文章编号:1004-0609(2007)05-0770-05

熔体保温时间对类K445合金组织及硬度的影响

赵永芹,范志康,邹军涛,肖 鹏,谢文江

(西安理工大学 陕西省电工材料与熔(浸)渗技术重点实验室,西安 710048)

摘 要:采用真空熔炼工艺制备类K445高温合金,研究熔炼保温时间对其铸态组织及硬度的影响。结果表明,熔体保温时间对合金的相种类没有影响,合金均由树枝状γ基体、弥散分布于基体的γ′相、枝晶间的γ+γ′共晶、γ′′相、MC碳化物、少量M3B2硼化物等强化相组成;但随熔体保温时间的延长,枝晶尺寸先减小后增大,MC碳化物含量先减少后增多,γ+γ′共晶和γ''相含量先增多后减少;同时合金的硬度呈先升高后降低的趋势;保温30 min时枝晶最细小、γ+γ′共晶和γ′′含量最多、MC碳化物含量最少,且平均硬度达到最高值HB 381。

关键词:类K445高温合金;熔体保温时间;显微组织;硬度

中图分类号:TG 132.32 文献标识码:A

Effects of melt holding time on microstructure and

hardness of similar-K445 superalloy

ZHAO Yong-qin, FAN Zhi-kang, ZOU Jun-tao, XIAO Peng, XIE Wen-jiang

(Shaanxi Province Key Laboratory for Electrical Materials and Infiltration Technology,

Xi’an University of Technology, Xi’an 710048, China)

Abstract: The effects of melt holding time on the microstructure and hardness of similar-K445 superalloy were investigated. The results show that melt holding time has no effect on the sorts of phases. The as-cast microstructure consists of MC carbide, eutectic γ′, γ′′, a spot of M3B2 borides in dendritic regions and secondary γ′ phase distributed in γ matrix. However, with increasing melt holding time, the sizes of dendrites as well as content of MC carbide increase before reduction, the contents of eutectic γ′ and γ′′ as well as the hardness of the alloys decrease before increase. When melt holding time is 30 min, the alloy gets the finest dendrites, the biggest contents of eutectic γ′ and γ′′, the least content of MC carbide and the highest hardness of HB 381.

Key words: similar-K445 superalloy; melt holding time; microstructure; hardness

自从20世纪40年代初期第一台航空喷气发动机采用高温合金铸造涡轮工作叶片以来,高温合金的发展经历了一段曲折而又辉煌的历程[1]。随着对涡轮叶片各方面性能要求的不断提高,近年来对高温合金的研究工作更多地集中在单晶[2-4]和高温合金的热处理工艺上[5],关于熔炼工艺对高温合金铸态组织及性能影响的研究相对较少。铸造高温合金中γ′相和碳化物的析出量与分布、组织中枝晶多少、正负偏析元素的分布、晶粒大小等因素不同程度地影响合金的性能,而这些因素又强烈地依赖于熔炼工艺,对发挥合金的强化效果有十分重要的意义[6-7]。由于针对熔炼过程中熔体保温时间对高温合金组织及性能影响的相关报道甚少,因此,本文作者采用真空熔炼工艺制备以类K445镍基铸造高温合金,以期能在节约成本的基础上通过调整保温时间来改善合金铸态组织及硬度,探求最佳的保温时间。

1 实验

本实验以类K445合金作为研究对象,其化学成分如表1所示。熔炼前按合金成分称取各种金属粉末(用TiC代替C)进行配料,并在混料机上搅拌6 h使合金粉末充分均匀,而后将松装粉末置入氧化铝坩埚中,最后将其放入真空炉中进行熔炼。熔炼采用ZRS-18Q型微机程控真空高温烧结炉,并在1 500 ℃分别保温15、30、60、90和120 min,然后均进行随炉冷却。将所得铸锭的底面经砂轮打磨后在HB-3000布氏硬度计上测试硬度。

