Effects of Al-10Sr master alloys on grain refinement of AZ31 magnesium alloy

来源期刊:中国有色金属学报(英文版)2008年第1期

论文作者:杨明波 潘复生 程仁菊 汤爱涛

文章页码:52 - 58

Key words:Al-10Sr master alloy; AZ31 magnesium alloy; grain refinement; Al4Sr phase

Abstract: The effects of Al-10Sr master alloys on grain refinement of AZ31 magnesium alloy were investigated, and the refinement efficiency of different Al-10Sr master alloys (commercial, solubilized, rolled and remelted+rapidly cooled) was compared and analyzed. The results indicate that the morphology and size of Al4Sr phases in the microstructures of different Al-10Sr master alloys, are of great difference. For the commercial Al-10Sr master alloy, the Al4Sr phases evolve from coarse block shape to relatively fine block shape after being dissolved at 500 ℃ for 4 h and followed by water quenching; but after being rolled at 300 ℃ for 50% reduction or remelted and followed by rapid cooling, the Al4Sr phases mainly exhibit fine granule and fibre shapes. In addition, the different Al-10Sr master alloys can effectively reduce the grain size of AZ31 magnesium alloy, but their refinement efficiency is different. The refinement efficiency of the Al-10Sr master alloy obtained by remelting and rapid cooling is the best, then the rolled, solubilized and commercial Al-10Sr master alloys are in turn. The difference of refinement efficiency for different Al-10Sr master alloys may be related to the dissolution rates of Al4Sr phases with different morphologies and sizes in the melt of AZ31 magnesium alloy.

基金信息:the National Natural Science Foundation for Distinguished Young Scholar in China

the National Basic Research Program of China

YANG Ming-bo(杨明波)1, 2, PAN Fu-sheng(潘复生)2, CHENG Ren-ju(程仁菊)2, TANG Ai-tao(汤爱涛)2

1. College of Materials Science and Engineering, Chongqing Institute of Technology, Chongqing 400050, China;

2. College of Materials Science and Engineering, Chongqing University, Chongqing 400030, China

Received 26 March 2007; accepted 11 June 2007

Abstract: The effects of Al-10Sr master alloys on grain refinement of AZ31 magnesium alloy were investigated, and the refinement efficiency of different Al-10Sr master alloys (commercial, solubilized, rolled and remelted+rapidly cooled) was compared and analyzed. The results indicate that the morphology and size of Al4Sr phases in the microstructures of different Al-10Sr master alloys, are of great difference. For the commercial Al-10Sr master alloy, the Al4Sr phases evolve from coarse block shape to relatively fine block shape after being dissolved at 500 ℃ for 4 h and followed by water quenching; but after being rolled at 300 ℃ for 50% reduction or remelted and followed by rapid cooling, the Al4Sr phases mainly exhibit fine granule and fibre shapes. In addition, the different Al-10Sr master alloys can effectively reduce the grain size of AZ31 magnesium alloy, but their refinement efficiency is different. The refinement efficiency of the Al-10Sr master alloy obtained by remelting and rapid cooling is the best, then the rolled, solubilized and commercial Al-10Sr master alloys are in turn. The difference of refinement efficiency for different Al-10Sr master alloys may be related to the dissolution rates of Al4Sr phases with different morphologies and sizes in the melt of AZ31 magnesium alloy.

Key words: Al-10Sr master alloy; AZ31 magnesium alloy; grain refinement; Al4Sr phase

1 Introduction

At present, the AZ series of magnesium alloys have been widely applied in industrial production, but their mechanical properties and processing performances still can not meet the needs of some important parts in vehicles and other application fields. Therefore, many ways are being investigated in the world in order to further improve the mechanical properties and processing performances of the AZ series of magnesium alloys[1-4]. It is well known that grain refinement is an important method of elevating property and improving formability for magnesium alloys. Recent results indicate that Sr additions such as Al-Sr master alloys that have been widely used in industrial practice especially for the modification of Al-Si alloys, were thought as an effective means of grain refinement for Mg-Al series alloys[5-7]. For example, SRINIVASAN et al[8] and NAM et al[9] reported that adding Al-10Sr master alloy to a Si-containing AZ91-Mg alloy appeared to refine the microstructure by promoting a finer grain size, and similar results were also obtained respectively in AM50-Mg alloy and AZ91-Mg alloy by ZHAO et al[10] and HIRAI et al[11]. In addition, ZENG et al[12] and CHEN et al[13] respectively reported that adding pure Sr or Al-10Sr alloy to AZ31-Mg alloy effectively reduced its grain size, and similar results were reported by other researchers[5-6].

