Improved model and 3D simulation of densification process for iron powder

来源期刊:中国有色金属学报(英文版)2010年第8期

论文作者:宋毅 李元元 周照耀 郑振兴 陈普庆

文章页码:1470 - 1475

Key words:powder compaction; simulation; iron; density distribution; constitutive model

Abstract: A new model for describing the compaction process of iron powder was proposed based on the continuum hypothesis and elliptical yield criterion. To simulate the densification behaviour, the constitutive model was implemented in Marc computer program. For the relationship between load and displacement, different models were compared and the influence of the parameters in the constitutive equations was determined by means of simulation and experiments. The density distribution of a balancer was measured and simulated. The results show that the parameter η adopted plays a modification role for the load-displacement curve, and compared with other models the present model fits better with the experimental data in the later stage of the compaction process mainly due to the different parameters A and B. The friction on the contact surface contributes to the inhomogeneous density distribution under large deformation of the workpiece. The comparison between the simulation and experimental data indicates that this model can be used to predict the powder compact process precisely and effectively.

基金信息:the National Natural Science Foundation of China

China Education and Research Grid (China Grid)

the Natural Science Foundation of Guangdong Province, China

SONG Yi(宋 毅), LI Yuan-yuan(李元元), ZHOU Zhao-yao(周照耀),

ZHENG Zhen-xing(郑振兴), CHEN Pu-qing(陈普庆)

School of Mechanical and Automative Engineering, South China University of Technology, Guangzhou 510640, China

Received 1 September 2009; accepted 2 February 2010

Abstract: A new model for describing the compaction process of iron powder was proposed based on the continuum hypothesis and elliptical yield criterion. To simulate the densification behaviour, the constitutive model was implemented in Marc computer program. For the relationship between load and displacement, different models were compared and the influence of the parameters in the constitutive equations was determined by means of simulation and experiments. The density distribution of a balancer was measured and simulated. The results show that the parameter η adopted plays a modification role for the load-displacement curve, and compared with other models the present model fits better with the experimental data in the later stage of the compaction process mainly due to the different parameters A and B. The friction on the contact surface contributes to the inhomogeneous density distribution under large deformation of the workpiece. The comparison between the simulation and experimental data indicates that this model can be used to predict the powder compact process precisely and effectively.

Key words: powder compaction; simulation; iron; density distribution; constitutive model

1 Introduction

Powder forming is a highly developed process of manufacturing ferrous matrix or ceramic matrix composite material products, which combines the cost and material saving advantages of conventional powder metallurgy with the high production rates and property enhancement of forging. Some important factors, such as pressure, temperature and strain rate, determine the product quality. Therefore, these process factors should be optimized by using theoretical methods or experimental approaches to manufacture high strength and accuracy parts with homogeneous density distribution[1-5].

During the deep exploration of powder forming phenomenon, a number of constitutive models were proposed based on the hypothesis that powder was considered as a continuous, elasto-plastic, and compressible medium. With some classical elliptical yield equations[6-9], they are commonly integrated with finite element method (FEM) for the investigation of metal powder. However, most of these models[10-12] are based on the constitutive function of porous material which is not in accordance with the properties of the powder material completely.

A new constitutive relation under a general form of the yield function with an ellipsoidal yield surface for the densification process of iron powder during the cold compaction was reported which was put forward based on the speciality of powder. The action mechanisms of different parameters in the yield function were analyzed in detail. And the finite element calculations derived from user-subroutines of Marc were compared with experimental data.

2 Constitutive model

Taking into account of the influence of porosity and hydrostatic pressure of porous materials, one general form of the yield criterion is

![]() (1)

(1)

where ![]() and J1 are the second invariant of deviatoric stress tensor and the first invariant of stress tensor, respectively. σs is the yield stress of the dense reference material and σR is the flow stress of the porous material. The parameter η is a function of relative density ρ and represents contribution of geometric hardening. A and B are the coefficients of the yield criterion which can be presented as functions of material Poisson ratio

and J1 are the second invariant of deviatoric stress tensor and the first invariant of stress tensor, respectively. σs is the yield stress of the dense reference material and σR is the flow stress of the porous material. The parameter η is a function of relative density ρ and represents contribution of geometric hardening. A and B are the coefficients of the yield criterion which can be presented as functions of material Poisson ratio ![]() . KUHN and DOWNEY[6], and DORAIVELU et al[8] put forward the following functions:

. KUHN and DOWNEY[6], and DORAIVELU et al[8] put forward the following functions:

A=2(1+![]() ), B=(1-2

), B=(1-2![]() )/3 (2)

)/3 (2)

For the uniaxial stress condition, J1=![]() ,

, ![]() and

and ![]() =

=![]() , i.e. A and B satisfy the following relationship:

, i.e. A and B satisfy the following relationship:

A/3+B=1 (3)

Various relationships between ![]() and ρ were proposed by many investigators[6, 8, 13]. According to the experimental data, ZHDANOVICH[14] assumed that

and ρ were proposed by many investigators[6, 8, 13]. According to the experimental data, ZHDANOVICH[14] assumed that

![]() =0.5ρn (4)

=0.5ρn (4)

KUHN and DOWNEY[6], and DORAIVELU et al[8] applied n=2 to the yield criterion. WANG et al[15] adopted a linear relationship between ![]() and ρ for iron powder material[15]:

and ρ for iron powder material[15]:

![]() =0.93ρ-0.43 (5)

=0.93ρ-0.43 (5)

Compared with KUHN’s[6] formula by compaction experiments of iron powder, Eq.(5) fits better with the experimental data. Therefore, Marx-Davies function was adopted in this work for the higher precision.

WANG[15] et al Submitted Eq.(5) to Eq.(2) and scaled the parameter B properly. The yield criterion can be written as

![]() (6)

(6)

It is noteworthy that when materials are of full density, i.e. in the state of ρ=1 and ![]() =0.5, this yield criterion reduces to the usual von Mises yield criterion. Although when ρ≠1, Eq.(6) does not accord with the uniaxial stress condition, Eq.(3). KIM et al[2] mentioned that Eq.(3) is mandatory for porous materials, but not for powder.

=0.5, this yield criterion reduces to the usual von Mises yield criterion. Although when ρ≠1, Eq.(6) does not accord with the uniaxial stress condition, Eq.(3). KIM et al[2] mentioned that Eq.(3) is mandatory for porous materials, but not for powder.

The foctor η was introduced via the flow stress in order to characterize geometrical and strain hardening which is generally considered as the function of relative density. DORAIVELU et al[8] assumed that

![]() (7)

(7)

where ρc is an experimental parameter that is referred as the critical relative density for the state of the porous material without flow stress. The value of ρc should be very close to the initial relative density. Based on the DORAIVELU’s formula[8], an expression of the factor η was proposed by LI et al[16]:

![]() (8)

(8)

It produced better results with the experimental data. In this work, the elasto-plastic deformation of iron powder with low initial density was analyzed and the yield criterion was put forward as follows:

![]()

(9)

During the compaction of powder material, the density is closely related to the plastic strain. The density increases gradually with the cumulation of plastic strain and the property of material changes simultaneously. The evolution of density must follow the mass conservation equation and the relationship between relative density and plastic strain is given as follows:

![]()

![]() (10)

(10)

where ρ0 and (ρ+?ρ) are the relative densities before and after deformation, li and (li+?li) are the dimensions of a micro-unit before and after deformation, and ![]() is the cumulative logarithmic plastic strain.

is the cumulative logarithmic plastic strain.

3 Three-dimensional FEM analysis and experiments of compaction process

This new constitutive model was employed into MSC. Marc. User subroutines which used the implicit code to simulate the compaction process of pure iron powder and the corresponding experimental data were presented to verify the simulation results.

In the following simulations, eight-noded and full-integration solid elements were adopted to build the 3D finite element models. The material parameters were set as: ρc=0.457 9, σs=405 MPa, ρ0=0.458 and elastic modulus E=210ρ GPa.

3.1 Comparison of different models

An uniaxial compaction experiment of a block workpiece was conducted on the test machine SANS-CMT5105. Pure iron powders were filled in a die with a square cross-section of 10 mm×10mm in size, and the filling height was 19.65 mm. The load on the upper punch increased linearly from 0 to 70 kN. The load- displacement curves were recorded by test machine.

In the simulations, the influence of inertia force was ignored because it was far less than the pressure of the upper punch actually. The upper punch, the lower punch, and the die were assumed as rigid walls. A coulomb friction model with an additional stress limit was used. The friction coefficients at the interfaces were supposed to be 0.1. With relative residual testing, the check for convergence was made whether the largest residual force divided by the maximum reaction force was smaller than the tolerance of 0.1.

