文章编号:1004-0609(2010)S1-s0452-05

TC4叶片精锻过程中摩擦对模具应力及温度场的影响

汪 宇,刘郁丽,杨 合

(西北工业大学 凝固技术国家重点实验室,西安 710072)

摘 要:基于三维有限元模拟软件DEFORM-3D,建立了TC4叶片精锻过程的三维热力耦合有限元模型,并以塑泥为材料,采用物理模拟方法对叶片精锻有限元模型进行了试验验证,得到了不同摩擦条件下模具等效应力、温度场及载荷的分布规律。结果表明:随着摩擦因数的增大,模具等效应力增大;模具叶身与榫头过渡区域及榫头旁侧温度分布较高,摩擦对模具叶身处温度分布的影响最大;摩擦因数增大将增加锻造的消耗能量及最大载荷。

关键词:TC4叶片;模具;摩擦;应力场;温度场

中图分类号:TG 316 文献标志码:A

Influence of friction on stress and temperature fields of die in TC4 blade forging process

WANG Yu, LIU Yu-li, YANG He

(State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: A 3D coupled thermo-mechanical finite-element model for TC4 blade forging process was built on the basis of DEFORM-3D. Furthermore, the model was validated with physical trial using plasticine material. Then the distribution laws of effective stress, temperature and load of die were obtained. The results show that the value of effective stress increases with the increase of the friction factor; the temperature in the transition region between blade body and tenon as well as the temperature in the region near the tenon are high. Besides, the friction greatly influences the temperature distribution of blade body; the forging energy and maximum load increase under severe friction condition.

Key words: TC4 blade; die; friction; effective stress field; temperature field

TC4叶片精密锻造过程中,苛刻的加工工艺条件对模具的性能提出了很高的要求。由于高温及大变形力使得模具的工作环境恶劣,极有可能产生热损 坏、磨损甚至破裂,这将严重影响模具的使用寿命[1-2]。模具一旦失效,将会对产品质量、生产进度和经济效益产生严重的影响[3-4]。影响模具寿命的因素很多,如摩擦与润滑条件、模具材料及坯料温度等[5-8],其中摩擦是决定模具寿命的重要边界条件之一。摩擦条件不合理不仅增大变形力、引起变形的不均匀,同时还会造成模具过快磨损、破裂,降低模具的使用寿命[9]。因此,研究摩擦对叶片精锻过程中模具应力及温度的影响具有重要的理论意义及实用价值。

国内外已有学者对不同摩擦条件下叶片精锻过程进行了研究。LIU等[10]模拟研究了不同摩擦条件下材料充填模腔的过程,得到了叶片精锻过程中摩擦对预成形毛坯位置的影响规律;OU等[11]对叶片精锻成形过程中,不同摩擦条件下模具与坯料的接触应力分布规律进行了探讨;邓华红等[12]模拟分析了摩擦对叶片成形过程中温度场、等效应变场及载荷行程曲线的影响规律。这些研究侧重于分析不同摩擦条件下叶片精锻成形规律,而有关摩擦对叶片精锻模具应力及温 度的影响规律的报道还很少。为此,本文作者基于DEFORM-3D软件,建立TC4单榫头叶片精锻过程的三维热力耦合有限元模型,并在此基础上研究叶片锻造过程中摩擦对模具应力、温度及载荷的影响规律,以期为实际应用摩擦条件的设置及模具失效部位的预测、修复提供理论指导。

2 有限元模型建立及数值模拟条件

2.1 有限元模型建立

2.1.1 摩擦模型

本研究中采用热塑性有限元模拟中应用较广泛的剪切摩擦模型描述叶片精锻过程中工件与模具之间的摩擦。叶片锻造过程中成形力很大,剪切摩擦模型不考虑接触面正应力的大小,可以避免因接触压力过高而错估摩擦作用的情况,如式(1)所示:

(1)

(1)

