文章编号:1004-0609(2015)-01-0030-06

Si和Zn对铝/钢异种金属熔钎焊接头界面组织的影响

石 玗,李 杰,黄健康,顾玉芬,樊 丁

(兰州理工大学 省部共建有色金属先进加工与再利用国家重点实验室,兰州 730050)

摘 要:采用脉冲旁路耦合电弧MIG熔钎焊方法用ER4043铝合金焊丝对5052铝合金/镀锌钢异种金属进行搭接焊,通过扫描电镜、能谱仪、X射线衍射仪对所获得的铝/钢连接界面进行了分析与研究。结果表明:焊接接头焊趾处是一个Zn的富集区,通过对该区域组织进行分析发现,焊趾处的物相由靠近钢侧的Fe2Al5Zn0.4和焊缝中的Al-Zn固溶体组成。焊缝中的Si元素参与了界面处化合物层的反应,并生成了Al8Fe2Si三元金属间化合物,该三元金属间化合物沿着焊缝侧金属间化合物FeAl3的边缘分布。进一步线扫描发现:Si元素在整个界面反应层中有明显富集现象。此外,在测试结果的基础上对Fe-Al-Si三元金属间化合物的生长过程进行探讨。

关键词:铝/钢熔钎焊;扩散;金属间化合物;接头界面

中图分类号:TG401 文献标志码:A

Effects of Si and Zn on interface microstructures of aluminum/steel welding-brazing joint

SHI Yu, LI Jie, HUANG Jian-kang, GU Yu-fen, FAN Ding

(State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals,

Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: The dissimilar metals of 5052 aluminum alloy/galvanized steel were joined with lap joint by pulsed double electrode gas metal arc welding-brazing with ER4043 filler metal. The interfacial microstructures of the joints were analyzed by scanning electron microscopy, energy dispersive spectroscopy and X-ray diffractometry. The results show that a zinc-rich zone locates at the weld toe,which is mainly composed of Al-Zn solid solution at the weld seam side and Fe2Al5Zn0.4 at the galvanized steel side. Si element in weld seam involves in metallurgy reaction of intermetallic compound formation and the Al8Fe2Si ternary phase is found, the phase Al8Fe2Si forms along FeAl3 side. The results of linear scanning indicate that Si atom obviously aggregates in the intermetallic compound layers. Further, the formation process of Fe-Al-Si ternary intermetallic compound was discussed on the basis of the test results.

Key Words: aluminum/steel welding-brazing; diffusion; intermetallic compounds; interface microstructure

汽车轻量化等工业发展的要求使得低密度和高比强度的铝合金得到了广泛应用。既能降低汽车质量又能满足结构性能要求的铝/钢复合结构被人们广泛关注。目前,国内外学者对铝/钢异种金属的焊接开展了大量的研究[1-5],特别是合金元素对铝/钢界面的影响成了学者们研究的热点。

镀锌钢板是重要的汽车车身用钢,在铝与镀锌钢板异种金属焊接的过程中常采用4043等Al-Si焊丝。现有大量研究已表明:镀锌层和Al-Si焊丝较低的熔点一定程度上均有助于液态铝在钢表面的浸润与铺展,但是关于合金元素Si、Zn对铝/钢异种金属界面反应层金属间化合物组成及形态影响的研究,目前尚未形成统一的定论。一部分学者认为Si在金属间化合物层没有参与反应,只是以第二相的形式存在。雷振等[6]分析了铝/镀锌钢复合热源熔钎焊接头中Al-Fe金属间化合物层的相结构,认为Si元素以第二相的形式在Al-Fe化合物周边析出并富集,未发现有Al-Fe-Si三元化合物存在。另一部分学者提出:Si在铝铁界面层参与了反应并生成了Al-Fe-Si三元金属间化合物。赵旭东等[7]研究了铝/钢光纤激光填充粉末熔钎焊接头的界面组织,填充粉末为AlSi12,研究发现界面反应层中生成了Al2Fe3Si3的金属间化合物。SONG等[8]研究了Si对铝/钢熔钎焊金属间化合物层的影响,当使用Al-Si焊丝时在铝侧生成的金属间化合物为Al7.2Fe1.8Si,钢侧发现了Fe(Al,Si)3的金属间化合物。HADDADI等[9]研究发现采用不同镀锌层钢板进行铝/钢焊接时,其接头的浸润性及力学性能有明显的差异。在铝/镀锌钢异种金属熔钎焊焊接过程中Zn除了可增加液态铝在钢表面的浸润与铺展外,还可改变电弧的加热行为、降低焊接过程中的热输入[10]。由此可见,合金元素Si、Zn对铝/钢焊接接头的界面组织及力学性能有显著的影响,因此,有必要进一步研究Si、Zn对铝/钢焊接接头界面组织的影响。

