稀土Ce的添加方式对WC-Co硬质合金性能的影响

史晓亮1,杨凯华2, 汤凤林2, 邵刚勤1

(1.武汉理工大学 材料复合新技术国家重点实验室,湖北 武汉,430070;

2.中国地质大学 工程学院,湖北 武汉,430074)

摘要: 采用以共沉淀方法制备的Ni-Ce复合粉末、真空蒸镀W的金刚石等为原料,热压活化烧结,制取了具有高强度、高硬度的稀土金刚石增强WC-10%Co-5%Ni硬质合金复合齿。观察稀土金刚石增强WC-10%Co-5%Ni硬质合金复合齿的显微结构,测试其硬度、密度、断裂强度、抗冲击性能、磨耗比。研究结果表明:采用热压活化烧结获得的稀土金刚石增强WC-10%Co-5%Ni硬质合金复合齿的洛氏硬度为90,断裂强度为1918 MPa,抗冲击性能>200 J,磨耗比为30.21。采用中间合金Ni-Ce的方式加入稀土Ce使稀土在合金中的分布更均匀。

关键词: 共沉淀; 硬质合金; 铈

中图分类号:TF125.3 文献标识码:A 文章编号: 1672-7207(2005)02-0204-05

Effect of Adding Method of Rare Earth Ce on Property of WC-Co Cemented Carbide

SHI Xiao-liang1, YANG Kai-hua2, TANG Feng-lin2, SHAO Gang-qin1

(1. State Key Laboratory of Advanced Technology for Materials Synthesis and Processing,

Wuhan University of Technology, Wuhan 430070, China;

2. Engineering Faculty, China University of Geosciences, Wuhan 430074, China)

Abstract: WC-10%Co-5%Ni cemented carbide enhanced by rare-earth and diamond was prepared in a hot-pressing activated sintering process with Ni-Ce composite powder produced with coprecipitation technology and diamond plated W by vacuum vapor deposit. The microstructure of cemented carbide was observed, and the hardness, density, strength, toughness against impact and wear ratio were tested. The results show that hardness of WC-10%Co-5%Ni cemented carbide prepared in the hot-pressing activated sintering is 90, strength is 1918 MPa, toughness against impact is more than 200 J, and wear ratio is 30.21.Rare earth Ce can be made more homogeneous in the alloy by adding Ni-Ce powder produced with coprecipitation.

Key words: coprecipitation; cemented carbide; cerium

-

WC-Co硬质合金具有耐腐蚀性强、硬度高、断裂韧性大和抗压强度高的特点,在机械、冶金、矿山、精密仪器、军事等工业中具有极其重要的作用[1,2]。但钴作为一种战略物资,我国大部分需要进口,这使得钴类硬质合金的价格偏高,其应用受到了一定的限制。长期以来,世界各国硬质合金研究者致力于研究采用较廉价的金属和合金取代钴作为硬质合金粘结相。其中,以铁镍代钴的研究较多,但这些工作绝大部分属于理论试验研究,并无大量开发生产[3,4]。

在现有材料中,金刚石具有最强的耐磨性和研磨能力。由于其具有极高的硬度和优良的机械性能,金刚石工具在石油钻井、地质勘探、石材加工、建筑装潢等领域得到了非常广泛的应用,但金刚石的热稳定性和抗冲击韧性较弱,严重阻碍了其在凿岩工具中的应用。若能将金刚石与硬质合金有机地结合起来,将大大提高金刚石硬质合金复合材料的综合性能。

稀土可以提高硬质合金的机械性能,在改善材料的性质方面具有广泛的应用。但是,若在合金中直接加入稀土,则在球磨混料等工艺过程中,稀土非常容易氧化,同时由于添加量很少,就使得稀土在混料中的均匀弥散性难以保证,使工艺的可重复性及稳定性难以保证[5-10]。为解决稀土元素在混料中易出现分散不均匀和氧化等问题,采用共沉淀法制备成稀土Ce的中间合金再往硬质合金中添加的方法,保证稀土元素在硬质合金中弥散均匀,使材料获得最佳的综合性能。研究结果表明,采用适当的稀土添加工艺,可使金刚石超硬复合材料的抗弯强度提高10%以上[11-17]。

