注射成型螺旋模具中熔体流动比

王道宏1, 2,蒋炳炎1,申瑞霞1,邓益善1

(1. 中南大学 机电工程学院 现代复杂装备设计与极端制造教育部重点实验室,湖南 长沙,410083;

2. 嘉兴职业技术学院,浙江 嘉兴,314036)

摘 要:对聚丙烯(PP)和聚乙烯(PE) 2种塑料在阿基米德螺旋线与方形螺旋线流动性测试模具中的流动性能进行研究,分析塑料流动比与型腔轮廓特征的关系;引入修正系数β,对流动比校核公式进行修正。研究结果表明:在阿基米德螺旋线模具中,PP在注射压力为150~160 MPa时取得最大流动比485,PE在注射压力为160~170 MPa时取得最大流动比419;在方形螺旋线模具中,PP在注射压力为100,120和150 MPa,PE在注射压力为130和140 MPa时流动比及所对应的注射速率出现波动,且流动性好的熔体波动更为严重;PP在阿基米德螺旋线模具中的流动比均值较其在方形螺旋线模具中大6%,而PE大4%;在阿基米德螺旋线模具中流动比均值PP比PE的流动比均值大19%,而在方形螺旋线模具中PP的流动比均值比PE的大15%;流动性好的熔体受模具型腔轮廓特征影响大。因此,实际生产中应充分考虑型腔轮廓特征对熔体流动比的影响,当模具型腔轮廓特征复杂时,宜采用较大的注射压力及注射速率。

关键词:注射成型;螺旋模具;流动长度;流动比;轮廓特征

中图分类号:TG76;TQ320.66+2 文献标识码:A 文章编号:1672-7207(2008)06-1251-06

Melt flow ratio in spiral mold of injection molding

WANG Dao-hong1, 2, JIANG Bing-yan1, SHEN Rui-xia1, DENG Yi-shan1

(1. Key Laboratory of Modern Complex Equipment Design and Extreme Manufacturing, Ministry of Education,

School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. Jiaxing Vocational Technical College, Jiaxing 314036, China)

Abstract: The flow properties of the polypropylene(PP) and polyethylene(PE) were studied using Archimedes spiral and square spiral melt fluidity test molds, which had the same shape of cross section but different cavity profiles, and then relationship between melt flow ratio and cavity profile was analyzed. Correctional checking formula of melt flow ratio in injection molding was obtained by introducing a correction coefficient β which reflected the complexity degree of mold cavity. The results show that, the maximum flow ratio of 486 can be obtained when injection pressure ranges from 150 MPa to 160 MPa in Archimedes spiral mold for PP, while maximum flow ratio of 419 can be obtained when injection pressure ranges from 160 MPa to 170 MPa for PE. There is a local fluctuation phenomenon for flow ratio and corresponding injection rate in square spiral mold when injection pressure of 100, 120 and 150 MPa for PP and 130, 140 MPa for PE are reached respectively,and this phenomenon is more serious for good fluidity of melt. The average flow ratio in Archimedes spiral mold is 6% larger than that in square spiral mold for PP, and 4% for PE, the average flow ratio of PP is 19% bigger than PE in Archimedes spiral mold, and 15% in square spiral mold. The influence of the cavity profiles on the melt flow ratio is more significant for good fluidity of melt. So, the influence of the cavity profiles on the melt flow ratio must be fully considered in the production practice, high injection pressure and injection rate are recommended when the cavity profile is complex.

