可熔振动头式机械振动细化 Al-5%Cu铝合金晶粒

来源期刊:中国有色金属学报(英文版)2014年第8期

论文作者:郭洪民 章爱生 杨湘杰 严明明

文章页码:2489 - 2496

关键词:Al-Cu合金;晶粒细化;凝固;机械振动

Key words:Al-Cu alloy; grain refinement; solidification; mechanical vibration

摘 要:介绍一种机械振动细化凝固组织的工艺,振动能量由振动头直接导入熔体,该振动头在振动过程中熔化。研究振动加速度和质量比对Al-5%Cu合金微观组织的影响。结果表明:该机械振动可实现熔体内部冷却,冷却速度取决于振动加速度;若在振动过程中,熔体的温度保持在液相线温度以上,该机械振动很难实现晶粒细化;若在凝固初期阶段施加机械振动,凝固组织可以被有效细化。另外,探讨了在机械振动条件下,凝固组织细化的基本机理。

Abstract: A mechanical vibration technique to refine solidified microstructure was reported. Vibration energy was directly introduced into a molten alloy by a vibrating horn, and the vibrating horn was melted during vibration. Effects of vibration acceleration and mass ratio on the microstructure of Al-5% Cu alloy were investigated. Results show that the present mechanical vibration could provide localized cooling by extracting heat from the interior of molten alloy, and the cooling rate is strongly dependent on vibration acceleration. It is difficult to refine the solidified microstructure when the treated alloy keeps full liquid state within the entire vibrating duration. Significantly refined microstructure was obtained by applying mechanical vibration during the initial stage of solidification. Moreover, mechanisms of grain refinement were discussed.

Trans. Nonferrous Met. Soc. China 24(2014) 2489-2496

Hong-min GUO1,2, Ai-sheng ZHANG1, Xiang-jie YANG2, Ming-ming YAN1

1. School of Materials Science and Engineering, Nanchang University, Nanchang 330031, China;

2. Key Laboratory of High Performance Precision Forming in Jiangxi Province, Nanchang University, Nanchang 330031, China

Received 11 July 2013; accepted 11 October 2013

Abstract: A mechanical vibration technique to refine solidified microstructure was reported. Vibration energy was directly introduced into a molten alloy by a vibrating horn, and the vibrating horn was melted during vibration. Effects of vibration acceleration and mass ratio on the microstructure of Al-5% Cu alloy were investigated. Results show that the present mechanical vibration could provide localized cooling by extracting heat from the interior of molten alloy, and the cooling rate is strongly dependent on vibration acceleration. It is difficult to refine the solidified microstructure when the treated alloy keeps full liquid state within the entire vibrating duration. Significantly refined microstructure was obtained by applying mechanical vibration during the initial stage of solidification. Moreover, mechanisms of grain refinement were discussed.

Key words: Al-Cu alloy; grain refinement; solidification; mechanical vibration

1 Introduction

Refining solidified microstructure is an important route to improve mechanical properties of metals. Among developed techniques, applying mechanical vibration into a molten alloy during solidification has been developed as an advantageous method to obtain fine grains because of low cost and simple system, compared with ultrasonic or electromagnetic vibration [1-3]. In the carried out investigations, the methods applying mechanical vibration can be classified into two types. In one type, mechanical vibration is introduced into the solidifying metals under continuous cooling during casting. It has been revealed that mechanical vibration has strong effects on final ingot or cast component, such as grain refinement, degassing and mechanical properties [4-9]. In the other type, mechanical vibration is used to treat a molten alloy at various solid fractions in the mushy zone. It has been shown that semi-solid slurry or billet could be produced [10-12].

In the aforementioned investigations, the energy resulted from superheat and latent heat of molten alloy during solidification is absorbed mainly by the mold, and the mechanical vibration is indirectly introduced into molten alloy by vibrating the mold. In the present work, mechanical vibration was directly introduced into a molten alloy by a vibrating probe, and the vibrating probe will be melted during vibration. The energy produced during solidification is absorbed mainly by the melting of vibrating probe. Effects of vibration intensity and mass ratio on solidified microstructure of Al-5%Cu alloy were investigated. Furthermore, mechanisms of the microstructure formation were proposed when considering the role of these variables upon solidification.