本文作者针对铝/镀锌钢板焊接中合金元素Si、Zn对金属间化合物组成、形态影响的问题,采用脉冲旁路耦合电弧MIG熔钎焊方法(Pulsed DE-GMAW welding-brazing)用ER4043铝合金焊丝进行了铝/钢搭接焊试验。采用扫描电镜(SEM)、X射线能量色散谱仪(EDS)测试手段对熔钎焊接头界面区的化合物层进行了分析,通过对剥落面进行X射线衍射(XRD)分析发现界面处生成Fe-Al-Si及Fe2Al5Zn0.4的三元金属间化合物。采用能谱仪分析发现Si元素在整个金属间化合物层有富集现象,最后基于试验结果提出Fe-Al-Si三元金属间化合物的生长过程。

1 实验

试验采用脉冲旁路耦合电弧MIG熔钎焊的方法进行了铝/镀锌钢板异种金属的搭接焊,该焊接方法可以实现铝/钢异种金属的连接[11-12]。试验中用氩气作为保护气,主路氩气流量为20 L/min,旁路氩气流量为5 L/min。焊接主路平均电流35 A,旁路平均电流27 A,旁路、主路采用同步脉冲,脉冲频率80 Hz,焊接速度0.8 m/min。本试验采用直径1.2 mm的4043(Al-Si)铝合金焊丝进行了镀锌钢板(基体为Q235低碳钢)与5052铝合金的搭接焊。焊丝化学成分如表1所列,板材规格均为200 mm×80 mm×1 mm。在上述焊接参数下焊接得到的焊缝形貌如图1所示。

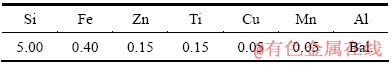

表1 ER4043铝合金焊丝的化学成分

Table 1 Chemical composition of ER4043 (mass fraction, %)

图1 铝/镀锌钢板熔钎焊焊缝形貌

Fig. 1 Weld seam morphology of aluminum/galvanized steel welding-brazing

2 结果与分析

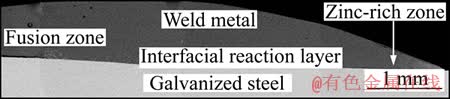

2.1 铝/钢熔钎焊接头

采用扫描电镜对铝/钢熔钎焊焊缝宏观形貌进行了观察,由于铝和钢的熔点差异很大,在焊接过程中铝熔化而镀锌钢板未熔化,形成了铝/钢异种金属的熔钎焊连接,如图2所示。整个焊接接头由铝熔合区、焊缝、富锌区、界面反应区组成。

图2 铝/钢脉冲旁路耦合电弧MIG熔钎焊焊缝宏观形貌

Fig. 2 Macrostructure of cross-section of aluminum/steel by pulsed DE-GMAW welding-brazing

焊后试样采用线切割横向切取铝/镀锌钢熔钎焊搭接接头试样,按要求制成金相试样,用5%硝酸+95%酒精(体积分数)腐蚀镀锌钢的一侧,用5%(体积分数)的氢氟酸腐蚀铝的一侧。采用金相显微镜、SEM 及EDS对铝和镀锌钢熔钎焊接头的显微组织进行观察和分析;采用XRD对焊缝剥落面上的化合物进行分析。

