文章编号:1004-0609(2012)09-2461-08

轧制复合铝/不锈钢界面金属间化合物的生长动力学

周德敬1,尹 林2,张新明2,唐建国2,刘星兴2

(1. 银邦金属复合材料股份有限公司,无锡 214145;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:对轧制复合铝合金/不锈钢双层复合材料进行不同温度和时间的退火,借助Zeiss Ax10金相显微镜、Quanta-200型扫描电镜、EDAX能谱仪和D-max X射线衍射仪对复合界面结合区进行金相组织观察、元素成分线扫描分析、界面化合物EDS分析及XRD物相鉴定,研究复合界面上金属间化合物的生长行为。结果表明:复合界面金属间化合物(IMC)主要为Fe2Al5相,当退火温度达773 K时,Fe2Al5已在界面上生成;随退火时间的延长, Fe2Al5的增厚符合抛物线法则;界面金属间化合物Fe2Al5的生长激活能为162.3 kJ/mol,并获得其生长动力学模型,通过此模型可对化合物层厚度进行初步计算。

关键词:铝/不锈钢层状复合材料;金属间化合物;轧制复合;生长激活能;生长动力学

中图分类号:TG146 文献标志码:A

Growth kinetics of intermetallic compounds at

aluminum/stainless steel interface bonded by rolling

ZHOU De-jin1, YIN Lin2, ZHANG Xin-ming2, TANG Jian-guo2, LIU Xing-xing2

(1. Yin Bang Clad Material Co., Ltd., Wuxi 214145, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The aluminum/stainless steel clad plates bonded by hot-rolling were annealed at different temperatures for different times. The microstructure, element distribution and identification of the intermetallic compound (IMC) at the interface were studied with Zeiss Ax10 optical microscope, Quanta-200 scanning electron microscope, EDAX energy dispersive spectrometer, D-max XRD, respectively. The influence of annealing temperature and time on the formation and growth of the IMC at the interface was investigated. The results show that the IMC (Fe2Al5) forms at the interface, which begins to form when the temperature is up to 773 K. With elongation of the annealing time, it becomes thicker according to the parabolic law. The growth activation energy for the growth of the compound is 162.3 kJ/mol, and the growth kinetics model is obtained, by which the thickness of the IMC can be evaluated.

Key words: aluminum/stainless steel cladding material; intermetallic compound; roll bonding; growth activation energy; growth kinetics

基金项目:科技基础设施建设计划—江苏省企业院士工作站资助项目(BM2010470)

收稿日期:2012-05-25;修订日期:2012-08-20

通信作者:张新明,教授,博士;电话:0731-88830265;E-mail: xmzhang_cn@yahoo.cn

铝合金/不锈钢层状复合材料兼具不锈钢的耐腐蚀、耐磨损和良好的力学性能以及铝合金良好的导热、导电、低密度性能的优点,在汽车、航空、化工、炊具和家电等领域有着广泛应用前景[1-5]。铝钢轧制复 合材料后续一般要进行扩散退火处理,其目的是通过原子的互扩散形成冶金结合,同时消除轧制过程中形成的残余应力,便于后续深加工,如剪切、弯曲等加工工艺[6]。但是,在退火过程中铝钢复合界面容易生成脆性Fe-Al金属间化合物,这种脆性化合物相会严重破坏基体间的冶金结合。因此,深入认识铝钢复合材料退火过程中金属间化合物的演变规律,揭示金属间化合物的生长机制具有重要意义。

国内外关于铝钢界面化合物的研究多集中在热浸镀铝、铝钢扩散焊接以及铝合金/碳钢层状复合材料等方面,而对铝合金/不锈钢轧制复合材料界面化合物生长机制的研究鲜有报道。SPRINGER等[7]利用OM、SEM、EBSD和TEM等手段研究了碳钢/纯铝、碳钢/铝- 硅合金扩散组在不同条件下扩散处理后界面化合物的生长规律,对Fe2Al5等金属间化合物相进行了衍射斑点鉴定。KOBAYASHI和KAKOU[8]研究了渗铝碳钢在873~1 323 K温度条件下扩散退火处理后界面金属间化合物的生长情况,研究结果表明,在 873~923 K温度范围内主要生成Fe2Al5相,而当温度高于1 273 K后FeAl和Fe3Al相开始生成。JINDAL和SRIVASTAVA[9]研究了轧制复合IF-钢/铝合金在773 K温度下退火不同时间后界面金属间化合物Fe2Al5的生长规律,指出Fe2Al5相的厚度随退火时间增加遵循方程 (Δx)2=2kt,其中k=3.38×10-14m2/s。CHENG和WANG[10]研究了不同Si含量对中碳钢热浸镀铝界面化合物的影响。YOUSAF等[11]的研究结果表明,热浸镀时金属的化学元素组成、热浸镀温度以及时间都影响金属间化合物(Fe2Al5)的生长速度以及其形貌。韩丽青等[12]研究了钛/不锈钢焊接界面金属间化合物的生长动力学,得出了界面金属间化合物生长动力学方程W=1.15×106exp[-50.93/(RT)]t1/2。

