文章编号: 1004-]0609(2005)08-]1243-]05

超薄快速铸轧轧制压力分布计算

熊勇刚1, 2, 谭建平2, 李小东1, 2

(1. 株洲工学院 机械学院, 株洲 412008; 2. 中南大学 机电学院, 长沙 410083)

摘 要: 针对快速超薄铸轧材料、 几何、 摩擦等多重非线性, 将铸轧辊与板坯之间的力学行为视为热弹塑性接触问题, 应用无网格—有限元耦合方法建立了计算模型, 该模型较好地解决了板坯剧烈变形有限元网格畸变问题。 对轧制过程中轧制压力分布进行了分析, 得到其分布规律为轧制压力在变形区中间区达到最大值, 而在入口和出口处逐渐减少。 计算结果基本与实测结果吻合, 说明该计算模型和计算是比较有效和可靠的。

关键词: 轧制压力; 接触问题; 耦合模型 中图分类号: TG331

文献标识码: A

Calculation of rolling-force distribution of thin gauge roll-casting

XIONG Yong-gang1, 2, TAN Jian-ping2, LI Xiao-dong1, 2

(1. School of Mechanical Engineering,Zhuzhou Institute of Technology, Zhuzhou 412008, China;

2. School of Mechanical and Electronical Engineering,Central South University, Changsha 410083, China)

Abstract: As regarding the non-linearity of thin roll-casting materials, geometry and friction. The mechanics beheavior was taken as thermo-elastoplastic contact problem between the roller and slab. By using Element-Free Galerkin-Finite Element(EFG-FE) coupling method, computation model was established to overcome the inconvenience of applying remesh method, for the slab is deformed greatly which leads to the mesh distortion with the the traditional finite element simulation. The rolling force distribution was analyzed to obtain its character which reaches the maximum value in the centre of the rolling zone, while at the entrance and exit, the stress fades away. The results show that the calculated results by the coupling model are close to the measured ones.

Key words: rolling-force; contact problem; coupling model

轧制力是超薄快速铸轧生产中的重要参数之一, 轧制力不仅直接影响板坯形状, 也通过铸轧辊的变形间接影响板型控制等; 探求其分布规律, 可进一步了解铸轧板坯成形的过程, 文献[1-5]从解析法或者温度场角度对常规铸轧、 快速铸轧进行仿真计算, 主要研究轧制力对参数的影响。

目前分析体积成形的商品化软件大都没能很好解决因网格的存在带来的问题。 应用传统有限元模拟时, 由于板坯变形剧烈, 使得有限元网格发生畸变, 因而要对网格进行重新划分, 每次网格重划时, 节点场变量的传递使得计算的效率和精度受到严重的影响。 Belytschlko等[6]提出的无网格伽辽金—有限元耦合方法不仅适用于大规模问题的求解, 而且减小了运算量, 提高了效率, 消除了无网格方法处理边界条件的局限性。

因此根据快速超薄铸轧机铸轧辊的特点(图1), 针对铸轧辊一板坯之间的接触行为, 为了克服板坯变形剧烈而使得有限元网格发生畸变的问题, 应用无网格—有限元耦合方法建立计算模型。 从接触力学的角度, 计算得到轧制力, 并通过设计的测试系统测试验证该模型和计算的可靠性和精确性, 为进一步分析快速超薄铸轧辊变形、 铸轧辊设计、 制造、 板形控制等提供了可靠依据。

1 热弹性接触问题基本理论

用伽辽金法建立有限元列式, 瞬态热接触基本方程为:

应用伽辽金法, 轴对称问题的上述各矩阵和向量的表达式为

2 计算模型与基本参数

2.1 基本假设

基于建立轧制压力模型的需要, 计算中进行了如下基本假设[3-7]:

1) 由于铸轧坯厚度远小于铸轧区长度与板坯宽度, 因此把三维问题简化为平面应变问题;

2) 仅涉及铸轧辊与板坯接触界面上的单位压力分布的计算;

