文章编号:1004-0609(2008)06-1152-07

基于混合粒子群算法的铅锌烧结过程产量质量优化

丁 雷1, 2,吴 敏1,曹卫华1,王春生1

(1. 中南大学 信息科学与工程学院, 长沙 410083;

2. 吉首大学 物理科学与信息工程学院,吉首 416000)

摘 要:建立铅锌烧结过程的产量质量预测模型及其数学优化模型,利用混合粒子群优化算法对其进行优化。将质量约束的产量优化问题转换为两个目标函数的优化问题,即产量目标函数和违反质量约束条件的程度函数。采用联赛选择算子比较粒子群算法所搜索到的解。当粒子群算法收敛停滞时,沿着当代全局最优解和前一个不同的全局最优解矢量之差的方向进行线性搜索,将搜索到的更优解作为粒子群的当代全局最优解,从而保持粒子群算法的活性。针对工况波动,利用专家规则修正优化参数。实际运行结果表明,该优化方法能在保证质量的情况下在一定程度上提高产量。

关键词:铅;锌;烧结;质量预测模型;混合粒子群优化算法;联赛选择算子

中图分类号:TP 391 文献标识码:A

Quantity and quality optimization for lead-zinc sintering process based on hybrid PSO algorithm

DING Lei1, 2, WU Min1, CAO Wei-hua1, WANG Chun-sheng1

(1.School of Information Science and Engineering, Central South University, Changsha 410083, China;

2. School of Physics Science and Information Engineering, Jishou University, Jishou 416000, China)

Abstract: The quantity and quality prediction model for lead-zinc sintering process was proposed, the corresponding mathematic optimization model was built, and the hybrid particle swarm optimization (PSO) was applied to optimize the mathematic model. The quantity optimization problem with quality-constraint was converted into a two-objective optimization problem, one of which is the objective function of quantity, the other is the degree function of constraint violation of quality. To perform the parallel optimization, the comparison used in tournament selection was employed to compare the searched solutions of the PSO. When the PSO stagnates, the line searching algorithm is executed with a certain probability, which executes the line searching in the direction of the difference between the current global optimum and the last global optimum, and the better searched solution is taken as the current global optimum. Thus it keeps the swarm particle algorithm alive. In order to decrease the fluctuation of sintering process, expert rules were established to modify the calculated optimization parameters, and the practical result shows that the optimization method can increase the quantity to a certain extent and ensure the quality of sinter.

Key words: lead; zinc; sinter; quality prediction model; hybrid particle swarm optimization algorithm; tournament selection

铅锌烧结过程是将粉状物或细粒矿进行高温加热,在不完全熔化的情况下烧结成块的过程,可以分为干燥、加热、反应和烧结这4个阶段[1]。铅锌烧结过程最直接的控制目标是烧结矿产量和质量指标。目前关于铅锌烧结产量和质量指标的建模与优化控制研究已经取得了一定的进展,如ER等[2]和王雅琳等[3]采用智能方法来预测铅锌烧结块成分,杜玉晓等[4]建立了产量质量模型,在工况较差情况下,采用聚类搜索、专家系统进行优化,给出指导参数。目前在铅锌烧结过程中如何获得最佳的指导操作参数,达到产量最大且质量合格的目标,还有待进一步研究。因此研究如何获得指导实践的最佳操作参数,并在此操作参数的指导下,针对实际工况,结合人工专家经验对参数进行适当调整,具有重要的意义。

约束最优化问题是人们在实践中遇到最多的数学规划问题之一,传统的求解方法[5]将约束问题转化为无约束问题求解,如可行方向法、梯度下降法和罚函数法等,这些方法存在的主要问题是需要设置很好的初始信息才能得到较好的优化结果,如果初始信息选择得不好,则将会较早地收敛于某个局部最优点。

为了避免因初始信息的设置不当带来的影响,近年来将约束优化问题转化为多目标优化问题得到了极大的重视。粒子群算法[6]是一种仿生算法和随机搜索算法,其根据个体的适配信息进行搜索,因此不受函数约束条件的限制具有全局优化能力。目前粒子群 算法已经成为求解约束优化问题的研究热点[7-11],但其本身的一个最大缺点是其早熟性难以克服。CAMPONOGARA 等[12]提出的线性搜索法是一个搜索效果很好的多目标优化方法,但其搜索的最优值很大程度上受其初始值的影响,初始值的不同导致出现不同的最优值,容易陷入局部最优值。因此将粒子群算法和线性搜索法有机结合起来,充分利用粒子群算法强大的全局搜索能力、线性搜索法强大的局部搜索能力共同进行优化,在一定程度上能起到克服标准粒子群算法早熟带来的影响。