本文作者通过对热轧复合AA3003铝合金/SUS304不锈钢层状复合材料进行不同条件的扩散退火处理,研究铝/不锈钢界面反应物相与时间和温度的关系,探讨金属间化合物的形成和生长过程。

1 实验

实验母材为退火态AA3003铝合金和退火态SUS304不锈钢,两种母材的化学成分见表1。AA3003铝合金复合尺寸为300 mm×150 mm×4 mm;SUS 304不锈钢复合尺寸为300 mm×150 mm×1.2 mm。

热轧复合前两种母材先用丙酮浸泡5 min,以去除表面油脂及脏污。用钢丝刷将不锈钢表面进行打 磨,使其表面具有一定的粗糙度,再用清水冲洗干净, 吹干;铝合金用10%NaOH溶液碱洗5 min,热水冲洗,再用10%HNO3酸洗5 min,冷水冲洗,热风吹干。之后将两种母材按照铝/不锈钢/不锈钢/铝4层对称的方式进行组合,以防止轧制过程中由于铝与不锈钢金属流动性差异大造成的板材弯曲。将组合料头尾部用铆钉进行铆接,以保证复合过程中的精确对中。轧制复合实验在d 350 mm两辊不可逆轧机上进行,热轧复合工艺为723 K下保温30 min,采用单道次热轧,变形率为40%。退火热处理实验在箱式电阻炉上进行,出炉空冷。

表1 AA3003铝合金及SUS304不锈钢化学成分

Table 1 Chemical compositions of AA3003 aluminum and SUS304 stainless steel

借助Zeiss AX10金相显微镜(OM)观察复合界面结合区的界面形貌并测量化合物层的厚度;借助D-max X射线衍射仪(XRD)、Quanta-200型环境 扫描电镜(SEM)和配备的EDAX能谱仪(EDS)分析铝/不锈钢界面区Fe和Al等元素的分布情况,并确定化合物相组成。

2 结果与分析

在铝钢层状复合材料退火过程中,复合界面上金属间化合物的生长对复合材料的组织性能影响很大,其反应过程十分复杂,受退火温度和时间的控制。

2.1 退火温度和时间对界面化合物生长的影响

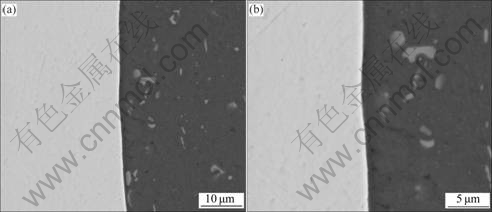

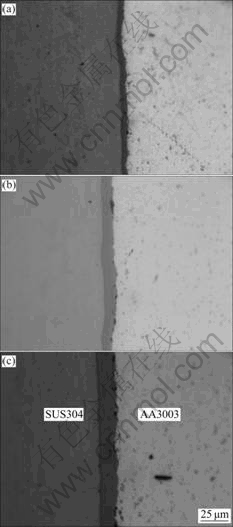

图1所示为不同温度退火1 h后复合界面的金相显微组织形貌。其他工艺参数为轧制温度723 K,采用1道次轧制,变形量为40%。图1(a)所示为轧制复合后未退火状态,从图1(a)可以看出,复合界面较平直,两种母材结合效果良好;对其进行SEM高倍观察可见,界面上没有氧化物的存在(见图2)。图1(b)和(c)所示分别为经723和748 K退火1 h后的界面金相显微组织形貌,与未退火状态(见图1(a))相比,经此条件退火后复合界面形貌基本无变化,界面上没有金属间化合物生成。当退火温度提高到773 K时,界面上出现一薄层金属间化合物(见图1(d)),厚度约为 2 μm,说明773 K时金属间化合物已很明显。随着退火温度的升高,界面化合物层厚度增加,当退火温度达823 K时,界面化合物的厚度增加到10 μm(见图1(f))。随退火温度的升高,界面两侧Fe和Al等元素的扩散速率加快,从而在同一时间内通过界面扩散的元素含量增加,使得化合物层厚度增加。

