文章编号: 1004-0609(2005)02-0248-06

纳米晶W-Cu复合粉末烧结行为

曹顺华, 林信平, 李炯义

(中南大学 粉末冶金国家重点实验室, 长沙 410083)

摘 要: 研究了机械合金化制备的纳米晶W-xCu(x=15, 20, 25)复合粉末的烧结行为。 结果表明, 纳米晶W-Cu复合粉末烧结致密化强烈地依赖于烧结温度与烧结时间。 当烧结温度从1150℃提高到1200℃时, 烧结30min后的烧结体相对密度由91%~94%增加到97%~98%; 当烧结温度超过1300℃时, 烧结体发生快速致密化, 5min内相对密度即可达到98%左右。 研究还发现, W-Cu合金中W晶粒尺寸也强烈地依赖于烧结温度, 即烧结温度愈高, W晶粒长大愈显著。 当压坯在1200~1250℃烧结30min后, 所得到的晶粒度约为300~500nm, 其中经1200℃烧结时的晶粒尺寸约为300~350nm。 另外, Cu含量增加有利于烧结致密化, 并降低W晶粒长大的趋势。

关键词: 纳米W-Cu; 烧结致密化; 烧结 中图分类号: TF123.7

文献标识码: A

Sintering behavior of nanograined W-Cu composite powder

CAO Shun-hua, LIN Xin-ping, LI Jiong-yi

(State Key Laboratory for Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Sintering behavior of nanograined W-xCu(x=15, 20, 25) composite powder produced by mechanical alloying was studied. The results show that sintering densification of nanograined powder is largely dependent on sintering temperature and time. Relative density rises from 91%-94% to 97%-98% when sintering temperature increases from 1150℃ to 1200℃. When the sintering temperature is higher than 1300℃, faster densification can be performed within shorter time, e.g. relative density can reach about 98% within 5 min. Likewise, W grain size is also greatly dependent on sintering temperature, so that W grain gradually coarsens with the increasing sintering temperature. The grain size of 300-500nm can be achieved after sintering at 1200-1250℃ for 30min and the grain size is only about 300-350nm at 1200℃. In addition, the increasing Cu content is beneficial to further sintering densification and less grain growth.

Key words: nanograined W-Cu; sintering densification; sinter

钨铜复合材料具有良好的耐电弧侵蚀性、 抗熔焊性和高强度、 高硬度等优点, 目前被广泛地用作电触头材料, 电阻焊、 电火花加工和等离子电极材料, 军用发汗材料, 电子封装与热沉材料等[1-3]。 W、 Cu之间互不相溶而且润湿性较差, 因此, 在常规熔渗、 液相烧结条件下其致密化过程进行比较困难, 难以达到高致密化和得到理想的组织结构[4, 5]。 纳米晶W-Cu粉末储存了极高的比表面能和晶格畸变能, 使后续烧结过程得以活化。 其结果, 一方面致密化迅速进行[6], 在1200℃的较低烧结温度下(比传统工艺低100~150℃), 可得到致密度为98%以上的W-Cu合金; 同时, 也为烧结过程中的W颗粒长大提供了巨大的驱动力[7]。 目前用于制备纳米晶W-Cu粉末的主要技术有: 机械合金化[8, 9], 溶胶-凝胶[10], 热化学工艺[11, 12], 热机械法[13, 14]等。 其中, 机械合金化尽管存在粉末脏化问题, 但由于其工艺简单、 易于操作, 适合批量生产, 因而在纳米W-Cu材料制备中备受关注。 研究表明: 纳米晶W-Cu粉末在1000~1083℃间烧结, 其致密度可由40%增加到95%, 当温度高于1200℃时可获得高于98%的相对密度[15]; 同时烧结过程中W晶粒也迅速长大, 在1200℃烧结时, W晶粒尺寸最小仅为1μm左右[15, 16], 其晶粒尺寸仍有望进一步降低。