3) 凝固前沿简化为直线。

2.2 基本参数

轧辊和轧件的基本计算参数列于表1。

图1 铸轧辊结构示意图

Fig.1 Sketch of roller structure

表1 轧辊和轧件的基本计算参数

Table 1 Calculated parameter of roller and workpiece

2.3 计算模型

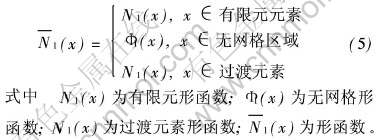

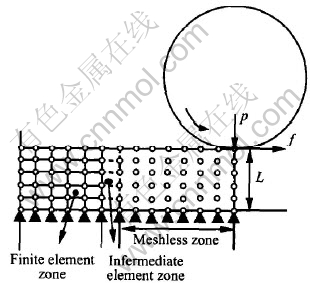

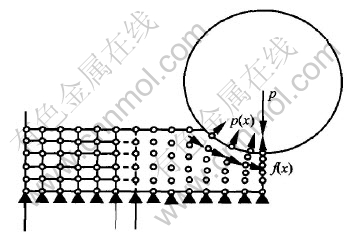

图2~4所示为铸轧辊、 板坯之间的接触问题的无网格—有限元耦合模型。 在快速超薄铸轧中, 铝液经过快速冷却、 轧制成为板坯的这一过程是一个温度、 体积、 形态的剧变过程。 所以建立模型时, 铝液区采用有限元网格, 板坯为无网格区域, 二者之间为过渡区域, 图2 给出了无网格—有限元耦合模型的耦合关系: 包括无网格和有限元区域及虚线元素(过渡元素)耦合[8, 9]。 详见式(4)和(5)和图3、 4。

图2表示各元素的物理几何的分布连接。 图3表示铸轧辊、 板坯之间接触问题的无网格—有限元耦合模型的各区域元素。

图2 无网格—有限元耦合方法示意图

Fig.2 Sketch of coupling method of meshless-finite element

图3 初始无网格—有限元耦合模型

Fig.3 Initial coupling model meshless—finite element

图4 变形后无网格—有限元耦合模型

Fig.4 Deformed coupling model of meshless—finite element

在无网格方法中, 影响域半径d对计算效率和精度都有很大的影响。 但其值的选取带有一定的任意性[10-13], 在这里权函数影响域最大半径的选择为d=3c, c为可调经验常数, c=2/5~2/3mm[14-16]。

2.4 计算步骤

1) 由力学理论计算出铸轧辊热装配时由于过盈量产生的装配应力, 沿铸轧辊轴线方向视为均布应力:

2) 铸轧区长度的大致确定: 接触区域的大致确定, 将计算限制在接触区域的小范围内, 减少盲目搜索过程, 减少了运算时间。

3) 把以上边界条件加入铸轧辊无网格—有限元耦合模型。

4) 计算铸轧辊应力: 铸轧辊寸尺较大, 为了节省时间, 只取其辊套套并为刚性目标面, 液铝及板坯为柔性体目标面。 接触算法为惩罚函数法和拉格朗日法。 接触面必须给目标面施加一定的约束条件, 才能满足接触相容性和力的相容性。 由于这些约束条件随接触状态的改变而改变, 一般采用增量迭代法进行求解。

计算中先采用线性规划法求解各增量载荷的全弹性接触反力增量, 再运用增量初应力法进行材料性态判断, 对进入塑性的单元套用塑性公式进行迭代计算求出塑性位移增量, 回代求出弹塑性状态下的接触反力增量, 最后对弹塑性接触反力增量累加得到弹塑性接触反力总量, 从而求得弹塑性接触体的位移、 应变、 应力。