图1 不同温度退火1 h后复合界面的金相显微组织

Fig. 1 Microstructures of cladding interface annealed at different temperatures for 1 h: (a) Untreated; (b) 723 K; (c) 748 K; (d) 773 K; (e) 798 K; (f) 823 K

图2 轧制态复合材料界面的SEM像

Fig. 2 SEM images of interface of composite after hot rolling: (a) Lower magnification; (b) Higher magnification

退火时间对界面金属间化合物的生长也有明显的影响。在同一退火温度下,随着退火时间的延长,界面两侧元素扩散越充分,因此,化合物层的厚度逐渐增加。图3所示为复合材料经823 K不同时间退火后的界面化合物显微组织。由图3(a)可以发现,经0.5 h退火后,界面上产生了金属间化合物层,其厚度为5.53μm。当退火保温时间从0.5 h延长至3 h (见图3(c))时,复合界面间的化合物生长迅速,厚度达到16 μm左右。

图3 823 K退火不同时间复合界面的金相显微组织

Fig. 3 Microstructures of cladding interface annealed at 823 K for different times: (a) 0.5 h; (b) 1 h; (c) 3 h

2.2 界面金属间化合物层SEM及XRD分析

图4所示为723 K退火1 h后复合界面的SEM像及其界面两侧Fe和Al等元素线扫描结果。从图4可以看出,在复合界面处Fe和Al等元素强度呈陡坡状变化,在界面上并没有发现金属间化合物层,界面两侧只存在少量的元素互扩散。

图4 723K退火1 h后界面的SEM像及元素线扫描结果

Fig. 4 SEM image (a) and element line scanning results (b) of cladding interface annealed at 723 K for 1 h

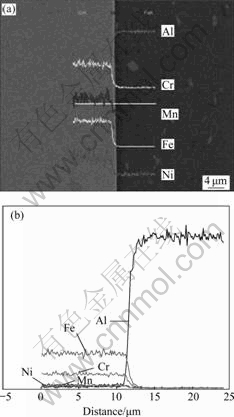

图5所示为798 K退火1 h后界面的SEM像及其界面两侧各元素线扫描结果。由图5可以看出,经798 K退火1 h后,在整个复合界面上,Fe、Al和Cr等元素均发生了明显的互扩散,元素的含量在扩散区域内的变化趋势为先线性下降,后基本恒定,之后再线性下降,即在扩散区域内有Fe、Al和Cr元素成分均几乎保持不变的“平台”[13]区域,其宽度大约为5 μm,“平台”特征表明这是一层成分稳定的新相。

图5 798 K退火1 h后界面的SEM像及元素线扫描结果

Fig. 5 SEM image (a) and element line scanning results (b) of cladding interface after annealed at 798 K for 1 h

对798 K退火1 h后界面金属间化合物层进行EDS分析(见图6),其金属间化合物各元素的成分分析结果见表2。将图6对应的试样沿复合界面剥离,对剥离后的不锈钢侧复合表面进行XRD分析(见图7)。由图7中XRD分析可见,不锈钢基体上主要化合物为Fe2Al5相,还有少量的FeAl3相。结合EDS与XRD分析结果,可以确定复合界面上生成的金属间化合物主要为Fe2Al5相,且其中固溶了4%~5%的Cr元素。

图6 798 K退火1 h后界面金属间化合物的EDS分析结果

Fig. 6 SEM image (a) and EDS analysis results (b) of IMC after annealed at 798 K for 1 h

表2 界面金属间化合物的EDS分析结果

Table 2 EDS analysis results of intermetallic compound

图7 不锈钢剥离表面的XRD谱

Fig. 7 XRD patterns of peeled surface of stainless steel

2.3 界面金属间化合物层的生长动力学

表3所列为不同温度,经过不同时间退火后界面化合物的平均厚度。从表3可以看出,随退火温度升高和时间延长,界面金属间化合物层厚度增加,但不是简单的正比关系。

表3 不同退火条件下金属间化合物的平均厚度

Table 3 Mean thickness of IMC annealed under different conditions

大量研究结果表明[8-9, 14-15],铝钢界面Fe-Al金属间化合物层的生长是由扩散控制的,化合物层厚度随退火时间的变化满足抛物线规律,即式中:X为化合物层的厚度,m; k为金属间化合物的生长常数(或者称为生长速率),m2/s;t为扩散时 间,s。

