文章编号:1004-0609(2013)10-2817-08

Al2O3/Mo纳米粉末模压成形烧结及其动力学

陈 闯1,魏世忠2,徐流杰2,张国赏1,李继文1

(1. 河南科技大学 材料科学与工程学院,洛阳 471003;

2. 河南科技大学 河南省耐磨材料工程技术研究中心,洛阳 471003)

摘 要:对Mo和Al2O3/Mo纳米粉末进行模压成形,研究纯Mo和Al2O3/Mo压坯在1 700~2 000 ℃温度范围内的等温烧结过程,并结合烧结模型分析材料烧结过程中的动力学;利用SEM和TEM分析复合材料的显微组织。结果表明:压坯密度与Al2O3的加入量有关,高温烧结时Al2O3/Mo复合材料的致密度高于纯Mo的致密度;在Al2O3/Mo复合材料烧结过程中,烧结机制既有体积扩散又有晶界扩散,且随着Al2O3含量的增加,晶界扩散趋势明显;纯Mo和Al2O3体积分数为5%、10%和15% Al2O3/Mo复合材料的烧结激活能分别为254.24、234.04、221.40和164.37 kJ/mol;Al2O3的加入可促进晶粒的均匀化和组织的细化。

关键词:Al2O3;Mo;纳米粉末;烧结;动力学;激活能

中图分类号:TG 344.1;TF 125.3 文献标志码:A

Sintering and kinetics of Al2O3/Mo nanometer powders by molding formation

CHEN Chuang1, WEI Shi-zhong2, XU Liu-jie2, ZHANG Guo-shang1, LI Ji-wen1

(1. College of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471003, China;

2. Henan Engineering Research Center for Wear of Materials, Henan University of Science and Technology, Luoyang 471003, China)

Abstract: By molding formation, the isothermal sintering processes of pure Mo and Al2O3/Mo green compact were investigated in the temperature range of 1 700-2 000 ℃. And combined with sintering model, the sintering kinetics was studied. The microstructures of the composites were analyzed by SEM and TEM. The results show that the green compact density and the adding amount of Al2O3 are related, and the composite density is higher than that of pure Mo in high temperature sintering process. During Al2O3/Mo composite sintering process, the sintering mechanism is proved to contain volume diffusion and grain boundary diffusion, and with the increase of Al2O3 content, the latter trend is obvious. The sintering activation energies of pure Mo and Al2O3 composites with volume fractions of 5%, 10% and 15% are 254.24, 234.04, 221.40 and 164.37 kJ/mol, respectively. The addition of Al2O3 can promote the uniformity and refining for the grains.

Key words: Al2O3; Mo; nanometer powder; sintering; kinetics; activation energy

钼是一种难熔金属,具有强度和硬度高、抗腐蚀、导热导电性能好的特点[1]。在钼基体上加入耐高温的Al2O3陶瓷硬质颗粒制得的Al2O3/Mo复合材料,综合了钼基体和Al2O3增强相各自的优点,可作为高温耐磨结构材料使用[2-4]。目前,大多数钼基合金产品采用粉末冶金工艺生产,即通过机械压制和后序的烧结来获得致密度高、微观结构理想的产品。烧结是粉末冶金的关键工序,对材料和制品的性能有着决定性的影响。很多学者对烧结过程的初期、中期及末期的动力学和烧结机制进行了研究[5],并建立了烧结模型。利用烧结动力学模型和阿累尼乌斯(Arrhenius)公式可计算出烧结激活能。

20世纪60年代初,就有关于纯Mo在1 450 ℃烧结的研究报道。近期MAJUMDAR等[6]研究了粉末颗粒尺寸和压制压力对Mo强化作用的影响;但对Mo和Al2O3/Mo纳米粉末机械压制成型及压坯在不同温度下等温烧结的动力学研究鲜有报道。为此,本文作者研究Mo和Al2O3/Mo复合材料在常压下的烧结机制和动力学规律,有助于从理论上研究和阐述材料在烧结过程中的致密化机理。

1 实验

实验中所用Mo粉和Al2O3/Mo混合粉末采用溶 胶-凝胶法、氢气两段还原法制得,Mo粉颗粒尺寸在500 nm左右,Al2O3颗粒平均尺寸约为65 nm,混合粉末成分均匀,颗粒无明显团聚现象。利用油压机和钢制压模对粉末进行模压成形,在300 MPa压制力下保压5 min,得到直径为20 mm、高度为7 mm的圆柱状压坯。将压坯置于真空感应加热炉中,加热前先抽炉内真空为15 Pa,然后通入流动氩气进行烧结,氩气流量为1.2 m3/h,压力为1.013×105 Pa。按照升温曲线,对压坯分别进行1 700、1 800、1 900和2 000 ℃等温烧结,烧结保温时间分别为30、60、90和 120 min,然后增大氩气流量至3 m3/h,使试样快速冷却至室温,得到纯Mo和Al2O3体积分数为5%、10%和15%的复合材料试样(本研究中含量均以体积分数表示)。

采用GB 3850—83《致密烧结金属材料与硬质合金密度测定方法》[7]中规定的排水法测量压坯和烧结体的密度,具体测量方法如下:先测定试样在空气中的质量,再测定试样在蒸馏水中的质量,应用阿基米德原理算出试样的密度。本实验中相对密度的计算为压坯或烧结体的密度与同一成分的复合材料的理论密度之比。由于Al2O3/Mo之间相互作用较弱,可采用加和法求其理论密度,据此计算出Al2O3体积分数为5%、10%和15%的复合材料理论密度分别为9.89、9.58和9.27 g/cm3。用千分尺多次测量求平均值的方法测出烧结前后试样的尺寸,进而算出线性收缩率。根据实验数据,建立烧结动力学方程,并结合阿累尼乌斯公式计算烧结激活能。应用JSM-5610LV扫描电镜和JEM-2100型高分辨透射电镜观察烧结体的显微组织。