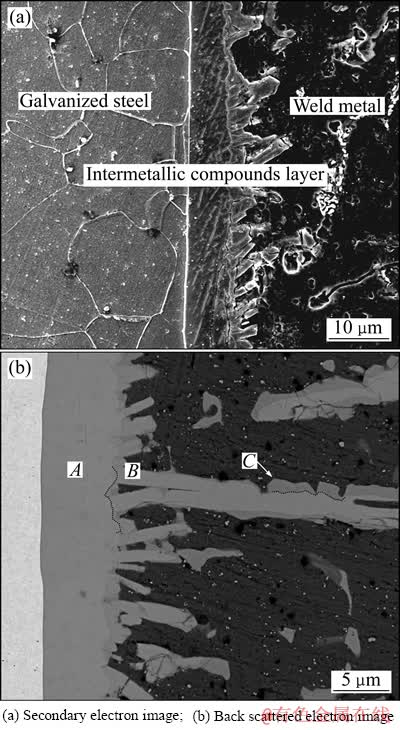

2.2 熔钎焊焊接接头微观组织及物相组成

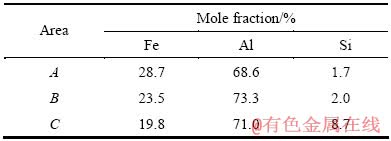

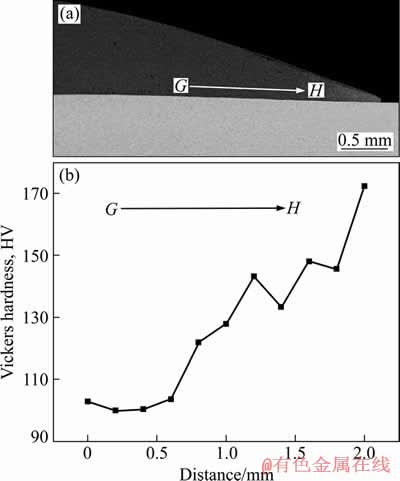

为了深入分析铝/钢熔钎焊焊接接头的显微组织,采用SEM对焊接接头不同区域的组织进行了观察,如图3所示。图3(a)为二次电子像,图3(b)为背散射电子像。由图3可以发现,在铝/钢熔钎焊界面处生成了厚度约10 μm的金属间化合物层且化合物层包含两层,靠近铝一侧化合物呈枝晶状向铝方向生长;靠近镀锌钢板一侧的化合物以层状向镀锌钢板侧生长。由背散射电子像可以看出,金属间化合物层至少有3种物相组成,靠近镀锌钢侧层状的化合物为一种物相,而靠近Al侧呈枝晶状的化合物由两种不同的物相组成。为了分析界面层金属间化合物层的物相组成,用EDS对图3(b)中A、B、C处物相进行了点分析,根据表2中EDS结果显示A区域中的Fe和Al的摩尔比约为2:5,B区域中的Fe和Al的摩尔比约为1:3,C区域中Fe,Al和Si的摩尔比约为2:8:1。结合已有的研究[11, 13-14]确定A区域中的物相是Fe2Al5,B区域中的是FeAl3,C区域中的物相是Al8Fe2Si(τ5)。金属间化合物τ5层的拉伸性能要略高于Fe2Al5 层和Fe(Al,Si)3层的拉伸性能[8],所以,金属间化合物Al8Fe2Si在一定程度上对提高焊接接头的力学性能是有利的。

图3 铝/钢熔钎焊界面微观组织

Fig. 3 Interfacial microstructures of cross-section by aluminum/steel welding-brazing

