levels graph of two-step aging

2 实验结果

2.1 正交试验结果与分析

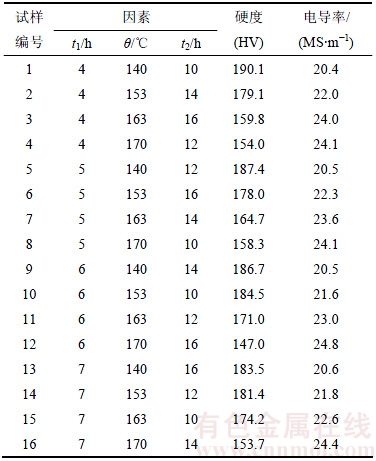

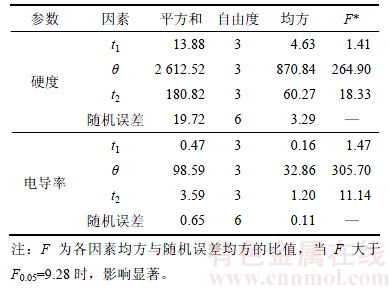

为了比较各因素对性能影响的显著性,对正交试验结果(表2)进行方差分析,得到硬度和电导率的方差分析表(表3)。采用方差分析法,不仅能对各因素的重要程度进行精确的数量估计,有利于选取影响显著的因素的最佳水平, 而且对影响不显著的因素可以选取有利于指标要求的水平[14]。由表2和表3可知:随二级时效温度提高和时间延长,合金的硬度降低,电导率提高;二级时效温度的方差和F值均最大,二级时效时间次之,预时效时间最小,即3个因素对硬度和电导率影响的显著性由大到小顺序为二级时效温度、二级时效时间、预时效时间。由此可见,二级时效温度是影响合金性能的决定因素,在一定范围内改变二级时效时间可微调合金性能,预时效时间的影响可 忽略。

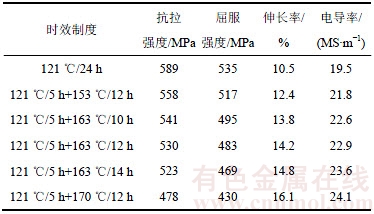

AMS 4329A标准规定7085铝合金板材T76状态的抗拉强度大于515 MPa,电导率大于22.6 MS/m[15]。结合正交试验结果可知:当二级时效温度不低于163 ℃时,合金的电导率超过22.6 MS/m,同时,为了获得较高的强度,选择163 ℃为第二级时效温度。

2.2 时效制度对室温拉伸性能和电导率的影响

为进一步优化7085铝合金的双级时效工艺,根据正交试验结果,选定预时效制度为121 ℃/5 h,选择153,163和170 ℃为二级时效温度,10,12和14 h为二级时效时间,测试室温拉伸性能以验证正交试验结果。

表2 正交试验表及结果

Table 2 Orthogonal experiment table and corresponding results

表3 硬度和电导率方差分析表

Table 3 Analysis of variance for hardness and conductivity

表4所示为经过不同时效制度处理的7085铝合金室温拉伸性能和电导率。由表4可知:随着二级时效温度提高和时间延长,合金的屈服强度和抗拉强度降低,伸长率提高;且二级时效温度对性能造成的影响大于二级时效时间所造成的影响,与正交试验结果相符。经 121 ℃/5 h+163 ℃/12 h处理后,合金的抗拉强度、屈服强度、伸长率和电导率分别达到530 MPa,483 MPa,14.2%和22.9 MS/m,此时,屈服强度比121 ℃/24 h峰时效时降低10%,抗拉强度降低9.7%,而伸长率提高35%,电导率提高17%。因此,选择121 ℃/5 h+163 ℃/12 h作为7085铝合金板材T76双级时效制度。

表4 不同时效制度下7085铝合金的室温拉伸性能和电导率

Table 4 Mechanical properties and conductivity of 7085 alloy under different aging treatments