式中:f为摩擦应力,m为摩擦因数,k为剪切流动极限, 为等效应力。

为等效应力。

2.1.2 有限元模型

首先在UG软件中建立坯料及模具的几何模型,以STL文件格式输入到DEFORM-3D中。然后采用四节点四面体单元分别对上模、下模及坯料进行网格划分,其中坯料榫头和叶尖部位及模具凹槽部分采用密度窗口进行网格细化,解决了变形过程中复杂形状处网格产生的严重畸变问题,提高了模拟的精度。所建立的叶片精锻三维刚塑性有限元模型如图1所示。

图1 叶片锻造三维有限元模型

Fig.1 3D-FE model of blade forging

2.2 数值模拟条件[13]

叶片材料选用Ti-6Al-4V钛合金,模具材料选用4Cr5MoSiV1热作模具钢,钛合金及模具钢的材料本构模型取自DEFORM-3D自带数据库。坯料的初始温度为940 ℃,模具初始温度为300 ℃,锻造过程中界面接触换热系数为4 kW/(m2·K),对流换热系数为0.002 95 kW/(m2·K),上模压下速度为20 mm/s,摩擦因数为0.2。

2.3 模型可靠性验证

为了验证所建立的叶片精锻三维有限元模型的正确性,以彩色塑泥为材料对叶片精锻成形过程进行了物理模拟。图2所示为试验用模具及采用局部分层方法制作的坯料。

图2 试验坯料及模具

Fig.2 Billet and dies for experiment: (a) Top die; (b) Bottom die; (c) Billet

为便于分析,选取图2(c)中的榫头截面A-A′和叶身截面B-B′作为典型截面进行研究,利用DEFORM截面跟踪法,将典型截面分成与物理模拟坯料相对应的四层,然后追踪其形变特征。图3所示为不同压下量下典型截面A-A′ 和B-B′ 物理模拟结果与有限元模拟结果的对比。可以得知有限元模拟与物理模拟得到的典型截面形状基本一样,飞边形状大致相同,材料的流动趋势也基本相同。这表明有限元模拟结果与物理模拟结果吻合良好,从而说明所建立的叶片精锻三维有限元模型是可靠的,利用该模型得到的模拟结果是可信的。

图3 不同压下量下典型截面物理模拟结果与有限元模拟结果对比

Fig.3 Result comparison of FEM simulation and physical modeling of typical sections: (a) A-A′ section, 0 mm; (b) A-A′ section, 15.6 mm; (c) A-A′ section, 19.8 mm; (d) B-B′ section, 0 mm; (e) B-B′ section, 15.6 mm; (f) B-B′ section, 19.8 mm

3 模拟结果与分析

叶片精锻生产过程采用玻璃润滑剂,坯料与模具之间摩擦因数可以保证在0.1~0.3之间[13-14],因此研究摩擦对模具应力及温度场的影响时,摩擦因数分别取0.1、0.15、0.2、0.25和0.3。

3.1 模具应力场分析

热模锻过程中,下模工况较上模恶劣[15-16],故模具应力场的研究中以下模作为分析对象。图4所示为不同摩擦因数下锻造结束后下模等效应力分布云图。由图可知等效应力的最大值出现在模具榫头圆角区域,这是因为该处变形材料流动受到限制最大,与模具相互作用剧烈,形成较大的机械载荷;随着摩擦因数的增大,模具叶身处等效应力值逐渐增加,模具榫头区域出现应力集中的可能性增大,在该部位模具容易产生裂纹,并扩展而造成破裂。

图4 不同摩擦因数下模等效应力分布云图

Fig.4 Distribution of effective stress of bottom die under various friction factors: (a) m=0.1; (b) m=0.2; (c) m=0.3