本文作者采用混合粒子群算法对烧结过程中产量质量进行优化,获得指导实践的优化操作参数。根据某烧结厂的铅锌烧结过程建立其产量质量预测模型;建立质量约束条件的产量优化模型,为保证算法的优化效果,研究利用混合粒子群算法来进行优化;并预测模型进行验证,结合专家经验规则对优化后的参数进行适当修正,并给出结论。

1 产量质量预测模型

铅锌烧结是一个非常复杂的过程,影响烧结过程产量、质量的因素很多,因此需要对具体的烧结过程进行分析,找出主要的影响因素,以降低建模的难度和提高模型预测的准确性。

神经网络模拟非线性过程的能力非常强,目前已经广泛应用在各种非线性过程建模中。因此,针对烧结过程的强非线性,采用神经网络来建立产量、质量预测模型。

1.1 烧结过程机理分析

物料每8 h进行一次配料,得到含铅量、含锌量和二氧化硅含量等配比的精矿。一次配料后,每3 min进行一次二次配料,并给出相应的烧结操作参数。首先,通过皮带秤进行二次配料,添加合适比例的返粉,得到合适含硫量的混合料,以及添加少量的石灰石熔剂。然后,混合料经过混合料圆筒和制粒圆筒,添加一定比例的水分,成为具有合适水分的混合料料球。最后,系统给出和二次配料相应的台车速度、点火温度、风机风量等操作参数,并开始进行烧结。

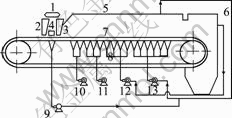

图1所示为DL型移动带式鼓风烧结机结构示意图。混合料球通过梭式布料机分别送入点火仓和主料仓,点火仓的混合料球分布到烧结机的台车上形成约3 cm厚的薄层矿料,称为点火层。通过调节煤气流量控制合适的点火温度,对点火层混合料进行点火,点火后的混合料跟随台车一起移动。当混合料移动到烧结机机头后部主料仓时,再布上混合料,形成约30~40 cm厚的总料层。由于混合料含硫较高,硫化物氧化反应放出的热量使反应扩展到整个物料层,无需外加燃料整个鼓风烧结焙烧过程就能顺利进行。混合料随台车一起移动,经过干燥、加热、反应和烧结这4个过程,混合料球烧结成为具有一定结构的烧结块料,并在烧结机尾产出。

图1 DL型移动带式鼓风烧结机结构示意图

Fig.1 Schematic diagram of Dwight-Lioyd sintering machine:

1—Shuttle distributor; 2—Igniton container; 3—Main bed container; 4—Ignition furnance; 5—Gas hood; 6—End gas hood; 7—Troolley; 8—Bellows; 9—Ignition draft fan; 10—Fresh blower 1; 11—Fresh blower 2; 12—Returning gas blower 2; 13—Returning gas blower 1

4台风机提供脱硫氧化反应中所需要的氧气和进行必要的热循环。烧结块料经过两级破碎,大小合适的烧结块进入熔炼炉;规格不合适的烧结块料再经过两级破碎成为返粉,重新进入烧结机。烧结过程中硫因发生剧烈燃烧转变为SO2气体,而其它成分基本上没有变化。因此,除了硫含量外,返粉的其它成分和混合料的一样。为了有效利用烟气中的热量及预防污染,将铅锌精矿鼓风烧结时机头、机尾产生的低浓度SO2烟气和新鲜空气一起送入烧结机中。4台风机中,1#返烟风机主要是冷却作用,对产量质量影响作用较小,且其风机流量基本不变化,所以建模时不需要考虑1#返烟风机的影响。