2.3 双级时效制度对抗应力腐蚀性能的影响

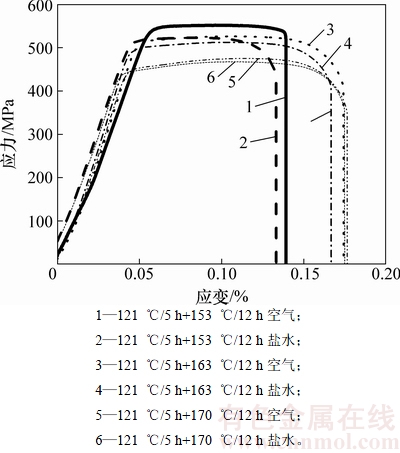

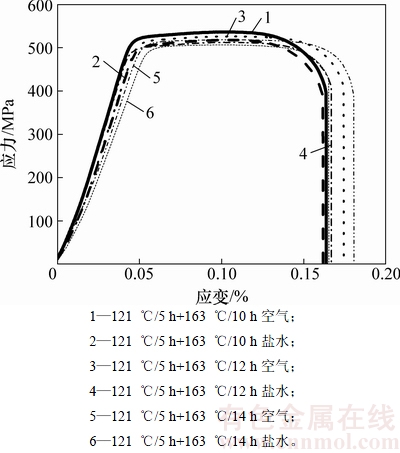

图1和图2所示分别为经不同双级时效处理的7085铝合金在空气和3.5%(质量分数)NaCl溶液中的慢应变速率拉伸曲线。从图1和图2可知:随着二级时效温度提高和时间延长,合金在断裂前的位移增大,而位移越大表明样品的抗应力腐蚀性能越好[16],因此,7085铝合金的抗应力腐蚀性能随着二级时效温度提高和时间延长而增强。应力腐蚀指数ISSRT是将慢应变速率拉伸实验中的各项性能综合处理的结果,其计算式[17]为

(1)

(1)

式中:σN和δN分别为3.5%NaCl溶液中的抗拉强度和伸长率;σA和δA分别为空气中的抗拉强度和伸长率。ISSRT越小,合金抗应力腐蚀性能越好。表5所示为经不同双级时效制度处理的7085铝合金应力腐蚀指数。由表5可知:随着二级时效温度提高和时间延长,合金的应力腐蚀指数降低,抗应力腐蚀性能增强,且二级时效温度对抗应力腐蚀性能造成的影响大于二级时效时间所造成的影响。经121 ℃/5 h+170 ℃/12 h双级时效处理,合金的应力敏感指数仅为0.022,抗应力腐蚀性能最好。

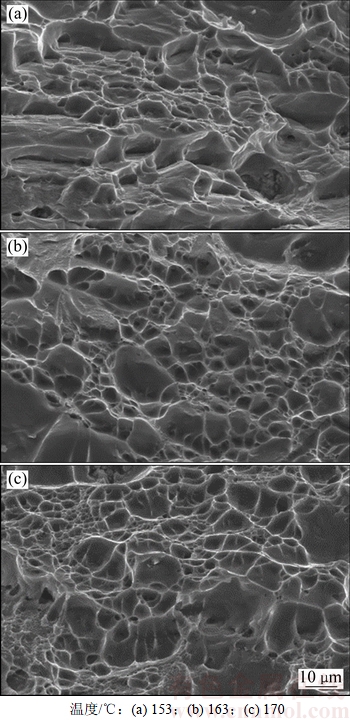

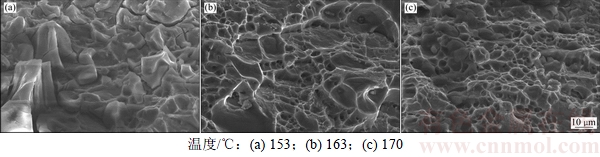

经不同二级时效温度时效12 h后,7085铝合金在空气和3.5%NaCl溶液中的慢应变速率拉伸断口形貌分布分别如图3和图4所示。从图3可知:合金在空气中的断裂方式均为韧窝型延性断裂,且随着二级时效温度的提高,韧窝数量增加,尺寸更加小,塑性增加。从图4可知:合金在质量分数为3.5%的NaCl溶液中为韧性断裂与沿晶断裂结合,且随着二级时效温度提高,韧窝数量增加,分布更加均匀。对比图3和图4,相比于3.5% NaCl溶液,合金在空气中的拉伸断口韧窝数量更多,尺寸更加小,塑性更好。这与慢应变速率拉伸试验数据规律相吻合。