本文作者利用机械合金化制备了纳米晶W-Cu复合粉末, 研究了纳米晶粉末的烧结致密化行为和显微组织演化, 为细晶粒的W-Cu合金的制备工艺的确定提供实验基础。

1 实验

本实验采用的原料粉末有4.3μm的W粉和粒径小于57μm的电解Cu粉。 按W-15Cu、 W-20Cu和W-25Cu(质量分数, %, 下同)3种成分进行配料。 将混合粉末在混料器中混合2h, 接着在以硬质合金球作研磨体的高能搅拌球磨机(球磨罐、 搅拌杆等组件均为硬质合金材质)中球磨数十小时。 激光粒度分析仪测试表明, 机械合金化后复合粉末颗粒大小约为0.5μm。 图1所示为机械合金化W-Cu复合粉末的X射线衍射谱。 利用小角度X射线衍射技术确定机械合金化W-Cu粉末中W的晶粒尺寸, 即Cauchy-Gauss近似函数法, 用Scherrer公式计算出W晶粒尺寸约为10nm, Cu晶粒尺寸约为20nm。

为了便于成形, 在复合粉末中添加1.5%PEG作成形剂。 W-Cu复合粉末在内径为10mm的模具内压制, 压坯质量为(8±0.2)g。 压坯在Mo丝炉中烧结, 采用H2保护。 烧结温度为1150、 1200、 1250、 1300、 1325、 1350和1375℃; 在各个温度点下的烧结时间为5、 10、 15、 20和30min。 烧结密度在精度为10-4 g的AEL-200电子分析天平上用排水法测定。 为了防止孔隙对测量结果的影响, 采用石蜡封孔。 烧结密度是对3个样品测量后取平均值得到的。

图1 机械合金化W-Cu粉末的XRD谱

Fig.1 XRD pattern of W-Cu powder produced by mechanical alloying

在布氏硬度测试机进行硬度检测, 最终硬度由3个硬度值取平均得到。

烧结样品经抛光后, 用质量比为1∶1的10%铁氰化钾和10%氢氧化钠的混合溶液腐蚀2min。 在Leica-Quant显微镜上观察显微组织和观测钨晶粒尺寸。

2 结果与讨论

2.1 烧结致密化行为

2.1.1 烧结温度、 时间对烧结致密化的影响

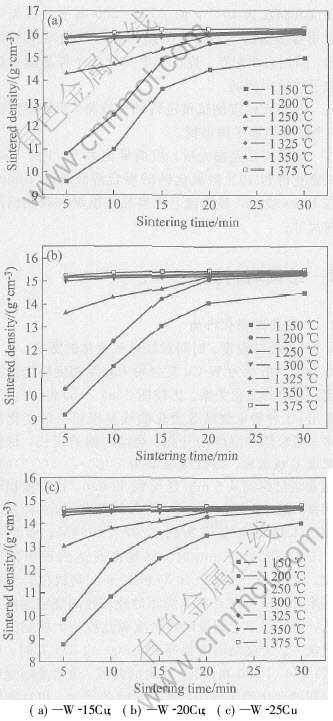

图2所示为W-Cu复合粉末烧结密度随烧结温度、 时间的变化关系。 比较图2(a)、 (b)和(c)可以看出, 3种粉末烧结致密化曲线呈现相似的变化规律。 随着烧结温度的升高、 烧结时间的延长, 材料密度不断增加。 当烧结温度为1150~1250℃时, 随着烧结时间从5min延长到30min, 致密度提高明显, 对于1200℃和1250℃时的曲线, 3种粉末烧结体相对密度均达到了97%~98%; 而当在1150℃烧结30min时, 材料没有达到理想的密度。 可见, 1200~1250℃和30min是机械合金化纳米晶W-Cu复合粉末烧结的较理想的烧结选择工艺, 这有利于达到烧结致密度和晶粒长大控制的有效统一。 当烧结温度提高到1300~1375℃时, 比较1150、 1200和1250℃时的曲线, 致密度随烧结时间的变化趋于平缓, 随着时间的增加, 相对密度提高不明显。 在1300~1375℃的温度范围内烧结30min时, 3种复合材料烧结体的相对密度均达到理论密度的98%~99%。 这些结果表明, 烧结温度对纳米晶W-Cu复合粉末的烧结致密化具有强烈的影响。 温度对W-Cu复合粉末烧结致密化行为的影响可以从两个方面来理解。 首先, 温度的升高改善铜液对固相W的润湿性, 有利于铜液充分铺展在W晶粒表面上, 从而有效地以液/固界面取代固/气界面, 消除W晶粒间的直接接触机会, 降低颗粒重排过程的阻力, 使颗粒重排得以充分进行, 提高致密化速度。 据文献[17]报道, 随着温度逐渐提高到1350℃左右, 润湿角可减小到0°。 同时, 温度升高可以降低铜液的粘度, 有利于提高铜液在毛细管力作用下的流动速度, 加快致密化速度。