在此,作者采用共沉淀法制备出Ni-Ce复合粉末,采用热压活化烧结制备出金刚石增强稀土WC-10%Co-5%Ni硬质合金复合齿,并与球磨掺杂稀土WC-10%Co-4.7%Ni-0.3%Ce硬质合金进行对比,分析共沉淀添加稀土Ce对金刚石增强WC-10%Co-5%Ni硬质合金复合齿性能的影响。

1 实 验

1.1 实验原料及设备

实验原料有:粉末冶金厂生产的普通WC(粒径约为38 μm)、 Co(粒径约为50 μm)、 Ni(粒径约为50 μm)粉、稀土Ce、红磷及真空蒸镀W的金刚石(粒径约为250 μm)。

设备有:KGPS100-1型中频感应烧结炉,加热功率为100 kW,中频频率为1 kHz;非接触式光纤测温仪,测量范围为600~1200 ℃; YH41-40C型单臂压力机,吨位为40 t。

1.2 实验方法

将基体粉料与己烷放入硬质合金球磨罐,球料质量比为8∶1,在球磨机上球磨48 h,球磨后在干燥箱中于90 ℃真空干燥。

烧结工艺是:烧结温度为1060 ℃,保温时间为3~4 min,烧结压力为50~60 MPa。

1.3 性能测试

磨耗比为标准硬质合金齿失重与金刚石增强硬质合金复合齿失重之比。标准硬质合金齿为国内某硬质合金厂生产的Q1422和WC-8Co硬质合金球齿。复合齿基体的断裂强度采用MTS810陶瓷测试系统按GB/T3851—1983标准测试,试样尺寸为20.00 m×6.50 m×5.25 m。洛氏硬度采用HRS-150型数显洛氏硬度计按GB/T3849—1983标准测试;密度采用METTLER TOLEDO AB-104N密度测试仪按GB/T 3850—1983标准测试。采用华中科技大学材料科学与工程学院材料试验室BUEHLER公司生产的PHOENIX4000型研磨机、抛光机进行磨耗比测试,测出复合齿试样相对于硬质合金齿Q1422的相对耐磨性,测试条件是:回转速度为200 r/min,压力为0.26 MPa,磨耗时间为10 min。复合齿的抗冲击性能采用单齿抗冲击仪测试。采用JSM-5610LV扫描电子显微镜(SEM)观察烧结试样的断口,分析微观组织结构。

2 结果与分析

2.1 共沉淀Ni-Ce复合粉的制备

将氯化镍与氯化稀土按一定的比例制成混合溶液,用草酸盐或碳酸盐作沉淀剂,可得到均匀分散的稀土和镍的草酸盐。这些沉淀物由于溶解度相近而具有共沉淀性。

沉淀时发生以下反应:

Ni2++C2O2-4=NiC2O4↓(1)

2Ce3++3C2O2-4=Ce2(C2O4)3↓(2)

共沉淀物经过滤、洗涤等将酸根离子、盐离子去除,然后进行干燥、煅烧、氢还原,得到镍和稀土(稀土活性氧化物)的混合物。

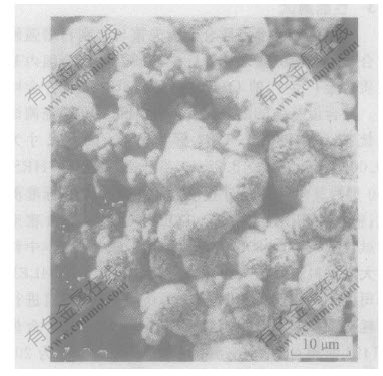

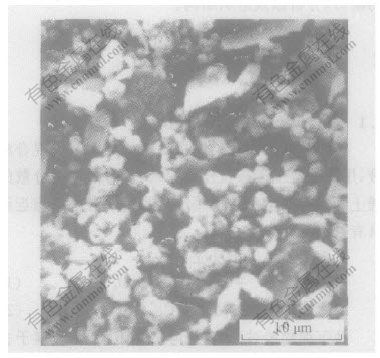

共沉淀过程中,用TiH2粉作还原剂进行还原处理,主要目的是还原出部分稀土金属Ce,将还原反应产生的气体通入饱和的NaOH溶液中处理,避免污染环境。未用TiH2还原的Ni-Ce共沉淀粉和用TiH2还原的Ni-Ce共沉淀粉的SEM形貌如图1和图2所示。可见,未用TiH2还原的Ni-Ce共沉淀粉存在明显的团簇现象,这将降低组织活性而不利于粉末烧结;用TiH2还原的Ni-Ce共沉淀粉,团簇现象减少,保证了共沉淀粉在混料球磨过程中分散均匀。图中不规则粒状为Ti的化合物,粒径约为10 μm。引入微量Ti可以消除复合粉末中部分的游离碳,同时生成TiC晶粒生长抑制剂来抑制晶粒生长。