2 Experimental

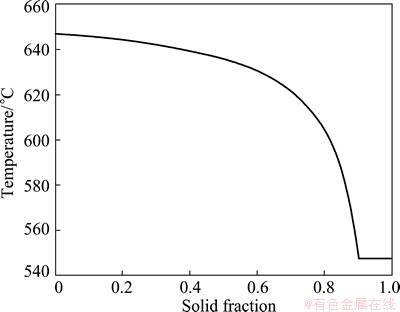

Al-5%Cu alloy was prepared by melting pure aluminum (99.9% purity) and pure Cu (99.99% purity) and casting into small billets. The temperature versus solid fraction curve of this alloy was calculated using a thermodynamic database software package called Pandat based on Scheil equation (non-equilibrium solidification), as shown in Fig. 1. The eutectic and liquidus temperatures are 547.6 °C and 647.5 °C, respectively.

Fig. 1 Curve of temperature versus solid fraction

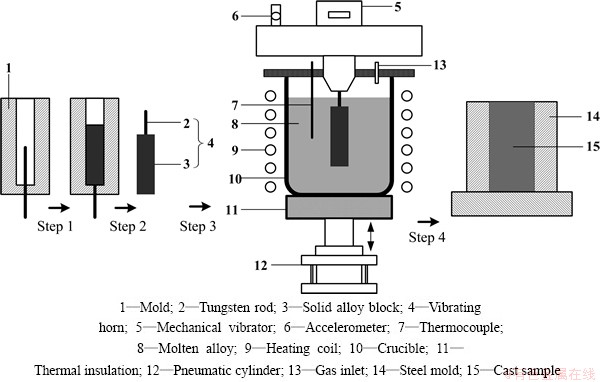

Figure 2 shows the schematic sketch of equipment employed, mainly including a mechanical vibrator, a vibrating probe, and a stainless steel crucible. The vibrating probe consists of a tungsten rod with a diameter of 6 mm and a solid alloy block (SAB). The SAB having the same compositions as that of the experimental alloy, was cast on the tungsten rod. The SAB will dissolve in the molten alloy during vibration, in other words, the vibrating horn will be melted during vibration. The vibrating horn was connected to the mechanical vibrator to provide vibration energy. The vibrator could generate sinusoidal waveform. The frequency (f) and amplitude (A) of the vibration had a fixed relationship, and the maximum amplitude was 2 mm. It has been indicated that both frequency and amplitude significantly influenced the melt convection, which in turn affected the solidified microstructure [4-12]. Investigations of CAMPBELL [4] argued that parameter like acceleration (combining frequency and amplitude) could describe the vibration better than frequency and amplitude alone. So, the vibration acceleration (VA) was used to define the vibration intensity, and was defined as Eq. (1). A pneumatically operated device was installed to move the stainless steel crucible. The time to move the vibrating horn into (out of) the molten alloy could be precisely controlled.

(1)

(1)

In this study, the mass of treated molten alloy was determined as 1.5 kg. To study the influence of the mass ratio of SAB to the treated molten alloy, the vibration acceleration was kept constantly at 19 m/s2, the mass ratio varied from 3% to 6%. With respect to the solidified microstructure as a function of the vibration acceleration, 6% SAB was set, and vibration acceleration was a variable ranging from 2.5 to 19 m/s2. Al-5%Cu alloy billets were melted in an electric resistance furnace. After the molten alloy was heated to 720 °C, it was degassed for 15 min with argon gas, and then was cooled to 680 °C. Predetermined mass of molten alloy was cast on the tungsten rod, and then the SAB was obtained and cooled to room temperature of about 16 °C. At the same time, the stainless steel crucible was heated to 660 °C. 1.5 kg of molten alloy was poured into the stainless steel crucible, and was slowly cooled down to 656 °C. Then the vibrating probe was quickly immersed into the molten alloy, introducing mechanical vibration. When the SAB was melted completely and the temperature was balanced, mechanical vibration was terminated and simultaneously, treated melt was poured into a steel mold that had been preheated to 350 °C. The steel mold consisted of a cylindrical block with diameter of 100 mm, incorporating a cylindrical cavity of 50 mm in diameter and 100 mm in depth. During treatment, a K-type thermocouple was inserted into the molten alloy to monitor the temperature history, as shown in Fig. 2. The thermocouple was positioned at the center between the SAB and the crucible, and the center between the melt surface and the crucible bottom. Both melting and mechanical vibration treatment were conducted under the protection of argon gas.

