文章编号:1004-0609(2010)S1-s1016-05

钛及钛合金等通道转角挤压变形工艺研究现状

张永强,郭鸿镇,赵 严,王 涛,王彦伟,姚泽坤

(西北工业大学 材料学院,西安 710072)

摘 要:等通道转角挤压( Equal channel angular pressing,ECAP)是一种通过纯剪切变形制备高性能材料的独特的加工方法,它可以有效地细化合金组织,得到具有高强度和优异超塑性能的超细晶材料。综述钛及钛合金等通道转角挤压(ECAP)工艺的晶粒细化机理、变形特点和影响晶粒细化的因素,讨论ECAP工艺存在的主要问题,并对ECAP工艺的前景进行展望。

关键词:等通道转角挤压(ECAP);纯剪切变形;晶粒细化;细化机理;影响因素

中图分类号:TG 376 文献标志码:A

Research status of equal channel angular pressing titanium and titanium alloy

ZHANG Yong-qiang, GUO Hong-zhen, ZHAO Yan, WANG Tao, WANG Yan-wei, YAO Ze-kun

(School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: Equal channel angular pressing (ECAP) is a unique processing method for preparing high-performance material by pure-shear deformation, which can effectively refine the grain of alloy and obtain ultra-fine grained materials with high strength and excellent superplasticity. An overview of the grain refinement mechanism, the deformation characteristics and the factors influencing grain refinement during ECAP process of titanium and titanium alloy was given, and the main problems of ECAP were discussed and prospects of ECAP were presented.

Key words: ECAP; pure-shear deformation; grain refinement; refining mechanism; influence factors

钛性能优良,储量丰富,且具有两个最为显著的优点:比强度高和耐腐蚀性好,因此,钛及钛合金在航空、航天、舰船、兵器、核能等领域有着广泛用途。

等通道转角挤压(ECAP)是一种可以显著细化材料晶粒组织的加工方法[1],在等通道转角挤压过程中,试样产生近似理想的剪切变形,试样内部产生剧烈的塑性变形,可获得均匀的亚微晶或纳米结构,使材料具有良好的超塑性能。近年来,ECAP工艺受到各国研究人员的重视,在钛及钛合金等材料中均获得了亚微晶组织。

采用ECAP技术制备的超细晶钛和钛合金,在强度、疲劳极限、热稳定温度和超塑性能等方面都显著提高。室温下对工业纯钛进行8道次ECAP变形,晶粒由23 μm细化到约0.2 μm,抗拉强度由407 MPa提高到791 MPa[2]。经ECAP变形后,Ti-6A1-4V的晶粒细化到300 nm以下,屈服强度和极限强度都明显的提高,材料的疲劳性能也显著的改善。对超细晶Ti-6AI-4V的超塑性性能研究表明[3]:采用ECAP方式获得的超细晶钛合金有利于提高钛合金的超塑性。

1 ECAP基本原理

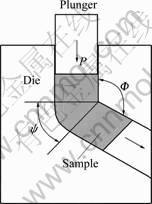

等通道转角挤压的模具由两个成一定角度的等径通道组成,可以在不改变试样尺寸的前提下进行多次挤压变形,增大总应变量。等通道转角挤压的原理示意图如图1所示。将试样放入等径的弯曲通道中,试样在压力(p)作用下通过通道,在弯曲处产生均匀的纯剪切变形,试样所受剪切应变示意图如图2所示,其中:1和2分别为经过转角前后的试样。

图1 等通道转角挤压原理图示意图

Fig.1 Schematic diagram of principle of ECAP

图2 试样挤压及所受剪切应变示意图

Fig.2 Sketch diagram of pressing (a) and ECAP shear strain (b)

在试样与模壁完全润滑的条件下,N道次变形后试样所得的等效应变量是ECAP模具通道内转角Φ和外转角Ψ的特征函数[4]:

(1)

(1)

式中:N为变形道次,εN是N道次变形后试样所得的总应变量。模型实验及二维有限元分析都证实了上述公式的合理性。

2 晶粒细化机理

ECAP过程中材料的变形机理是通过剪切形变的交互作用使晶粒细化。变形初期的塑性变形导致了高密度的位错缠结,相互缠结的位错间会相互作用并重新排列。随着变形程度增加,在亚晶内部产生更多的位错,并且这些可动位错被亚晶界进一步吸收,从而使得亚晶间的位向差增加,以至于亚晶界逐渐形成小角度晶界,然后又演化为大角度晶界,从而实现组织的超细化。