图1 不同二级时效温度时效12 h的7085铝合金慢应变速率拉伸曲线

Fig. 1 Tensile curves of 7085 at slow strain rate at different secondary aging temperatures for 12 h

图2 二级时效温度为163 ℃时效不同时间的7085铝合金慢应变速率拉伸曲线

Fig. 2 Slow strain rate tensile curves of 7085 alloy of different secondary aging time at 163 ℃

表5 不同双级时效制度下7085铝合金的应力腐蚀敏感性

Table 5 Stress corrosion cracking susceptibility of 7085 alloy under different two-step agings

图3 不同二级时效温度时效12 h的7085铝合金在空气中的慢应变速率拉伸断口形貌

Fig. 3 Fracture surfaces of 7085 alloy in air at different secondary aging temperatures for 12 h

2.4 双级时效制度对显微组织的影响

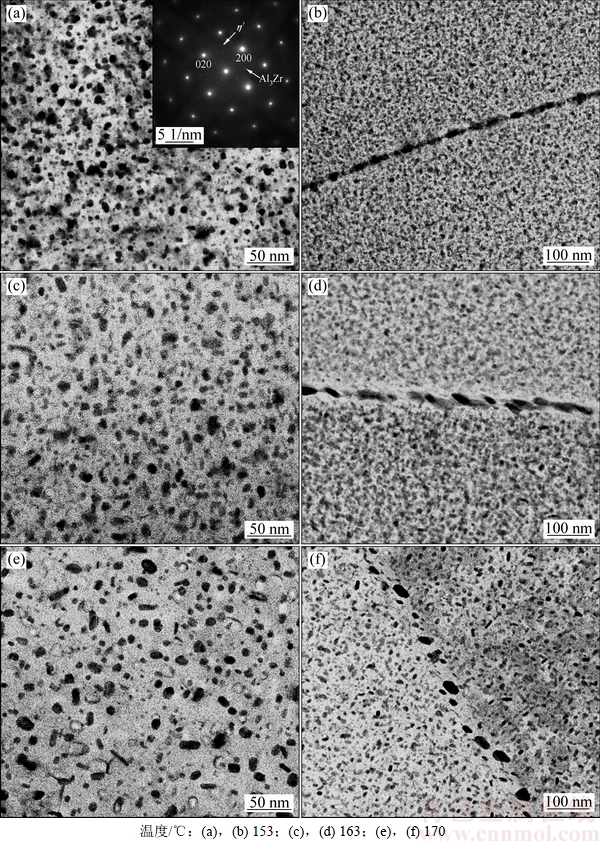

图5所示为7085铝合金经不同二级时效温度时效12 h后沿<001>方向的晶内、晶界相形貌。经121 ℃/5 h+153 ℃/12 h时效后,晶内析出细小而弥散的球状η′相,粒径为4~7 nm(图5(a));当二级时效温度提高到163 ℃时,晶内球状η′相数量减少而粒径增大,粒径为7~12 nm(图5(c));当二级时效温度进一步提高到170 ℃时,晶内析出2种不同形状的相:球状的η′相(粒径为13~15 nm)和短棒状的η相(长约为21 nm,宽约为14 nm)(图5(e))。由于位错的切过机制比绕过机制对合金的强化效果好,因此,Al-Zn-Mg-Cu合金的力学性能主要由晶内析出的GP区和η′相的体积分数、形貌、尺寸和分布所决定,析出相的体积分数越大,分布越均匀致密,合金的强度越高[18]。随着二级时效温度提高,η′相发生明显粗化,且大量η′转变为η相,降低对位错的阻碍作用,导致合金强度显著降低;当二级时效制度为170 ℃时,晶内出现η相导致合金的力学性能急剧下降。为保证合金强度,晶内应该避免出现η相[19],因此,合适的二级时效温度为163 ℃。