Fig. 2 Schematic sketch of experimental setup used in this study

Metallographic specimens were cut from the middle section of cast samples, and were etched with Keller’s reagent. Microstructure observations and quantitative measurements were performed on a Zeiss optical microscope equipped with a Zeiss Axio Vision image analyzer. The linear intercept technique was used to measure the grain size. Four fields were randomly measured to ensure a reliable result from the point of view of statistics. In order to identify the uniformity of microstructure, two parameters such as dmax(0.2) and dmin(0.2) were used to reveal the scattering tendency. The dmax(0.2) presents the maximum average grain size corresponding to the size of grain at which the grain number fraction is 20% when all measured grains are sequenced from small to large ones. Accordingly, the dmin(0.2) presents the minimum average grain size with the grain number fraction of 20% in the same sequencing operation.

3 Results

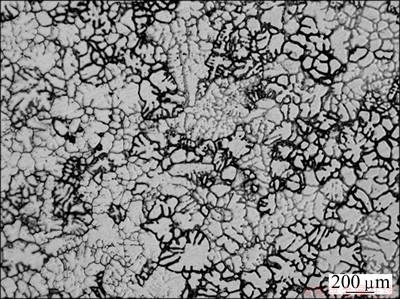

Figure 3 shows the typical microstructure of Al-5%Cu alloy solidified without treatment (cast at 656 °C directly into the steel mold preheated to 350 °C). Coarse dendrites with average grain size of 488 μm are present, indicating a normal dendrite growth mode.

Fig. 3 Representative micrograph of Al-5%Cu alloy solidified without mechanical vibration