(1)

(1)

将表3中金属间化合物平均厚度X对时间t1/2作图,并线性拟合(见图8),可以求出773、798和823 K下金属间化合物的生长常数k,其结果列于表4。本研究结果在773 K时的生长常数k(4.58×10-15 m2/s)与JINDAL和SRIVASTAVA[9]研究结果中的k(3.38×10-14 m2/s)相比要小,是因为JINDAL和SRIVASTAVA[9]研究中使用的是IF-钢和纯铝,而本研究中使用的是304不锈钢和3003铝合金, 其中的Mn、Cr和Ni等元素能够阻碍Fe和Al元素之间的互相扩散,从而使生长常数减小。高超等[16]的研究结果也表明,微量元素Si的加入能显著抑制钢/铝界面Fe-Al化合物的生成,抑制效果随Si含量的增加更明显。

化合物生长常数k与温度T之间的关系满足Arrhenius方程[17-18]:

(2)

(2)

图8 金属间化合物厚度与时间t1/2的关系

Fig. 8 Relationship between IMC thickness and t1/2

表4 不同温度下的化合物生长常数k

Table 4 Variation of parabolic rate constant k with temperature

式中:k0为指前因子,m2/s;Q为界面化合物生长激活能,kJ/mol;R为摩尔气体常数,8.314 J/(mol·K);T为退火温度(绝对温度),K。

将式(2)两边取对数得:

(3)

(3)

以ln k对1/T作图(见图9),得一直线,该直线的斜率即为-Q/R,其在纵坐标上的截距为ln k0。经计算得出Q=162.3 KJ/mol,k0= 4.18×10-4m2/s。

图9 ln k与1/T的关系

Fig. 9 Relationship between ln k and 1/T

将式(2)代入式(1)中且两边平方可得

(4)

(4)

将Q和k0等数据代入式(4)中,计算得出金属间化合物Fe2Al5的生长动力学模型为可用式(5)对铝/不锈钢界面化合物的厚度进行初步估算,以确立退火温度与保温时间的最佳耦合值。

(μm) (5)

(μm) (5)

3 结论

1) 铝/不锈钢双层轧制复合材料在773 K退火1 h时后,界面出现金属间化合物,该金属间化合物主要为Fe2Al5相,其中固溶了4%~5%的Cr元素。

2) 界面金属间化合物Fe2Al5的生长由界面两侧元素的扩散过程控制,其厚度随退火温度和时间的变化符合抛物线规律。

3) Fe2Al5的生长激活能为162.3 kJ/mol,其生长动力学模型为X=(kt)1/2=2.04×104exp( )·

)·

t1/2(μm),通过此数学模型可对化合物层厚度进行初步估算。

REFERENCES

[1] 朱兆华, 胡文韬, 梁惠冬. 不锈钢/铝/不锈钢轧制复合工艺的研究[J]. 铝加工, 2002, 25(4): 8-10, 13.

ZHU Zhao-hua, HU Wen-tao, LIANG Hui-dong. Study on compoud rolling process of stainless steel/aluminum/stainless steel [J]. Aluminium Fabrication. 2002, 25(4): 8-10, 13.

[2] 李民权, 蒋福林, 张 辉, 李落星. 钢/铝复合板热轧复合变形规律[J]. 中国有色金属学报, 2009, 19(4): 644-648.

LI Min-quan, JIANG Fu-lin, ZHANG Hui, LI Luo-xing. Deformation rule of steel/aluminum metal-laminate material during hot roll bonding [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(4): 644-648.

[3] 袁鸽成, 朱兆华, 胡文韬, 梁惠冬, 尹德艳, 黎祚坚. 温度对不锈钢/铝/不锈钢层状材料轧制复合行为的影响[J]. 机械工程材料, 2004, 28(2): 24-26, 37.

YUAN Ge-cheng, ZHU Zhao-hua, HU Wen-tao, LIANG Hui-dong, YIN De-yan, LI Zuo-jian. Effect of temperature on rolling bond behaviours of laminated stainless steel/Al/stainless steel composites [J]. Materials for Mechanical Engineering, 2004, 28(2): 24-26, 37.

[4] 祖国胤, 王 磊, 王 威, 于九明. 退火对轧制包覆碳钢/铝夹层带材组织与性能的影响[J]. 东北大学学报: 自然科学版, 2009, 30(8): 1127-1130, 1134.