混合料含硫量影响到烧结过程的结块率和硬度,以及烧结矿的产量,对含铅量也有一定影响,是影响质量的最重要因素。混合料含锌量对烧结矿的产量有一定影响,对含硫量也有一定影响。SiO2是一种加硬剂,对烧结矿结块率和产量有很大影响,也影响到含硫量。加热至900 ℃以上石灰石分解为CaO和CO2,并吸收大量热量,能防止炉料过早结块,减少铅在烧结时的挥发损失。CO2气体可提高炉料的透气性,提高烧结块的空隙度。CaO可将硫化物机械隔开,因此,直接影响到烧结矿的结块率、产量、含铅量和含硫量。混合料的含铁量会影响到烧结矿的硬度。混合料中其他元素汞、砷和氟含量较少,对烧结过程影响很小,因此可以忽略其影响。

1.2 产量质量预测模型

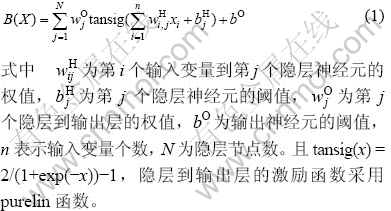

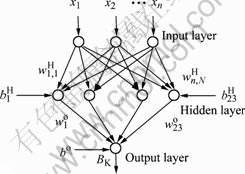

预测模型采用3层结构,BP神经网络的结构示意图如图2所示[13],且可表示为

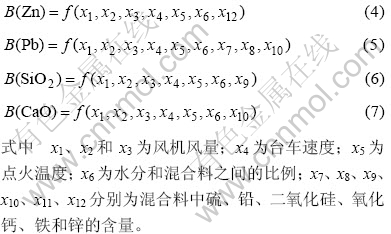

建立的烧结矿产量的预测模型可表示为

烧结矿含硫量的预测模型可表示为

图2 BP神经网络预测模型结构图

Fig.2 BP NN prediction model structure

2 优化算法

在实际生产中,在提高铅锌烧结矿产量的同时必须保证其质量,因此有必要建立以产量为目标,质量要求为约束条件的优化数学模型。

针对粒子群算法早熟的特点,首先,利用粒子群算法的全局搜索能力找到一个可行解;然后,在粒子群算法收敛停滞时,利用线性搜索方法找到一个更好的解来刺激粒子群算法的活性,从而在一定程度上达到克服粒子群算法早熟性的目的。

2.1 产量质量优化数学模型

某烧结冶炼厂的合格烧结矿的部分化学成分有严格要求[1],铅含量为17%~21.5%,二氧化硅含量3%~4.5%,氧化钙含量为5.5%~7.0%,1.4<m(CaO)/m(SiO2)<1.7,0.45<m(Pb)/m(Zn)<0.55,硫含量小于1.0%。理论上如果给定了一次配料的配比,要实现产量最大、质量合格的目标,二次配料只有惟一的配比。因此,结合某烧结冶炼厂的工艺参数要求,可以建立如下的数学优化模型:

工艺上,经过二配后的混合料中硫、氧化钙的百分比含量有一定要求。式中C与ci(i = 1, ???, 4)表示常量,是不需要参与优化的量。此外,B(Zn)、B(Pb)、B(S)、B(SiO2)和B(CaO)分别表示烧结矿成分中锌、铅、硫、二氧化硅和氧化钙含量的预测值。

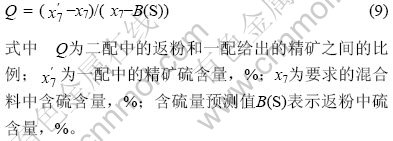

实际二配中,添加的石灰石熔剂量很小,混合料总量(不含水分)近似为一配给出的精矿和二配给出的返粉量。因此,如果给出混合料含硫量的要求,则按照下式来改变所添加的返粉比例。

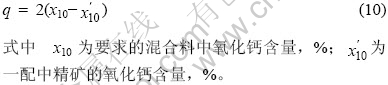

石灰石熔剂受热分解为氧化钙,根据添加的氧化钙比例可以计算出需要添加的石灰石熔剂在混合料中所占的比例,即

2.2 多约束条件的优化方法

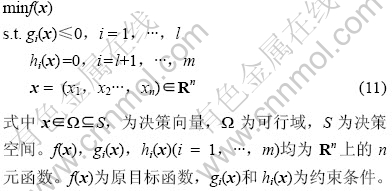

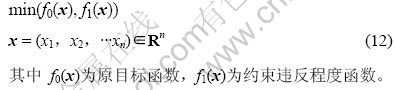

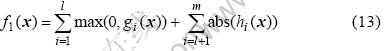

对于一个有多约束条件的优化问题可表示为

将式(11)变换为两个目标函数,如下式所示:

f1(x)可表示为

对于可行最优解来说,f1(x)的函数值为0。因此,可以通过判断f1(x)的值是否为0来判断计算出的值是否是可行解。

DEB等[14]和王勇等[15]提出一种锦标赛选择算子,并采用如下的准则来比较个体:

1) 当2个个体均为可行解时,比较它们的目标函数值,目标函数值小的个体占优。

2) 当2个个体均为不可行解时,比较它们违反约束条件的程度,违反约束条件程度小的个体占优。

3) 可行解总是优于不可行解。

定义1. 假设给定的目标函数为fi(x), i = 0,???,k,如果?i∈{1,???,k}满足fi(x1)≤fi(x2),且至少存在一个 fj(x1)<fj(x2),j∈{1,???,k},则记为x1 优超于 x2。

2.3 改进粒子群多目标优化算法

粒子群优化算法的基本思想是通过群体中个体之间的协作和信息共享来寻找最优解,即初始化为一群随机粒子(随机解),然后通过迭代找到最优解。PSO的优势在于简单但容易实现,没有较多参数的调节。SHI等[16-17]对标准粒子群算法进行了修正,引入惯性权重因子w。PSO算法在每一次的迭代中,粒子通过跟踪两个“极值”(pbest, i, gbest)来更新自己,其中pbest, i表示第i个个体最优值,gbest表示当代全局最优值。粒子通过下式来更新自己的速度和位置。

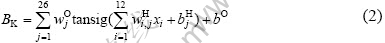

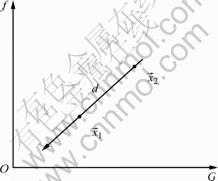

CAMPONOGARA和TALUKDAR[13]采用Pareto策略将约束优化问题转换为一个具有两个目标的优化问题,其主要特征是从Pareto集合中计算改进方向。对于两个Pareto集合中的两个个体x1和x2,如果x1 优超于 x2,则得到改进方向。

由个体x1优超x2得到的搜学方向如图3所示。

图3 由个体x1优超x2得到的搜索方向

Fig.3 Searching direction obtained by points x1 pareto x2

由以上分析可知,粒子根据式(16)不断地进行搜索,寻找一个同时Pareto优超x1和x2的个体x3,

整个改进粒子群多目标优化算法步骤如下:

Step 1:将有约束条件的优化函数转化为有两个目标的优化函数,并初始化学习因子(c),惯性权重(w),每个粒子的初始位置、初始速度以及最大迭代次数。

Step 2:用锦标赛准则计算当代全局最佳粒子,个体历史最佳粒子。如果当代全局最佳粒子和上次迭代过程中的全局最佳粒子不一样,则将上一个全局最佳粒子记录下来。

Step 3:根据个体历史最佳粒子和当代全局历史最佳粒子位置,调整粒子速度和位置。

Step 4:判断是否停滞,如果没有则转到Step 2,否则转Step 5。

Step 5:根据当代全局最优解x和所记录的前一个全局最优解x2,有  ,按照式(14)进行线性搜索,如搜索到一个合适的解,则将它作为粒子群算法的当代全局最优解,并记录x1。为防止可能出现搜索不到可行解的情况,设置一个最大的搜索次数。

,按照式(14)进行线性搜索,如搜索到一个合适的解,则将它作为粒子群算法的当代全局最优解,并记录x1。为防止可能出现搜索不到可行解的情况,设置一个最大的搜索次数。

Step 6:判断迭代次数是否达到最大次数,如果达到则结束,否则转Step2。

3 仿真与优化结果分析

根据产量质量预测模型,从样本统计库选择合格样本进行训练,并验证所提出的预测模型的有效性。

在每8 h进行一次配料后,根据优化模型进行相关参数优化,得出指导参数。在实际操作中每3 min给出一次操作参数,如果工况稳定则操作参数不需要调整,但实际生产中可能遇到工况波动情况,因此,需要利用专家规则对相关参数进行适当的调整。