3.1 Effect of vibration acceleration on microstructure

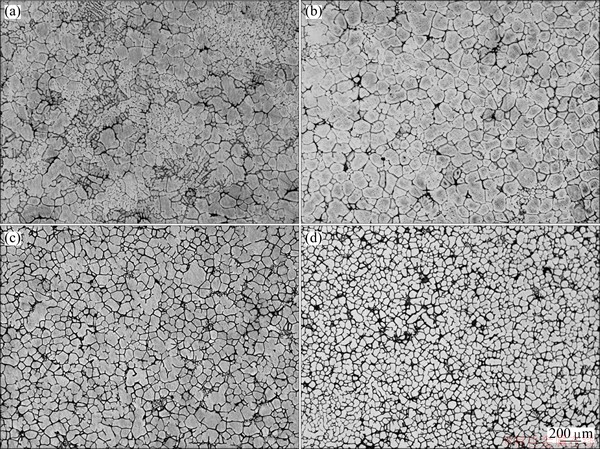

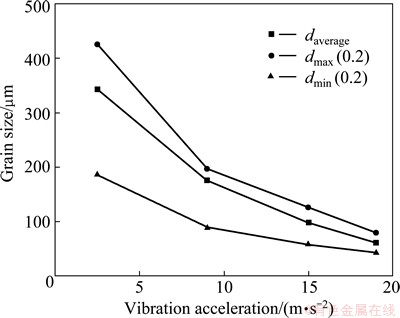

Figure 4 shows the microstructures treated byusing different vibration accelerations. Figure 5 shows the analysis result of grain size as a function of vibration acceleration. With vibration acceleration of 2.5 m/s2, the microstructure is a mixture of coarse dendrites and fine particles. The average grain size, daverage, is about 343 μm, as shown in Fig. 4(a). When the vibration acceleration is 8.0 m/s2, the dendritic microstructure is broken up into a some what globular grain microstructure. The average grain size is about 176 μm, as shown in Fig. 4(b). With increasing vibration acceleration to 15.0 m/s2 and 19.0 m/s2, little difference in terms of grain morphology was observed by comparing Figs. 4(c) and (d). However, the average grain size is further reduced form 98 μm to 61 μm. Both dmax(0.2) and dmin(0.2) as a function of vibration acceleration are marked in Fig. 5 by the solid circle and triangle. It is evident that the difference of the grain size between the dmax(0.2) and dmin(0.2) at vibration acceleration of 2.5 m/s2, covers a long distance, indicating that the treated microstructure is highly scattered in grain size distribution. This is consistent with the hybrid feature with coarse dendrites and fine particles in Fig. 4(a). With increasing vibration acceleration, the difference between dmax(0.2) and dmin(0.2) decreases and reaches its minimum at vibration acceleration of 19.0 m/s2, indicating that the microstructure becomes more uniform.

It can be concluded from Figs. 4 and 5 that the present mechanical vibration has a marked effect on the solidified microstructure. As the vibration acceleration increases, the average grain size decreases from 343 μm to 61 μm, and coarse dendritic microstructure transforms into a refined, uniform and non-dendritic one.

Fig. 4 Microstructures of Al-5% Cu alloy treated under vibration acceleration of 2.5 m/s2(a), 8.0 m/s2 (b), 15.0 m/s2 (c) and 19.0 m/s2 (d) with mass ratio of SAB as 6%

Fig. 5 Grain size as a function of vibration acceleration

3.2 Effect of mass ratio of SAB on microstructure

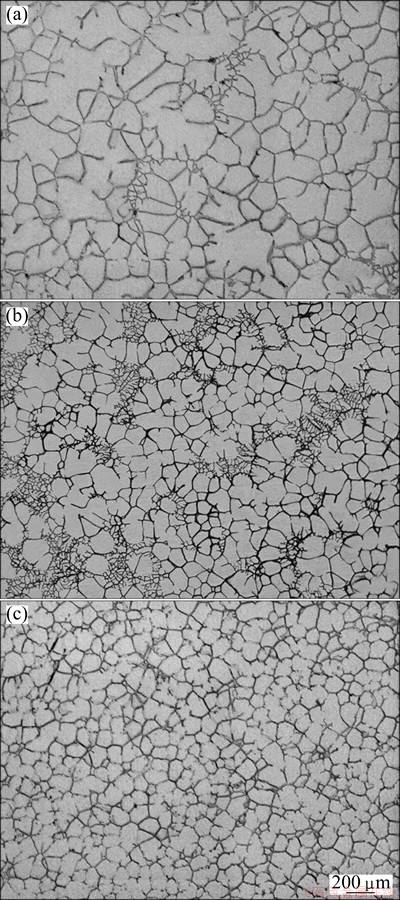

Mechanical vibration treatment by different mass ratios of SAB was then carried out on the molten alloy. Figure 6 and Fig. 4(d) show the microstructures obtained under four conditions: vibration using mass ratio of SAB of 3% (Fig. 6(a)), 4% (Fig. 6(b)), 5% (Fig. 6(c)) and 6% (Fig. 4(d)). At a low mass ratio of SAB of 3%, developed dendrites can be obtained. Applying 4% SAB results in a clearly different microstructure shown in Fig. 6(b). The microstructure does not show primary stems of dendrite, and consists of individual particles. However, the longitudinal and cross-section arrangement of the particles suggests agglomeration type morphology. When the mass ratio of SAB reaches 5%-6%, the microstructure principally consists of particle-like refined grains, as shown in Fig. 6(c) and Fig. 4(d).