实验证明,ECAP晶粒细化机制一般考虑剪切应变平面、晶体结构和形变织构3个因素的影响。不同挤压方式可以获得相同剪切平面夹角,但是挤压后晶粒的细化效果存在明显的差异[5],这表明单纯的剪切应变夹角和累积应变并不足以决定晶粒细化的效果。挤压材料的晶体结构也会影响晶粒细化的效果,钛属于密排六方晶体结构,滑移系较少,孪生在塑性变形中起重要的作用。另外,方晓强等[5]研究表明,形变织构能够影响挤压过程中的晶粒细化。钛及钛合金的ECAP晶粒细化机制还有待于进一步研究,其中,变形织构演化将是重要的研究方向。

3 ECAP变形参数

3.1 挤压次数

根据等效应变公式(见式(1)),随着挤压次数的增加,累积的塑性变形量就会越大,晶粒细化的程度应该更高,但试验的结果却不同。CHANG等[6]研究得出,经若干次ECAP挤压之后,晶粒得到了显著细化,但此后随着挤压次数的增加,晶粒的几何尺寸基本不再变化。

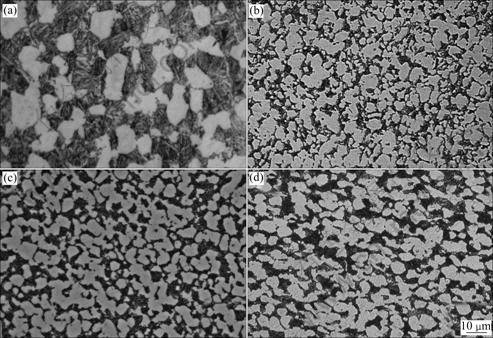

对于钛和钛合金,特别是高温钛合金,由于变形温度高,挤压次数过多,回复作用逐渐明显,细化效果反而会有所下降。对TA15钛合金试样分别挤压2次、4次和8次发现(见图3),挤压4次时,晶粒细小,且最为均匀,等轴化程度高,8次挤压后的细化效果并没有太大变化,由于反复加热,晶粒反而略有长 大[7]。

3.2 挤压路径

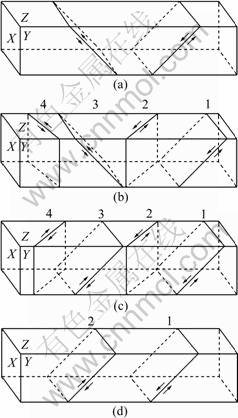

根据反复挤压过程中相邻道次间试样的旋转情况,将目前常采用的挤压路径分为4种:路径A(试样不旋转,同一方向的变形逐渐增大)、路径BA(两次挤压之间试样旋转±90?,每道剪切面互相垂直)、路径BC(两次挤压之间试样旋转+90?,每道剪切面互相垂直)和路径C(两次挤压之间试样旋转+180?,剪切面一定,但剪切方向在两道次间更迭)。

图3 不同挤压次数后试样TA15的组织

Fig.3 Microstructures of samples processed by ECAP for different times: (a) Initial sample; (b) 2 passes; (c) 4 passes; (d) 8 passes

采用不同的挤压路径对晶粒细化效果具有重要的影响。STOLYAROV等[8]对纯钛在400~450 ℃进行路径BA, BC和C挤压时发现,路径BC的细化效果最明显,获得的等轴晶粒的平均尺寸为260 nm,而路径BA和C挤压后的组织为拉长的非等轴晶。对TA15试样按路径A、BC和C挤压2次后发现,经路径C挤压后等轴化程度更高,等轴α相的平均尺寸约为1~5 μm,细化效果优于路径A和BC的。而GHOLINIA等[9]挤压铝合金后则认为路径A最为有效。针对以上不同的实验结果,IWAHASHI等[10]研究了各路径挤压时相邻道次的剪切面的位向关系变化(见图4,图中1、2、3和4所示平面为该挤压道次时的剪切面),认为由于亚晶带在相互交截的剪切面上的各自发展促进了大角度晶界的迅速形成和晶粒的细化。

3.3 模具通道转角

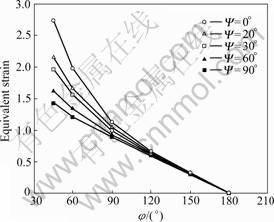

图5所示为内转角和外转角对等效应变的影响。由式(1)可得:模具内角Φ越大,模具外角Ψ越小,总的等效应变值就越大;模具内角为90?时,单道次的等效应变接近1。目前,已进行过实验研究的模具转角最小为60?,最大为157.5?。