图4 不同二级时效温度时效12 h的7085铝合金在3.5%NaCl中的慢应变速率拉伸断口形貌

Fig. 4 Fracture surfaces of 7085 alloy in 3.5%NaCl at different secondary aging temperatures for 12 h

图5 不同二级时效温度时效12 h的7085铝合金TEM组织

Fig. 5 TEM micrographs of 7085 alloy at different secondary aging temperatures for 12 h

由图5(b),(d)和(f)可见:随着二级时效温度提高,晶界相明显粗化,逐渐变得不连续。Al-Zn-Mg-Cu合金的应力腐蚀开裂机理主要为阳极溶解和氢致开裂[20-21]。晶界η相电位低于Al基体,优先发生腐蚀溶解,断续分布的η相阻碍腐蚀的扩展;同时晶界处粗大的η相捕捉H重新合成H2从而降低晶界处H的浓度并且降低裂纹扩展速率,显著提高抗应力腐蚀性能[22]。

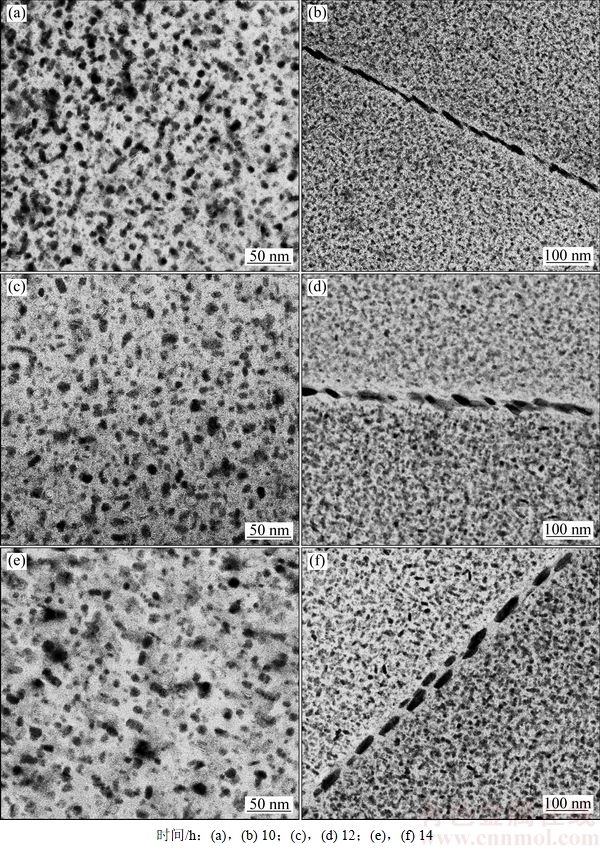

图6所示为7085铝合金二级时效温度为163 ℃时效不同时间后沿<001>方向的晶内、晶界相形貌。经 121 ℃/5 h+163 ℃/10 h时效后,晶内析出细小而弥散的球状η′相,其粒径为6~10 nm(图6(a));当二级时效时间延长到12 h时,晶内相数量减少而尺寸增大,粒径为7~12 nm(图6(c));当二级时效时间延长到14 h时,晶内析出相由少量短棒状的η相(长约为18 nm,宽约为12 nm)和大量球状的η′相(粒径为11~13 nm)组成(图6(e))。随着二级时效时间的延长,η′相粗化,且少量η′转变为η相,合金力学性能降低。