Fig. 6 Microstructures of Al-5% Cu alloy treated under mass ratio of SAB of 3% (a), 4% (b) and 5% (c) at vibration acceleration of 19.0 m/s2

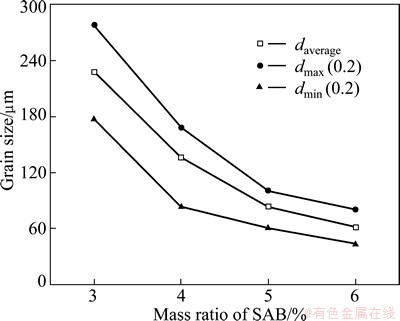

Figure 7 shows the measured data of average grain size, daverage, versus mass ratio of SAB. There is a sharp decrease in daverage from about 228 μm at 3% SAB to about 83 μm at 5% SAB. A further increasing mass ratio of SAB from 5% to 6%, leads to a further reduction from about 83 μm to 61 μm. Moreover, both dmax(0.2) and dmin(0.2) were used to reveal the scattering degree of microstructure, which are marked in Fig. 7. With the increasing of mass ratio of SAB, the scattering interval decreases from a wide range at 3% SAB to a narrow range at 5% SAB and keeps almost a constant from 5% SAB to 6% SAB with a rather small gap.

Fig. 7 Grain size as function of mass ratio of SAB at vibration acceleration of 19.0 m/s2

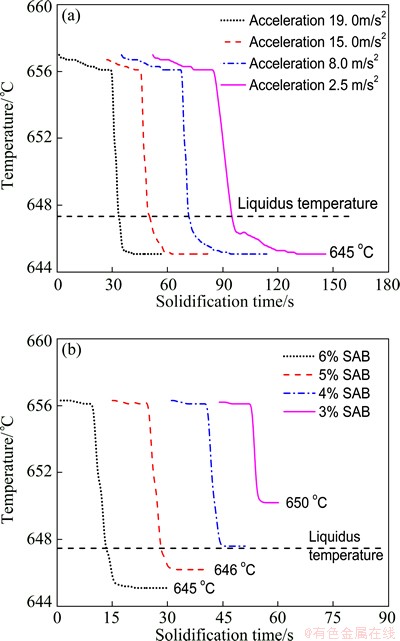

3.3 Temperature profiles

Figure 8 shows typical temperature profiles recorded during vibration. It can be found from Fig. 8(a) that the vibration acceleration has no effect on the steady state temperature at which the SAB is melted completely and the thermal balance is achieved, but affects cooling conditions significantly. With increasing vibration acceleration from 2.5 to 19.0 m/s2, the vibrating duration is decreased from 40 to 7 s. The cooling rates within the total vibrating duration under vibration acceleration of 2.5, 8.0, 15.0 and 19.0 m/s are 0.27, 0.54, 0.9 and 1.54 °C/s, respectively.

Figure 8(b) shows the influence of mass ratio of SAB on the thermal history during vibration. A decreased mass ratio of SAB increases the steady state temperature. The difference between steady state temperatures is increased for a decreased mass ratio of SAB. When the mass ratio of SAB is less than 4%, the steady state temperature is close to or higher than the liquidus temperature of alloy.

647.5 °C is the liquidus temperature of the alloy, and 646 and 645 °C are the temperatures where the corresponding solid fractions are about 0.09 and 0.16, respectively, according to Fig. 1. Nucleation behavior has occurred in the temperature range from the liquidus temperature to 645 °C. Combining results from Figs. 3-8, the following interesting observations can be made. The melting of vibrating probe can effectively extract heat from the interior of molten alloy. The present mechanical vibration can provide effectively localized cooling in a molten alloy during initial stage of solidification. Solidified microstructure is difficult to be refined when the treated alloy keeps full liquid state throughout the vibrating duration. A uniform and non-dendritic microstructure can be obtained and grain is significantly refined by applying mechanical vibration during the initial stage of solidification.

Fig. 8 Representative cooling curves under various vibration accelerations (a) and mass ratios of SAB (b)

4 Discussion

The solidified microstructure of metals is mainly dependent on heterogeneous nucleation and subsequent growth conditions which are significantly influenced by heat extraction and fluid flow during solidification. The investigations have confirmed that mechanical vibration could continuously make the heterogeneous nuclei form on the cold mold wall, fall off and move into the molten alloy, and produce the fragmentation of formed dendrites, resulting in microstructure refinement [4-13]. In the case of investigations [4-9,13], the mechanical vibration is exerted into a molten alloy under continuous cooling conditions with a higher cooling rate. The higher cooling rates may make the formation of solidification shell on the mold wall, which is not beneficial for the formed crystal nuclei to be dissociated from the mold wall, so the microstructure refinement is limited to some degree. For the isothermal vibration in semi-solid range [10-12], the number of formed nuclei or free crystals is reduced because of the low cooling rate, and the detachment of formed dendrites or grain multiplication may be the main mechanism of microstructure refinement. However, the treating time of mechanical vibration should be prolonged to 5-15 min to obtain a suitable refinement degree.