Key words: injection molding; spiral mold; flow length; flow ratio; profile feature

在注射成型工艺中,通常以熔体流动性评价熔体的成型性能。衡量熔体流动性的指标有很多,如表观黏度、熔融指数、阿基米德螺旋线长度、流动比(又叫流长比)、流动指数等[1-2]。目前,熔体流动性测量方法主要有毛细管流变仪表观黏度测定法、转矩流变仪旋转黏度测定法、熔融指示仪测定热塑性塑料的熔融指数(MI)和阿基米德螺旋线模具测定流动长度等。

流变仪、熔融指示仪测试塑料得到的流变特性曲线或熔体黏度[3-5],与各加工工艺参数(如注射温度、注射压力、注射速率等)无直接的对应关系,无法有效地指导注射工艺设计。

阿基米德螺旋线测试模具来评价熔体流动 性[6-11],将更直接有效。但现有的阿基米德螺旋线测试模具还存在没有浇口和模腔等问题。整个模腔是一条长的、通向大气的流道,这种“开放式”型腔,无法真实地模拟出实际生产中熔体的注射成型。此外,利用螺旋测试模具测试塑料的流动长度时,测试结果会因螺旋测试模具的截面几何形状的不同而不同,无法有效指导注射成型工艺和模具设计。

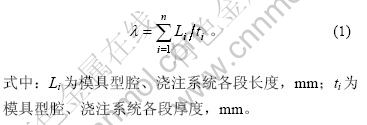

流动比是指在熔体的可加工条件范围内,某一注射压力条件下,调整注射速率和温度所得到的熔体在流道(包括模具型腔、浇注系统)中最大流动长度与流道壁厚的比值。流动比不受测试仪器、测试方法的影响。用流动比来衡量熔体流动性更科学。注射成型模具流动比(λ)公式为[12]:

然而,在实际生产中,常常因为模具型腔、浇注系统的几何特征的复杂性使λ校核还不够准确,出现模腔充填不足的现象,因此,对流动比有待进一步研究。在此,本文作者将在熔体流动性螺旋测试模具基础上,以聚丙烯(PP)、聚乙烯(PE) 2种典型的工程塑料为实验材料,通过注射成型实验研究塑料的流动比,掌握塑料流动比与轮廓特征的关系,进而有效地指导注射成型模具设计、工艺设计及产品设计。

1 实 验

1.1 实验材料

实验测试采用PP-T30S和PE-2909这2种材料,分别由中国石油化工股份有限公司荆门分公司及中国石油天然气股份有限公司抚顺石化分公司生产。其技术指标如表1所示。

1.2 实验方法

在阿基米德螺旋线矩形截面及方形螺旋线矩形截面[13]熔体流动性测试模具中,通过改变实验测试条件(包括注射压力、注射速率等工艺参数),得到PP-T30S和PE-2909在熔体流动性测试模具中不同流动长度,进而得到各注射压力所对应的最大流动长度。通过各注射压力对应的最大流动长度与熔体流动性测试模具型腔厚度之比,得到PP-T30S和PE-2909在熔体流动性测试模具中的一系列流动比。

1.3 实验设备

a. 注射机。采用SZ250/1200型注射机,主要技术参数如下:额定注射速率为130 g/s,额定注射压力为171 MPa,理论注射量为254 cm3。

b. 测试模具。为了弥补现有阿基米德螺旋线模具的不足,使模具结构更接近于实际的注射成型生产模具,将本实验模具型腔设计成封闭式,并增设浇口,流道旁增加刻度标志点以便实验时读取和计算熔体流动长度。为研究不同轮廓特征对熔体流动比的影响规律,自行研制了2种不同轮廓形状的测试模具——阿基米德螺旋线矩形截面测试模具和方形螺旋线矩形截面测试模具。

表1 PP-T30S和PE-2909的相关技术指标

Table 1 Technical index of PP-T30S and PE-2909

1.4 熔体流动长度的测量

熔体流动长度的测量采取与美国标准[14-16]相同的原则,即试件有效长度的起点为阿基米德螺旋线或方形螺旋线的始点,终点为熔体完全充满测试模具型腔的最远点,测量基准为试件的中线。