图6 二级时效温度为163 ℃时效不同时间的7085铝合金TEM组织

Fig. 6 TEM micrographs of 7085 alloy of different secondary aging time at 163 ℃

由图6(b),(d)和(f)可见:随着二级时效时间延长,晶界相粗化,逐渐变得不连续,合金的抗应力腐蚀性能增强。

由图5和图6可见:二级时效温度从153 ℃提高到170 ℃时,晶内η′相由4~7 nm粗化到13~15 nm,出现较多的大尺寸短棒状η相;而二级时效时间从10 h延长到14 h时,晶内η′相仅由6~10 nm粗化到11~12 nm,短棒状η相数量较少。二级时效温度的提高对晶内和晶界特征的影响远大于时间延长造成的影响,因此,二级时效温度是影响合金性能的决定因素,而改变二级时效时间可微调合金性能。

3 结论

1) 双级时效制度中二级时效温度是影响合金性能的决定因素,在一定范围内改变二级时效时间可微调合金性能。

2) 7085铝合金T76双级时效工艺为:121 ℃/5 h+ 163 ℃/12 h,其抗拉强度和屈服强度分别为530 MPa和483 MPa,伸长率为14.2%,电导率为22.9 MS/m。

3) 随二级时效温度提高和时间延长,晶内由η′相转变为η相,且数量减少、尺寸增大,晶界相逐渐粗化且不连续,导致合金的强度降低,电导率和抗应力腐蚀性能提高。

参考文献:

[1] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials and Design, 2014, 56: 862-871.

[2] 张新明, 邓运来, 张勇. 高强铝合金的发展及其材料的制备加工技术[J]. 金属学报, 2015, 51(3): 257-271.

ZHANG Xinming, DENG Yunlai, ZHANG Yong. Development of high strength aluminum alloys and processing techniques for the materials[J]. Acta Metallurgica Sinica, 2015, 51(3): 257-271.

[3] HEINZ A, HASZLER A, KEIDEL C, et al. Recent development in aluminum alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 280(3): 102-107.

[4] WALLANDE W, BEDDOES J C, MALHERBE M C. A new approach to the problem of stress corrosion cracking in 7075-T6 aluminum[J]. Canadian Aeronautics and Space Journal, 1981, 27(3): 222-232.

[5] MARLAUD T, DESCHAMPS A, BLEY F, et al. Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2010, 58(1): 248-260.

[6] XU D K, BIRBILIS N, ROMETSCH P A. The effect of pre-ageing temperature and retrogression heating rate on the strength and corrosion behaviour of AA7150[J]. Corrosion Science, 2012, 54(1): 17-25.

[7] 田福泉, 李念奎, 崔建忠. 超高强铝合金强韧化的发展过程及方向[J]. 轻合金加工技术, 2005, 33(12): 1-9.

TIAN Fuquan, LI Niankui, CUI Jianzhong. Research and development of ultra high strength aluminum alloys[J]. Light Alloy Fabrication Technology, 2005, 33(12): 1-9.

[8] OLIVEIRA A F, BARROS M C, CARDOSO K R, et al. The effect of RRA on the strength and SCC resistance on AA7050 and AA7150 aluminum alloys[J]. Materials Science and Engineering A, 2004, 379(1/2): 321-326.

[9] LIU Yingying, XIA Changqing, PENG Xiaomin, et al. Effect of heat treatment on microstructures and mechanical properties of Al-6Zn-2Mg-1.5Cu-0.4Er alloy[J]. Journal of Central South University of Technology, 2010,17(1): 24-27.

[10] 冯春, 刘志义, 宁爱林, 等. 超高强铝合金RRA热处理工艺的研究进展[J]. 材料导报, 2006, 20(4): 98-101.

FENG Chun, LIU Zhiyi, NING Ailin, et al, Research and progress in retrogression and reaging treatment of super-high strength aluminum alloy[J]. Materials Review, 2006, 20(4): 98-101.

[11] 田福泉, 崔建忠. 双级时效对7050铝合金组织和性能的影响[J]. 中国有色金属学报, 2006, 16(6): 958-963.

TIAN Fuquan, CUI Jianzhong. Effect of duplex aging on microstructure and properties of 7050 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(6): 958-963.

[12] 张新明, 宋丰轩, 刘胜胆, 等. 双级时效对7050铝合金板材剥蚀性能的影响[J]. 中南大学学报(自然科学版), 2011, 42(8): 2252-2259.