According to the industrial practice of Al-Sr master alloys for the modification and refinement of aluminum alloys, high dissolution rate can be obtained for the finer Al4Sr phases in Al-Sr master alloys (for a given alloy in contact with the melt for a given time), thereby enhancing the efficiency of modifiers, and this refinement of Al4Sr phases could be achieved by deformation, rapid solidification or heat treatment [14-17]. But up to now, limited research work about the effects of Al4Sr phase in Al-Sr master alloys on the microstructure of AZ serious alloys has been carried out.

In the present work, the effects of solution heat treatment, rolling treatment and remelting+rapid cooling treatment on the microstructure of commercial Al-10Sr master alloy were investigated firstly. Then the effects of these Al-10Sr master alloys on the grain refinement of AZ31 magnesium alloy were compared and analyzed.

2 Experimental

The rods of commercial Al-10Sr master alloy that were prepared by traditional casting and subsequent extrusion at Changzhou Metal Materials Company Limited in China, were used for solid solution treatment, rolling treatment and remelting + rapid cooling treatment respectively. The solid solution treatment was carried out at 500 ℃ for 4 h and followed by water quenching. The rolling treatment was carried out at 300 ℃ for reduction level of 50%, and the hot rolling process included a 20% reduction level at the beginning at a predetermined temperature. For further reduction levels, the sample was again heated to the same temperature and rolled. The remelting and rapid cooling treatment was carried out in an electrical resistance furnace using a graphite crucible. The rods of commercial Al-10Sr master alloy were melted firstly. After the melt was held at 740 ℃ for 60 min, the melt was poured into a water cooling permanent mould whose mould cavity is 50 cm×0.5 cm×60 cm.

The commercial and treated Al-10Sr master alloys were used to refine the microstructure of AZ31 magnesium alloys respectively. The refinement treatment was carried out in an electrical resistance furnace using a graphite crucible and protected by a flux addition. When the melt temperature reached 740 ℃ approximately, the Al-10Sr master alloys whose mass was calculated according to the Sr adding amount, 0.01%, 0.05% and 0.1%, were added to the melt. After being held for 20, 40 and 60 min respectively, the melt was poured into a permanent mould whose mould cavity is d 20 mm×90 mm. Moreover, in order to show the crystal grains of the AZ31 magnesium alloys clearly, the solid solution treatment of the obtained castings was carried out at 415 ℃ for 12 h and followed by water quenching. Finally, optical microscopic samples of experimental AZ31 magnesium alloys were etched with a solution of 1.5 g picric, 25 mL ethanol, 5 mL acetic acid and 10 mL distilled water and then were examined using an Olymous optical microscope. The grain size analysis was carried out by the standard linear intercept method using an Olympus stereo-microscope. The phases in the AZ31 magnesium alloys were also analyzed by D/Max-1200X type analyzer operated at 40 kV and 30 mA.

3 Results and discussion

3.1 Microstructure of Al-10Sr master alloys

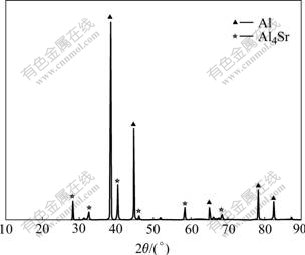

Fig.1 shows the XRD patterns of the Al-10Sr master alloy obtained by remelting and rapid cooling. It is found that the master alloy is composed of α(Al) and Al4Sr phase. It is well known that the commercial, dissolved and rolled Al-10Sr master alloys are also composed of α(Al) and Al4Sr phases respectively. Then it is believed that the treatment processes do not influence the phase composition of the commercial Al-10Sr master alloy.

