DOI:10.19476/j.ysxb.1004.0609.2019.02.09

低浓度Cu-Ni-Si合金的组织与性能

刘 峰1, 2,米绪军1,马吉苗2,黄国杰1,洪松柏2,解浩峰1,彭丽军1, 2

(1. 北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088;

2. 宁波兴业盛泰集团有限公司,宁波 315336)

摘 要:采用金相显微镜、透射电子显微镜(TEM)等分析测试手段系统研究不同固溶、冷变形与时效组合工艺对低浓度Cu-Ni-Si合金的晶粒尺寸、析出相粒子尺寸及分布规律,同时对合金的力学与电学性能进行测试。结果表明,相对于其他四种工艺制度,低浓度Cu-Ni-Si合金经过立式在线固溶处理+冷变形+时效组合形变热处理工艺后,合金组织晶粒更加细小(平均晶粒尺寸为25 μm),析出相分布更加弥散,抗拉强度为579 MPa,屈服强度为521 MPa,屈强比为0.9,伸长率为9%,导电率为52.2%IACS;与常用汽车连接器用C70250和TMg0.5合金综合性能进行对比,低浓度Cu-Ni-Si合金具有优良的综合性能,在大功率电流使用时表现出良好的散热性及可靠的尺寸稳定性,可作为高强高导弹性材料广泛应用于汽车连接器等领域。

关键词:低浓度Cu-Ni-Si合金;时效处理;微观组织;屈强比;应力松弛

文章编号:1004-0609(2019)-02-0286-09 中图分类号:TG111.5 文献标志码:A

随着“互联网+”和电子信息化时代的到来,电子、通讯及汽车行业处于高速发展阶段,对接插件、连接器等弹性元件用铜基弹性合金的需求量日益增加,对合金综合性能提出了更加苛刻的要求,如要求合金具有高强度、高导电、高抗应力松弛性能、高疲劳强度等性能[1-3]。

目前市场上常用的铜基弹性材料主要以铍青铜和锡磷青铜合金为主,其中铍青铜作为“有色金属材料弹性之王”,具有其他材料不可比拟的性能优势,但由于铍元素对人的健康和环境具有严重的损害作用,同时铍青铜合金的加工热处理工艺复杂,生产难度大,使其只应用于航空、航天等特殊领域[4-7]。传统锡磷青铜合金,锡含量高,一般为5%~10%,水平连铸生产后铸坯易产生严重的锡偏析现象,需要长时间的均匀化热处理来消除,生产效率低,且锡的价格昂贵,生产成本较高[8]。在20世纪80年代后期,美国、前苏联、日本和中国己经开发了Cu-Al-Ni、Cu-Ni-Sn、Cu-Ti、卡密隆、卡密林等新型无铍高强高弹(抗拉强度≥1000 MPa,弹性模量≥130 GPa)导电铜合金,但这类铜基合金的导电率均太低,不超过25%IACS,难以满足现代元器件对材料对导电率性能的基本要求[9-10]。因此,开发出高强度、导电、无铍、具有良好抗应力松弛性能的弹性铜合金是国内外研究与攻关的重点。

Cu-Ni-Si系合金是典型的固溶时效强化型合金[11-12],通过时效处理后,合金能析出弥散分布的δ-Ni2Si和β-Ni3Si相[13-15],使合金具有高强度、高弹性、高疲劳性、高导电性和优良抗应力松弛等综合性能,可以应用于连接器、电器接插件等弹性元件,在很多要求高导电性场合能够取代高弹性铍青铜合金[16-17]。目前,国内外对实验室研制出的较高溶质含量的Cu-Ni-Si系合金(其中镍和硅的质量分数一般分别大于2.0%和0.5%)的时效、高温热变形和疲劳过程中微观组织演变与性能的内在关系及合金元素对合金组织性能的影响规律进行了较为系统的研究,取得了一定的研究成果[18-27],但未对低含量Cu-Ni-Si合金微观组织与性能的关系,尤其在产业化过程中生产工艺对合金组织性能的影响规律进行系统研究。本文作者分别将镍和硅含量降低至1.37%和0.28%,同时添加了微量的磷、锌、锡和镁元素,设计出了低浓度Cu-Ni-Si合金,通过对合金进行不同的固溶时效与冷变形组合工艺,重点研究不同生产工艺对合金的综合性能、晶粒尺寸、强化相粒子尺寸及分布的影响规律,确定出合金具有高强高导、高屈强比及优良复杂折弯成型性性能的加工热处理制度,为合金的产业化生产提供理论依据和生产借鉴。