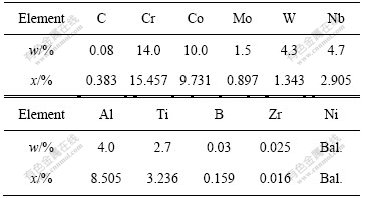

表1 类K445合金成分

Table 1 Composition of similar- K445 superalloy

在所得5种铸锭的相同部位线切割出所需小块金相试样,将试样纵断面经粗磨、细磨、金刚石研磨剂抛光,并采用腐蚀剂(20 g CuSO4+100 mL HCl+5 mL H2SO4+ 80 mL H2O)[8]腐蚀,最后在XJL-D2型立式金相显微镜上进行组织观察。

2 结果与分析

2.1 保温时间对合金组织的影响

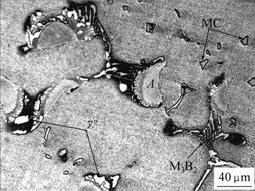

2.1.1 类K445合金组织的相组成

在1 500 ℃保温30 min 制备的类K445合金组织形貌如图1所示。从图1中可以看出,熔体保温后随炉冷却,γ固溶体基体均呈树枝状分布;基体上弥散分布着细小的γ′强化相;与其它大多数高温合金一样,在凝固过程中由于显微偏析[9],晶界和枝晶间的Al、Ti、Nb等元素含量高,促使共晶γ'形成,共晶组织(图1中A区)主要呈蘑菇状或葵花状。此外,图1中还可以见到不规则大片状γ′′、块状MC型碳化物以及少量骨架状M3B2硼化物等强化相。

图1 类K445合金典型显微组织形貌

Fig.1 Typical microstructure of similar- K445 superalloy

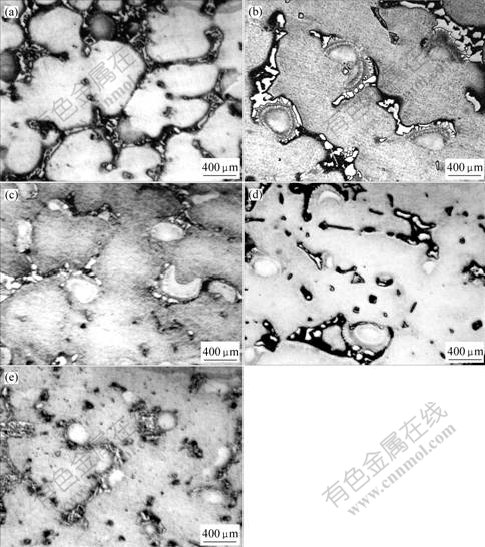

2.1.2 保温时间对类K445合金显微组织的影响

不同保温时间条件下合金的枝晶形貌如图2所示。由图2可以看出,保温15 min时枝晶粗大,随保温时间的延长,枝晶的尺寸先减小后增大,30 min时晶粒最细小。保温15、90和120 min时均形成发达的树枝晶,其中保温15 min时枝晶最粗大,保温30和60 min时枝晶组织明显细化,一次枝晶臂大量熔断,晶界增多,保温时间超过90 min后枝晶又开始粗化。图3所示为不同保温时间下合金的显微组织。由图3可以看出,随保温时间的延长,共晶组织和γ′′强化相含量先增多后减少,碳化物含量先减少后增多。保温15 min时,组织分布不均匀;保温30和60 min时,γ+γ′共晶和γ′′尺寸和分布都很均匀,且数量较多,但碳化物较少;图中还能明显看到γ′相弥散分布于基体上。保温90 min后,γ+γ′共晶和γ′′相减少,但碳化物明显增多,且组织的均匀性又开始降低。

图2 不同保温时间后合金的枝晶形貌

Fig.2 Dendrite morphologies of superalloys treated for different holding time: (a) 15 min; (b) 30 min; (c) 60 min; (d) 90 min; (e) 120 min

图3 不同保温时间合金后的显微 组织

Fig.3 Microstructures of superalloys treated for different holding time: (a) 15 min; (b) 30 min; (c) 60 min; (d) 90 min; (e) 120 min