5) 计算轧制力及其分布: 对计算所得的应力进行积分。

3 实验

为了验证计算结果, 设计如图5所示的实验系统对轧制力进行了测试。 对某厂d960mm×1600mm铸轧机生产72mm×1160mm铝带坯(合金牌号为1235)进行计算。 其它实际测量数据为: 铸轧区长度73mm, 铸轧速度0.92m/min, 铸轧辊直径918mm, 辊套厚度59mm, 冷却水流量80m3/h, 冷却水温21℃, 浇注温度686℃。 其数据结果如图6所示。

4 讨论

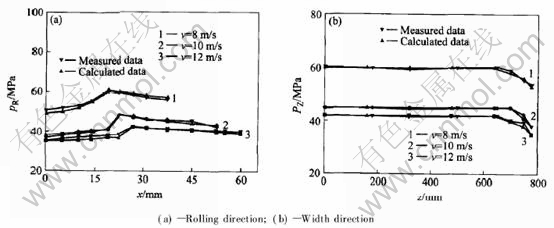

图6所示为轧制力在轧制方向和宽度方向的分布。 将计算所的轧制应力场的分布, 将其积分可得轧制力, 计算时间约为3800s, 正如文献[16]而言精度较高而计算效率需提高。

由图6可知, 轧制力分布规律为: 在出口和入口, 轧制(应)力很小, 中间偏前为最大, 轧制应力的最大值出现在铸轧区的中间部位, 入口和出口两端轧应力偏小, 这是因为入口处液铝还未放热凝固, 这也符合前面的假设。

由图6(a)可见: 轧制压力具有单峰值。 在相同条件下, 随着铸轧速度增大, 峰值降低, 且峰值出现的位置向铸轧区出口处移动, 相同断面处轧制压力也随着铸轧速度增大而降低; 在相同条件下, 随着铸轧速度增大, 峰值降低, 峰值出现的位置向铸轧区出口处移动的同时中性面也向铸轧区出口处移动。

由图6(b)可见: 沿板坯宽度方向的非边缘区轧制力接近均匀分布, 但是在边缘突减, 相同断面处轧制压力也随着铸轧速度增大而降低。

图6(b)所示为现场测试数据, 与计算值之差约为5%~10%, 虽然与实测数据有一定的差别, 在两者反映的基本规律是一致的; 轧制压力的不均匀分布(峰值出现和边缘突减), 因此而引起的轧辊变形也会是不均匀分布, 进而影响轧辊设计和板形控制。

图5 轧制压力的测量系统

Fig.5 Experiment measurement system of rolling force

图6 不同方向轧制应力分布曲线

Fig.7 Distribution curves of rolling-force in different directions

5 结论

从热弹塑性接触问题角度, 采用无网格—有限元耦合模型, 计算分析轧制压力分布, 与实验研究结果相吻合, 且与前面基本假设相符, 表明计算模型和结果是有效和可靠的。 此法精度较高而需提高计算效率, 克服应用传统有限元对板坯进行网格划分和重划的不便或可能无法进行分析计算, 为铸轧辊设计、 制造、 板形控制等提供了可靠依据。

REFERENCES

[1] 熊勇刚. 铸轧辊热力耦合模型研究[J]. 中南大学学报, 2002, 29(3): 412-415.

XIONG Yong-gang. Calculating the strain coupling thermal-force for thin-gauge high-speed roll casting[J]. Journal of Central South Unviersity, 2002, 29(3): 412-415.

[2] 熊勇刚. 铸轧辊热凸度仿真及其实验研究[J]. 中国有色金属学报, 2001, 11(3): 486-492.

XIONG Yong-gang. Emulation and research of temperature field and thermal crown for super-thin mills roll[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 486-492.

[3] 朱志华, 肖文锋. 超薄快速铸轧过程轧制压力分布的数学模型与实验研究(Ⅰ)—铸造区轧制压力分布的数学模型[J]. 上海有色金属, 2001, 22(9): 107-110.

ZHU Zhi-hua, XIAO Wen-fen. Modelling and simulating investigation of rolling pressure distribution at ultra thin high speed roll casting(Ⅰ)[J]. Shanghai Nonferrous Metal, 2001, 22(9): 107-110.