3.1 产量质量预测

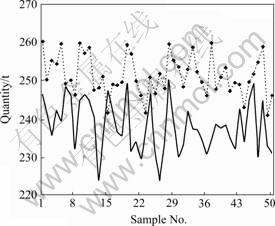

对于产量、质量预测模型来说通过限幅滤波的方法,分别从统计样本库选取1 000个合格样本数据,其中950个样本用来训练网络,另外50个样本用来验证预测模型。其中产量样本的期望值为每8 h检测一次的数据,质量样本的期望值为每2 h检测一次的数据。烧结矿产量预测的相对误差绝对平均值为3.1%,仿真结果如图4所示(实线为样本,菱形虚线为预测值)。

图4 烧结矿产量预测模型仿真结果

Fig.4 Prediction results of quantity of sintered ore

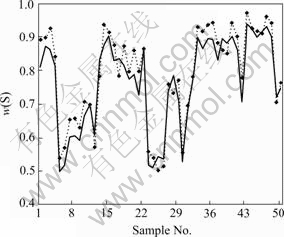

烧结矿含硫量预测的相对误差绝对平均值为4.9%,仿真结果如图5所示(实线为样本,菱形虚线为预测值)。

图5 烧结矿含硫量预测模型仿真结果

Fig.5 Prediction result of S content of sintered ore

此外,预测的锌、铅、氧化钙和二氧化硅的含量的相对误差绝对平均值分别为3.7%、4.7%、4.1%和3.9%。从仿真结果可以看出,神经网络能较准确地预测铅锌烧结过程的产量和质量。

3.2 优化结果分析

每8 h进行一次一配后,根据优化模型,得到相应的优化参数。针对实际烧结过程可能出现工况波动情况,利用专家经验规则来对相关操作参数进行适当调整,如:1) If 透气性差,and 混合料含水量高,Then 适当降低混合料含水量;2) If 烧结块含硫高,Then 适当减小精矿返粉比;若出现其他情况,亦进行其他相应调整。

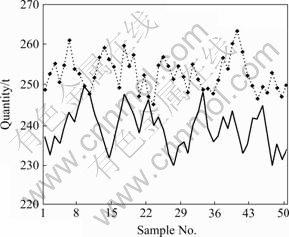

图6 产量优化结果

Fig.6 Optimization results of quantity of sintered ore

将该算法和人工专家经验结合后用于实际的生产优化中,分别选取优化前50个连续历史的产量和优化后连续检测的50个产量结果进行对比(时间间隔为8 h)。利用混合粒子群算法来进行优化,在约束条件的违反程度为0,即完全满足约束条件的前提下,优化后的产量检测结果如图6所示(实线为优化前历史样本,菱形虚线为优化结果值)从对比结果可以看出,相对于样本,优化后的实际生产平均产量要提高13 t左右,约提高5.4%左右。

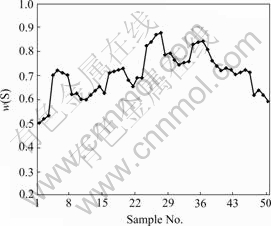

烧结矿含硫量(每2 h检测一次)优化结果如图7所示。

图7 烧结矿含硫优化结果

Fig.7 Optimization results of S content of sintered ore

从实际优化结果可以看出,本文作者提出的优化算法在保证质量的前提下,能够在一定程度上提高产量。

4 结论

1) 对铅锌烧结过程的机理进行了分析,建立了产量和质量的预测模型,并验证了预测模型的有效性。

2) 在产量和质量预测模型的基础上,建立了以产量为原目标函数,以质量要求为约束条件的优化模型。将有约束条件的优化模型转化为有两个目标函数的优化问题。其中一个以产量为原目标函数,另一个为违反质量约束条件的程度函数,采用锦标赛比较准确达到并行优化的目的。为了改善优化效果,将粒子群算法和线性搜索法有机结合起来,共同进行多目标优化算法。

3) 在给定一配的情况下,按照优化模型获得相应的指导参数。针对实际的工况,利用人工专家经验对指导参数进行适当修正。

REFERENCES

[1] 杜玉晓. 铅锌烧结过程智能集成优化控制技术及其应用研 究[D]. 长沙: 中南大学, 2004.

DU Yu-xiao. Study on intelligent integrated optimal control technique and application to lead-zinc sintering process[D]. Changsha: Central South University, 2004.

[2] ER M J, LIAO J, LIN J. Fuzzy-neural-network-based quality prediction system for sintering process[J]. IEEE Trans Fuzzy Syst, 2000, 8(3): 314-324.