图 1 未用TiH2还原的Ni-Ce共沉淀粉

Fig. 1 SEM image of Ni-Ce coprecipitating powders before deoxidized by TiH2

图 2 用TiH2还原的Ni-Ce共沉淀粉

Fig. 2 SEM image of Ni-Ce coprecipitating powders deoxidized by TiH2

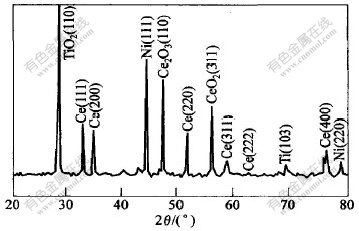

用TiH2还原处理得到的Ni-Ce共沉淀粉的X射线衍射图谱如图3所示。可见,在粉末的X衍射曲线中,存在Ce衍射峰和Ni衍射峰。

2.2 添加共沉淀稀土Ce对金刚石增强硬质合金组织性能的影响

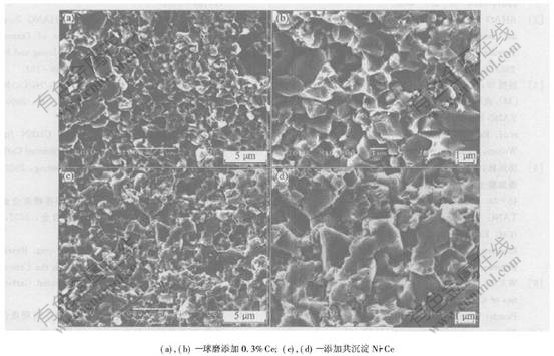

球磨混料和添加共沉淀Ni-Ce复合粉末2种添加方式制得的烧结体的断口形貌如图4所示。图4(a)和4(b)所示为球磨添加0.3%Ce的烧结体的断口形貌,可以看出,烧结体的局部晶粒得到了明显细化、球化,而其他部分则存在着晶粒粗化的现象,并且烧结体断裂的路径不太曲折。这主要是由于稀土Ce的添加量很少,在球磨添加过程中很难保证其分散均匀,存在稀土Ce的部位,晶粒得到了细化,而不存在稀土Ce的部位,晶粒得不到细化,造成组织结构不均匀,使烧结的性能降低。图4(c)和4(d)所示为添加Ni-Ce共沉淀复合粉末的烧结体的断口形貌,由于稀土Ce在烧结体中的分布均匀,使烧结体的组织均匀,其平均晶粒度明显小于球磨添加稀土的烧结体的平均晶粒度。在烧结过程中,随着温度的升高,晶粒逐渐长大,晶粒的比表面积反而减小,从而晶粒与晶粒之间的接触面也减小。Ni-Ce共沉淀复合粉末中稀土Ce以及还原过程中产生的TiC晶粒阻止了晶粒的过分长大,增大了晶粒之间的接触面积,烧结体断裂的路径加长,从而阻止烧结体发生断裂。

图 3 采用共沉淀法制取的Ni-Ce粉用TiH2还原处理后的X射线衍射图谱

Fig. 3 XRD pattern of Ni-Ce coprecipitating powders deoxidized by TiH2

同时,球磨添加0.3%Ce的烧结体中孔隙度较高,大大影响烧结体的性能。由于球磨添加0.3%Ce不能保证其均匀分散,局部过多的稀土Ce在WC/WC界面产生偏析,从而降低了烧结体的强度。