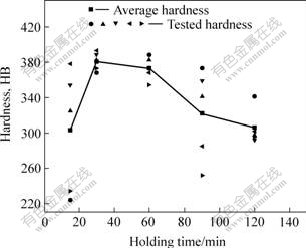

2.2 保温时间对类K445合金硬度的影响

一般情况下,合金的强度和硬度成正比关系,硬度的变化也能间接反映出合金强度的变化。由于硬度测试法具有简单易行、可重复性好等特点,因此,本实验对类K445合金进行硬度测试。不同保温时间制备的合金硬度如图4所示。由图4可以看出,在熔炼温度一定的情况下,随保温时间的延长,类K445合金的硬度呈先增大后减小的变化趋势。保温时间为30和60 min时合金的硬度较大,保温30 min时合金硬度达到最大值HB381,且此时所测硬度值很集中地分布在平均硬度的两侧,说明宏观偏析程度很小。

图4 不同保温时间合金的硬度

Fig.4 Hardness of superalloys treated for different holding time

2.3 分析与讨论

体系从一个定态到达另一个定态需要一定的驰豫时间。保温15 min时时间太短,熔体中各成分扩散不充分,组织分布不均匀,宏观偏析严重。此时,熔体中存在尺寸较大的TiC质点,可以作为碳化物的形成核心,所以在凝固过程中形成了较多尺寸较大的碳化物。随着保温时间的延长,熔体结构不断趋于该过热温度下的平衡态,即熔体结构随着保温时间的延长变得更加均匀,熔体中的难熔粒子部分熔化,原子集团的平均尺寸减小。从图2可以看出,保温30 min时枝晶最细小,晶粒也就越细,因而强化效果也最好[10]。此外,由图3可知,保温30 min时组织分布最均匀,共晶和γ′′相最多,碳化物含量最少。碳化物形成元素主要是Nb、Ti、W、Mo等[11],碳化物含量减少使得基体中固溶了更多的难熔元素W和Mo,增强了固溶强化效果,提高了硬度。同时,Nb、Ti向枝晶间富集,使共晶和γ′′增多,γ′′和γ间的点阵失调度增大,共格应力强化作用显著[12],其含量增加也相应增强了对合金的强化作用。但保温时间过长时,基体中的固溶强化元素又部分析出,碳化物增多,元素固溶度减小,降低了合金强度。在熔体温度和外界压力一定的条件下,元素挥发与保温时间几乎成正比,保温时间越长,元素挥发越多[13],所以保温时间太长导致Al、Ti等元素严重烧损,且能引起合金液与坩埚间的激烈反应而造成合金冶金质量的下降[14]。同时在熔体的保温过程中存在着有害物质排出(夹杂沉降和气体逸出)和熔体表面氧化,所以保温时间会对合金熔体的纯净度产生影响,从而影响合金的力学性能[15]。因此,保温时间过短或过长都会使合金存在严重的宏观偏析,降低材料的性能。

3 结论

1) 真空熔炼类K445高温合金时,熔体保温时间对类K445合金的相种类没有影响,合金组织均由树枝状γ固溶体基体、弥散分布于基体的γ′相、枝晶间的γ+γ′共晶、不规则大片状γ′′相、不规则块状MC碳化物、少量M3B2硼化物等强化相组成。

2) 随保温时间的延长,类K445合金组织中枝晶尺寸先减小后增大,分布于枝晶间的共晶及γ′′相含量先增多后减少,MC碳化物含量先减少后增多。保温30 min时合金组织中的共晶及γ′′相含量最多,MC碳化物含量最少。

3) 随保温时间的延长,类K445合金的硬度先提高后降低,保温时间为30 min时合金硬度达到最高值HB381,且硬度值分布最集中,宏观偏析程度很小。

REFERENCES

[1] 李耀彪. 高温熔体处理对M963合金组织及性能的影响[D]. 沈阳:中国科学院金属研究所,2002.

LI Yao-biao. Effect of BTOP on the microstructure and properties of M963 superalloy[D]. Shenyang: Institute of Metal Research, Chinese Academy of Sciences, 2002.

[2] Al-Jarba K A, Fuchs G E. Effect of carbon additions on the as-cast microstructure and defect formation of a single crystal Ni-based superalloy[J]. Mater Sci Eng A, 2004, 373: 255-267.

[3] Tin S, Pollock T M. Phase instabilities and carbon additions in single-crystal nickel-base Superalloys[J]. Materials Science and Engineering A, 2003, 348: 111-121.