钛和钛合金是难变形材料,在选取相应的挤压角度时要充分考虑材料的变形难度。当模具内角Φ过小时,变形抗力大,不易挤压;而Φ过大时,单次变形

图4 不同路段的剪切平面示意图

Fig.4 Schematic diagram of shear plane in various routes: (a) Route A; (b) Route BA; (c) Route BC; (d) Route C

图5 内转角和外转角对等效应变的影响

Fig.5 Effect of channel angle Φ and arc of curvature angular Ψ on equivalent strain

获得的等效应变小,达不到晶粒细化的效果。SEMENOVA等[11]对Ti-6Al-4V钛合金在700 ℃条件下,分别用135?、120?挤压角的模具进行ECAP变形,获得了均匀的超细晶组织,135?挤压12道次和120?挤压8道次可获得大致相等的等效应变,但是前者晶粒尺寸一般为600~800 nm,其中夹杂厚度约50 nm的薄片状孪晶组织,而后者不存在这种孪晶组织,晶粒大小更为均匀。袁士翀等[12]对Ti-1023试样分别在Φ=105?、Φ=90?的模具中进行挤压发现,Φ=90?的模具所得试样中细小晶界片状α相较多,原始β晶粒更细小。其他研究也表明,兼顾细化效果和挤压可行性,参数Φ=90?最佳 。

3.4 挤压温度

在金属ECAP变形中,随着温度的升高,原子动能增加,位错活动性提高、滑移系增多,晶粒容易发生回复和再结晶,金属的塑性得到提高,有利于挤压的进行和晶粒的细化。但温度升高,晶粒尺寸会明显变大,不容易形成大角度晶界。因此,ECAP变形过程中温度对晶粒细化必然产生重要影响。

KIM等[13]在对纯钛的挤压中发现温度对晶粒的细化有影响,在变形温度为350 ℃时,获得了均匀细化的组织。温度过低,晶粒细化极不均匀,而温度过高,由于高温再结晶作用,沿剪切方向出现了大量细长的再结晶组织。ZHAO等[7]在900、925和950 ℃对TA15合金进行了挤压,结果表明,挤压温度越高,晶粒尺寸越大,细化效果越差。

在试样能够均匀变形的前提下,尽量降低变形温度,可以降低回复和再结晶对晶粒细化效果的影响,有利于晶粒的细化。但对一些难变形金属,适当提高挤压操作时的温度有利于ECAP的顺利进行。

3.5 挤压速率

变形速率与金属的流动阻力以及温度效应密切相关。但对于难变形材料,如钛及钛合金,对应变速率具有很强的敏感性,屈服强度随应变速率的增大显著提高。一般选取较低的挤压速度,变形过程中的回复作用时间较长,可以使晶界吸收更多的位错,这使得材料的微观结构就更加均匀。

3.6 背压

带背压的ECAP原理是在出口通道设置反向顶杆,挤压时根据需要向试件施加背压。在ECAP挤压过程中会有变形死区的产生,适当增加背压,可以消除变形死区的影响,改善金属流变过程中组织的均匀性,有效控制和改善材料的微观组织和机械性能。试验证实,施加背压后,工件的均匀变形区增大;但过大的背压导致靠近转角一侧的变形区变形加剧。

3.7 摩擦条件

对于塑性变形,摩擦会增大变形抗力,引起材料的不均匀变形,产生附加应力和残余应力,降低模具寿命。在ECAP过程中,摩擦因数增大,材料平均等效应变基本不变,而芯部应变不均匀程度增大。因此,应保证挤压凹模内壁表面光洁度以及试样和模具的润滑,以减小摩擦,减小载荷,从而改善细晶的均匀性。

影响晶粒细化效果的各因素不是简单的叠加作用,而是有着相互影响、相互制约的多样性和复杂性。如何获得材料的最佳工艺参数,获得均匀分布的超细晶组织,并通过反复试验探寻ECAP细化晶粒的内在影响因素和作用机理,将是今后研究的主要方向。

4 结语

ECAP可以在不改变试样横截面积的基础上实现剧烈的塑性变形,获得超细晶组织,从而提高材料的综合性能,ECAP已在钛、铝、镁、铜等多种合金中获得了超细晶组织。近年来,ECAP在钛及钛合金中的应用取得了重大的进步,但是还需对如下一些问题进行要深入研究:1) 影响ECAP加工的路径、次数、摩擦条件等因素,还有待全面系统的研究。对于不同钛合金ECAP工艺参数的选择和优化还没有形成体系;2) 尚未提出一种完善的机制来描述各因素之间的相互作用效应,许多实验结果还未得到合理的解释;3) 高温钛合金ECAP关键工艺技术方面还存在许多难题。