表2 图3中界面处不同区域的成分

Table 2 Compositions of different areas of interface in Fig. 3

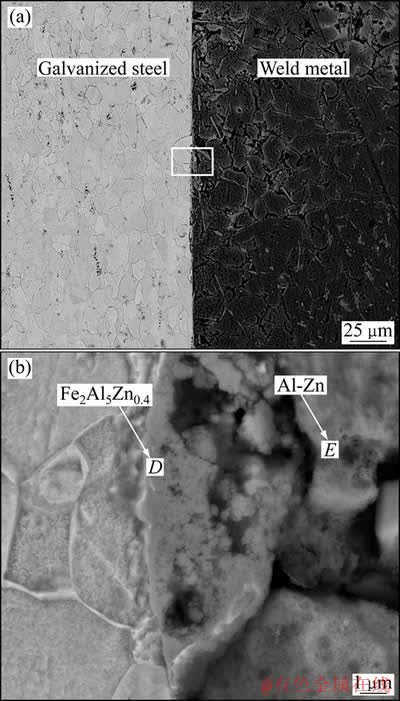

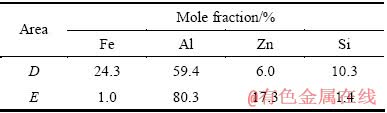

通过对熔钎焊焊接接头焊趾处不同区域进行分析发现,该区域是一个锌的富集区。焊趾处的显微形貌如图4所示,用EDS对图中D、E两处进行点分析,表3中分析结果表明D区域中的Fe、Al和Zn摩尔比约为2:5:0.4,E区域Fe的含量很少。由此可以推断,焊趾处的物相由靠近钢侧的Fe2Al5Zn0.4和焊缝中的Al-Zn固溶体组成。Fe2Al5Zn0.4是非脆性金属间化合 物[15],一定程度上有利于改善接头的力学性能。为了分析Al-Zn固溶体对焊接接头力学性能的影响,对焊缝侧不同区域的显微硬度进行了测试,其结果如图5所示。从测试结果可以看出,焊趾区Al-Zn固溶体的显微硬度要高于其他区域的显微硬度。此外,越接近焊趾处的区域,其显微硬度越高,这是由于在接近焊趾处的位置,会有更多的锌固溶在铝中,Al-Zn固溶体固溶强化的效果更为显著所致。

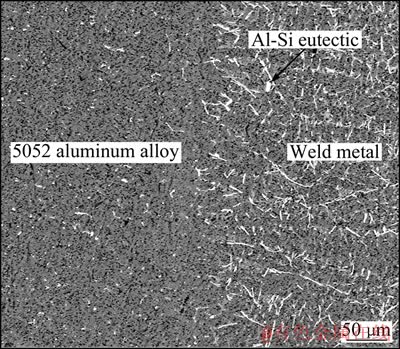

进一步对Al熔合区的显微组织进行了分析,发现熔合区两侧组织分布不均匀(见图6),用EDS并结合Al-Si合金相图确定焊缝侧组织主要由白色的Al-Si共晶体和α(Al)组成,且Al-Si共晶体组织沿晶界分布。

图4 铝/钢焊接接头富锌区组织

Fig. 4 Microstructures of zinc-rich region by aluminum/steel welded joint

表3 界面处不同区域的成分

Table 3 Compositions of different areas of zinc-rich region in Fig. 4

图5 焊缝侧显微硬度分布

Fig. 5 Distribution of vickers hardness at weld metal side

图6 铝/钢焊接接头Al熔合区显微组织

Fig. 6 Microstructure of aluminum fusion area by aluminum/steel welded joint

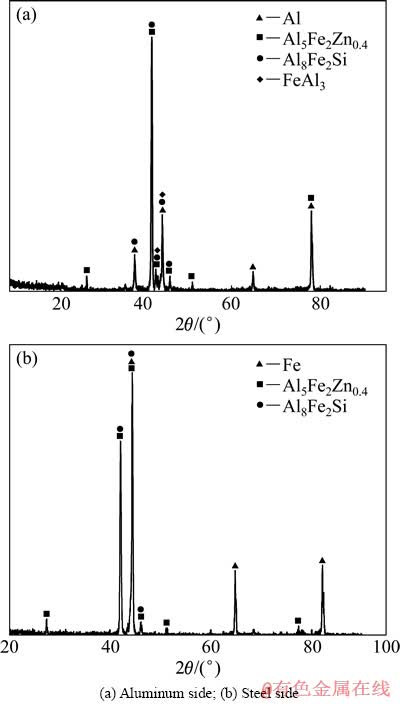

为了进一步确定界面反应层化合物的物相组成,将铝/钢熔钎焊界面进行了机械分离并对分离界面进行了XRD分析,其结果如图7所示。XRD结果表明:在铝/钢界面处有FeAl3、Al8Fe2Si、Fe2Al5Zn0.4金属间化合物生成。综上所述,铝/镀锌钢熔钎焊界面反应层靠近钢侧层状金属间化合物为Fe2Al5,靠近Al侧金属间化合物为FeAl3及靠近FeAl3边缘的Al8Fe2Si组成,焊接接头焊趾处界面反应层的金属间化合物为Fe2Al5Zn0.4。