3.2 模具温度场分析

锻造过程中锻件的热量传给上模较少,大部分的热量传给下模,下模的温度工况恶劣程度远远超过上模[16],故模具温度场的研究中仍以下模作为分析对象。图5所示为不同摩擦因数下锻造结束后下模温度场分布。从图5中可以看出,模具的最高温度区域主要集中在模具叶身与榫头的过渡区域及榫头右侧,较高温度区域主要集中在模具叶身的中间部分,这是因为这些区域坯料与模具相对运动剧烈,变形量大,产生热量多,从而导致温度较高;随着摩擦因数的增大,模具表面温度逐渐升高,特别是模具叶身部分较高温度区域有明显增大的趋势,模具叶身与榫头过渡区域及榫头右侧变化不明显,这是因为坯料叶身中间部分较难与外界环境的进行对流散热,且与模具接触面积大,摩擦产生的热量较多。因此,实际生产中,为防止模具叶身处热载荷产生的缺陷(如热疲劳裂纹、热磨损)可以通过改善润滑条件来实现,而模具叶身与榫头过渡区域及榫头右侧应通过其它途径来预防热损坏。

图5 不同摩擦因数下模温度场分布

Fig.5 Distribution of temperature of bottom die under various friction factors: (a) m=0.1; (b) m=0.2; (c) m=0.3

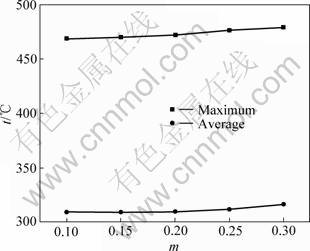

图6所示为摩擦因数与下模平均温度及最高温度的关系。由图可知,随着摩擦因数的增加,平均温度逐渐升高,但变化不大,在309.5~316.6 ℃之间。下模最高温度随摩擦因数的增大有逐渐上升的趋势,但变化不明显。结合图5可知摩擦因数对模具与叶片的接触表面温度分布,特别是叶身区域影响较大,而对其它部分影响较小。

图6 摩擦因数与平均温度、最高温度的关系

Fig.6 Relationships among friction factor and average temperature, maximum temperature

3.3 模具载荷分析

将叶片精锻过程中的载荷—行程曲线积分可求得锻造过程中载荷所作的功,如图7所示。由图可知,随着摩擦因数增大,载荷作功不断增大,且增大的趋势随摩擦因数的增大而加快。摩擦因数为0.1时载荷作功为38.43 kJ,而摩擦因数为0.3时,载荷达到43.93 kJ,增加了5.5 kJ,这增加的能耗都将用于克服变形力及摩擦做功。因此,摩擦因数的增大将使变形力和能耗增加,这将加剧模具的工作环境,缩短模具的使用寿命。

图7 不同摩擦因数下载荷作功大小

Fig.7 Consumed energy of load under various friction factors

图8所示为不同摩擦条件下模具所受的最大载荷值。当摩擦因数为0.1时,载荷最小(3 160.66 kN),随着摩擦因数的增大,载荷不断增加,当摩擦因数为0.3时,载荷增加到4 149.57 kN,是摩擦因数为0.1时的1.31倍,且摩擦因数越大,最大载荷增加趋势越明显。

图8 不同摩擦因数下模具最大载荷

Fig.8 Maximum load under various friction factors

4 结论

1) 随着摩擦因数的增大,模具的最大、最小应力逐渐增大,但变化不明显;模具榫头圆角部分承受巨大力学载荷容易产生缺陷。

2) 模具叶身与榫头过渡区域及榫头右侧温度最高;摩擦对模具最高及平均温度影响不大,对模具叶身温度的影响大于对模具叶身与榫头过渡区域及榫头的影响,因此实际生产中应采取不同方式防止热损坏。

3) 随着摩擦因数的增加,锻造消耗的能量及最大载荷增加,并且增加趋势明显。该研究对TC4叶片精锻过程中摩擦条件的设置、模具失效预测及模具优化具有指导意义。

REFERENCES

[1] 张志文. 叶片精锻[M]. 西安: 西安交通大学出版社, 1984: 83-89.

ZHANG Zhi-wen. Blade forging[M]. Xi’an: Xi’an Jiaotong University Press, 1984: 83-89.

[2] 李晓丽, 李淼泉, 李 峰, 熊爱明. TC6合金等温锻造过程中晶粒尺寸的数值模拟[J]. 中国有色金属学报, 2005, 15(9): 1332-1337.