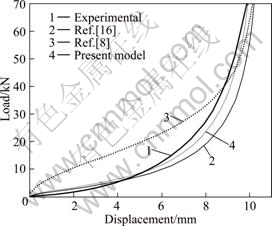

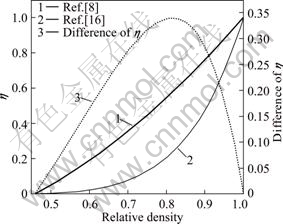

In Fig.1, the load vs displacement curve obtained from the experiment is compared with that of the simulation for the constitutive models of LI et al[16], DORAIVELU et al[8] and the present model. It can be found that the present model shows a higher accuracy in this case. Compared with model in Ref.[8], model of Ref.[16] has the same functions of the parameters A and B and the different expression of the parameter η, which makes the load-displacement cuve ‘softer’ because of its ‘softer’ relationship between relative density and η shown in Fig.2. Fig.2 suggests that η of these two models, Eq.(7) and Eq.(8), all approach to 1.0 as relative density approaches to the limit, and the difference of η increases gradually with the densification process to the maximum value at the relative density of 0.816, then decreases rapidly to zero. These evolution trends are also reflected on their comparison in Fig.1, and the start and end points

Fig.1 Load vs displacement curves of experiment and simulation

Fig.2 Parameter η as function of relative density

of these two load-displacement curves are almost the same. Although DORAIVELU’s model[8] fits well with the experiment in the later densification process, it is obvious that its error is large at the beginning. In one word, η is overestimated in DORAIVELU’s model. As mentioned above, η represents geometric hardening contribution, so in the prometaphase of compaction, the advance of the flow stress for powder material can be described more accurately by LI et al[16]. The expression proposed by LI et al[16], Eq.(8), was adopted in the present model.

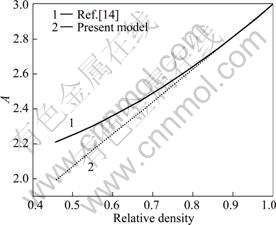

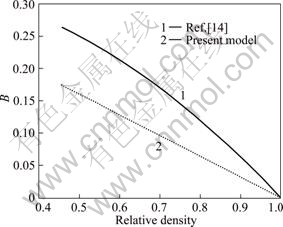

Compared with the model in Ref.[16], the present model has a similar load-displacement curve with the different functions of the parameters A and B and the same expression of the parameter η, because Fig.3 and Fig.4 show that there is not a great difference between these two models for the A and B functions of relative density. Although A and B of all models approach to 3.0 and 1.0, respectively, as relative density approaches to 1.0, which meets the constraint of von Mises yield criterion, the present model fits better with the experimental data in the later stage of the compaction mainly due to the more reasonable expression of ![]() ,

,

Fig.3 Parameter A as function of relative density

Fig.4 Parameter B as function of relative density

Eq.(5). The parameters A and B can be regarded as weighting factors for deviatoric stress and hydrostatic stress, respectively[1]. So, based on the parameters A and B modified through the experiments of iron powder, the present model behaves a more authentic status of elasto-plastic stress and strain for this material.

3.2 Simulation of density distribution

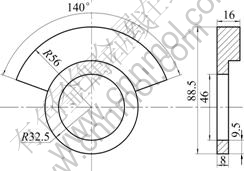

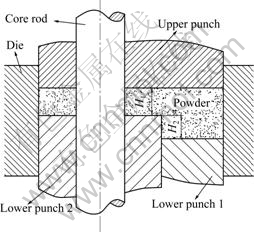

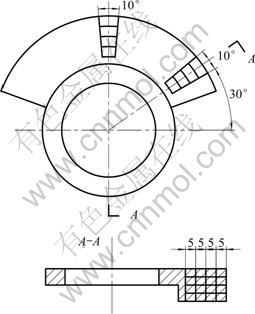

A balancer used in the piston mechanism is shown in Fig.5. In the compaction process, it is difficult to achieve a completely homogeneous density distribution because of the structure of two levels steps, which means the requirement of the elaborated process scheme. Fig.6 shows the schematic illustration of the die, powder and punches. In this case, the lower punch 2 and the upper punch were movable downwards to compact the powder, and their velocities were proportional to their final displacements. The initial positions of the lower punch 2 and the upper punch were set as H1=15.23 mm and H2=15.23 mm. The lower punch 1, die and core rod were fixed.

Fig.5 Schematic diagram of balancer (Unit: mm)

Fig.6 Schematic diagram of die, powder, core rod and punches

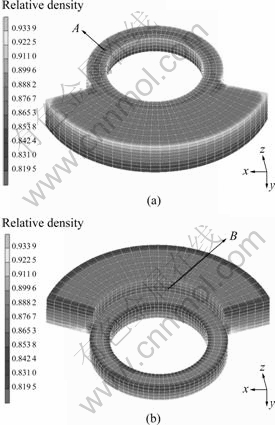

The constitutive model described above was implemented to simulate the densification process. A full 3D simulation was conducted using a mesh with 3 398 nodes and 2 400 hexahedral elements. The calculation was divided into 200 incremental steps. The updated Lagrangian approach was used in this procedure for a large-strain elasticity and plasticity analysis. The convergence criterion assumed that the residual force should be less than 1% of the reaction force. On a computer with 1.8 GHz CPU and 2 GB memory, the total time steps taked approximately 7 h.