1 实验

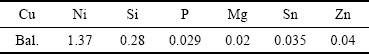

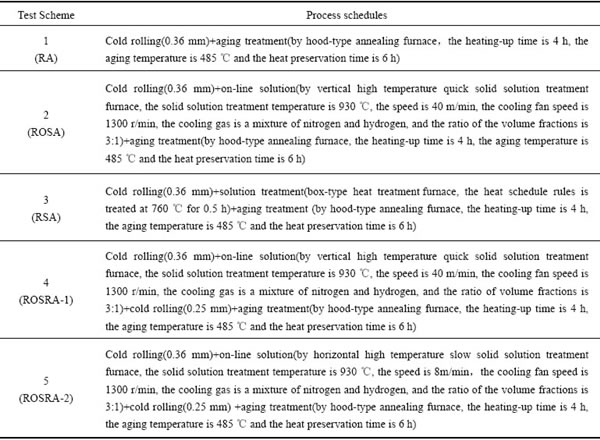

试验材料是厚度为0.36 mm冷轧态的低浓度Cu-Ni-Si合金,其化学成分如表1所列。为明确出不同的固溶时效与冷变形组合工艺对低浓度Cu-Ni-Si合金微观组织和综合性能的影响规律,确定出合理的形变热处理工艺制度。对加工态合金进行不同的形变热处理工艺,具体如表2所列。

表1 Cu-Ni-Si合金的化学成份

Table 1 Chemical Composition of Cu-Ni-Si alloy (mass fraction, %)

按照GB 6397—86标准,将合金试样沿轧制方向切割成哑铃状试样,采用Zwick电子万能拉伸试验机进行拉伸试验。按照GB/T 351—1995标准,对不同状态合金的电阻系数ρ进行测量,再通过公式0.017241/ρ×100%,可获得合金的导电率。采用HXD-1000数显维氏硬度计对不同状态的合金带材进行硬度测试。按照GB/T 15825.5标准,对不同状态的合金带材进行折弯试验。按照JCBA-T309—2004标准,对不同合金的应力松弛性能进行测试。将试样通过金相制样机和金相镶嵌机制成金相试样,经不同规格砂纸逐级打磨并进行抛光处理后,用一定比例FeCl3与HCl的水溶液对试样进行腐蚀,在德国莱卡金相显微镜下观察试样的组织形貌和测量平均晶粒尺寸。时效处理后微观组织在JEM 2100 LaB6型透射电镜下观察,试样制备过程:试样预先在砂纸上进行机械减薄至(50±5) μm时进行铳样,随后将样品放置双喷仪上进行减薄、穿孔。双喷液采用体积比为1:4的硝酸和甲醇混合液,工作温度为-40~-50 ℃。