For all of developed mechanical vibration techniques, the energy resulted from superheat and latent heat of molten alloy during solidification is absorbed mainly by the mold, and the mechanical vibration is indirectly introduced into the molten alloy by vibrating the mold. In the present mechanical vibration, the vibrating probe can directly introduce vibration energy into the molten alloy, resulting in vigorous convection. At the same time, the SAB is melted during vibration, so it can serve as an effective heat extractor. Due to the vibration, there is an enormous amount of changing interface area between the molten alloy and the SAB, from which heat extraction is enhanced. Thus, vibration acceleration determines the effective melting of the SAB, and then influences the cooling rate significantly, as shown in Fig. 8(a). Therefore, the main features of the present mechanical vibration can be characterized as vigorous convection combined with localized cooling during the initial stage of solidification.

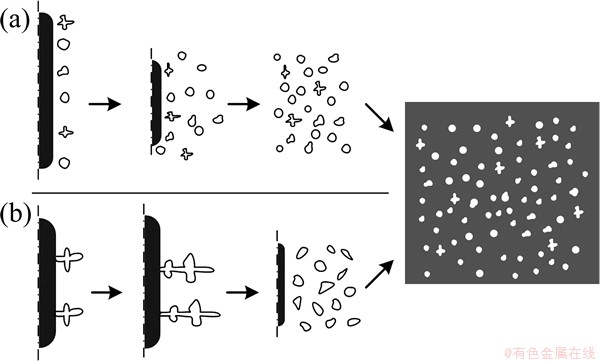

When the vibrating probe is immersed into the molten alloy, the liquid close to the SAB is rapidly cooled. A great number of embryonic grains can generate in the thermal undercooled liquid and they can be transferred and dispersed by vigorous convection, as shown in Fig. 9(a). At the same time, the molten alloy around the SAB is continuously replaced by new superheated liquid because of vibration. Local nucleation behavior can occur in the new undercooled liquid and go through the same cycle repeatedly until the SAB is melted completely. As shown in Fig. 9(b), it would be expected that grain would freeze as a collar around the part of the probe just below the surface of the liquid, but at greater depth and at its tip the probe would be melted. Thus chilled grains around the upper collar would be fragile as a result of their rapid freezing, and so easily fragment by mechanical fragmentation and melting off of dendrite arms at their roots [14,15], adding embryonic grains to the melt. Under the melt flows, the fragmented dendrite arms are rapidly taken away from their mother grains, where they can grow as new crystals, resulting in grain multiplication. This conclusion is corroborated by the absence of grain refinement at temperatures above the liquidus when, of course, no grains are present. By increasing the vibration acceleration, much vigorous convection and higher cooling rate are obtained. The increase in localized cooling and convection provides more nucleation and grain multiplication, leading to a higher refinement degree.

Fig. 9 Schematic representation of concept of free chill crystals mechanism (a) and fragmentation and multiplication mechanism (b)

Besides nucleation, the eventual efficiency of grain refinement also depends on the survival of formed crystals. The rate of crystal survival is determined by the superheat of local surrounding melt. There is a critical temperature or superheat at which the crystals will dissolve without any necessary diffusion in the solid when melting becomes purely heat transfer controlled [16]. Above this temperature, the melting rate increases rapidly and the survival probability effectively falls to zero. The locus of this critical temperature may be seen as the liquidus temperature corresponding to the original composition, such as 647.5 °C for Al-5%Cu. Because the superheat of molten alloy is continuously absorbed by the melting of SAB during vibration, the steady state temperature at which the SAB is melted completely is strongly dependent on the mass ratio of SAB as shown in Fig. 8(b). When the steady state temperature is below the alloy’s liquidus temperature, the treated melt is already thermally undercooled. Thus, numerous crystals formed can survive. As a result, they can grow into individual grains, resulting in significant grain refinement. However, when the mass ratio of SAB is less than 5%, the steady state temperature is close to or higher than the alloy’s liquidus temperature. The treated melt may not start to solidify, or fewer crystals will be produced and a small amount of them may survive, resulting in coarse microstructure. Consequently, it is difficult to refine the solidified microstructure when the treated alloy keeps full liquid state within the entire vibrating duration. Significantly refined microstructure can be obtained by applying mechanical vibration during the initial stage of solidification.