2 实验结果与分析

2.1 熔体流动性的分析

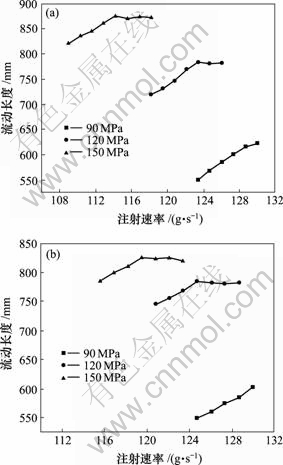

在PP-T30S 和PE-2909温度分别为250 ℃和200 ℃,模具温度为40 ℃的条件下进行注射成型实验,根据实验数据,绘制PP-T30S和PE-2909这2种材料在不同注射速率下注射压力与流动长度曲线,如图1和图2所示。

由图1和图2可见,PP-T30S和PE-2909的变化规律基本一致。在阿基米德螺旋线模具中,PP-T30S和PE-2909随着注射压力的增大流动长度逐渐增加,但增加的速度不断减小。流动长度曲线在高注射压力区段渐近于某一与注射压力轴平行的直线,即熔体流动长度增加不明显或不再增加。

(a) 阿基米德螺旋线模具;(b) 方形螺旋线模具

图1 不同注射速率下PP-T30S材料的P-L曲线

Fig.1 Relationship between flow length and injection pressure at different injection rates of PP-T30S

(a) 阿基米德螺旋线模具;(b) 方形螺旋线模具

图2 不同注射速率下PE-2909材料的P-L曲线

Fig.2 Relationship between flow length and injection pressure at different injection rates of PE-2909

在方形螺旋线模具中,随着注射压力的增大,PP-T30S和PE-2909的流动长度总体上呈增加趋势,但在型腔拐点附近会出现波动的现象。这主要是因为型腔拐点所引起熔体流动方向的突变(90?),导致熔体在型腔拐点处出现较大的压力损失和流速损失,因此,熔体在此处需要很大的注射速率和注射压力才能克服局部损失,以致在方形螺旋线模具中获得最大流动长度所需的注射速率和注射压力超过了实验测试条件设置范围。

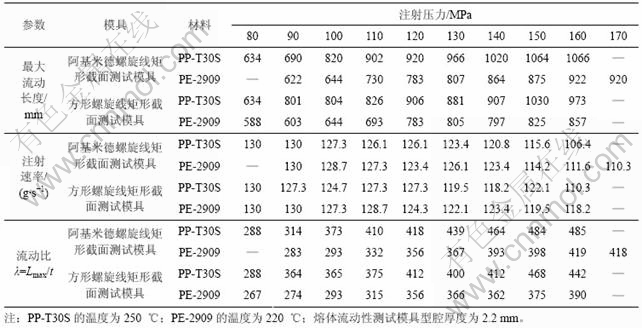

2.2 最大流动长度

PP-T30S和PE-2909这2种材料在不同注射压力下注射速率与流动长度曲线如图3和图4所示。

(a) 阿基米德螺旋线模具;(b) 方形螺旋线模具

图3 不同注射压力下PP-T30S材料的Q-L曲线

Fig.3 Relationship between flow length and injection rate at different injection pressures of PP-T30S

根据图3和图4曲线可拟合出不同注射压力下的最大流动长度,以PP-T30S在阿基米德螺旋线模具的流动长度曲线为例,如图3(a)所示压力为90 MPa、注射速率为130 g/s时,PP-T30S流动长度达到最大值 690 mm,最大流动长度与型腔厚度的比值即流动比为314。

以此类推,根据实验数据可得到PP-T30S和PE-2909这2种材料在不同注射压力下最大流动长度、流动比及所对应的注射速率。如表2所示。

2.3 熔体流动比与型腔轮廓特征的关系

阿基米德螺旋线模具与方形螺旋线模具具有相同的型腔面积及矩形截面形状,但型腔轮廓形状不同。图5和图6所示为PP-T30S和PE-2909这2种材料的流动比与型腔轮廓的关系,其中λ1为阿基米德螺旋线模具中流动比;λ2为方形螺旋线模具中流动比。