表2 不同工艺制度

Table 2 Different process schedules

2 结果与分析

2.1 不同工艺制度对低浓度Cu-Ni-Si合金组织性能的影响

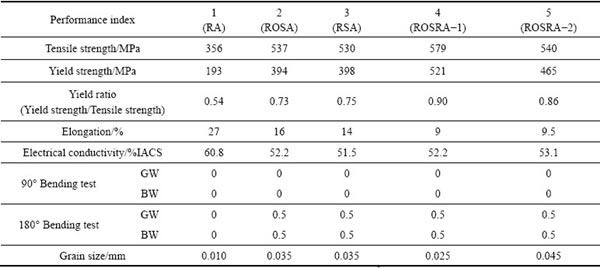

表3所列为低浓度Cu-Ni-Si合金不同工艺制度下的综合性能。由表3可知,RA工艺的力学性能最低,导电性能最优,其抗拉强度、屈服强度、屈强比和导电率分别为356 MPa、193 MPa、0.54和60.8%IACS,说明合金在经过热轧、在线水冷、冷轧、时效处理后,合金产生的时效效果有限,导致合金的强度和屈强均比较低,无法满足连接器、接插件对材料综合性能的使用要求;当对固溶处理后的合金进行时效处理,如ROSA与RSA组合工艺,合金具有明显的固溶时效强化效果,且两种工艺下的综合性能相接近。相对于RA工艺而言,合金的抗拉强度、屈服强度和屈强比分别提高了约180 MPa、200 MPa和0.2,导电率为稍有下降;为了进一步提高合金的综合性能,对固溶处理后的带材进行塑性变形,如ROSRA-1和ROSRA-2。由ROSA和ROSRA-1两种工艺下的综合性能可知,经过30%的冷变形后时效,合金的力学性能得到显著提升,其中屈服强度和屈强比较为明显,分别增加了127 MPa和0.17,说明了形变热处理对于提升合金的屈服强度和屈强比具有显著作用。综合比较立式在线高温快速固溶 (立式光亮退火炉) 与卧式在线高温慢速固溶 (卧式气垫式退火炉) 对合金综合性能的影响可知,即ROSRA-1和ROSRA-2两种工艺对比,经过立式在线高温快速固溶后合金具有更加优异的综合性能,尤其具有高屈强比性能,能满足抗拉强度≥550 MPa,导电率≥50%IACS高导电类弹性元器件的接插功能使用要求。

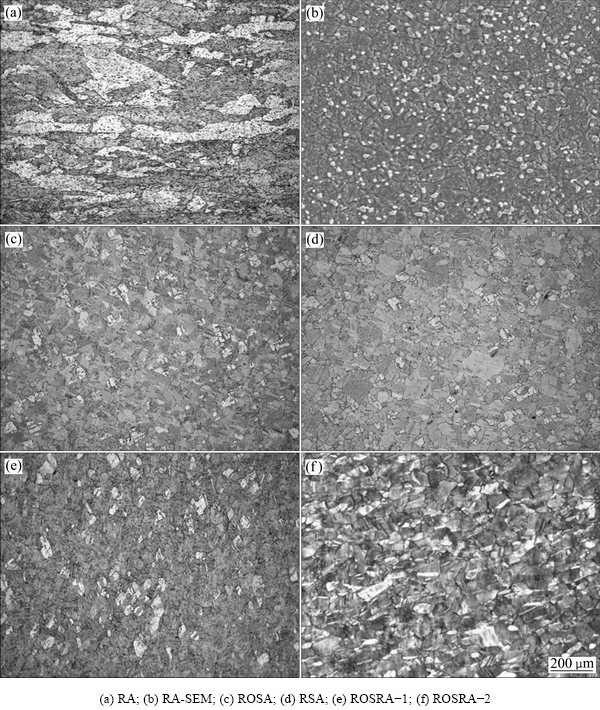

图1所示为低浓度Cu-Ni-Si合金不同工艺制度的显微组织。由图1(a)可见,合金经RA工艺后,其显微组织为拉长的变形组织,同时还有许多粗大的第二相存在,如图1(b)所示,这主要是因为热轧终轧温度只有700 ℃,在此温度下合金元素的固溶度不高,这也造成了合金经热轧在线固溶处理后,组织中仍有许多粗大的第二相残留,降低了后续时效过程中合金元素的析出动力,第二相粒子体积分数不高,这也是合金强度不能大幅度提高的主要原因;当合金经过固溶时效处理后,合金中没有出现未固溶的第二相粒子,其显微组织均为等轴组织,同时存在许多细小的孪晶,如图1(c)~(f)所示。通过对以上几种状态的合金晶粒尺寸统计,发现经过立式在线高温快速固溶处理后,合金的晶粒度为0.025 mm(见图1(e)),要明显小于卧式在线高温慢速固溶处理后的晶粒度0.045 mm,如图1(f)所示,这主要是因为在高温快速固溶处理条件下,合金发生明显的固溶和再结晶两个过程。由于合金带材厚度只有0.36 mm,在退火速度为40 m/min,保温区长度为30 m,保温时间不到1 min的条件下,能很好在保证合金具有过饱和固溶度的前提下,晶粒尺寸不发生明显长大,从而达到既能满足折弯成型,又能避免因组织偏大,使合金表面出现橘皮缺陷的要求。