It has been proposed that the high density of formed crystals allows non-dendritic growth [17,18]. Under vibration acceleration less than 8.0 m/s2 or mass ratio of SAB less than 5%, the growth of a small number of formed crystals will lead to solute enrichment ahead of each growing front, and the solute diffusion controlled mechanism will become prominent [14,19]. During subsequent growth, they will ripen into grains with relatively large size and more complex shape. If the present mechanical vibration is able to produce a sufficient number of crystals during initial stage of solidification, the gradients of solute concentration/ temperature in the liquid drop very rapidly due to the overlapping of the solute/temperature diffusion layers around crystals [20,21]. Furthermore, the temperature and solute distribution in all directions around crystals will be much more uniform due to the vigorous convection and rotation of grains [14,15,22]. All of these conditions are beneficial to prohibit the dendritic growth, and refined non-dendritic microstructure can be obtained.

5 Conclusions

1) The present mechanical vibration can provide localized cooling through extracting heat from the interior of molten alloy by means of the melting of SAB. The cooling rate within the total vibrating duration is strongly dependent on the vibration acceleration.

2) Solidified microstructure is difficult to be refined when the treated alloy keeps full liquid state throughout the vibrating duration.

3) Significantly refined microstructure is obtained by applying mechanical vibration during the initial stage of solidification. When the molten alloy is treated from 656 to 645 °C, with increasing vibration acceleration from 2.5 to 19 m/s2, the average grain size decreases from 343 to 61 μm, and coarse dendritic microstructure transforms into a fine, uniform and non-dendritic one.

References

[1] KHOSRO M A, NIROUMAND B. Effects of ultrasonic treatment on microstructure and tensile strength of AZ91 magnesium alloy [J]. Journal of Alloys and Compounds, 2011, 509: 114-122.

[2] RAMIREZ A, QIAN M, DAVIS B, WILKS T, STJOHN D H. Potency of high-intensity ultrasonic treatment for grain refinement of magnesium alloy [J]. Scripta Materialia, 2008, 59: 19-22.

[3] MIZUTANI Y, OHURA Y, MIVA K, YASUE K, TAMURA T, SAKAGUCHI Y. Effect of electromagnetic vibration intensity on microstructural refinement of Al-7%Si alloy [J]. Materials Transactions, 2004, 45: 1944-1948.

[4] CAMBELL J. Effect of vibration during solidification [J] International Materials Reviews, 1981, 2: 71-106.

[5] TAMURA T, MATSUKI T, MIWA K. Refinement factors of mechanical vibrations on microstructure of Al-7mass% Si alloys [J]. Materials Transactions, 2011, 52: 830-833.

[6] ZHANG Ying, WANG Meng, DU Li-cheng, LIN Xin, HUANG Wei-dong. In-situ observation of crystal detachment behavior in NH4Cl-H2O system from chilling metal surface with vibration [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: s821-s825.

[7] TIAN Xue-feng, FAN Zi-tian, HUANG Nai-yu. Effect of mechancial vibration on microstructure and mechanical properties of lost foam casting magnesium alloy [J]. The Chinese Journal of Nonferrous Metals, 2006, 16(11): 1838-1844. (in Chinese)

[8] KOCATEPE K. Effect of low frequency of vibration on porosity of LM25 and LM6 alloys [J]. Materials & Design, 2007, 28: 1767-1775.

[9] CHIRITA G, STEFAESCU I, SOARES D, SILVA F S. Influence of vibration on the solidification behavior and tensile properties of an Al-18%Si alloy [J]. Materials & Design, 2009, 30: 1575-1580.