图2 W-Cu合金的烧结密度与烧结工艺之间的关系

Fig.2 Relationships between sintered density and sintering process of

different W-Cu alloys

从图2中还可以发现, 当烧结温度达到1300℃以后, 烧结体经过5min就实现了快速致密化。 关于这一现象可根据液相烧结的驱动力即毛细管压力来解释。 毛细管压力为[18]

式中 γLV为液-汽界面能; θ为接触角; d为固相晶粒间液膜厚度。 当铜含量固定时, 经机械合金化处理的W-Cu复合粉末中的W晶粒愈细小, d值就愈小。 d值的降低意味着铜液在固相W晶粒间形成的月牙弯曲面的半径减小, 作用在W晶粒上的毛细管力增大。 由于复合粉末中Cu晶粒尺寸为20nm左右, 在制备传统W-Cu合金中, 经成形后并考虑到液相的迅速铺展, 假定W颗粒间的液膜厚度为1μm则前者在液相烧结过程中的毛细管力为后者的50倍。 因而, 实验中纳米晶W-Cu复合粉末经5min就可以实现足够的烧结致密化。

2.1.2 Cu含量对烧结致密化的影响

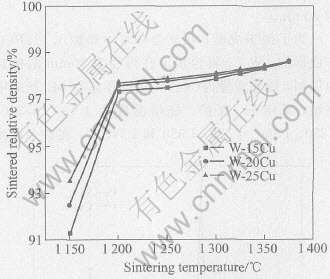

图3所示为3种不同Cu含量的粉末压坯经烧结30min后得到的相对密度随烧结温度的变化曲线。 从图中可以看出, 在相同的烧结温度下, W-25Cu的相对密度最高, W-20Cu次之, W-15Cu最低。 这一现象说明Cu含量增加有利于提高粉末的烧结致密化速度。 这是由于Cu含量越高, 在烧结过程中形成的液相越多, 减小固相W晶粒之间的接触程度, 从而降低颗粒重排阻力, 便于获得较高的相对密度。 从图中还可发现, 在1150℃烧结30min后, 材料没有达到理想的相对密度, 仅为91%~94%; 在1200~1250℃烧结30min后, 材料相对密度达到了97%~98%, 因此, 在该温度区间内烧结有利于达到高致密度和细晶粒度的有效结合; 烧结温度增加到1300~1375℃时, 相对密度虽可以提高到98%~99%, 但该温度区存在W晶粒长大现象。

图3 Cu含量对烧结致密度的影响

Fig.3 Effect of Cu content on sintered relative density

2.2 烧结显微组织演变

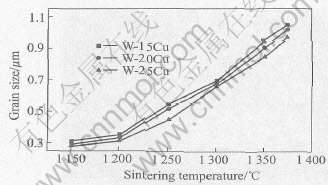

图4所示为3种粉末在不同烧结温度烧结30 min后所得到的晶粒尺寸随烧结时间变化的关系曲线。 图5~7所示分别为不同Cu含量纳米晶W-Cu 粉末在不同温度烧结30min所得到的显微组织。