表3 Cu-Ni-Si合金不同工艺制度的综合性能

Table 3 Comprehensive properties of different process schedules of Cu-Ni-Si alloy

图1 Cu-Ni-Si合金不同工艺制度的显微组织

Fig. 1 Microstructures of different process schedules of Cu-Ni-Si alloy

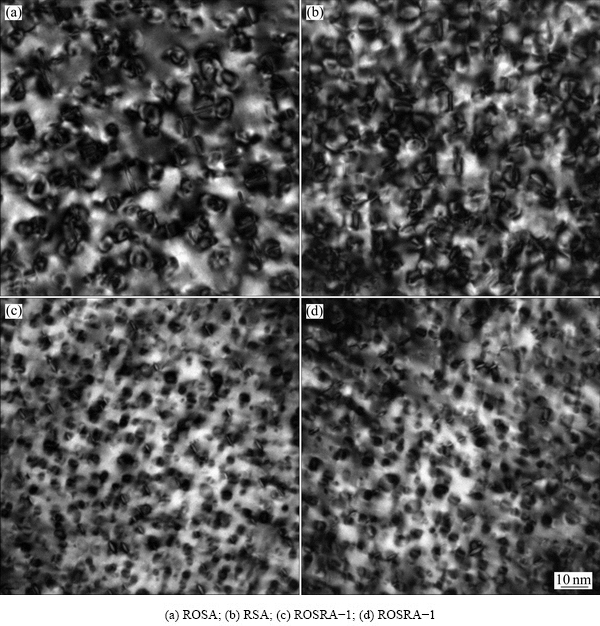

图2所示为低浓度Cu-Ni-Si合金不同工艺制度的TEM像。从图2中可以看出,经时效处理后,合金基体组织中弥散分布着细小的第二相颗粒,这也是Cu-Ni-Si合金经不同时效处理后具有优异综合性能的重要原因。比较四种工艺制度的微观组织发现,ROSA、RSA、ROSCA三种工艺中第二相粒子均弥散在基体组织中,但ROSA、RSA组合工艺中第二相粒子数目数量较少且尺寸较大,如图2(a)和(b)所示,这主要是由于合金未经冷变形加工,析出相形核率较小造成的,合金此时只有时效强化的效果;当合金经过固溶+冷变形+时效处理后(ROSCA组合工艺),由于经过固溶、冷变形后,合金组织中存在大量的位错和空位,在后续的时效处理过程中,以上缺陷都成为了析出相形核,能促进析出相的析出,合金中析出第二相粒子数量相明显增多,如图2(c)和(d)所示,尺寸也明显减小,使得合金同时具有时效强化与冷变形强化的双重效果,这也是此种工艺制度下,合金具有优异综合性能的主要原因。

2.2 应力松弛性能

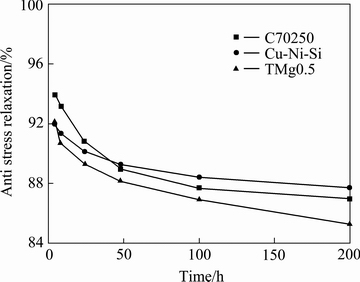

图3所示为三种常用高强高导铜基弹性合金的应力松弛特性曲线。在三种材料特性状态及力学性能相当的情况下(其中C70250、Cu-Ni-Si、TMg0.5三种合金的抗拉强度为550~620 MPa),对其进行(125 ℃, 8~100 h)不同制度的应力松弛试验。由图3可知,三种材料随着应力松弛时间的延长,应力松弛率均呈先增大后趋于稳定的趋势,其中C70250合金的耐应力松弛特性较好,Cu-Ni-Si合金的抗应力松弛率次之,TMg0.5合金最差。这主要是由于C70250 (Cu-2.6Ni- 0.6Si-0.05Mg) 和Cu-Ni-Si均为固溶时效强化型合金,经过时效处理后,合金组织析出大量弥散分布的镍硅强化相,能有效地阻碍位错的运动,但由于Cu-Ni-Si溶质元素浓度低,析出相体积分数较低,阻碍位错的能力相对于C70250较弱。因此,C70250合金的抗应力松弛能力要强于后者。而TMg0.5合金为典型的加工硬化型合金,其组织为典型的纤维变形组织,该组织中存在高密度位错,经过低温应力松弛处理后时,合金内会发生异号位错相互抵消的现象,位错密度显著下降,降低合金的抗应力松弛性能。