[4] 李晓谦, 湛利华. 连续铸轧塑变与温变强耦合接触压力计算模型[J]. 矿冶工程, 2000, 20(2): 50-52.

LI Xiao-qian, ZHAN Li-hua. Calculation model for contact pressure under intense coupling condition of rolling deformation and temperature variation[J]. Mining and Metal Urgical Engineering, 2000, 20(2): 50-52.

[5] 刘立忠, 刘相华, 王国栋. 轧制过程的显式动力学有限元法模拟[J]. 东北大学学报, 2001, 22(3): 327-330.

LIU Li-zhong, LIU Xiang-hua, WANG Guo-dong. Simulation on the strip by dynamic explicit FEM[J]. Journal of Northeastern University, 2001, 22(3): 327-330.

[6] Belytschko T, Gu L, Lu Y Y. Fracture and crack growth by element-free Galerkinmethods[J]. Model Simul Master Sci Engrgdbch, 2004, 2: 519-534.

[7] 李润方. 瞬志耦合热弹塑性接触有限元分析方法[J]. 计算结构力学及其应力, 1993, 10(3): 25-26.

LI Run-fang. Finte element mothod of transient coupled thermo-elastoplastic contact problem[J]. Computational Structural Mechanics and Applications, 1993, 10(3): 25-26..

[8] 刘天祥, 刘 更. 二维无网格伽辽金一有限元耦合方法的研究[J]. 机械强度, 2002, 24(4): 602-607.

LIU Tian-xiang, LIU Geng. Studies on two dimen-sional element free galerkin in finite element coupling method[J]. Journal of Mechanical Strength, 2002, 24(4): 602-607.

[9] 刘天祥, 刘 更. 二维接触问题的无网格伽辽金一有限元耦合方法[J]. 西北工业大学学报, 2003, 21(4): 503-506.

LIU Tian-xiang, LIU Geng. On applying EFG-FE(element-free Galerkin-finite element) coupling method to solve 2-dimension contact problems[J]. Journal of Northwestern Polytechnical University, 2003, 21: 503-506.

[10] Philippe J, Denis T. Thermo mechanical modelling of 3C roll casting of alloys[J]. Light Metals, 1996: 905-991.

[11] Berg B S, Hansen V. Gauge reduction in twin roll casting of an AA5052 aluminium alloy: the effects on microstructure[J]. J Materials Processing Thechnology, 1995, 53: 65-74.

[12] Fukumura M, Fujikake M, Fujita F, et al. Elasto-plastic finite element simulation of flat rolling process by dynamic explicit method[A]. Proceeding of the 7th International Conference on Steel Rolling[C]. Chiba, 1998. 260-265.

[13] Takaaki I, Owen D R J, Liu G Q. Analysis of rolling process by dynamic explicit elasto-plastic finite element method[A]. Proceeding of the 7th International Conference on Steel Rolling[C]. Chiba, 1998. 266-271.

[14] Nayroles B, Touzot G, Villon P. Generalizing the finite element method: diffuse approximation and diffuse elements[J]. Comput Mech, 2002, 10: 307-318.

[15] Babuvka I, Melenk J M. The partition of unity finite element methods: basic theory and applications[J]. Computer Methods in Applied Mechanics and Engineering, 2001, 139: 91-158.

[16] Lucky L B. A numberical approach to the testing of the fission hypothesis[J]. The Astron J, 1977, 12(8): 1013-1024.

基金项目: 国家重点基础研究发展规划资助项目(G1999064906); 国家计委重点科技攻关资助项目(计高技1989(1985)); 湖南省自然科学基金资助项目(04JJ40037)

收稿日期: 2005-]04-]21;

修订日期: 2005-]07-]10

作者简介: 熊勇刚(1966-), 男, 副教授, 博士研究生.

通讯作者: 熊勇刚, 副教授; 电话: 0733-2622949; E-mail: XYGYXJ@163.com

(编辑 龙怀中)