鉴于存在的以上问题,今后ECAP研究的方向主要在以下两个方面: 1) 剪切平面、晶粒结构、变形织构对钛合金ECAP的相互影响规律;2) 超细晶ECAP钛合金(尤其是高温钛合金)性能(如热稳定性、疲劳强度、超塑性)的改善。

钛及钛合金经ECAP变形后所获得的超细晶组织的优异性能决定了ECAP工艺在钛工业领域内有非常广的应用前景,如通过ECAP提高难变形材料的可加工性、实现低温超塑性等。随着研究的深入,ECAP 技术将会引起人们更多的关注与重视,从而促进该技术的长足发展和进步,带动相关产业(如钛工业)的发展。

REFERENCES

[1] Segal V M, Reznikov V I, DrobysheVskiY A E, Kopylov V I. Plastic working of metals by simple shear [J]. Russian Metallugy, 1981, 19(1): 99-105.

[2] 王幸运, 赵西成, 杨西荣, 王 成. ECAP制备超细晶钛的力学性能研究[J]. 材料热处理技术, 2009, 38(10): 10-11.

WANG Xing-yun, ZHAO Xi-cheng, YANG Xi-rong, WANG Cheng. Study on mechanical properties of ultra-fine grained pure-Ti processed by ECAP [J]. Material & Heat Treatment, 2009, 38(10): 10-11.

[3] SAITOVA L R, SEMENOVA I P, RAAB G I, VALIEV R Z, LOWE T C, ZHU Y T. Improving the mechanical properties of Ti-6Al-4V alloy by equal channel angular pressing[J]. NATO Science Series, 2006, 212: 241-246.

[4] Iwahashi Y, Wang J, Horita Z, Nemoto M, Langdon T G. Principle of equal channel angular pressing for the processing of ultra-fine grained materials [J]. Scripta Materialia, 1996, 35(2): 143-146.

[5] 方晓强, 李淼泉, 林莺莺. 应用等通道转角挤压(ECAP)技术制备超细晶钛合金[J]. 材料导报, 2006, 20(10): 107-110.

FANG Xiao-qiang, LI Miao-quan, LIN Ying-ying. Formation of ultra-fine grained titanium alloy by equal channel angular pressing [J]. Materials Review, 2006, 20(10): 107-110.

[6] Chang J Y, Yon J S, Kim G H. Development of Submicmn sized grain during cyclic equal channel angular pressing [J]. Scripta Materialia, 2001, 45(3): 347-354.

[7] Zhao Yan, Guo Hong-zhen, Zhang Yong-qiang, Yao Ze-kun, Shi Zhi-feng. Influence of ECAP processing parameters on microstructure of TA15 titanium alloy [J]. Steel Research International, 2010, 81(9). (to be published)

[8] STOLYAROV V V, ZHU Y T, ALEXANDROV I V, LOWE T C, VALIEV R Z. Influence of ECAP routes on the microstructure and properties of pure Ti [J]. Materials Science and Engineering A, 2001, 299(1/2): 59-67.

[9] Gholinia A, Prangnell P B, Markushev M V. The effect of strain on the development of deformation structures in severely deformed aluminum alloys processed by ECAE [J]. Acta Materialia, 2000, 48(5): 1115-1130.

[10] Iwahashi Y, Horita Z, Nemoto M, Langdon T G. The process of grain refinement in equal channel angular pressing [J]. Acta Materialia, 1998, 46(9): 3317-3331.

[11] SEMENOVA I P, RAAB G I, SAITOVA L R, VALIEV R Z. The effect of equal-channel angular pressing on the structure and mechanical behavior of Ti-6Al-4V alloy [J]. Materials Science and Engineering A, 2004, 387/389: 805-808.

[12] 袁士翀. Ti-1023合金ECAP细化工艺及机理研究.[D]西安: 西北工业大学材料学院, 2008.

YUAN Shi-chong. Research on ECAP refining technology and mechanism of Ti-1023 alloy [D]. Xi’an: Northwestern Polytechnical University, School of Materials Science and Engieering, 2008.

[13] Kim I, Kim J, Shin D H, Lee C S, Hwang S K. Effects of equal channel angular pressing temperature on deformation structures of pure Ti [J]. Materials Science and Engineering A, 2003, 342(2): 302-310.

(编辑 刘华森)

通信作者:张永强; 电话: 029-88493744; E-mail: zhyq1987@hotmail.com