图2 Cu-Ni-Si合金不同工艺制度的TEM像

Fig. 2 TEM images of different process schedules of Cu-Ni-Si alloy

图3 三种高强高导弹性铜合金的应力松弛特性曲线

Fig. 3 Stress relaxation curves of three kinds of high strength and high electrical conductivity elastic copper alloy

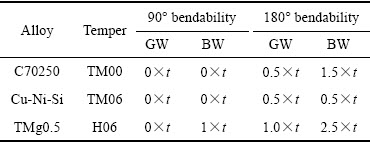

2.3 折弯性能

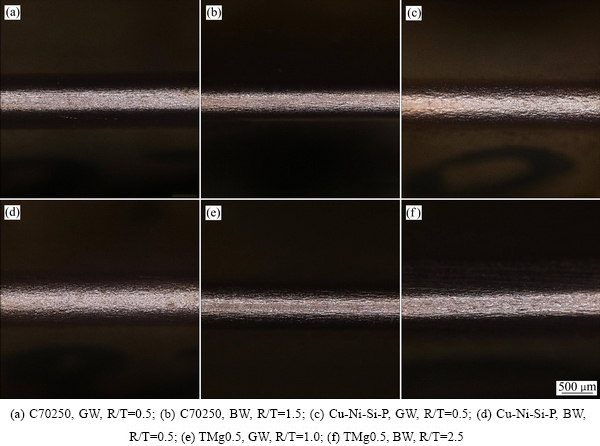

表4和图4所示分别为三种常用高强高导弹性铜合金材料的折弯性能和折弯后的宏观照片,表中的t表示带材厚度,X×t表示X倍的带材厚度,0×t表示弯曲半径≤0.1 mm。由表4和图4可知,三种合金90°折弯时,在GW/BW均表现出较好的折弯性能;而180°折弯性能差异性较大,在GW无明显差异性,但在BW差异明显,其中Cu-Ni-Si折弯性能最好,C70250次之、TMg0.5合金最差。综合比较,Cu-Ni-Si合金的折弯性能优于其他合金,而C70250合金的性能略微低于Cu-Ni-Si-P合金,TMg0.5合金最差,即Cu-Ni-Si合金是一种具有优良冲压成型性的铜基弹性材料。

表4 三种常用高强高导弹性铜合金材料的折弯性能

Table 4 Bending properties of three kinds of high strength and high conductivity elastic copper alloy

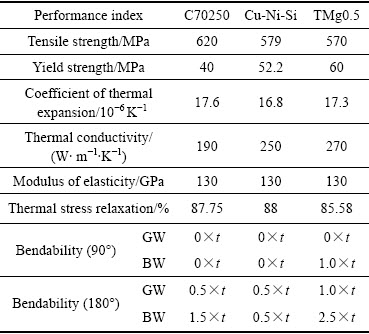

2.4 综合性能对比

表5 常用引线框架材料综合性能对比分析

Table 5 Comprehensive properties of traditional lead frame

图4 三种常用高强高导弹性铜合金材料折弯性能(180°)

Fig. 4 Bending properties (180°) of three kinds of high strength and high conductivity elastic copper alloy(R—Radius bending,

T—Thickness of strip)

表5所示为三种常用高强高导弹性铜合金材料的综合性能对比表,分别选取C70250、Cu-Ni-Si-P、TMg0.5合金的TM00、TM08、H06状态,应力松弛制度为(125 ℃,100 h)。由表5可知,Cu-Ni-Si合金与C70250合金相比,Cu-Ni-Si合金的TM08态力学性能与C70250的TM00状态相当,其热导率、导电率和热膨胀系数均优越于C70250合金的,在大功率电流使用时表现出良好的散热性及可靠的尺寸稳定性,可作为高强高导弹性材料广泛应用于汽车连接器等领域。而Cu-Ni-Si合金与TMg0.5合金相比,前者力学和电学性能可与后者相媲美,但后者的热膨胀系数偏高,在加之其抗应力松弛性能差,难以满足高端电子元器件使用的寿命要求。

