文章编号:1004-0609(2012)07-1871-12

回归再时效对7050铝合金强度和断裂韧性的影响

韩念梅,张新明,刘胜胆,黄乐瑜,辛 星,何道广

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用光学显微镜、扫描电镜、透射电镜、常温拉伸及断裂韧性实验研究回归温度及回归时间对7050铝合金力学性能和断裂韧性的影响。结果表明:回归过程中,一部分GP区回溶进入基体,另一部分长大转变为η′相,同时η′相转变为η相,η相则不断粗化。随着回归时间的延长,合金的强度先下降至一谷值然后上升至一峰值再单调下降;再时效态合金强度先增大后减小,再时效态合金强度大于对应回归态合金强度。在190 ℃回归时,回归及再时效7050合金(RRA)的断裂韧性均随回归时间的延长而不断增大;然而,在170和150 ℃回归时,回归及再时效7050合金的断裂韧性先增大至一峰值然后下降至一谷值再增大。回归态合金的断裂韧性大于对应再时效态合金的断裂韧性。随着回归时间的延长,合金的断裂模式由沿晶断裂向穿晶韧窝断裂过渡。

关键词:7050铝合金;回归再时效;拉伸性能;断裂韧性

中图分类号:TG146.1 文献标志码:A1

Effects of retrogression and reaging on strength and fracture toughness of aluminum alloy 7050

HAN Nian-mei, ZHANG Xin-ming, LIU Sheng-dan, HUANG Le-yu, XIN Xing, HE Dao-guang

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of retrogression and reaging (RRA) on the tensile property and fracture toughness of aluminum alloy 7050 were investigated by optical microscopy, scanning electron microscopy, transmission electron microscopy, tensile and toughness tests. The results show that during the retrogression treating, one part of GP zone dissolves into Al matrix and the other grows, and then transforms into η′ phase. At the same time, the η′ phase transforms into η phase constantly. And the η phase becomes coarse gradually. With the retrogression time elongating, the strength of the alloy falls to a valley value before increasing to a peak value, and then monotonically decreases. Meanwhile, the strength of the reaged alloys first increases and then decreases. The strength of the reaged alloys is larger than that of the retrogressed alloys. With the retrogression time elongating, the fracture toughness of alloy 7050 RRA retrogressed at 190 ℃ increases. However, the fracture toughness of alloy 7050 RRA retrogressed at 170 ℃ and 150 ℃ increases to a peak value before decreasing to a valley value and then increases. The fracture toughness of the retrogressed alloys is larger than that of the reaged alloys. With the retrogression time elongating, the main fracture mechanism changes from the intergranular fracture to transgranular fracture.

Key words: aluminum alloy 7050; retrogression and reaging; tensile property; fracture toughness

7050铝合金是美国在20世纪70年代后期,在7075铝合金的基础上通过降低Fe、Si杂质和调整主成分研制成功的高性能铝合金, 具有韧性好、疲劳强度高、抗应力腐蚀性能和淬透性能好等优良的综合性能[1]。目前7050铝合金,特别是7050-T7451铝合金预拉伸厚板,广泛用于美国的第四代战斗机F-22、F-35的主体结构件,并在未来军用及民用飞机上有着广阔的应用前景[2]。

为了满足航空工业对材料性能要求的不断提高,A1-Zn-Mg-Cu合金的性能沿着单一的高强度→高强耐腐蚀→高强高韧耐腐蚀→高强高韧耐腐蚀抗疲劳→高淬透性高综合性能5个阶段发展[3-5]。目前,断裂韧性已经和强度、抗蚀性能、抗疲劳性能并列成为高强铝合金的4项主要考核指标,只有在这几方面均满足设计和使用要求,才是具备良好的综合性能。因此,提高断裂韧性成了高强铝合金重要的研究方向之一。

7050铝合金有多种时效处理制度,其中,峰值时效可以使合金获得较高的强度,但抗腐蚀性能和断裂韧性较差;过时效(T74)可以提高合金抗腐蚀性能和断裂韧性,但却以牺牲强度为前提[6]。MARLAUD等[7]及张新明等[8]的研究表明,合金经回归再时效(RRA)处理后,在不损失强度的前提下,抗腐蚀性能大大提高。LI等[3]及HAN等[6]的研究表明,虽然回归再时效态合金可以取得较高的强度和较好的抗腐蚀性能,但其断裂韧性相对于T74态合金还是较低。如何调节RRA制度中的参数,使强度及断裂韧性都优于T74态合金,是一个值得研究的问题。目前,国外对RRA工艺还处于保密阶段,其详细的技术措施无从查阅。而我国对RRA处理的研究仅仅表明某一种RRA态合金的断裂韧性比峰值时效态合金高,比过时效态合金低,很少有关于回归过程中7050铝合金断裂韧性连续变化的研究。因此,本文作者研究热风循环空气炉条件下回归温度和回归时间对7050铝合金组织、力学 性能及断裂韧性的影响,旨在为超高强铝合金厚板的制备工艺优化提供理论和实验依据。