ZU Guo-yin, WANG Lei, WANG Wei, YU Jiu-ming. Effect of annealing process on microstructure and properties of Al-carbon steel-Al sandwich strip by roll cladding [J]. Journal of Northeastern University: Natural Science, 2009, 30(8): 1127- 1130, 1134.

[5] 彭大暑, 刘浪飞, 朱旭霞. 金属层状复合材料的研究状况与展望[J]. 材料导报, 2000, 14(4): 23-24.

PENG Da-shu, LIU Lang-fei, ZHU XU-xia. Review in research and development of clad metal sheets [J]. Materials Review, 2000, 14(4): 23-24.

[6] 焦少阳, 董建新, 张麦仓, 郑 磊. 双金属热轧复合的界面结合影响因素及结合机理[J]. 材料导报, 2009, 23(1): 59-62.

JIAO Shao-yang, DONG Jian-xin, ZHANG Mai-cang, ZHENG Lei. Influencing factors and bonding mechanism of hot rolling bonded bimetals [J]. Materials Review, 2009, 23(1): 59-62.

[7] SPRINGER H, KOSTKA A, PAYTON E J, RAABE D, KAYSSER-PYZALLA A, EGGELER G. On the formation and growth of intermetallic phases during interdiffusion between low-carbon steel and aluminum alloys [J]. Acta Materialia, 2011, 59(4): 1586-1600.

[8] KOBAYASHI S, YAKOU T. Control of intermetallic compound layers at interface between steel and aluminum by diffusion-treatment [J]. Materials Science and Engineering A, 2002, 338(1/2): 44-53.

[9] JINDAL V, SRIVASTAVA V C. Growth of intermetallic layer at roll bonded IF-steel/aluminum interface [J]. Journal of Materials Processing Technology, 2008, 195(1/3): 88-93.

[10] CHENG W, WANG C. Effect of silicon on the formation of intermetallic phases in aluminide coating on mild steel [J]. Intermetallics, 2011, 19(10): 1455-1460.

[11] YOUSAF M, IQBAL J, AJMAL M. Variables affecting growth and morphology of the intermetallic layer (Fe2Al5) [J]. Materials Characterization, 2011, 62(5): 517-525.

[12] 韩丽青, 王自东, 龙 斌, 林国标, 张 鸿, 乔建生. 钛/不锈钢焊接界面金属间化合物的生成动力学[J]. 材料热处理学报, 2011, 32(2): 61-64.

HAN Li-qing, WANG Zi-dong, LONG Bin, LIN Guo-biao, ZHANG Hong, QIAO Jian-sheng. Formation kinetics of interfacial intermetallic compounds of TA2/316L welding joints [J]. Transactions of Materials and Heat Treatment, 2011, 32(2): 61-64.

[13] PILONE D, FELLI F, BERNABAI U. Production of aluminum coated ferritic stainless steel by co-rolling and annealing [J]. La Metallurgia Italiana, 2006, 98(7/8): 55-59.

[14] 吴铭方, 司乃潮, 陈 健. 铝/镀银层/钢的扩散钎焊及界面化合物的生长行为[J]. 中国有色金属学报, 2010, 20(6): 1209-1213.

WU Ming-fang, SI Nai-chao, CHEN Jian. Diffusion brazing of Al/Ag plating layer/steel and growth behavior of interface compound [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1209-1214.

[15] JINDAL V, SRIVASTAVA V C, DAS A, GHOSH R N. Reactive diffusion in the roll bonded iron-aluminum system [J]. Materials Letters, 2006, 60(13/14): 1758-1761.

[16] 高 超, 高 明, 王 平. 硅对钢/铝轧制复合界面化合物抑制效应的研究[J]. 沈阳师范大学学报: 自然科学版, 2010, 28(2): 185-188.

GAO Chao, GAO Ming, WANG Ping. The influence of Si on the control effects of intermetallics on the steel/aluminum interface [J]. Journal of Shenyang Normal University: Natural Science, 2010, 28(2): 185-188.

[17] ZHANG X F, GUO J D, SHANG J K. Growth kinetics of intermetallic compounds between Sn-9Zn solder and electroplated Fe-42Ni metallization [J]. Journal of Alloys and Compounds, 2009, 487(1/2): 776-780.

[18] XU L, CUI Y Y, HAO Y L, YANG R. Growth of intermetallic layer in multi-laminated Ti/Al diffusion couples [J]. Materials Science and Engineering A, 2006, 435/436: 638-647.

(编辑 陈卫萍)