[4] 马文有,李树索,乔 敏,等. 热处理对镍基单晶高温合金微观组织和高温持久性能的影响[J]. 中国有色金属学报,2006,16(6): 937-944.

MA Wen-you, LI Shu-suo, QIAO Min, et al. Effect of heat treatment on microstructure and stress rupture life of Ni-base single crystal superalloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(6): 937-944.

[5] Razavi S H, Mirdamadi S H. Improvement of age-hardening process of a nickel-base superalloy, IN738LC, by induction aging[J]. Journal of Materials Science, 2002, 37: 1461-1471.

[6] 李耀彪,孙晓峰,张承忠,等. 冶炼工艺对M963合金高温持久性能的影响[J] . 机械工程材料,2003,27(4):18-20.

LI Yao-biao, SUN Xiao-feng, ZHANG Cheng-zhong, et al. Effect of smelting processing on the high temperature creep rupture property of a nickel-based superalloy M963[J]. Materials For Mechanical Engineering, 2003, 27(4): 18-20.

[7] LIU Feng, YANG Gen-cang. Effect of microstructure and γ′ precipitate from undercooled DD3 superalloy on mechanical properties[J]. Journal of Materials Science, 2002, 37: 2713-2719.

[8] 高温合金金相图谱编写组. 高温合金金相图谱[M]. 北京: 冶金工业出版社,1979.

The Editor Group of Metallographic Atlas of Superalloys. Metallographic atlas of superalloys[M]. Beijing: Metallurgical Industry Press, 1979.

[9] 郑 亮. Ta和Ru对低铬高钨铸造镍基高温合金组织及性能的影响[D]. 西安:西安理工大学,2004.

ZHENG Liang. The effects of tantalum and ruthenium on the microstructures and properties of low chromium and high tungsten content cast nickel-base superalloys[D]. Xi’an: Xi’an University of Technology, 2004.

[10] 崔忠圻. 金属学与热处理[M]. 北京:机械工业出版社,2000.

CUI Zhong-qi. Metallography and heat treatment[M]. Beijing: China Machine Press, 2000.

[11] 郑运荣,张德堂. 高温合金与钢的彩色金相研究[M]. 北京:国防工业出版社,1999.

ZHENG Yun-rong, ZHANG De-tang. The colour metallography research of superalloys and steels[M]. Beijing: National Defence Industry Press, 1999.

[12] 李玉清,刘锦岩. 高温合金晶界间隙相[M]. 北京:冶金工业出版社,1990.

LI Yu-qing, LIU Jin-yan. Grain boundary interstitial phase of superalloys[M]. Beijing: Metallurgical Industry Press, 1990.

[13] 司玉峰,陈子勇,孔凡涛,等. Ti-22Al-25Nb合金ISM熔炼过程中的成分控制[J]. 铸造技术,2004,25(11):834-836.

SI Yu-feng, CHEN Zi-yong, KONG Fan-tao, et al. Composition control in induction skull melting of Ti-22Al-25Nb alloy[J]. Foundry Technology, 2004, 25(11): 834-836.

[14] 王建明,袁 超,牛建平,等. 高温精炼处理对铸造镍基高温合金组织与性能的影响[J]. 中国有色金属学报,2004,14(5):713-717.

WANG Jian-ming, YUAN Chao, NIU Jian-ping, et al. Effect of melt superheating treatment on microstructure and mechanical properties of cast nickel-base superalloy[J]. The Chinese Journal of Nonferrous Metals, 2004,14(5):713-717.

[15] 张 军,罗志华,李培杰,等. 保温时间及结晶条件对AZ91D组织和性能的影响[J]. 特种铸造及有色合金,2006,26(2):65-67.

ZHANG Jun, LUO Zhi-hua, LI Pei-jie, et al. Effects of smelting and crystallization condition on microstructure and properties of AZ91D alloy[J]. Special Casting & Nonferrous Alloys, 2006, 26(2): 65-67.

基金项目:教育部博士点基金资助项目(20050700002)

收稿日期:2006-09-04;修订日期:2007-01-31

通讯作者:范志康,教授,博士;电话:029-82312181;E-mail:fanzk@xaut.edu.cn

(编辑 何学锋)