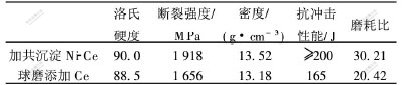

分别采用球磨混料和添加共沉淀Ni-Ce复合粉末添加稀土Ce制得的烧结体性能如表1所示。可见,添加Ni-Ce共沉淀复合粉末的烧结体的各项参数均明显高于球磨混料方式添加Ce的烧结体的对应参数。材料的硬度与材料的平均晶粒度有密切的关系,平均晶粒度越细,其洛氏硬度越高。而且,在材料的断裂过程中,晶粒越小,断裂的路径越长,阻止材料发生断裂。材料的抗弯强度主要取决于晶粒的大小和晶粒之间的接触面积,故添加Ni-Ce共沉淀复合粉末的烧结体的断裂强度较高。

图 4 不同稀土Ce添加方式的硬质合金基体断口形貌

Fig. 4 SEM images of fractured surface of composite button matrix by different adding Ce methods

表 1 共沉淀Ni-Ce复合粉对复合齿基体性能的影响

Table 1 Influence of Ni-Ce coprecipitating powders on properties of composite

button matrix

稀土Ce分散均匀,能有效地与基体合金元素作用而形成密度较高且分布均匀的各种位错及较大尺寸的位错环,使其他金属元素更易与之形成固溶体或微合金化合物,起到固溶强化、弥散强化及相应的催化活化作用。稀土化合物富集于界面并吸附Si和Ca等夹杂、减少杂质在基体金属中的溶解度,降低了界面能量而强化了组织和晶粒界面,提高了与界面有关的性能,如抗弯强度、硬度、冲击韧性、耐磨性,提高了再结晶温度,抑制了晶粒长大,使烧结体组织更均匀、细小。

以Ni-Ce中间合金方式添加Ce制成的金刚石增强硬质合金复合齿的性能完全满足潜孔锤钻头冲击凿岩的需要,从而可以用于解决传统超硬材料抗冲击性能低的问题,也可用于矿床勘探钻探、水文工程地质勘探和煤田、油气田钻探时堆积的卵砾石层等特殊地层的钻进。

3 结 论

a. 采用热压活化烧结获得了洛氏硬度为90,断裂强度为1918 MPa,抗冲击性能>200 J,磨耗比为30.21,具有高强度、高硬度的金刚石增强稀土WC-10%Co-5%Ni硬质合金复合齿。

b. 采用以共沉淀Ni-Ce复合粉添加稀土Ce的方式保证了稀土在混料中的均匀弥散性,从而使金刚石增强型硬质合金复合齿性能大大提高。

参考文献:

[1]CHA SEUNG I, HONG SOON H, HA GOOK H, et al. Mechanical Properties of WC–10.21Co Cemented Carbides Sintered from Nanocrystalline Spray Conversion Processed Powders[J]. International Journal of Refractory Metals and Hard Materials, 2001, 19(4-6): 397-403.

[2]SHAO Gang-qin, DUAN Xing-long, XIE Ji-ren, et al. Sintering of Nanocrystalline WC-Co Composite Powder[J]. Reviews on Advanced Materials Science, 2003, 5(4):281-286.

[3]杨凯华,段隆臣,汤凤林,等.新型金刚石工具研究[M].武汉:中国地质大学出版社,2001.

YANG Kai-hua, DUAN Long-chen, TANG Feng-lin, et al. Research on New Kinds of Diamond Tools[M]. Wuhan: China University of Geosciences Press, 2001.

[4]汤凤林,杨凯华,邹庆化,等.金刚石碎岩工具胎体材料添加稀土元素的试验研究[J].探矿工程, 2001,(1):45-48.

TANG Feng-lin, YANG Kai-hua, ZOU Qing-hua, et al. Experimental Research on Adding of Rare Earth Elements to Matrix of Diamond Tools[J]. Exploration Engineering, 2001,(1):45-48.

[5]WANG Shi-yuan. Influence of Rare Earths on Properties of Cemented Tungsten Carbide-nickel[J]. Metal Powder Report, 1997, 52(11):39.

[6]XU Chong-hai, AI Xing, HUANG Chuan-zhen. Research and Development of Rare-earth Cemented Carbides[J]. International Journal of Refractory Metals and Hard Materials, 2001,19(3):159-168.

[7]XU Chong-hai, AI Xing. Particle Dispersed Ceramic Composite Reinforced with Rare Earth Additions[J]. International Journal of Refractory Metals and Hard Materials, 2001, 19(2):85-88.