ZHANG Xinming, SONG Fengxuan, LIU Shengdan, et al. Influence of two-step aging on exfoliation corrosion properties of 7050 aluminum alloy plate[J]. Journal of Central South University (Science and Technology), 2011, 42(8): 2252-2259.

[13] 闫焱, 郑子樵, 龙佳. 7A55铝合金预拉伸板材的双级时效工艺[J]. 材料热处理学报, 2010, 31(11): 128-133.

YAN Yan, ZHENG Ziqiao, LONG Jia. Double aging studying of pre-stretched 7A55 aluminum alloy plate[J]. Transactions of Materials and Heat Treatment, 2010, 31(11): 128-133.

[14] 刘瑞江, 张业旺, 闻崇炜, 等. 正交试验设计和分析方法研究[J]. 实验技术与管理, 2010(9): 52-55.

LIU Ruijiang, ZHANG Yewang, WEN Chongwei, et al. Study on the design and analysis methods of orthogonal experiment[J]. Experimental Technology and Management, 2010(9): 52-55.

[15] AMS4329A, Aluminum alloy, plate (7085-T7651) 7.5Zn-1.6Cu- 1.5Mg-0.12Zr solution heat treated, stress-relieved, and overaged[S].

[16] SONG R G, DIETZEL W, ZHANG B J, et al. Stress corrosion cracking and hydrogen embrittlement of an Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2004, 52(16): 4727-4743.

[17] 黎彦希, 陈康华, 陈送义, 等. 添加Cr和Yb对Al-Zn-Mg-xCu-Zr超强铝合金组织与性能的影响[J]. 中南大学学报(自然科学版), 2015, 46(12): 4422-4433.

LI Yanxi, CHEN Kanghua, CHEN Songyi, et al. Effect of Cr and Yb additions on microstructure and properties of Al-Zn-Mg-xCu-Zr alloy[J]. Journal of Central South University (Science and Technology), 2015, 46(12): 4422-4433.

[18] MARLAUD T, DESCHAMPS A, BLEY F, et al. Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys[J]. Acta Materialia, 2010, 58(1): 248-260.

[19] SHARMA M M, AMATEAU M F, EDEN T J. Hardening mechanisms of spray formed Al-Zn-Mg-Cu alloys with scandium and other elemental additions[J]. Journal of Alloys and Compounds, 2006, 416(1/2): 135-142.

[20] COOPER K R, KELLY R G. Crack tip chemistry and electrochemistry of environmental cracks in AA 7050[J]. Corrosion Science, 2007, 49(6): 2636-2662.

[21] NAJJAR D, MAGNIN T, WARNER T J. Influence of critical surface defects and localized competition between anodic dissolution and hydrogen effects during stress corrosion cracking of a 7050 aluminum alloy[J]. Materials Science and Engineering A, 1997, 238(2): 293-302.

[22] 李波, 潘清林, 李晨, 等. 时效处理对含钪Al-Zn-Mg-Zr合金腐蚀行为的影响[J]. 中南大学学报(自然科学版), 2013, 44(10): 3998-4005.

LI Bo, PAN Qinglin, LI Chen, et al. Influence of aging treatment on corrosion behavior of Al-Zn-Mg-Zr alloy with Sc element[J]. Journal of Central South University (Science and Technology), 2013, 44(10): 3998-4005.

(编辑 杨幼平)

收稿日期:2017-04-29;修回日期:2017-06-22

基金项目(Foundation item):国家重点基础研究发展计划(973计划)项目(2012CB619500);国家重点研发计划项目(2016YFB0300901);国家自然科学基金资助项目(51375503)(Project(2012CB619500) supported by the National Basic Research Program (973 Program) of China; Project(2016YFB0300901) supported by Major State Research Program of China; Projects(51375503) supported by the National Natural Science Foundation of China)

通信作者:范世通,博士研究生,从事高性能铝合金研究;E-mail:fanstone95@163.com