Fig.1 XRD pattern of Al-10Sr master alloy obtained by remelting and rapid cooling

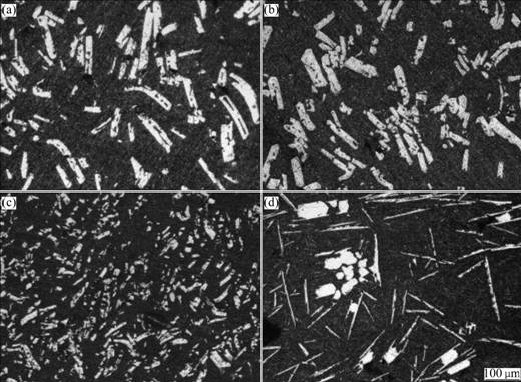

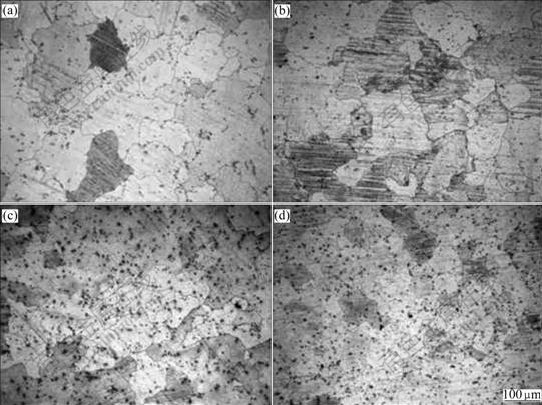

Fig.2 shows the microstructures of different Al-10Sr master alloys (commercial, solubilized, rolled and remelted + rapidly cooled). As shown in Fig.2, the morphology and size of Al4Sr phases in the microstructures of different Al-10Sr master alloys are of great difference. For the commercial Al-10Sr master alloy, the Al4Sr phases evolve from coarse block shapes to relatively fine block shapes after being dissolved at 500 ℃ for 4 h and followed by water quenching. However, the Al4Sr phases mainly exhibit fine granule and fibre shapes after being rolled at 300 ℃ for 50% reduction or remelted and followed by rapid cooling.

Fig.2 Microstructures of different Al-10Sr master alloys: (a) Commercial; (b) Solubilized; (c) Rolled; (d) Remelted and rapidly cooled

3.2 Microstructure of AZ31 magnesium alloy

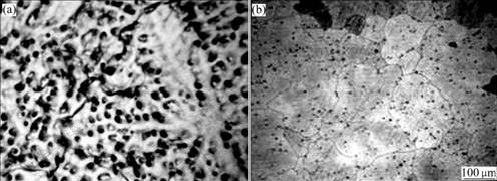

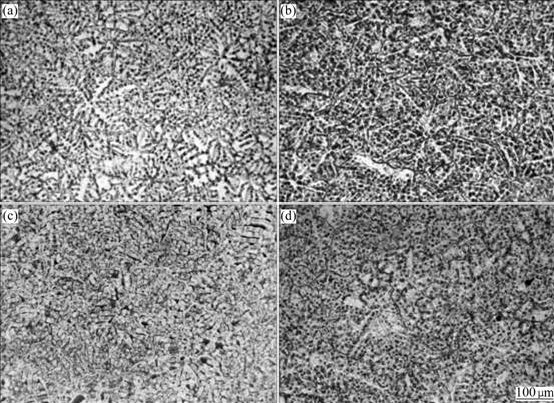

Fig.3 shows the as-cast and solubilized microstructures of AZ31 magnesium alloy untreated. At the same time, under the condition of Sr adding amount being 0.1% and melt holding time being 60min, the as-cast and solubilized microstructures of AZ31 magnesium alloys treated by different Al-10Sr master alloys, are shown in Fig.4 and Fig.5. It can be seen from Fig.3 that the dendritic arm spacing and grain size of AZ31 magnesium alloy untreated by Al-10Sr master alloy, are big. However, after being treated by the different Al-10Sr master alloys, the dendritic arm spacings and grain sizes decrease (see Fig.4 and Fig.5). Then it is believed that different Al-10Sr master alloys, could effectively refine the microstructure of AZ31 magnesium alloy. By comparing Fig.4 with Fig.5, it is found that the refinement efficiency of commercial and solubilized Al-10Sr master alloys is relatively low. Oppositely, the Al-10Sr master alloys obtained by rolling or remelting + rapid cooling have relatively high refinement efficiency, thereinto the efficiency of Al-10Sr master alloy obtained by remelting and rapid cooling is higher than that of the rolled one.