1 实验

实验选用的材料为80 mm厚7050铝合金热轧板。合金实际化学成分为(质量分数,%):Zn 6.06,Mg 2.20,Cu 2.12,Zr 0.11,Fe 0.08,Si 0.04,余量为Al。

固溶处理在空气炉中进行,固溶处理制度为 (450 ℃,1.5 h)+(480 ℃,0.5 h)。淬火转移时间≤15 s,淬火水温<25 ℃, 淬火后,立即在101A-3型热风循环空气炉中进行回归再时效处理。预时效制度为 (120 ℃,21 h)[8],回归温度取150、170和190 ℃,回归时间为2~720 min,再时效制度为(120 ℃,24 h),各级时效间采用室温(约20 ℃)水冷。

样品经过粗磨、抛光后用铬酸试剂腐蚀, 在XJP-26A型金相显微镜上进行组织观察。

在板材1/4厚度处取厚度为2.5 mm的板材,按国家标准GB/6497—14规定,加工轧向的拉伸试样,在CSS 44100电子万能实验机上进行拉伸力学性能测试,每个测定值取3个试样的平均值。

按照国家标准GB—4161规定,在板材1/4厚度处取24 mm厚板材,制备L-T取向的标准紧凑拉伸试样,在CSS 44100电子万能实验机上测量断裂韧性,每个测定值取3个试样的平均值。采用KYKY-2800扫描电镜观察断裂韧性试样断口形貌,加速电压为20 kV。

采用TecnaiG2 20型透射电镜观察合金的组织,加速电压为200 kV。透射电镜样品先磨成0.1 mm厚的薄片,然后冲成d=3 mm圆片,最后进行双喷减薄。电解液为(体积分数) 30% HNO3 + 70% CH3OH,温度控制在-30 ℃左右。

2 结果

2.1 强度和断裂韧性随回归温度及时间的变化

图1所示为不同回归温度下,回归(Retrogression aging, RA)与再时效(Retrogression and reaging, RRA)过程中强度及断裂韧性随回归时间的变化曲线。由图1可知,回归过程中,随着回归时间的延长,合金的强度先下降至谷值,后上升至峰值,再单调下降。再时效后, 随着回归时间的延长,强度先上升至最大值,后单调下降。再时效后合金强度值大于相应回归态合金的强度值。不同回归温度下,回归态及再时效态合金强度的极值及对应回归时间如表1所列。由表1可 知,在190 ℃回归过程中,合金强度在6 min即达到谷值,30 min后达到峰值, 再时效过程中合金在6 min即达到峰值。在170 ℃回归过程中,30 min达到谷值,60 min 后达到峰值,170 ℃回归态合金的谷值和峰值比190 ℃回归态合金的谷值和峰值低;再时效过程中合金在60 min后达到峰值,比190 ℃回归的再时效态合金的峰值大。在150 ℃回归过程中,合金强度在150 min达到谷值,300 min后达到峰值,150 ℃回归态合金的谷值和峰值比170 ℃回归态合金的谷值和峰值低;再时效过程中合金在240 min达到峰值,比170 ℃回归的再时效态合金的峰值大。综上所述,回归温度越高,回归过程中合金强度达到谷值和峰值的时间越短,对应的峰值和谷值越大;再时效过程中,回归温度越高,合金强度达到峰值的时间越短,对应的峰值越小。表1中亦列出了峰值时效态合金及过时效态合 金的强度[6],对比可知,所有RRA处理的合金强度峰值均超过了峰值时效态合金的强度。

图1 不同回归温度下回归(RA)及再时效(RRA)过程中7050铝合金强度及断裂韧性的变化曲线

Fig. 1 Variations curves of strength and fracture toughness of 7050 aluminum alloy during retrogression and reaging treatment at different temperatures: (a), (b) 190 ℃; (c), (d) 170 ℃; (e), (f) 150 ℃

190 ℃回归时,在回归及再时效过程中,断裂韧性随回归时间的延长不断增大;170和150 ℃回归及再时效过程中,随着回归时间的延长,断裂韧性先增大到峰值,后减小到谷值,再逐渐增大。但150 ℃回归时,断裂韧性到达峰值和谷值的时间比170 ℃回归时的长。回归态合金的断裂韧性均大于对应再时效态合金的断裂韧性,并且所有RRA态合金的断裂韧性均大于峰值时效态合金的断裂韧性(28.5 MPa·m1/2)。