图4 晶粒度与烧结温度的关系

Fig.4 Relationships between W grain size and sintering temperature

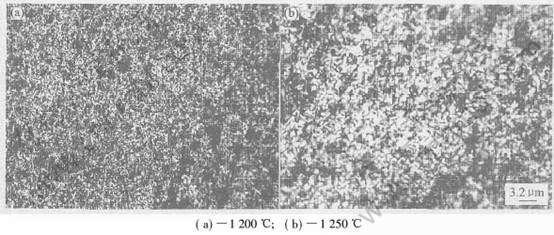

从图5~7中可以看到, 随着烧结温度的升高, W晶粒逐渐长大。 从图4可知, 1150℃烧结30min后W-Cu复合材料的晶粒大小约为300nm左右; 当烧结温度为1200~1250℃时, 晶粒长大到300~500nm, 而在1200℃时晶粒度为300~350nm左右, 这明显低于国内外的研究水平(纳米晶W-Cu复合粉末在1200℃烧结时, W晶粒尺寸最小仅为1μm左右[15, 16]); 当烧结温度升高到1300~1375℃时, 晶粒尺寸约为700~1000nm。 可见, 在研究的范围内, 随着温度的升高,W晶粒没有出现剧烈的尺寸长大现象。 在烧结过程中的W晶粒长大主要表现为聚晶长大。 由于Cu对W的润湿性不甚理想, 这为烧结过程中的W颗粒聚集提供了条件。 由于纳米晶W的高活性, 相互接触的纳米

图5 纳米晶W-20Cu粉末经过不同温度烧结后的显微组织

Fig.5 Microstructures of nanograined W-20Cu powder

sintered at different temperatures

图6 纳米晶W-15Cu粉末经1200和1250℃烧结后的显微组织

Fig.6 Microstructures of nanograined W-15Cu powder sintered

at 1200℃ and 1250℃

图7 纳米晶W-25Cu粉末经1200和1250℃烧结后的显微组织

Fig.7 Microstructures of nanograined W-15Cu powder

sintered at 1200℃ and 1250℃

W晶粒通过表面扩散逐渐聚集长大并发生球化。 随着烧结温度的增加、 时间延长, 聚晶长大效果越加明显。 另外, 从图4还可看出, 在相同的烧结温度下, W-15Cu的晶粒尺寸均高于W-20Cu和W-25Cu, W-25Cu的烧结晶粒度最小, 即随着Cu含量的增加, W晶粒尺寸变小。 这主要是因为, 随着Cu含量的增多, W颗粒之间接触的几率减小, 由聚晶长大而造成的晶粒粗化程度降低。

2.3 W-Cu合金硬度

图8所示为烧结30min所得的W-Cu材料硬度随烧结温度的变化曲线。 随着烧结温度的升高, 硬度不断增加, 当烧结温度从1150℃升高到1200℃时, 硬度随烧结温度的提高变化明显, W-15Cu、 W-20Cu和W-25Cu烧结坯硬度分别达到HB302、HB264和HB237, 这是由于材料密度增加引起的; 当烧结温度超过1300℃时, 硬度变化曲线变得平缓, 这是因晶粒长大所造成的。 烧结温度达到1375℃时, 3种粉末体系对应的硬度值分别为HB341、 HB321和HB274, 其硬度值比常规熔渗等工艺提高了50%~80%, 这说明材料细晶强化效果显著。

图8 硬度与烧结温度的关系

Fig.8 Relationships between hardness

and sintering temperature

3 结论

1) 随着烧结温度的升高、 烧结时间的延长, 纳米晶W-Cu复合粉末压坯致密度不断增加。 当烧结温度从1150℃提高到1200℃时, 相对密度由91%~94%增加到97%~98%; 烧结温度超过1300℃时, 相对密度变化不显著。 在1200~1250℃烧结30min是较理想的烧结选择工艺。

2) 随着烧结温度的升高, W晶粒尺寸不断增加, 并且晶粒分布愈加均匀。 在1200~1250℃烧结30min后, 所得到的晶粒度约为300~500nm, 其中1200℃烧结30min时对应的晶粒尺寸约为300~350nm。

3) 当烧结温度达到1300℃以后, 烧结体发生快速致密化, 经5min就可以获得98%左右的相对密度。

4) Cu含量增加有利于烧结致密化, 并降低W晶粒长大的趋势。

REFERENCES

[1]吕大铭. 钨铜复合材料研究的新进展[J]. 中国钨业, 2000, 15(6): 27-31.