Fig.3 Microstructures of AZ31 magnesium alloy untreated: (a) As-cast; (b) Solubilized

Fig.4 As-cast microstructures of AZ31 magnesium alloy treated by different Al-10Sr master alloys: (a) Commercial; (b) Solubilized; (c) Rolled; (d) Remelted and rapidly cooled

Fig.5 Solubilized microstructures of AZ31 magnesium alloy treated by different Al-10Sr master alloys: (a) Commercial;(b) Solubilized; (c) Rolled; (d) Remelted and rapidly cooled

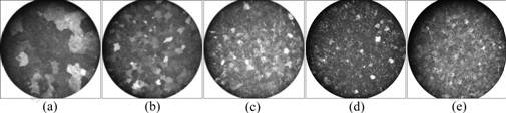

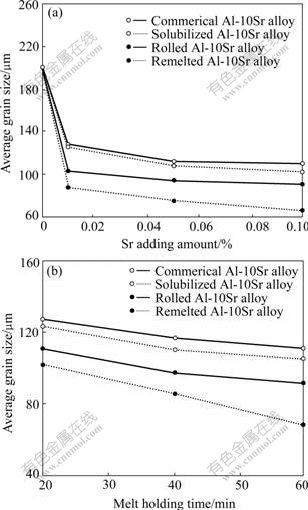

Under the condition of Sr adding amount being 0.1% and melt holding time being 60 min, the macrostructures of AZ31 magnesium alloys treated by the different Al-10Sr master alloys, are shown in Fig.6.At the same time, for a given melt with holding time being 60 min or Sr adding amount being 0.1%, the effects of Sr adding amount or melt holding time on the grain sizes of AZ31 magnesium alloys are shown in Fig.7. According to Fig.6 and Fig.7, the experimental results obtained from Fig.4 and Fig.5 can be confirmed quantitatively. In addition, in Fig.7, it is also found that with the Sr adding amount increasing from 0 to 0.1% or melt holding time increasing from 20 min to 60 min, the refinement efficiencies of different Al-10Sr master alloys increase, and the increasing laws are similar.

Fig.6 Macrostructures of AZ31 magnesium alloy treated by different Al-10Sr master alloys (Diameter of each polished section is about 25 mm): (a) Untreated; (b) Commercial; (c) Solubilized; (d) Rolled; (e) Remelted and rapidly cooled

Fig.7 Effects of Sr adding amount (a) and melt holding time (b) on grain sizes of AZ31 magnesium alloy

3.3 Discussion

In general, the grain refinement in industrial applications usually involves adding nucleant and solute elements, and the effect of a solute element on grain refinement is explained in terms of the growth restriction factor GRF (Eqn(1)) [5-6,12]. At the same time, according to the research results obtained by LEE et al[5] and GRUZLESKI et al[6], the solid solubility of Sr in magnesium is relatively limited, and thus rapid enrichment of Sr in the liquid ahead of the growing interface will restrict the grain growth during solidification. So the mechanism of grain refinement by Sr in magnesium alloys is mainly believed to be the GRF mechanism. The bigger the GRF value, the higher the refinement efficiency of Sr in magnesium alloys.

![]() (1)

(1)

where mi is the slope of the liquidus line, c0i is the initial concentration of element i, ki is the partition coefficient. Under the experimental condition of this paper, i is Al, Zn and Sr element respectively.