综上所述,所有RRA态合金的强度峰值及断裂韧性均超过了峰值时效态合金的强度和断裂韧性,即回归再时效相对于峰值时效可同时提高合金的强度和

断裂韧性。下面研究回归过程中,RRA态合金的综合性能与T74态合金[6](σb=532 MPa,σ0.2=495 MPa, KIC= 36.1 MPa·m1/2)综合性能的比较。回归温度为190 ℃时,当回归时间t2<30 min时,RRA态合金的强度大于T74态合金的强度,但要使RRA态合金的断裂韧性大于T74态合金的断裂韧性,则需要回归时间t2>30 min,故在190 ℃回归时,再时效态合金相当于牺牲断裂韧性来换取较高的强度。回归温度为170 ℃时,当回归时间t2<240 min时,RRA态合金的强度大于T74态合金的强度,但要使RRA态合金的断裂韧性大于T74态合金的断裂韧性,则需要回归时间t2>120 min, 故在170 ℃回归时,当120<t2<240 min时,再时效态合金相对于T74态合金,强度和断裂韧性均得到了提高。回归温度为150 ℃时,当回归时间t2<480 min时,RRA态合金的强度大于T74态合金的强度,但要使RRA态合金的断裂韧性大于T74态合金的断裂韧性,则需要回归时间t2>300 min,故在150 ℃回归时,当300<t2<480 min时,再时效态合金相对于T74态合金,强度和断裂韧性均得到了提高。

2.2 微观组织随回归温度及时间的变化

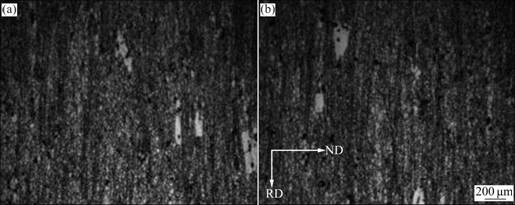

回归及再时效过程中7050铝合金的金相组织变化如图2所示。由图2可见,试样发生了部分再结晶,由大量细小的亚晶和一些粗大的再结晶晶粒组成。腐蚀后再结晶区域呈白色并沿轧向拉长,未再结晶区域含大量亚晶, 腐蚀后呈黑色,晶界和晶粒内部还存在部分未溶的第二相。从金相组织上看不出回归及再时效过程对合金组织有明显的影响,统计多张图片,不同时效制度下合金的再结晶百分数均在7%左右。

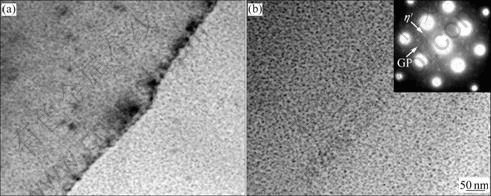

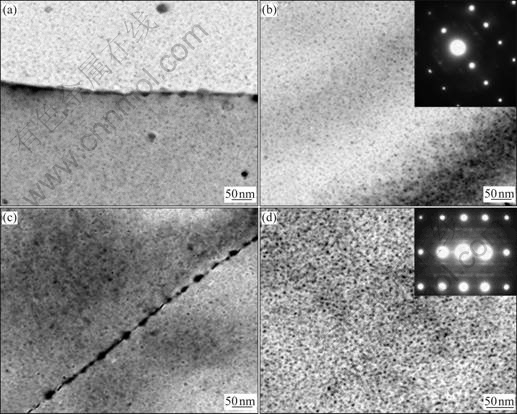

预时效(120 ℃,21 h)处理后7050铝合金的TEM像及á001?电子衍射花样如图3所示。由图3可知,合金晶内由均匀、细小弥散的强化相组成,电子衍射分析表明强化相为GP区和η′相,故合金的强度较高。晶界上的析出相沿晶界连续分布,晶界无沉淀析出带(PFZ)不明显。

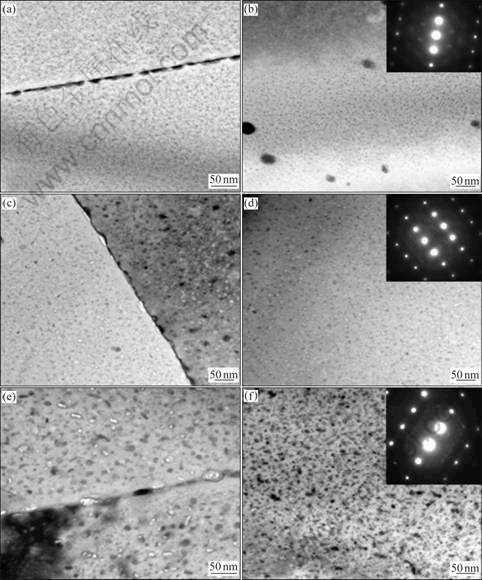

图4所示为190 ℃回归态7050铝合金的典型TEM像及á112?电子衍射花样。由图4可知,相对于预时效态合金,经6 min回归后,晶界析出相半连续分布,晶界析出相大小约为15 nm,间距约为3 nm,两侧有细小的无沉淀析出带。晶内析出相密度明显变小,由衍射斑点可知,GP区发生了回溶,根据有关文献报道,还有少量的小尺寸的η′相也会回溶[9]。经30 min回归后,晶界析出相变的更加粗大不连续,晶界析出相大小约为20 nm,间距约为48 nm,晶内析出相同时长大。经60 min回归后,晶界析出相进一步粗化,晶界析出相大小约为35 nm,间距约为62 nm,晶内析出相进一步长大,并出现棒状的η相。因此,随着回归时间的延长,晶内析出相先部分回溶,后不断析出并长大;晶界析出相逐渐粗化不连续,晶界析出相间距增大。