[8]SANTOS C, STRECKER K, BALDACIM S A, et al. Mechanical Properties Improvement Related to the Isothermal Holding Time in Si3N4 Ceramics Sintered with an Alternative Additive[J]. International Journal of Refractory Metals and Hard Materials, 2003, 21(5-6):245-250.

[9]杨小玲,刘沙,易丹青,等. 纳米晶掺Ce硬质合金粉末的制备[J]. 上海有色金属, 2002,23(2):49-52.

YANG Xiao-ling, LIU Sha, YI Dan-qing, et al. Preparation of Nano-crystalline Ce Doped WC/Co Powder[J]. Shanghai Nonferrous Metals, 2002,23(2):49-52.

[10]XIONG Ji, YANG Jian-gao, GUO Xing-hua. Application of Rare Earth Elements in Cemented Carbide Inserts, Drawing Dies and Mining Tools[J]. Materials Science and Engineering A, 1996, 209(1-2):287-293.

[11]刘宝昌,孙友宏,张祖培. 稀土强化金刚石-硬质合金复合凿岩柱齿的试验研究[J]. 矿冶工程, 2002, 22(2):99-102.

LIU Bao-chang, SUN You-hong, ZHANG Zu-pei. Effects of Rare Earth on Properties of Diamond-tipped Tungsten Carbide Insert[J]. Mining and Metallurgical Engineering, 2002, 22(2):99-102.

[12]雍志华,汪仕元,程娟,等. WC-8(Fe/Ni/Co)R硬质合金的研究[J].稀有金属材料与工程, 2000,29(4):273-275.

YONG Zhi-hua, WANG Shi-yuan, CHEN Juan, et al. Study of WC-8(Fe/Ni/Co)R Cemented Carbide[J]. Rare Metal Materials and Engineering, 2000,29(4):273-275.

[13]魏庆丰,孙景,李昌青. 稀土添加剂在硬质合金中的应用研究[J]. 稀有金属与硬质合金, 2002, 30(2):33-36.

WEI Qing-feng, SUN Jing, LI Chang-qing. Research on the Application of RE Additives in the Cemented Carbide[J]. Rare Metals and Cemented Carbides, 2002, 30(2):33-36.

[14]熊继,沈保罗. 混合稀土CeLa对WC-Ni硬质合金性能和显微结构的影响[J]. 工具技术, 2003, 37(6):18-20.

XIONG Ji, SHEN Bao-luo. Influence of CeLa Misch Metal to Performance and Microstructure of WC-Ni Cemented Carbide[J]. Tool Techniques, 2003, 37(6):18-20.

[15]唐群. 金刚石复合片中稀土硬质合金基片的制备[J]. 稀有金属, 2003, 27(5):614-616.

TANG Qun. Preparation of Substrate of Cemented Carbide with Rare Earth Element for PDC[J]. Chinese Journal of Rare Metals, 2003, 27(5):614-616.

[16]张立, SCHUBERT W D,黄伯云,等. 含稀土硬质合金的表面观察[J]. 中南工业大学学报(自然科学版), 2003, 34(5):467-471.

ZHANG Li, SCHUBERT W D, HUANG Bai-yun, et al. Surface Observation of Rare Earth Doped Cemented Carbide[J]. J Cent South Univ Technol(Natural Science), 2003, 34(5):467-471.

[17]彭新林,龙志奇,崔梅生,等.共沉淀法合成铈锆复合氧化物及表征[J].中国稀土学报,2002, 20(3):104-107.

PENG Xin-lin, LONG Zhi-qi, CUI Mei-sheng, et al. Characterization and Preparation Cerium-Zirconium Composite Oxides by a Coprecipitation Approach[J].Journal of the Chinese Rare Earth Society, 2002, 20(3):104-107.

收稿日期:2004-10-19

基金项目:国土资源部大调查资助项目(20002010005016); 中国博士后科学基金资助项目(2003034504)

作者简介:史晓亮(1974-),男,黑龙江佳木斯人,博士,从事纳米复合技术与纳米材料的研究

论文联系人: 史晓亮,男,博士;电话:027-62871836(O);E-mail:sxl@mail.whut.edu.cn