[3] 王雅琳, 桂卫华, 阳春华, 陈晓方, 张传福. 基于综合建模方法的铅锌烧结块成分预测[J]. 中南大学学报: 自然科学版, 2005, 36(1): 113-118.

WANG Ya-lin, GUI Wei-hua, YANG Chun-hua, CHEN Xiao-fang, ZHANG Chuan-fu. Prediction for composition of Pb/Zn agglomerate based on integrated modeling[J]. Journal of Central South University of Technology: Natural Science, 2005, 36(1): 113-118.

[4] 杜玉晓, 吴 敏, 桂卫华. 面向生产目标的铅锌烧结过程智能集成建模与优化控制技术[J]. 中国有色金属学报, 2004, 14(1): 142-148.

DU Yu-xiao, WU Min, GUI Wei-hu. Intelligent integrated modelling and optimization control technology of product-orient for lead-zinc sintering process[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 142-148.

[5] 吴祈宗. 运筹学与最优化方法[M]. 北京: 机械工业出版社, 2003.

WU Qi-zhong. Operations research and optimization methods [M]. Beijing: China Machine Press, 2003.

[6] KENNEDY J, EBERHART R C. Particle swarm optimization [C]// Proceedings of the IEEE International Conference on Neural Networks. Perth: IEEE Press, 1995: 1942-1948.

[7] HE Qie, WANG Ling. A hybrid particle swarm optimization with a feasibility-based rule for constrained optimization[J]. Applied Mathematics and Computation, 2007, 186(2): 1407-1422.

[8] LUO Yi-qing, YUAN Xi-gang, LIU Yong-jian. An improved PSO algorithm for solving nonconvex NLP/MINLP problems with equality constraints[J]. Computers & Chemical Engineering, 2007, 31(3): 153-162.

[9] ZHANG Hong, LI Heng, TAM C M. Particle swarm optimization for resource-constrained project scheduling[J]. International Journal of Project Management, 2006, 24(1): 83-92.

[10] KJIRATIKARL C A, YENRADEE P, DRAKE P R. PSO-based algorithm for home care worker scheduling in the UK[J]. Computers & Industrial Engineering, 2007, 53(4): 559-583.

[11] CAI Jie-jin, MA Xiao-qian, LI Li-xiang, PENG Hai-peng. Chaotic particle swarm optimization for economic dispatch considering the generator constraints[J]. Energy Conversion and Management, 2007, 48(2): 645-653.

[12] CAMPONOGARA E, TALUKDAR S N. A genetic algorithm for constrained and multiobjective optimization [C]// 3rd Nordic Workshop on Genetic Algorithm and Their Application. Finland, 1997: 49-62.

[13] HAGAN M T, DEMUTH H B, BEALE M. Neural network design[M]. Beijing: China Machine Press, 2002.

[14] DEB K. An efficient constraint handling method for genetic algorithms [J]. Computer Methods in Applied Mechanics and Engineering, 2000, 86(2/4): 311-338.

[15] 王 勇, 蔡自兴, 曾 威, 刘 慧. 求解约束优化问题的一种新的进化算法[J]. 中南大学学报: 自然科学版, 2006, 37(1): 119-123.

WANG Yong, CAI Zi-xing, ZENG Wei, LIU Hui. A new evolutionary algorithm for solving constrained optimization problems[J]. Journal of Central South University of Technology: Natural Science, 2006, 37(1): 119-123.

[16] SHI Y, EBERHART R C. A modified particle swarm optimizer [C]// Proceedings of the IEEE Congress on Evolutionary Computation. Piscataway: IEEE Press, 1998: 303-308.

[17] 潘 峰, 陈 杰, 甘明刚, 蔡 涛, 涂序彦. 粒子群优化算法模型分析[J]. 自动化学报, 2006, 32(3): 368-376.

PAN Feng, CHEN Jie, GAN Ming-gang, CAI Tao, TU Xu-yan. Model analysis of particle swarm optimizer[J]. Acta Automatica Sinica, 2006, 32(3): 368-376.

基金项目:国家杰出青年科学基金资助项目(60425310)

收稿日期:2007-10-24;修订日期:2008-03-10

通讯作者:吴 敏,教授,博士;电话:0731-8836091;E-mail: min@ csu.edu.cn

(编辑 龙怀中)