表1 回归及再时效过程中强度的极值点分布及对应的时间

Table 1 Peak and valley strengths and corresponding time at different retrogression temperatures in RA- or RRA-treating

图2 不同时效制度下7050铝合金的金相照片

Fig. 2 Optical micrographs of 7050 aluminum alloy treated under different conditions: (a) (120 ℃, 24 h)+(190 ℃, 6 min); (b) (120 ℃, 24 h)+(150 ℃, 240 min)+(120 ℃, 24 h)

图3 预时效态7050铝合金的典型TEM像及á001?电子衍射花样

Fig. 3 Typical TEM images of pre-aged 7050 aluminum alloy and corresponding SAD pattern for [001]m: (a) Near grain boundary? (b) Center of grain and SAD pattern for [001]m

图4 190 ℃回归态7050铝合金的典型TEM像及á112?电子衍射花样

Fig. 4 Typical TEM images of 7050 aluminum alloy retrogressed at 190 ℃ for different times and corresponding SAD patterns for [112]m: (a), (b) 6 min; (c), (d) 30 min; (e), (f) 60 min

图5所示为190 ℃回归+(120 ℃,24 h)再时效态7050铝合金的TEM像及á112?电子衍射花样。由图5可知,回归时间为6 min时,再时效态合金的晶界析出相呈不连续分布,晶界析出相大小约为15 nm,间距为13 nm左右,晶内析出大量细小弥散分布的GP区和η′相。随着回归时间的延长,晶界析出相更加粗化不连续分布,晶界析出相间距增大。同时,晶内析出相尺寸也逐渐变大,棒状的η相越来越多。

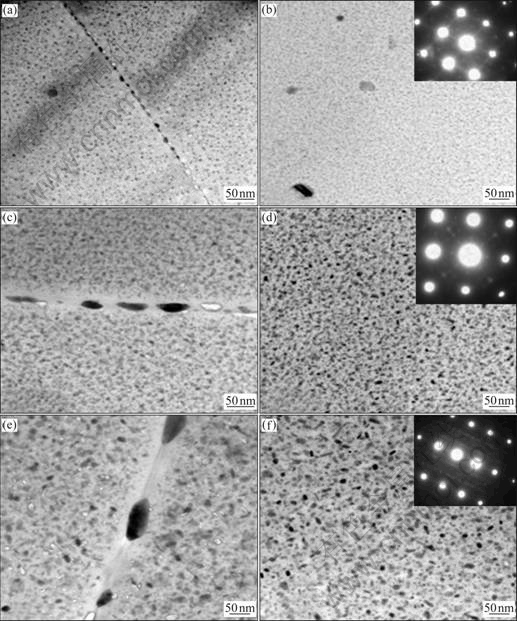

图6所示为150 ℃回归态7050铝合金的典型TEM像及á112?电子衍射花样。由图6可知,相对于预时效态合金,即使经150 min回归后,晶内析出相密度还是很小,说明GP区的回溶还在继续,析出相尺寸没有发生明显长大。即降低回归温度,GP区回溶的时间将大大延长。随着回归时间的延长,晶界析出相逐渐粗化不连续分布。由图4(e)可知,190 ℃回归态合金经60 min回归后,晶界析出相大小约为35 nm,间距约为62 nm,而150 ℃回归态合金即使经过240 min回归后,晶界析出相平均直径约为28 nm,间距也只有30 nm左右(如图6(c)所示)。即延长回归时间,150 ℃回归态合金的晶界粗化不连续现象没有190 ℃回归态合金的晶界粗化不连续现象明显。相对于回归时间,回归温度对晶界析出相有更大的影响。

图5 190 ℃再时效态7050铝合金的典型TEM像及á112?电子衍射花样

Fig. 5 Typical TEM image of 7050 aluminum alloy retrogressed at 190 ℃ for different times and then reaged at 120 ℃ for 24 h and corresponding SAD patterns: (a), (b) 6 min; (c), (d) 60 min; (e), (f) 120 min

图6 150 ℃回归态7050铝合金的经典TEM像及á112?电子衍射花样

Fig. 6 Typical TEM images of 7050 aluminum alloy retrogressed at 150 ℃ for different times and corresponding SAD pattern for [112]m: (a), (b) 150 min; (c), (d) 240 min