图7 铝/钢熔钎焊界面XRD谱

Fig. 7 XRD patterns of interface by aluminum/steel welding- brazing

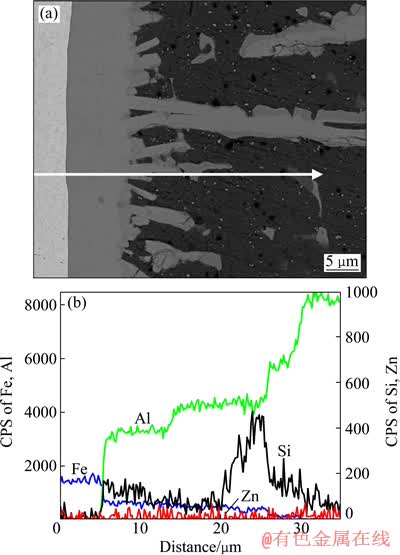

2.3 熔钎焊焊接接头元素扩散

为了研究铝/钢界面反应区的元素扩散,用EDS对其进行了线扫描,其结果如图8所示。通过线扫描可以看出,Al原子在界面反应区有两个明显的平台,即是金属间化合物Fe2Al5和FeAl3层。由线扫描并结合表2中 Si元素的EDS结果发现,Si元素向镀锌钢侧基本没有发生扩散,但在整个金属间化合物层有明显富集现象。由文献[16]可知:Fe2Al5相的C轴方向存在着大量的空位,在焊接过程中合金元素Si融入Fe2Al5中占据了大量空穴,从而减缓了Al原子向铁中扩散的速度,最终导致Fe2Al5以层状的形态向铁基体侧生长。Al、Fe原子反应生成Fe2Al5时体积会发生明显的膨胀,这样冷却过程中,在基体与金属间化合物层间会产生较大的热应力,影响了钎接面的力学性 能[17-18],Si的加入可以减小Fe2Al5层的厚度从而对提高铝/钢钎接面的力学性能是十分有利的。靠近焊缝侧的Si在金属间化合物层中分布并不均匀且有明显的起伏,是因为在部分FeAl3边缘生成了Fe-Al-Si的三元金属间化合物。在电弧热的作用下,位于电弧下方一定区域镀锌钢表面的Zn发生了大量挥发,因此,在界面反应层中几乎没有检测到Zn的存在,只有在焊趾处存在较多的Zn。

图8 铝/钢熔钎焊界面线扫描分析图

Fig. 8 Linear scanning image of cross-section by aluminum/steel welding-brazing

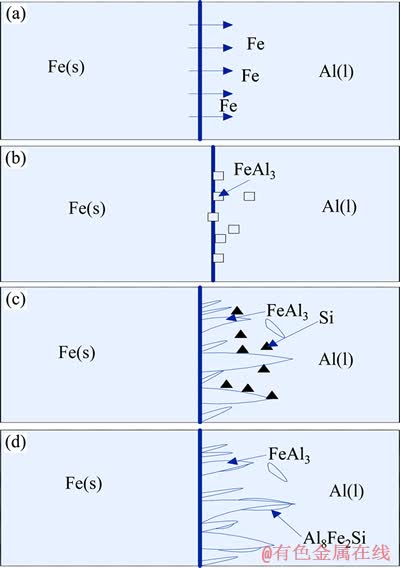

3 Al-Fe-Si金属间化合物生长过程

从测试结果可知,界面反应区靠近铝侧的金属间化合物由FeAl3和靠近FeAl3边缘的Al8Fe2Si组成。图9所示为Al侧金属间化合物形成过程的示意图。图9(a)所示为Fe原子向液态Al中的溶解阶段,当液态Al中的Si含量从0%、5%增加到10%(质量分数)时,Fe在液态铝中的溶解度将从5.30%、8.7%增加到12%(质量分数)[19]。因此,采用Al-Si合金丝作为填充金属时可增加Fe在液态铝中的溶解度和溶解速率。随着温度的降低,Fe在液态Al中的溶解度降低,大多数FeAl3优先在Al、Fe界面上形核,少量会在液态Al液中形核如图9(b)所示。图9(c)所示为金属间化合物FeAl3的长大阶段,由于 FeAl3是小平面相,晶面择优取向特别强,在通常生长条件下,FeAl3相将以(100)和(001)两个晶面沿[010]晶向生长[20],因此,焊缝中长大的FeAl3相呈枝晶状。在枝晶状FeAl3形成的同时破坏了局部区域Al-Si体系的平衡, FeAl3形成的过程中将有多余的Si原子在FeAl3周边析出,这样就会提高周围液态Al中的Si含量。图9(d)所示为Al-Fe-Si金属间化合物的形成阶段,结合Al-Fe-Si合金相图,大约在650 ℃时,满足浓度条件的液态Al会与FeAl3发生包晶反应,金属间化合物Al8Fe2Si将沿着FeAl3边缘生成。