[10] ZHAO Jun-wen, WU Shu-sen, XIE Li-zhi, AN Ping, MAO You-wu. Effects of vibration and grain refiner on microstructure of semisolid slurry of hypoeutectic Al-Si alloy [J]. Transactions of Nonferrous Metals Society of China, 2008, 18: 842-846.

[11] TAGHAVI F, SAGHAFIAN J, KHARRAZI Y H K. Study on the effect of prolonged mechanical vibration on the grain refinement and density of A356 aluminum alloy [J]. Materials & Design, 2009, 30: 115-121.

[12] LIMMANEEVICHITR C, PONGANANPANYA S, KAJORNCHAIYAKUL J. Metallurgical structure of A356 aluminum alloy solidified under mechanical vibration: An investigation of alternative semi-solid casting routes [J]. Materials & Design, 2009, 30: 3925-3930.

[13] HUTT J, STJOHN D H. The origins of the equiaxed zone—Review of theoretical and experimental work [J]. International Journal of Casting Metals Research, 1998, 11: 13-22.

[14] FLEMINGS M C. Behavior of metal alloys in the semisolid state [J]. Metallurgical Transactions A, 1991, 22: 957-981.

[15] FAN Z. Semisolid metal processing [J]. International Materials Reviews, 2002, 47: 49-85.

[16] HANSEN G C, HELLAWELL A, LU S Z, STEUBE R S. Some consequences of thermosolutal convection: the grain structure of castings [J] Metallurgical and Materials Transactions A, 1996, 27: 569-581.

[17] FLEMINGS M C. Coarsening in solidification processing [J]. Materials Transactions, 2005, 46: 895-900.

[18] GUO H M, YANG X J. Morphology evolution of primary particles in LSPSF rheocasting process [J]. International Journal of Modern Physics B, 2009, 23: 881-887.

[19] QIAN M, CAO P, EASTON M A, McDONALD SD, StJOHN D H. An analytical model for constitutional supercooling-driven grain refinement and grain size prediction [J]. Acta Materialia, 2010, 58: 3262-3270.

[20] JACOT A, RAPPAZ M. A pseudo-front tracking technique for the modelling of solidification microstructures in multi-component alloy [J]. Acta Materialia, 2002, 50: 1909-1926.

[21] FADDEN S M, BROWNE D J. Meso-scale simulation of grain nucleation, growth and interaction in castings [J]. Scripta Materialia, 2006, 55: 847-850.

[22] LI T, LIN X, HUANG W. Morphology evolution during solidification under stirring [J]. Acta Materialia, 2006, 54: 4815-4824.

郭洪民1,2,章爱生1,杨湘杰2,严明明1

1. 南昌大学 材料科学与工程学院,南昌 330031;

2. 南昌大学 江西省高性能精确成形重点实验室,南昌 330031

摘 要:介绍一种机械振动细化凝固组织的工艺,振动能量由振动头直接导入熔体,该振动头在振动过程中熔化。研究振动加速度和质量比对Al-5%Cu合金微观组织的影响。结果表明:该机械振动可实现熔体内部冷却,冷却速度取决于振动加速度;若在振动过程中,熔体的温度保持在液相线温度以上,该机械振动很难实现晶粒细化;若在凝固初期阶段施加机械振动,凝固组织可以被有效细化。另外,探讨了在机械振动条件下,凝固组织细化的基本机理。

关键词:Al-Cu合金;晶粒细化;凝固;机械振动

(Edited by Xiang-qun LI)

Foundation item: Project (50804023) supported by the National Natural Science Foundation of China; Project (GJJ12032) supported by the Education Department of Jiangxi Province, China; Project (20122BAB206021) supported by the Natural Science Foundation of Jiangxi Province, China; Project (20122BCB23001) supported by the Jiangxi Province Young Scientists Cultivating Programs, China

Corresponding author: Hong-min GUO; Tel: +86-791-83969611; E-mail: guohongmin@ncu.edu.cn

DOI: 10.1016/S1003-6326(14)63375-6