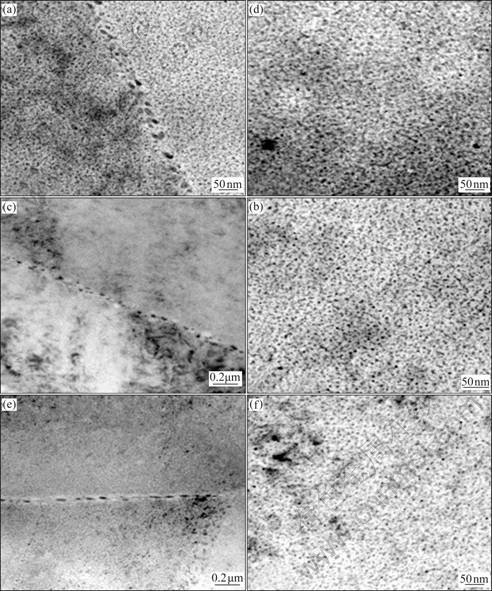

图7所示为150 ℃回归+(120 ℃,24 h)再时效态7050铝合金的TEM像。由图7可知,回归时间为150 min时,晶界析出相呈半连续分布;延长回归时间至240 min时,晶界析出相粗化不连续分布;继续延长回归时间至720 min时,晶界析出相进一步粗化不连续。但延长回归时间,回归720 min合金的晶内析出相和回归150 min的合金的晶内析出相并无明显的长大。故低温长时回归处理与高温短时回归相比,晶界析出相同样不连续分布,但晶内析出相更加细小弥散,该结构有利于在保持强度的同时提高断裂韧性。

2.3 断口形貌随回归温度及时间的变化

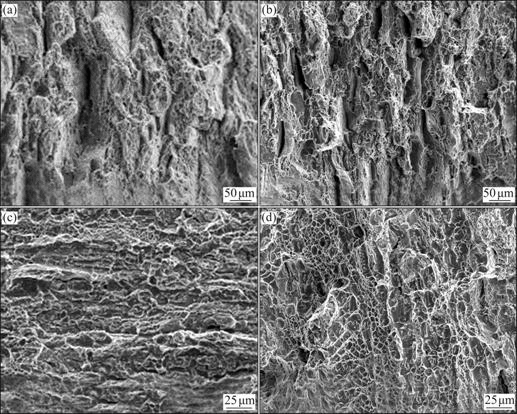

图8所示为190 ℃回归态7050铝合金的典型断口形貌。由图8可知,回归时间为6 min时,可观察到大量层状分布的沿晶裂纹和穿晶韧窝,合金的断裂方式是沿晶断裂和穿晶韧窝断裂的混合断裂;回归时间为30和60 min时,断口仍然是沿晶断裂和穿晶韧窝断裂的混合断裂,但随着回归时间的延长,沿晶断裂比例减少,穿晶韧窝断裂比例增大;回归时间为150 min时,断裂方式主要为穿晶韧窝断裂,平均韧窝尺寸为20 μm。

图9所示为190 ℃再时效态7050铝合金的典型断口形貌。由图9可知,对应的回归态合金的断口类 似,随着回归时间的延长,沿晶断裂比例逐渐减少,穿晶韧窝比例断裂逐渐增加,即随着回归时间的延 长,沿晶断裂逐渐向穿晶韧窝断裂过渡。回归时间为 150 min时,断口上主要是穿晶韧窝,韧窝平均尺寸为 12 μm。与相应的回归态合金的断口相比,再时效态合金的沿晶断裂比例增大,穿晶韧窝断裂比例 减小。

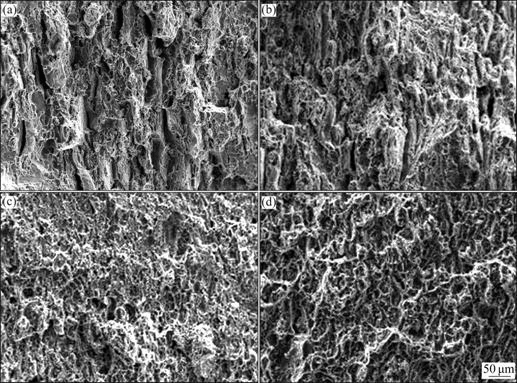

图10所示为150 ℃再时效态7050铝合金的典型断口形貌。由图10可知,与190 ℃再时效态合金的断口类似,随着回归时间的延长,沿晶断裂比例逐渐减少,穿晶韧窝断裂比例逐渐增大,即沿晶断裂逐渐向穿晶断裂转变。回归时间为150和240 min时,断口上主要是穿晶韧窝,但后者的韧窝比前者大。

图7 150 ℃再时效态7050铝合金的经典TEM像

Fig. 7 Typical TEM images of 7050 aluminum alloy retrogressed at 150 ℃ for different times and then reaged at 120 ℃for 24 h: (a), (b) 150 min; (c), (d) 240 min; (e), (f) 720 min

3 分析与实验

3.1 回归温度及时间对强度的影响

众所周知,时效强化型合金强度的增大是由析出相阻碍位错运动引起的。合金的强化机制分为切割和绕过两种:若析出相位于位错线的滑移面上,且不太硬时,位错线切割析出相强行通过;若析出相尺寸较大、强度较高并与基体的界面为非共格时,位错线将绕过。KOVACS等[10]对切割和绕过两种机制进行了详细的分析,得出以下关系式:

(1)

(1)

(2)

(2)