L Da-ming. The new progress of W-Cu composite materials[J]. China Tungsten Industry, 2000, 15(6): 27-31.

[2]黄伯云, 范景莲. 纳米钨合金材料的研究与应用[J]. 中国钨业, 2001, 16(5-6): 38-44.

HUANG Bai-yun, FAN Jing-lian. Research and application of nano-tungsten material[J]. China Tungsten Industry, 2001, 16(5-6): 38-44.

[3]Sebastian K V. Properties of sintered and infiltrated tungsten-copper electrical material[J]. International Journal Powder Metal and Powder Technology, 1998(4): 297-303.

[4]Yang B, German R M. Powder injection molding and infiltration sintering of superfine grain W-Cu[J]. The International Journal of Powder Metallurgy, 1997(4): 55-63.

[5]Johnson J L, German R M. Chemically activated liquid phase sintering of tungsten-copper[J]. The International Journal of Powder Metallurgy, 1994, 30(1): 91-102.

[6]Upadhyaya A, German R M. Densification and dilation of sintered W-Cu alloys[J]. The International Journal of Powder Metallurgy, 1998, 34(2): 43-52.

[7]Lee J S, Kim T H. Densification and microstructure of the nanocomposite W-Cu powders[J]. Nanostructured Materials, 1995, 6: 691-694.

[8]Xiong C S, Xing Y H, Dong E, et al. Synthesis and structural studies of the W-Cu alloys prepared by mechanical alloying[J]. Nanostructured Materials, 1995, 5(4): 425-432.

[9]Kim J C, Moon I H. Sintering of nanostructured W-Cu alloys prepared by mechanical alloying[J]. Nanostructured Materials, 1998, 10(2): 283-290.

[10]Strikanth R, David L B. Synthesis and evaluation of advanced nanocrystalline tungsten-based materials[J]. P/M Science and Technology Brief, 1999, 1(1): 9-14.

[11]Hong S H, Kim B K. Fabrication of W-20%Cu composite nanopowder and sintered alloy with high thermal conductivity[J]. Materials Letters, 2003, 57: 2761-2767.

[12]Lee G G, Ha G H, Kim B K. Synthesis of high density ultrafine W/Cu composite alloy by mechano-thermo chemical process[J]. Powder Metallurgy, 2000, 43(1): 79-82.

[13]Kim D G, Oh S T, Jeon H, et al. Hydrogen-reduction behavior and microstructural characteristics of WO3-CuO powder mixtures with various milling time[J]. Journal of Alloys and Compounds, 2003, 354: 239-242.

[14]Li Y P, Qu X H, Zheng Z S, et al. Properties of W-Cu composite powder produced by a thermo-mechanical method[J]. International Journal of Refractory Metals and Hard Materials, 2003, 21: 259-264.

[15]Kim J C, Ryu S S, Kim Y D, et al. Densification behavior of mechanically alloyed W-Cu composite powders by the double rearrangement process[J]. Scripta Materialia, 1998, 39(6): 669-676.

[16]Kim J C, Ryu S S, Lee H, et al. Metal injection molding of nanostructured W-Cu composite powder[J]. The International Journal of Powder Metallurgy, 1999, 35(4): 47-55.

[17]黄培云. 粉末冶金原理[M]. 北京: 冶金工业出版社, 1997. 308.

HUANG Pei-yun. Principles of Powder Metallurgy[M]. Beijing: Metallurgical Industry Press, 1997. 308.

[18]German R M. Liquid Phase Sintering[M]. New York: Plenum Publishing Corporation, 1985. 44-45.

收稿日期: 2004-07-15; 修订日期: 2004-09-30

作者简介: 曹顺华(1965-), 男, 教授, 硕士.

通讯作者: 曹顺华, 教授; 电话: 0731-8830724; 传真: 0731-8830724; E-mail: Shuacao@163.com

(编辑何学锋)