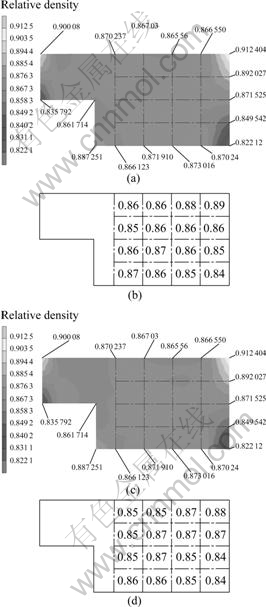

Fig.7 shows the contour plots of relative density of the sample. The highest relative density, 0.933 9, is at the upper joint of the ring part and the fan-shaped part. The relative density distribution from 0.911 0 to 0.933 9 appears mainly at the outter upside edge of the fan-shaped part. The lowest relative density, 0.819 5, is at the outter arc edge of the downside of fan-shaped part. The relative density distribution from 0.819 5 to 0.831 0 appears mainly at the outter edge of the downside of fan-shaped part. All the large gradients occur around the die, core rod, and punches where the flow of powders is constrained by the friction at interfaces, especially in the corners, but the relative density in inner districts presents a relatively homogeneous distribution.

Fig.7 Relative density distributions of simulation: (a) Top; (b) Bottom

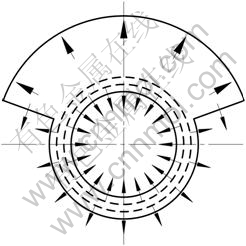

At the vertical interfaces between powders and the die, relative density exhibits a decreasing trend from up to down. However, the situation is contrary on the axial interface between powders and the lower punch 2 (i.e. surface B marked in Fig.7(b), because the downward friction, with the downward compaction of the lower punch 2, promotes the movement of powders to the bottom and densifies these regions. In addition, the places of lower density in the upside form an annular shape (i.e. A marked in Fig.7(a)), which is the joint effect of the horizontal friction from upper punch and the vertical friction from die and core rod. Fig.8 reveals the directions of the friction on upper surface and the dashed line represents the region A. As shown in Fig.8, the bilateral friction of the region A is completely reversed in direction, which causes the diffusion of the intermediate powders to the both sides and the downward. As a result, an annular low density distribution comes into being.

Fig.8 Directions of friction on upper surface

Fig.9 Cutting scheme for measuring relative density distribution

Two parts of the balancer shown in Fig. 9 were split into sixteen pieces respectively for measuring the relative density distribution by Archimedes’ method. Fig.10 shows the experimental and simulative results of the symmetry plane and A—A section. By comparison, the simulations are basically consistent with the experimental results. It is found that the span and the maximum value of relative density on the symmetry plane are greater than those in the A—A section. And the prediction mentioned above that the relative density nearby the interfaces is more inhomogeneous than that of the inner, is confirmed by the experiment.

Fig.10 Comparison of experimental and simulative results: (a) Simulative results on symmetrical plane; (b) Experimental results on symmetrical plane; (c) Simulative results in A-A section; (d) Experimental results in A-A section

4 Conclusions

1) The simulative load vs displacement curve of the new model agrees better with the experimental data. The parameters A, B and η produce different influence on the numerical solutions. The results show that the parameter η adopted plays a modification role for the load- displacement curve, because of the compaction of powder, which describes the increase of the flow stress more accurately. In the later stage of the compaction, the present model fits better with the experimental data compared with other models mainly due to the different parameters A and B which are based on the more reasonable expression of ![]() for the iron powder.

for the iron powder.

2) In the simulation of a balancer with a 3D finite element model, the relative density distribution was obtained by employing the constitutive function into MSC. Marc. User subroutines. The simulative results show that the friction on the contat surfaces contributes to the inhomogeneous density distribution of the workpiece under large deformation. For the relative density distribution, the simulation data are basically consistent with the experimental results. Some errors exist because the simulation data are obtained from nodes of the specified plane but the experimental data are from the solid entities.

References

[5] LEE S C, KIM K T. A densification model for powder materials under cold isostatic pressing—Effect of adhesion and friction of rubber molds [J]. Materials Science and Engineering A, 2008, 498(1/2): 359-368.

(Edited by LI Xiang-qun)

Foundation item: Project(50325516) supported by the National Natural Science Foundation of China; Project(CG2003-GA005) supported by China Education and Research Grid (China Grid); Project(003019) supported by the Natural Science Foundation of Guangdong Province, China; Project(2009ZM0290) supported by the Fundamental Research Funds for the Central Universities, China

Corresponding author: SONG Yi; Tel: +86-20-87112933; E-mail: songyi0591@gmail.com

DOI: 10.1016/S1003-6326(09)60323-X