式中:τG和τA分别为切割和绕过机制下合金的强度,Γ为反向畴界能,G为剪切模量,f为质点体积分数,D为质点半径,b为柏氏矢量, 为泊松比,r0为位错芯半径。

为泊松比,r0为位错芯半径。

图8 190 ℃回归态7050铝合金的断口形貌

Fig. 8 Fracture morphologies of 7050 aluminum alloy retrogressed at 190℃ for different times: (a) 6 min; (b) 30 min; (c) 60 min; (d) 150 min

图9 190 ℃再时效态7050铝合金的断口形貌

Fig. 9 Fracture morphologies of 7050 aluminum alloy retrogressed at 190 ℃ for different times and then reaged at 120 ℃ for 24 h: (a) 6 min; (b) 30 min; (c) 60 min; (d) 150 min

图10 150 ℃再时效态7050铝合金的断口形貌

Fig. 10 Fracture morphologies of 7050 aluminum alloy retrogressed at 150 ℃ for different times and then reaged at 120 ℃ for 24 h: (a) 30 min; (b) 60 min; (c) 150 min; (d) 240 min

由式(1)和(2)可知,切割机制的强化效应随析出相体积分数和尺寸的增大而增大,而绕过机制的强化效果则应随析出相体积分数减小和尺寸的增大而减小。时效过程中,存在一个由切割向绕过转变的临界半径,在这个半径下,强度具有最大值。

7050铝合金时效过程中析出相的沉淀顺序为:α (过饱和固溶体)→GP区→η′相(MgZn2)→η(MgZn2)[11]。其中,GP区与基体共格,变形过程中,位错滑移切割GP区,由式(1)可知,强度与析出相直径呈正比;η′相与基体半共格,变形过程中,位错线主要采取绕过的方式移动,对合金起到主要强化作用[12]。由式(2)可知,随着析出相直径的增大,强度先减小后保持不变;η相与基体非共格,尺寸较大,其强化作用较小。

7050铝合金经(120 ℃,21 h)预时效后,晶内分布着高密度的GP区和η′相,合金强度较高。回归过程中,由于回归温度较高,GP区和η′相发生回溶。根据文献[9]可知,并非所有的GP区和η′相都回溶,只有那些小于临界尺寸的GP区和η′相才能回溶,而大于临界尺寸的GP区和η′相将继续长大转变为η′相或η相。190 ℃回归时,回归初期(<6 min),小尺寸的GP区和η′相发生回溶(如图4(a)和(b)所示),晶内析出相的密度明显减少,由式(1)可知,回归态合金的强度逐渐减小;延长回归时间至30 min(如图4(c)和(d)所示),大的GP区演变成η′相,合金强度逐渐增大;继续延长回归时间(如图4(e)和(f)所示),析出相进一步长大,晶内出现棒状的η相,强化效果减弱,合金强度逐渐减小。因此,回归过程中,强度曲线分为3个阶段。第一阶段,强度从T6态下降至谷值,这个过程中起支配作用的是GP区的溶解;第二阶段,强度由谷值上升到峰值,但峰值点的值低于T6态,此时,起支配作用的是原有η′相长大和新的η′相的形成;第三阶段,强度从峰值点下降,并随回归时间的延长逐渐降低,主要是η非共格相的形成。

降低回归温度,溶质原子的扩散能力减弱,小于临界尺寸的GP区和η′相回溶速率减慢,大于临界尺寸的GP区和η′相析出及长大速率也减慢(如图6所示)。故回归过程中,回归温度越低,强度达到谷值和峰值的时间越长,对应的谷值和峰值也越小,如表1所列。

再时效后合金的强度曲线随回归时间的延长分为两个阶段(如图1所示)。第一阶段,强度从T6态上升到峰值。此时,回归过程中未回溶的GP区促进η′相形核,原有的η′相继续长大,同时有新的GP区产生,强化相体积分数增加,强化效果增加,基体组织主要为η′相(如图5和7所示)。第二阶段,强度从峰值点下降,并随回归时间的延长逐渐降低,这是由于形成棒状的η相,合金逐渐进入过时效。

回归温度同样对再时效态合金性能有很重要的影响。回归温度越高,则溶质原子扩散能力越强,GP区和细小的η′相回溶较快,对应再时效阶段可作为η′相形核核心的未回溶GP区越少,η非共格相的形成速率越快。故随着回归温度的升高,再时效合金到达峰值的时间越短,随后的下降速率却越大,即回归温度越高,保持具有较高强度的时间段越短,越容易出现过时效,在工艺上越难控制。适当降低回归温度,可使一部分GP区和细小的η′相回溶, 基体中原有的η′相可以继续长大,新的GP区可以产生,同时η非共格相形成较少,这样合金强度峰值增大,保持具有较高强度的时间段增长,越适用于大厚板的实际生产。