LI Xiao-li, LI Miao-quan, LI Feng, XIONG Ai-ming. Numerical simulation of grain size during isothermal forging of TC6 alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(9): 1332-1337.

[3] MOHAMED K, RIADH E, YANNICK D, XAVIER B, G?RARD D. Failure mechanisms of H13 die on relation to the forging process A-case study of brass gas valves[J]. Engineering Failure Analysis, 2010, 17: 403-415.

[4] 王乐安. 难变形合金锻件生产技术[M]. 北京: 国防工业出版社, 2005: 252-256.

WANG Le-an. Manufacturing engineering for hard wrought alloy forgings[M]. Beijing: National Defense Industry Press, 2005: 252-256.

[5] BARRAU O, BOHER C, GRAS R, REZAI A F. Analysis of the friction and wear behaviour of hot work tool steel for forging[J]. Wear, 2003, 255: 1444-1454.

[6] DEAN T A, SILVA T M. Die temperatures during production drop forging[J]. J Eng Ind, 1979, 101: 385-390.

[7] 曾苏明. 复合包套模锻新工艺[J]. 中国有色金属学报, 1996, 6(2): 93-97.

ZENG Su-ming. A new technology of die forging with compound jacket[J]. The Chinese Journal of Nonferrous Metals, 1996, 6(2): 93-97.

[8] LEE H C, KIM B M, KIM K H. Estimation of die service life in hot forging, considering lubricants and surface treatments[J]. Proc Inst Mech Eng, 2003, 217: 1011-1022.

[9] IWAMA T, MORIMOTO Y. Die life and lubrication in warm forging[J]. J Mater Process Technol, 1997, 71: 43-48.

[10] LIU Yu-li, YANG He, ZHAN Mei. A study of the influence of the friction conditions on the forging process of a blade with a tenon[J]. J Mater Process Tchol, 2002, 123: 42-46.

[11] OU H, BALENDRA R. Preform design for forging of aerofoil sections using FE simulation[J]. J Mater Process Tchol, 1998, 80/81: 144-148.

[12] 邓华红, 齐广霞, 梅瑞斌. 叶片精锻过程中摩擦影响的数值模拟[J]. 热加工工艺, 2006, 35(21): 88-90.

DENG Hua-hong, QI Guang-xia, MEI Rui-bing. Numerical simulation of friction effect during precision forging of blade[J]. Hot Forging Technology, 2006, 35(21): 88-90.

[13] HU Z M, BROOKS J W, DEAN T A. Experimental and theoretical analysis of deformation and microstructural evolution in the hot-die forging of titanium alloy aerofoil sections[J]. J Mater Process Tchol, 1999, 88: 251-265.

[14] KOBAYASHI.S, OH S I, ALTAN T. Mental forming and the finite-element method[M]. Oxford: Oxford University Press, 1989.

[15] 卫原平, 阮雪榆. 热锻过程中工模具温度场的有限元迭代解法[J]. 上海交通大学学报, 1994, 28(6): 15-19.

WEI Yuan-ping, RUAN Xue-yu. An FEM algorithm for solving temperature field in workpiece and dies in hot forging[J]. Journal of Shanghai Jiaotong University, 1994, 28(6): 15-19.

[16] 王华昌, 龙满林, 胡金焕, 刘德学, 王凯峰, 潘成刚. 锻模综合应力有限元仿真分析[J]. 武汉理工大学学报, 2003, 25(8): 43-47.

WANG Hua-chang, LONG Man-lin, HU Jin-huan, LIU De-xue, WANG Kai-feng, PAN Cheng-gang. FEM analysis for integrated stress of dies during hot forging process[J]. Journal of Wuhan University of Technology, 2003, 25(8): 43-47.

(编辑 李向群)

基金项目:国家杰出青年科学基金资助项目(50225578);西安科技计划资助项目(GG06046)

通信作者:刘郁丽,博士,教授;电话:029-88460212-803;E-mail: lyl@nwpu.edu.cn