由图5和图6可见,在阿基米德螺旋线模具中,随着注射压力的增加,PP-T30S和PE-2909的流动比不断增加,PP-T30S在注射压力为150~160 MPa时取得最大流动比485(如图5(a)所示);PE-2909在注射压力为160~170 MPa时取得最大流动比419(如图5(b)所示)。而在方形螺旋线模具中,随着注射压力的增加,PP-T30S和PE-2909的流动比在总体上呈上升趋势,但PP-T30S在注射压力100,120和150 MPa,PE-2909注射压力在130和140 MPa出现波动现象。这是由于拐点的存在,能量局部损失较大,以至于要得到流动比必须以较大的注射速率来弥补能量损失。

(a) 阿基米德螺旋线模具;(b) 方形螺旋线模具

图4 不同注射压力下PE-2909材料的Q-L曲线

Fig.4 Relationship between flow length and injection rate at different injection pressures of PE-2909

在相同注射压力条件下,PP-T30S和PE-2909在阿基米德螺旋线模具中的平均流动比较其在方形螺旋线模具中分别大6%和4%;PP-T30S阿基米德螺旋线模具和方形螺旋线模具中平均流动比较PE-2909的分别大19%和15%(如图5所示)。因此,流动性好的熔体受模具型腔轮廓特征影响要大。

表2 最大流动长度及流动比数据

Table 2 Data of flow ratio and maximum flow length

(a) PP-T30S;(b) PE-2909

图5 PP-T30S 和PE-2909材料的P-λ曲线

Fig.5 Relationship between flow ratio and injection pressure of PP-T30S and PE-2909

(a) PP-T30S;(b) PE-2909

图6 PP-T30S 和PE-2909材料的Q-λ曲线

Fig.6 Relationship between flow ratio and injection rate of PP-T30S and PE-2909

随着注射压力、流动比的增大,PP-T30S和PE-2909在方形螺旋线测试模具中流动比对应的注射速率总的趋势是减小,但在拐点附近会伴随着流动比出现波动现象。流动性好的熔体波动现象要大。

在实际生产中,当模具型腔轮廓特征复杂,宜采用较大的注射压力以得到具有可模塑性的熔体流动比,同时采用较大的注射速率,以增大熔体的初始能量,弥补充模过程中较大的能量局部损失。

为了反映型腔轮廓特征对熔体流动比的影响,对流动比校核公式进行修正,引入适当的修正系数β (β≤1),即 (当型腔轮廓为直线时,β =1)。

(当型腔轮廓为直线时,β =1)。

3 结 论

a. 在阿基米德螺旋线测试模具中,随着注射压力的增加,PP-T30S在注射压力150~160 MPa时取得最大流动比485;PE-2909在注射压力160~170 MPa时取得最大流动比419。

b. 在方形螺旋线测试模具中,随着注射压力的增加,PP-T30S和PE-2909的流动比在总体上呈上升趋势,但PP-T30S在注射压力为100,120和150 MPa,PE-2909在注射压力为130和140 MPa时出现波动现象;流动比对应的注射速率总的趋势是减小,在拐点附近也出现波动现象。流动性好的熔体波动大。

c. 相同注射压力条件下,PP-T30S和PE-2909在阿基米德螺旋线测试模具中的平均流动比较其在方形螺旋线测试模具中分别大6%和4%;阿基米德螺旋线测试模具和方形螺旋线测试模具中,PP-T30S的平均流动比较PE-2909的分别大19%和15%。流动性好的熔体受模具型腔轮廓特征影响大。

d. 引入反映型腔轮廓特征复杂程度的修正系数β(β≤1),得到修正后的流动比校核公式:

。

。

e. 在实际生产中,当模具型腔轮廓特征复杂时,宜采用较大的注射压力及注射速率。

参考文献:

[1] 余晓容, 申长雨, 杨晓东, 等. 塑料制件最大流长比算法研究与应用[J]. 中国塑料, 2004, 18(1): 88-91.

YU Xiao-rong, SHEN Chang-yu, YANG Xiao-dong, et al. Maximum flow length ratio of plastic product and its application[J]. China Plastics, 2004, 18(1): 88-91.