It is well known that the microstructure of Al-10Sr master alloy is composed of α(Al) and Al4Sr phase, and the Al4Sr phase is of a body centered tetragonal structure (DI3 with a=0.446 nm and c=1.107 nm)[18]. Obviously, the Al4Sr phases can not directly influence the grain refinement unless the free Sr can be obtained by the dissolution of Al4Sr phases. In this work, when different Al-10Sr master alloys (commercial, solubilized, rolled and remelted + rapidly cooled) are used to refine the microstructure of AZ31 magnesium alloy, the treatment conditions such as melt treatment temperature, holding time and Sr adding amount are the same. Then if the dissolution rates of Al4Sr phases for the different Al-10Sr master alloys in the melt of AZ31 magnesium alloy are equal, the initial concentration of free Sr should be equal. Accordingly, the GRF values are also equal according to the Eqn.(1). Then according to the GRF mechanism, the refinement efficiency of different Al-10Sr master alloys should be similar. However, the deducing conclusion does not agree with the actual situation. Then it is inferred that the dissolution rates of Al4Sr phases for different Al-10Sr master alloys in the melt of AZ31 magnesium alloy are different. This conclusion can be further confirmed from Fig.8. Fig.8 shows the XRD patterns of as-cast AZ31 magnesium alloys treated by commercial and remelted Al-10Sr master alloys under the condition of Sr adding amount being 0.1% and melt holding time being 60 min. As shown in Fig.8, the Al4Sr phase is detected in the as-cast microstructure of AZ31 magnesium alloy treated by commercial Al-10Sr master alloy (Fig.8(a)). However, opposite result is obtained for the as-cast AZ31 magnesium alloy treated by the remelted Al-10Sr master alloy (Fig.8(b)). Small amounts of strontium do not cause the formation of any new phase in the microstructure of magnesium alloy[10,12], it is inferred that parts of the Al4Sr phases do not dissolve into the melts, thus they are detected in Fig.8(a). Oppositely, the Al4Sr phases in the Al-10Sr master alloy obtained by remelting and rapid solidification, can completely dissolve into the melts of AZ31 magnesium alloy thus are not detected in Fig.8(b).

Fig.8 XRD patterns of as-cast AZ31 magnesium alloy treated by different Al-10Sr master alloys: (a) Commercial; (b) Re- melted and rapidly cooled

According to the results obtained by ZHANG et al[15], the effects of the morphology and size on the dissolution rates of Al4Sr phases are obvious. In general, high dissolution rates can be obtained for finer Al4Sr phases in Al-Sr master alloy. In Fig.2, the Al4Sr phases mainly exhibit fine granule and fibre shapes respectively after being rolled at 300℃ for 50% reduction or remelted and followed by rapid cooling for commercial Al-10Sr master alloy. Considering that the specific surface area and energy of Al4Sr phases with fine granule and fibre shapes are larger than those of the Al4Sr phases with coarse block shapes, inside the fine Al4Sr phases exists lots of linear dislocation, and the internal energy is high and the stability is low, then the dissolution rate of Al4Sr phases with fine flake shapes is higher[16]. Accordingly, the amount of free Sr and the GRF value are also higher. So the Al-10Sr master alloys obtained by rolling or remelting + rapid cooling exhibit relatively high refinement efficiency. In addition, in Fig.2, although the Al4Sr phases exhibit relatively fine block shapes after being dissolved at 500 ℃ for commercial Al-10Sr master alloy, the changing of morphology and size of the Al4Sr phases is not very obvious. Then their dissolution rates in the melt of AZ31 magnesium alloy are similar with the Al4Sr phases in the commercial Al-10Sr master alloy. So the refinement efficiency of the solubilized Al-10Sr master alloy is slightly improved.

In the melts of AZ31 magnesium alloy investigated, for a given commercial or treated Al-10Sr master alloy, the dissolution rate of Al4Sr phases is equal. Then the amount and dissolution time of Al4Sr phases increase with the Sr adding amount and melt holding time increasing respectively. Accordingly, the amount of free Sr and the GFR value increase. So as shown in Fig.8, with the Sr adding amount and melt holding time increasing, the refinement efficiencies of different Al-10Sr master alloys increase.

4 Conclusions

1) The morphology and size of Al4Sr phases in the microstructures of different Al-10Sr master alloys (commercial, solubilized, rolled and remelted + rapidly cooled) are of great difference. For the commercial Al-10Sr master alloy, the Al4Sr phases evolve from coarse block shape to relatively fine block shapes after being dissolved at 500 ℃ for 4 h and followed by water quenching, but after being rolled at 300 ℃ for 50% reduction or remelted and followed by rapid cooling, the Al4Sr phases mainly exhibit fine granule and fibre shapes.

2) The different Al-10Sr master alloys (commercial, solubilized, rolled and remelted + rapidly cooled) can effectively reduce the grains size of AZ31 magnesium alloys, but their refinement efficiencies are different. The refinement efficiency of the Al-10Sr master alloy obtained by remelting and rapid cooling is the best, then the rolled, solubilized and commercial Al-10Sr master alloys are in turn. The difference of refinement efficiencies for different Al-10Sr master alloys may be related to the dissolution rates of Al4Sr phases with different morphologies and sizes in the melt of AZ31 magnesium alloy.