图9 Al-Fe-Si金属间化合物形成过程示意图

Fig. 9 Schematic diagram of formation process of Al-Fe-Si interfacial compound

4 结论

1) 焊缝中的Si元素参与了界面反应区金属间化合物层的反应并生成了Al8Fe2Si的三元金属间化合物,金属间化合物Al8Fe2Si沿着焊缝侧金属间化合物FeAl3的边缘分布。

2) Si元素在整个界面反应层中有明显富集现象,且富集在Fe2Al5中的Si元素可抑制金属间化合物Fe2Al5的生长,对改善接头的力学性能是有利的。

3) 焊趾处界面反应区的金属间化合物为Fe2Al5Zn0.4,焊缝中组织为Al-Zn固溶体且越靠近焊趾处的区域,该组织显微硬度越高。

REFERENCES

[1] MATHIEU A, SHABADI R, DESCHAMPS A, SUERY M, MATTEI S, GREVEY D, CICALA E. Dissimilar material joining using laser (aluminum to steel using zinc-based filler wire)[J]. Optics and Laser Technology, 2007, 39(3): 652-661.

[2] TORKAMANY M J, TAHAMTAN S, SABBAGHZADEH J. Dissimilar welding of carbon steel to 5754 aluminum alloy by Nd:YAG pulsed laser[J]. Materials and Design, 2010, 31(1): 458-465.

[3] ZHANG H T, FENG J C, HE P. Interfacial phenomena of cold metal transfer(CMT) welding of zinc coated steel and wrought aluminium[J]. Materials Science and Technology, 2008, 24(11): 1346-1349.

[4] LIN Jian, MA Nin-shu, LEI Yong-ping, MURAKAWA Hidekazu. Shear strength of CMT brazed lap joints between aluminum and zinc-coated steel[J]. Journal of Materials Processing Technology, 2013, 213(8): 1303-1310.

[5] 周惦武, 吴 平, 彭 利, 张 屹, 陈根余. 镀Zn钢-6016铝合金异种金属的激光熔钎焊及数值模拟[J]. 中国有色金属学报, 2012, 22(6): 1738-1746.

ZHOU Dian-wu, WU Ping, PENG Li, ZHANG Yi, CHEN Gen-yu. Laser welding-brazing and numerical simulation of zinc-coated steel and 6016 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1738-1746.

[6] 雷 振, 王旭友, 王伟波, 林尚扬. 铝/镀锌钢复合热源熔-钎接头中的Al-Fe金属间化合物层分析[J]. 焊接学报, 2007, 28(11): 65-68.

LEI Zhen, WANG Xu-you, WANG Wei-bo, LIN Shang-yang. Analysis for Al-Fe intermetallic compounds layer of fusion-brazed joints between aluminium and zinc-coated steel by hybrid welding[J]. Transactions of the China Welding Institution, 2007, 28(11): 65-68.

[7] 赵旭东, 肖荣诗. 铝/钢光纤激光填充粉末熔钎焊接头界组织与力学性能[J]. 焊接学报, 2013, 34(5): 41-44.

ZHAO Xu-dong, XIAO Rong-shi. Microstructure and mechanical properties of aluminum alloy and galvanized steel joints by fiber laser fusion welding brazing using a rectangular spot with filler powder[J]. Transactions of the China Welding Institution, 2013, 34(5): 41-44.

[8] SONG J L, LIN S B, YANG C L, FAN C L. Effects of Si additions on intermetallic compound layer of aluminum-steel TIG welding-brazing joint[J]. Journal of Alloys and Compounds, 2009, 488(1): 217-222.