3.2 回归温度及时间对断裂韧性的影响

晶粒结构和粗大第二相对铝合金的断裂韧性有重要影响。一般认为未再结晶的纤维状组织断裂韧性最高,晶粒长宽比小的再结晶组织次之,粗等轴晶最 差[13]。粗大第二相在塑性变形中,易产生变形不协调,在第二相粒子和基体界面产生应力集中,形成裂纹源。随着粗大第二相体积分数的增大,断裂韧性减小[14]。由图2可知,改变回归温度与时间,对晶粒结构和粗大第二相没有影响,故由晶粒结构和粗大第二相引起的断裂是固定的。由断口分析可知,回归及再时效过程中,主要是穿晶韧窝断裂和沿晶断裂的竞争,它们主要受两个因素的影响:一是晶界析出相的大小和间距[15],二是晶内晶界强度差[16]。一般认为,晶界上的无沉淀析出带(其强度和纯铝类似,大约为70 MPa[17])比晶内软,可以释放应力集中。但晶界上的粗大析出相在塑性变形中,易产生变形不协调,在第二相粒子和基体界面产生应力集中,导致沿晶断裂。沿晶断裂随着晶界析出相的面积分数(Ag)的增大而增多,断裂韧性和 成反比[18]。但是,如果晶内强度非常小,则不等晶界上的空穴开始长大,晶内已经屈服,则晶内的空穴就会迅速长大,导致穿晶韧窝断裂,因此断裂韧性随着晶内晶界强度差的增大而减小。

成反比[18]。但是,如果晶内强度非常小,则不等晶界上的空穴开始长大,晶内已经屈服,则晶内的空穴就会迅速长大,导致穿晶韧窝断裂,因此断裂韧性随着晶内晶界强度差的增大而减小。

150 ℃回归过程中,断裂韧性先增大后减小再增大 (如图1所示),这是两因素共同影响的结果。回归初期(<6 min),小于临界尺寸的GP区和η′相回溶,合金强度降低,晶内晶界强度差减小,对断裂韧性有利。同时,晶界析出相逐渐粗化,呈不连续分布,导致晶界析出相的面积分数减小,也导致合金的断裂韧性增大。随着回归时间的延长,进入回归的第二阶段,虽然晶界析出相进一步呈不连续分布,晶界析出相的面积分数进一步减小,对提高断裂韧性有利,但是原有η′相长大和新的η′相的形成使晶内晶界强度差增大,合金总的断裂韧性减小。继续延长回归时间,基体析出η相,晶内晶界强度差减小,同时晶界析出相的面积分数减小,这都促使断裂韧性不断增大。

再时效过程的第一阶段也存在一个晶内η′相形核析出强化基体和晶界析出相粗化不连续的过程。如果回归时间较短,则析出的η′相较少,晶内晶界强度差较少,同时晶界有优先析出的倾向,晶界析出相面积分数减小,促使合金断裂韧性增大。延长回归时间,回溶的GP区和η′相较多,则再时效后析出的η′相也增多,晶内晶界强度差不断增大,导致断裂韧性减小。继续延长回归时间,η′相完全析出并开始向η相转化,晶内晶界强度差减小,同时晶界析出相面积分数减小,合金断裂韧性逐渐增大。因此,再时效过程中,合金断裂韧性先增大后减小再增大,断裂方式由沿晶断裂逐渐向穿晶韧窝断裂过渡。

回归温度也影响断裂韧性,随着回归温度的减小,晶内溶质原子扩散能力减弱,GP区和细小的η′相回溶较慢,新η′相的析出及向η相的转化也变慢,晶界优先析出倾向越严重,则合金到达断裂韧性峰值的时间也越长。150 ℃回归时,断裂韧性到达峰值和谷值的时间为120和240 min;170 ℃回归时,断裂韧性到达峰值和谷值的时间为60和120 min;而190 ℃回归时,合金断裂韧性随着回归时间的延长逐渐增大,没有减小的过程,这可能是由于回归温度过高,造成晶界析出相不连续分布明显,对断裂韧性的促进作用超过了新析出的η′相对断裂韧性的不利作用。

4 结论

1) 回归过程中,随着回归时间的延长,合金的强度先减小后增大再减小。再时效后,随着回归时间的延长,强度先增大后减小。再时效态合金强度值大于相应回归态合金的强度。

2) 190 ℃回归时,回归及再时效过程中,断裂韧性均随回归时间的延长而不断增大;170 和150 ℃回归及再时效过程中,断裂韧性均先增大后减小再增大。回归态合金的断裂韧性均大于再时效态合金的断裂韧性。随着回归时间的延长,合金的断裂模式由沿晶断裂逐渐向穿晶韧窝断裂过渡。

3) 回归过程中,随着回归时间的延长,晶内析出相先部分回溶,后不断长大,晶界析出相逐渐粗化不连续。降低回归温度,延长回归时间,晶内析出相长大不明显,晶界析出相却更加粗化不连续分布,该结构有利于在保持强度的同时提高断裂韧性。

4) 所有RRA态合金的强度峰值及断裂韧性均超过了峰值时效态合金的强度和断裂韧性。和T74态合金相比,190 ℃回归时,再时效态合金虽然取得了较高的强度,但断裂韧性较低;170 ℃回归120~240 min和150 ℃回归300~480 min时,再时效态合金相对于T74态合金,强度和断裂韧性均得到了提高。

REFERENCES

[1] DIXIT M, MISHRA R, SANKARAN K. Structure-property correlations in Al 7050 and 7055 high-strength aluminum alloys [J]. Materials Science and Engineering A, 2008, 478(1/2): 163-172.