[2] 陈 曦, 钱积新, 高福荣. 注塑过程熔体充填长度的动态神经网络软测量模型[J]. 化工自动化及仪表, 2002, 29(2): 43-46.

CHEN Xi, QIAN Ji-xin, GAO Fu-rong. Modeling of melt-flow-length during injection filling stage based on dynamic neural network soft-sensor[J]. Control and Instruments in Chemical Industry, 2002, 29(2): 43-46.

[3] Antonio M, Andrew O O, Quesada J C, et al. Flow properties of vacuum gas oil-low density polyethylene blends[J]. Fuel Processing Technology, 2008, 89(1): 83-89.

[4] Masayuki Y, Keiichi A. Effect of thermal degradation on rheological properties for poly(3-hydroxybutyrate)[J]. European Polymer Journal, 2006, 42(7): 1479-1486.

[5] Helson M C, Valéria D R, Marisa C R. Rheological properties of polypropylene during multiple extrusion[J]. Polymer Testing, 2005, 24(1): 86-93.

[6] Dobromyslov O M. Mold for studying fluidity of polymeric materials: SU, SU1753366[P]. 1992-08-07.

[7] Shajkin A E, Zakharov V N, Safiullina A S, et al. Apparatus for testing moulding properties of polymeric material: SU, SU1413482[P]. 1988-07-30.

[8] 李迎春, 申开智. 聚丙烯(PP)塑料注射模具点浇口大小的研究[J]. 华北工学院学报, 1998, 19(1): 30-34.

LI Ying-chun, SHEN Kai-zhi. Study of gate dimension for PP injection mold[J]. Journal of North China Institute of Technology, 1998, 19(1): 30-34.

[9] ZHANG Xiao-yu. The use of a spiral flow mold to measure processability of polymeric materials[D]. Lowell: University of Lowell, 1992.

[10] 谢 刚, 李明强, 张 新, 等. 高聚物注塑成型的可模性研究[J]. 黑龙江大学自然科学学报, 2005, 22(6): 729-731.

XIE Gang, LI Ming-qiang, ZHANG Xin, et al. Study on the mouldability of polymer injection molding[J]. Journal of Natural Science of Heilongjiang University, 2005, 22(6): 729-731.

[11] WU Hong-wu, XU Hai-hang, QU Jin-ping, et al. Cavity pressure response and melt flow length during dynamic injection molding[J]. Polymer-Plastics Technology and Engineering, 2006, 45(8): 935-937.

[12] 申开智, 叶淑静. 塑料成型模具[M]. 北京: 中国轻工业出版社, 1993.

SHEN Kai-zhi, YE Shu-jing. Plastics mould[M]. Beijing: China Light Industry Press, 1993.

[13] 蒋炳炎, 谢 磊, 谭险峰, 等. 流道截面形状对微流体流动性能的影响[J]. 中南大学学报: 自然科学版, 2006, 37(5): 964-969.

JIANG Bing-yan, XIE Lei, TAN Xian-feng, et al. Influence of section shape of micro channels on microfluid flowability[J]. Journal of Central South University: Science and Technology, 2006, 37(5): 964-969.

[14] ASTM D 569—90, Measurement systemof fluidity of thermoplastic mould material[S].

[15] ASTM D 3795—93, Test methods for measuring heat fluidity and solidification properties of thermosetting plastic using torque rheometer [S].

[16] ASTM D 3123—94, Spiral flow of low-pressure thermosetting molding compounds[S].

收稿日期:2008?01?09;修回日期:2008?04?09

基金项目:国家自然科学基金资助项目(50475140);中德合作项目(PPP)(2006103723);教育部科学技术研究重点资助项目(107086)

通信作者:蒋炳炎(1963?),男,浙江浦江人,教授,从事先进制造技术、微注射成型及MEMS的研究;电话:0731-8836035;E-mail: jby@mail.csu.edu.cn