[9] HADDADI F, STRONG D, PRANGNELL P B. Effect of zinc coatings on joint properties and interfacial reactions in aluminum to steel ultrasonic spot welding[J]. Journal of the Minerals, Metals and Materials Society, 2012, 64(3): 407-413.

[10] 张洪涛, 冯吉才, 何 鹏, 赵洪运. 镀锌层对铝/镀锌钢板CMT 熔-钎焊电弧加热行为的影响[J]. 焊接学报, 2009, 30(8): 37-40.

ZHANG Hong-tao, FENG Ji-cai, HE Peng, ZHAO Hong-yun. Effect of zinc coating on arc heating behavior for joining Al and zinc coated steel by welding-brazing process[J]. Transactions of the China Welding Institution, 2009, 30(8): 37-40.

[11] 石 玗, 温俊霞, 黄健康, 卢立晖, 樊 丁, 张裕明. 基于旁路耦合电弧的铝钢MIG熔钎焊研究[J]. 机械工程学报, 2011, 47(16): 25-29.

SHI Yu, WEN Jun-xia, HUANG Jian-kang, LU Li-hui, FAN Ding, ZHANG Yu-ming. Study on DE-GMAW MIG-brazing method for bonding steel with aluminum[J]. Journal of Mechanical Engineering, 2011, 47(16): 25-29.

[12] 石 玗, 王 钊, 黄健康, 卢立晖, 樊 丁. 铝/镀锌钢板脉冲旁路耦合电弧 MIG 熔钎焊工艺及接头组织分析[J]. 焊接学报, 2013, 34(5): 1-4.

SHI Yu, WANG Zhao, HUANG Jian-kang, LU Li-hui, FAN Ding. Study on microstructure of fusing-brazing joint of aluminum to galvanized steel by pulsed DE-MIG welding[J]. Transactions of the China Welding Institution, 2013, 34(5): 1-4.

[13] ZHANG M J, CHEN G Y, ZHANG Y, WU K R. Research on microstructure and mechanical properties of laser keyhole Welding-brazing of automotive galvanized steel to aluminum alloy[J]. Materials and Design, 2013, 45: 24-30.

[14] CHENG W J, WANG C J. High-temperature oxidation behavior of hot-dipped aluminide mild steel with various silicon contents[J]. Applied Surface Science, 2013, 274: 258-265.

[15] 石 玗, 邵 玲, 黄健康, 顾玉芬. 铝与镀锌钢板熔钎焊界面中Fe2Al5Zn0.4性能与形成[J]. 稀有金属学报, 2013, 42(2): 432-435.

SHI Yu,SHAO Ling,HUANG Jian-kang,GU Yu-fen. Performance of Fe2Al5Zn0.4 at interface of aluminum and galvanized steel welding-brazing and its formation[J]. Rare Metal Materials and Engineering, 2013, 42(2): 432-435.

[16] YIN Fu-cheng, ZHAO Man-xiu, LIU Yong-xiong, HAN Wei, LI Zhi. Effect of Si on growth kinetics of intermetallic compounds during reaction between solid iron and molten aluminum[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(2): 556-561.

[17] CHEN Z W, GREGORY J T, SHARP R M. Intermetallic phases formed during hot dipping of [J]. Metallurgical and Materials Transactions A, 1992, 23(9): 1073-5623.

[18] WANG Qian, LENG Xue-song, YANG Tian-hao, YAN Jiu-chun. Effects of Fe-Al intermetallic compounds on interfacial bonding of clad materials[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 279-284.

[19] CHANG Y Y, CHENG W J, WANG C J. Growth and surface morphology of hot-dip Al-Si on 9Cr-1Mo steel[J]. Materials Characterization, 2009, 60(2): 144-149.

[20] MCLEOD A J, HOGAN L M, ADAM C M. Growth Mode of the aluminum phase in Al-Si and Al-Al3Fe eutectics[J]. Journal of Crystal Growth, 1973, 19: 301-309.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51165023);兰州理工大学红柳杰出人才培养计划项目(J201201)

收稿日期:2014-05-07;修订日期:2014-07-20

通信作者:石 玗,教授,博士;电话:0931-2972765;E-mail:shiyu73@gmail.com