3 结论

1) 低浓度Cu-Ni-Si合金经高温快速固溶处理、冷轧、时效处理后,合金可获得时效强化与冷变形强化的双重效果。

2) 相对于卧式高温快速固溶处理 (ROSCA-2),低浓度Cu-Ni-Si合金经立式高温快速固溶处理后 (ROSCA-1),合金组织晶粒细小,可获得优异的综合性能,其抗拉强度为579 MPa,屈服强度为521 MPa,屈强比为0.9,伸长率为9%,导电率为52.2%IACS。

3) 相对于C70250和TMg0.5两种合金而言,低浓度Cu-Ni-Si合金具有更加优异的综合性能,在大功率电流使用时表现出良好的散热性及可靠的尺寸稳定性,可作为高强高导弹性材料广泛应用于汽车连接器等领域。

REFERENCES

[1] 唐人剑, 王 军, 殷俊林, 严 彪, 尤富强. 新型弹性合金研究[J].材料导报, 2005, 19(1): 54-55, 65-67.

TANG Ren-jian, WANG Jun, YIN Jun-lin, YAN Biao, YOU Fu-qiang. Studies on new elastic alloy[J]. Materials Reviews, 2005, 19(1): 54-55, 65-67.

[2] 温燕宁, 肖来荣, 张喜民, 李 威, 郑英鹏, 耿占吉. 铜基弹性材料的研究现状[J].材料导报, 2009, 23(专辑14): 503-506.

WEN Yan-ning, XIAO Lai-rong, ZHANG Xi-min, LI Wei, ZHENG Ying-Peng, GENG Zhan-ji. Research status of copper base elastic alloy[J]. Materials Reviews, 2009, 23(Special 14): 503-506.

[3] CEMOCH T, LANDAB M, NOVAK V, SEDLAK P, SITTNER P. Acoustic characterization of the elastic properties of austenite phase and martensitic transformations in CuAlNi shape memory alloy[J]. Journal of Alloys and Compounds, 2004, 378(1/2): 140-144.

[4] 严由意, 区国苑. 代铍铜导电弹性复合金属材料的研制[J].电工材料, 2005(4): 13-16.

YAN You-yi, QU Guo-yuan. Manufacture of elastic and elasticity clad metal replacing beryllium-copper alloy[J]. Electrical Materials, 2005(4):13-16.

[5] 王 军, 殷俊林, 严 彪. Cu-Ni-Sn合金的发展和应用[J]. 上海有色金属, 2004, 25(4): 184-186.

WANG Jun, YIN Jun-lin, YAN Biao. Development and application of Cu-Ni-Sn alloy[J]. Shanghai Non-ferrous Materials, 2004, 25(4): 184-186.

[6] 彭丽军, 熊柏青, 解国良, 洪松柏, 郑国辉, 王强松. C17200合金时效早期相变行为[J]. 材料热处理学报, 2013, 34(8): 42-46.

PENG Li-jun, XIONG Bai-qing, JIE Guo-liang, HONG Song-bai, ZHENG Guo-hui, WANG Qiang-song. Transformation of early stage of aging in C17200 alloy[J]. Transactions of Materials and Heat Treatment, 2013, 34(8): 42-46.

[7] 彭丽军, 熊柏青, 解国良, 洪松柏, 解浩峰. 时效态C17200合金的组织与性能[J]. 中国有色金属学报, 2013, 23(6): 1516-1522.

PENG Li-jun, XIONG Bai-qing, JIE Guo-liang, HONG Song-bai, XIE Hao-feng. Microstructure and properties of C17200 alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1516-1522.

[8] 张丽君, 钟相文. 新型弹性材料QSn4-1-0.04锡铁磷青铜[J]. 中国有色金属学报, 1998, 8(增刊2): 58-60.

ZHANG Li-jun, ZHONG Xiang-wen. A new elastic material QSn4-1-0.04 tin-phosphor-iron bronze[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(Suppl. 2): 58-60.

[9] 肖翔鹏. 新型高性能Cu-Ni-Co-Si合金制备及组织性能的研[D]. 北京: 北京有色金属研究总院, 2013.