[2] HEINZ A, HASZLER A, KEIDEL C, MOLDENHAUER S, BENEDICTUS R, MILLER W S. Recent development in aluminium alloys for aerospace applications [J]. Materials Science and Engineering A, 2000, 280(1): 102-107.

[3] LI Zhi-hui, XIONG Bai-qiang, ZHANG Yong-an, ZHU Bao-hong, WANG Feng, LIU Hong-wei. Investigation on strength, toughness and microstructure of an Al-Zn-Mg-Cu alloy pre-stretched thick plate in various ageing tempers [J]. Journal of Materials Processing Technology, 2008, 209(4): 2021-2027.

[4] MORGENEYER T F, STARINK M J, WANG S C, SINCLAIR I. Quench sensitivity of toughness in an Al alloy: Direct observation and analysis of failure initiation at the precipitate- free zone [J]. Acta Materialia, 2008, 56(12): 2872-2884.

[5] DUMONT D, DESCHAMPS A, BRECHET Y. On the relationship between microstructure, strength and toughness in AA7050 aluminum alloy [J]. Materials Science and Engineering A, 2003, 356(1/2): 326-336.

[6] HAN Nian-mei, ZHANG Xin-ming, LIU Sheng-dan, KE Bin, XIN Xing. Effects of pre-stretching and ageing on the strength and fracture toughness of 7050 aluminum alloy plate [J]. Materials Science and Engineering A, 2011, 528(10): 3714- 3721.

[7] MARLAUD T, DESCHAMPS A, BLEY F, LEFEBVRE W, BAROUX B. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al-Zn-Mg-Cu alloy [J]. Acta Materialia, 2010, 58(14): 4814-4826.

[8] 张新明, 李鹏辉, 刘胜胆, 李国峰, 朱航飞, 周新伟. 回归时间对7050铝合金晶间腐蚀性能的影响[J]. 中国有色金属学报, 2008, 18(10): 1801-1975.

ZHANG Xin-ming, LI Peng-hui, LIU Sheng-dan, LI Guo-feng, ZHU Hang-fei, ZHOU Xin-wei. Effect of retrogression time on intergranular corrosion of 7050 aluminum alloy [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(10): 1801-1975.

[9] 李国峰. 超强耐蚀7050铝合金的热处理技术研究[D]. 长沙: 中南大学, 2010.

LI Guo-feng. Investigation of heat-treatment techniques for 7050 aluminum alloy with super-strength and high corrosion resistance [D]. Changsha: Central South University, 2010.

[10] KOVACS I, LENDVAI J, UNGAR T, GROMA G, LAKNER J. Mechanical properties of AlZnMg alloys [J]. Acta Metallurgica, 1980, 28(12): 1621-1631.

[11] ROBSON J D. Microstructual evoluation in aluminum alloy 7050 during processing [J]. Materials Science and Engineering A, 2004, 382(1/2): 112-121.

[12] NING A N, LIU Z Y, PENG B S, ZENG S M. Redistribution and re-precipitation of solute atom during retrogression and reaging of Al-Zn-Mg-Cu alloys [J]. Transactions of Nonferrous Metal Society of China, 2007, 17(5): 1005-1011.

[13] 潘志军, 黎文献. 高强铝合金断裂韧性的研究现状及展望[J]. 材料导报, 2002, 16(7): 14-17.

PAN Zhi-jun, LI Wen-xian. Current status and future trends of research on fracture toughness of high strength aluminum alloys [J]. Materials Review, 2002, 16(7):14-17.

[14] CVIJOVI? Z, VRATNICA M, CVIJOVI?-ALAGI? I. The influences of multiscale-sized second-phase particles on fracture behaviour of overaged 7000 alloys [J]. Procedia Engineering, 2009, 1(1): 35-38.

[15] GERARD M L, DAVID E L. The influence of microstructure and strength on the fracture mode and toughness of 7××× Series aluminum alloys [J]. Metallurgical Transactions A, 1982, 13(3): 411-425.

[16] KAWABATA T, IZUMI O. Ductile fracture in the interior of precipitate free zone in an Al-6.0%Zn-2.6%Mg alloy [J]. Acta Metall, 1976, 24(9): 817-825.

[17] PARDOEN T, DUMONT D, DESCHAMPS A. Grain boundary versus transgranular ductile failure [J]. Journal of the Mechanics and Physics of Solids, 2003, 51(4): 637-665.

[18] UNWIN P N T, SMITH G C. The microstructure and mechanical properties of Al-6%Zn-3%Mg [J]. J Inst Met, 1969, 97: 229-310.

(编辑 何学锋)

基金项目:国家重点基础研究发展计划资助项目(2012CB619501)

收稿日期:2011-06-14;修订日期:2011-10-17

通信作者:张新明,教授,博士;电话:0731-88830265;E-mail: xmzhang@yahoo.cn