References

[1] LUO A A. Recent magnesium alloy development for elevated temperature applications [J]. International Materials Reviews, 2004, 49(1): 13-30.

[2] YANG M B, PAN F S, ZHANG J, ZHANG J. An analysis of the development and applications of current and new Mg-Al based elevated temperature magnesium alloys [J]. Materials Science Forum, 2005, 488/499: 923-926.

[3] PAN F S, YANG M B, ZHANG D F. Research and development of wrought magnesium alloys in China [J]. Materials Science Forum, 2005, 488/499: 413-418.

[4] PAN F S, YANG M B, MA Y L, COLE G S. Research and development of processing technologies for wrought magnesium alloys [J]. Materials Science Forum, 2007, 546/549: 37-48.

[5] LEE S, LEE S H, KIM D H. Effect of Y, Sr and Nd addition in the microstructure and microfracture mechanism of squeeze-cast AZ9lx magnesium alloys [J]. Metall Mater Trans A, 1998, 29A: l22l-l235.

[6] ALIRAVCI C A, GRUZLESKI J E, DIMAYUGA F C. Effect of strontium on the shrinkage microporosity in magnesium sand castings [J]. AFS Transactions, 1992, 100: 353-362.

[7] GRUZLESKI J E, ALIRAVCI C A. Low porosity, fine grain sized strontium-treated magnesium alloy casting [P]. US 5143564, 1992.

[8] SRINIVASAN A, PILLAI U T, SWAMINATHAN J, DAS S K, PAI B C. Observations of microstructural refinement in Mg-Al-Si alloys containing strontium [J]. Journal of Materials Science, 2006, 41: 6087-6089.

[9] NAM K Y, SONG D H, LEE C W. Modification of Mg2Si morphology in As-cast Mg-Al-Si alloys with strontium and antimony [J]. Materials Science Forum, 2006, 510/511: 238-241.

[10] ZHAO P, WANG Q D, ZAI C Q, ZHU Y P. Effects of strontium and titanium on the microstructure, tensile properties and creep behavior of AM50 alloys [J]. Mater Sci Eng A, 2007, 444: 318-326.

[11] HIRAI K, SOMEKAW H, TAKIGAW Y. Effects of Ca and Sr addition on mechanical properties of a cast AZ91 magnesium alloy at room and elevated temperature [J]. Mater Sci Eng A, 2005, 403: 276-280.

[12] ZENG X Q, WANG Y X., DING W J. Effect of strontium on the microstructure, mechanical properties, and fracture behavior of AZ31 magnesium alloys [J]. Metall Mater Trans A, 2006, 37A: 1333-1341.

[13] CHEN R J, TANG A T, YANG M B, PAN F S. Effects of Al-Sr master alloys on the as-cast microstructure of the AZ31 magnesium alloys [J]. Materials Science Forum, 2007, 546/549: 183-186.

[14] ZHANG Z H, BIAN X F, WANG Y. Growth of dendrites in a rapidly solidified Al-23Sr alloy [J]. Journal of Crystal Growth, 2002, 243: 531-538.

[15] ZHANG Z H, BIAN X F, WANG Y. Microstructural characterization of a rapidly solidified Al-Sr-Ti alloy [J]. Materials Research Bulletin, 2002, 37: 2303-2314.

[16] QI X G, BIAN X F, WANG Y. Grain refinement and modification effects of Al-Ti-B and Al-5%Sr master alloys on the wheel aluminum alloy [J]. Foundry, 2000, 49(6): 321-326. (in Chinese)

[17] MARTINEZ J D, CISNEROS M A, VALTIERRA S. Effect of strontium and cooling rate upon eutectic temperatures of A319 aluminum alloy [J]. Scripta Materialia, 2005, 52: 439-443.

[18] BAI J, SUN Y S, XUN S. Microstructure and tensile behavior of Mg-4Al based magnesium alloys with alkaline-earth elements Sr and Ca additions [J]. Mater Sci Eng A, 2006, 419: 181-188.

Foundation item: Project(50725413) supported by the National Natural Science Foundation for Distinguished Young Scholar in China; Project (2007CB613704) supported by the National Basic Research Program of China

Corresponding author: YANG Ming-bo; Tel: +86-23-68667455; E-mail: yangmingbo@cqit.edu.cn