XIAO Xiang-peng. Research on fabrication, microstructure and properties of Cu-Ni-Co-Si alloy with high performance[D]. Beijing: General Research Institute for Non-ferrous Metals, 2013.

[10] 王霖倩, 王日初, 王小锋, 彭 建, 邓 敏. 形变热处理对Cu-11Zn-0.5Cr合金时效组织和性能的影响[J]. 中国有色金属学报, 2017, 27(3): 496-503.

WANG Lin-qian, WANG Ri-chu, WANG Xiao-feng, PENG Jian, DENG Min. Effects of thermo-mechanical treatment on microstructure and properties of Cu-11Zn-0.5Cr Alloy.[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(3): 496-503.

[11] 董琦祎. 低浓度Cu-Ni-Si合金的组织及性能的研究[D]. 长沙: 中南大学, 2009.

DONG Qi-yi. Study on microstructure and properties of low concentration Cu-Ni-Si alloy[D]. Changsha: Central South University, 2009.

[12] LEI Q, LI Z, XIAO T, PANG Y, XIANG Z Q, QIU W T, XIAO Z. A new ultrahigh strength Cu-Ni-Si alloy[J]. Intermetallics, 2013, 42: 77-84.

[13] LEI Q, LI Z, WANG M P, ZHANG L, GONG S, XIAO Z, PAN Z Y. Phase transformation behavior in a Cu-8.0Ni-1.8Si alloy[J]. Journal of Alloys and Compounds, 2011, 509: 3617-3622.

[14] LEI Q, LI Z, WANG M P, ZHANG L, XIAO Z, JIA Y L. The evolution of microstructure in Cu-8.0Ni-1.8Si-0.15Mg alloy during aging[J]. Materials Science and Engineer A, 2010, 527: 6728-6733.

[15] CHENG J Y, TANG B B, YU F X, CHEN B. Evaluation of nanoscaled precipitates in a Cu-Ni-Si-Cr alloy during aging[J]. Journal of Alloys and Compounds, 2014, 614: 189-195.

[16] 谢水生, 李彦利, 朱琳. 电子工业用引线框架铜合金及组织的研究[J]. 稀有金属, 2003, 27(6): 772-776.

XIE Shui-sheng, LI Yan-li, ZHU Lin. Progress of study on lead frame copper alloy and its implementation in electronic industry[J]. Chinese Journal of Rare Metals, 2003, 27(6): 772-776.

[17] 肖翔鹏, 黄国杰, 程 磊, 袁孚胜, 吴 语. 固溶时效工艺对Cu-Ni-Si合金组织性能的影响[J]. 稀有金属, 2011, 35(5): 673-678.

XIAO Xiang-peng, HUANG Guo-jie, CHENG Lei, YUAN Fu-sheng, WU Yu. Effect of solution and aging technique on microstructure and properties of Cu-Ni-Si Alloy[J]. Chinese Journal of Rare Metals, 2011, 35(5): 673-678.

[18] HU T, CHEN J H, LIU J Z, LIU R Z, WU C L. The crystallographic and morphological evolution of the strengthening precipitates in Cu-Ni-Si alloys[J]. Acta Materialia, 2013, 61: 1210-1219.

[19] GHOLAMIC, VESELY J, ALTENBERGER I, KUHN H A, JANECEK M, WOLLMANN M, WAGNER L. Effects of microstructure on mechanical properties of CuNiSi alloys[J]. Journal of Alloys and Compounds, 2017, 696: 201-212.

[20] JIA Y L, WANG M P, CHEN C, DONG Q Y, WANG S, LI Z. Orientation and diffraction patterns of δ-Ni2Si precipitates in Cu-Ni-Si alloy[J]. Journal of Alloys and Compounds, 2013, 557: 147-151.

[21] XIAO X P, XIONG B Q, WANG Q S,XIE G L, PENG L J, HUANG Guo-xing. Microstructure and properties of Cu-Ni-Si-Zr alloy after thermomechanical treatments[J]. Rare Metals, 2013, 32(2): 144-149.

[22] WANG W, KANG H J, CHEN Z N,CHEN Z J, ZOU C L, LI R G, YIN G M, WANG T M. Effects of Cr and Zr additions on microstructure and properties of Cu-Ni-Si alloys[J]. Materials Science and Engineering A, 2016, 673: 378-390.

[23] ZHANG Y, LIU P, TIAN B H, LIU Y, LI R Q, XU Q Q. Hot deformation behavior and processing map of Cu-Ni-Si-P alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(8): 2341-2347.

[24] 王 晶, 李 周, 李 思, 邢 岩, 申镭诺, 雷 前. 超高强导电Cu-Ni-Si-Al合金的TTP曲线[J]. 中国有色金属学报, 2016, 26(7): 1466-1472.

WANG Jing, LI Zhou, LI Si, XING Yan, SHEN Lei-nuo, LEI Qian. TTP diagrams of Cu-Ni-Si-Al alloy with super high strength and good conductivity[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(7): 1466-1472.

[25] 黎三华, 申镭诺, 李 周, 董琦祎, 肖 柱, 邢 岩. 超高强Cu-6.5Ni-1Al-1Si-0.15Mg-0.15Ce合金的淬火敏感性[J]. 中国有色金属学报, 2015, 25(6): 1546-1552.

LI San-hua, SHEN Lei-nuo, LI Zhou, DONG Qi-yi, XIAO Zhu, XING Yan. Quench sensitivity of Cu-6.5Ni-1Al-1Si-0.15Mg- 0.15Ce alloy with super high strength[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1546-1552.

[26] 张 毅, 刘 平, 田保红, 陈小红, 刘 勇. Cu-Ni-Si-P-Cr合金高温热变形及动态再结晶[J]. 中国有色金属学报, 2013, 23(4): 970-976.

ZHANG Yi, LIU Ping, TIAN Bao-hong, CHEN Xiao-hong, LIU Yong. Hot deformation behaviors and dynamics recrystallization of Cu-Ni-Si-P-Cr alloy at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 970-976.

[27] ATAPEK S H, PANTELAKIS S G, POLAT S, CHAMOS A N, AKTAS G. Fractographical analysis of fatigue failed Cu-2.55Ni-0.55Si alloy[J]. Theoretical and Applied Fracture Mechanics, 2016, 83: 60-66.

Microstructure and properties of low concentration of Cu-Ni-Si alloy

LIU Feng1, 2, MI Xun-jun1, MA Ji-miao2, HUANG Guo-jie1, HONG Song-bai2, XIE Hao-feng1, PENG Li-jun1, 2

(1. State Key Laboratory of Nonferrous Metals and Process, General Research Institute for Nonferrous Metals, Beijing 100088, China;

2. Ningbo Xingyeshengtai Group Co. Ltd., Ningbo 315336, China)

Abstract: The effects of different theromechanical treatments on grain size, precipitate size and distribution of precipitation phase of low concentration of Cu-Ni-Si alloy were investigated by metallurgical microscopy, transmission electron microscopy. The mechanical properties and electrical conductivity of the alloy were also tested. The results show that the Cu-Ni-Si alloy has excellent properties (tensile strength is 579 MPa, yield strength is 521 MPa, yield-tensile ratio is 0.9, elongation is 9% and electrical conductivity is 52.2%IACS ) and the average of grain size is 25 μm,when the alloy is solution treated at vertical bright annealing furnace, cold rolled and aging treatment, which is relative to other four heat treatment processes. Compared with C70250 and TMg0.5 alloys, the low concentration of Cu-Ni-Si alloy has a good heat dissipation and reliable dimensional stability in the use processes of high power current, which can be widely used in the automotive connector field.

Key words: low concentration Cu-Ni-Si alloy; ageing treatment; microstructure; yield-tensile ratio; stress relaxation

Foundation item: Project(2016YFB0301300) supported by the National Basic Research Development Program of China; Projects(51601017, 51561008) supported by the National Natural Science Foundation of China

Received date: 2016-08-24; Accepted date: 2018-01-05

Corresponding author: PENG Li-jun; Tel: +86-10-60662668; E-mail: penglj@grinm.com

(编辑 何学锋)

基金项目:国家重点研发计划资助项目(2016YFB0301300);国家自然科学基金资助项目(51601017,51561008)

收稿日期:2016-08-24;修订日期:2018-01-05

通信作者:彭丽军,高级工程师,博士;电话:010-60662668;E-mail:penglj@grinm.com