2 结果和讨论

2.1 压坯密度与Al2O3含量的关系

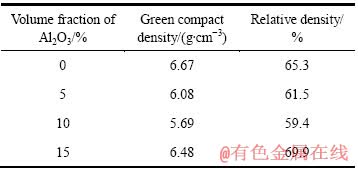

在相同压制条件下,压坯密度随Al2O3含量的增加先降低后升高,如表1所列。压坯的密度由其质量和体积决定,混合粉末中Mo粉和Al2O3粉末的质量及颗粒尺寸均相差较大,随着Al2O3含量的变化,质量和体积影响作用的不同是造成压坯密度先降低再升高的原因。当Al2O3体积分数为0时,纯Mo粉压坯密度为6.67 g/cm3,随着Al2O3体积比的增大,压坯质量减少,体积变化不明显,故密度变小。当Al2O3体积分数达到15%时,较小尺寸的Al2O3颗粒已将Mo颗粒间的空隙填充满,大尺寸的Mo颗粒逐渐减少,引起的体积减小成为主要影响因素,此时压坯密度变大。

表1 压坯密度

Table 1 Green compact density

2.2 Al2O3含量和烧结温度对烧结体密度的影响

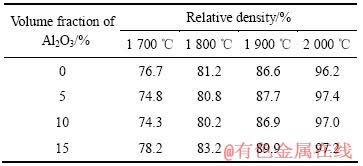

实验结果表明:2 000 ℃烧结且保温120 min时,纯Mo烧结体的相对密度为96.2%,随着Al2O3的加入,复合材料的相对密度有所增加,当Al2O3添加量为5%(体积分数)时,烧结体致密化程度较高。高温(2 000 ℃)烧结时,Al2O3含量对烧结体密度影响较小,较低温度(1 700 ℃)烧结时,Al2O3含量对烧结体密度影响明显,如表2所列。这可能是在烧结过程的低温阶段,Al2O3的含量对烧结速率影响明显,导致烧结体致密化程度不同步的结果。

当烧结温度低于1 800 ℃时,纯Mo的密度高于Al2O3含量为5%和10%复合材料的密度,但低于Al2O3含量为15%的复合材料的密度,这与压坯烧结致密化本质有关。由于压坯密度低,其中存在大量孔隙并呈现贯通态,烧结过程中,颗粒之间的孔隙随着晶粒的形成与长大逐渐被隔离,在晶界未完全闭合之前,可从Mo坯中逸出。Mo粉颗粒原始大小的差异会导致 粗细颗粒再结晶不同步,表现为细颗粒比大颗粒先结晶,即易于团聚的细颗粒中的孔隙不能完全排除,残留在晶体内部,当烧结温度高于1 700 ℃时,孔隙会逐渐合并球化。孔隙可以占据晶粒的棱边或晶粒内 部,前者可以发生烧结体的致密化,后者则不能发生致密化,形成闭孔隙[8]。当烧结温度低于1 800 ℃时,纯Mo颗粒较大且粒度分布均匀,孔隙多存在与晶粒的棱边处,有利于Mo坯的致密化;而对于Al2O3含量为5%和10%的复合材料,由于Mo与Al2O3颗粒尺寸相差较大,使部分孔隙闭合于晶粒内,降低了Mo坯的致密化程度。烧结温度较高时,复合材料中颗粒尺寸的影响作用凸显,含较小Al2O3颗粒的复合材料致密化速率较快,以致最终烧结成形时,纯Mo的致密度低于复合材料的致密度。线收缩率是烧结体致密化程度的反映,从表3可看出,线收缩率与烧结温度和烧结时间有关,但烧结温度的作用大于烧结时间的作用。这与文献[9]中关于Mo的致密化过程中,提高温度的作用远大于延长保温时间的作用结论一致。

表2 烧结时间为120 min时烧结温度和Al2O3含量对相对密度的影响

Table 2 Effect of sintering temperature and volume fraction of Al2O3 on relative density at sintering time of 120 min

2.3 Mo与Al2O3/Mo粉末模压成形烧结动力学

长期以来,许多学者对烧结理论进行了深入研究,但对烧结机制问题仍未形成统一的认识,建立烧结模型的研究方法是定量阐述烧结理论的有效途径。通过建立烧结模型,采用数学解析方法进行推导,可确定材料烧结过程中物质迁移机制[10]。在一定温度下,烧结动力学方程通式[11]为

(1)

(1)

经数学变化后,可得:

(2)

(2)

式中: 为试样的相对收缩率;A(T)为与烧结温度有关的实验常数;t为烧结时间(保温时间);n为烧结特征指数,根据n值可以判断烧结过程中的物质迁移机制。

为试样的相对收缩率;A(T)为与烧结温度有关的实验常数;t为烧结时间(保温时间);n为烧结特征指数,根据n值可以判断烧结过程中的物质迁移机制。

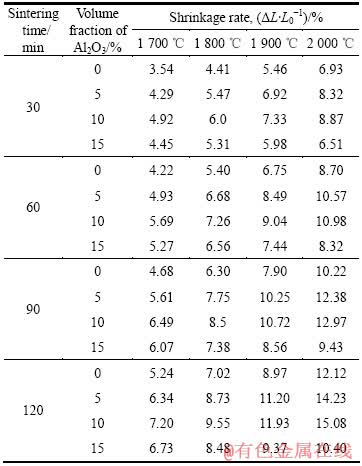

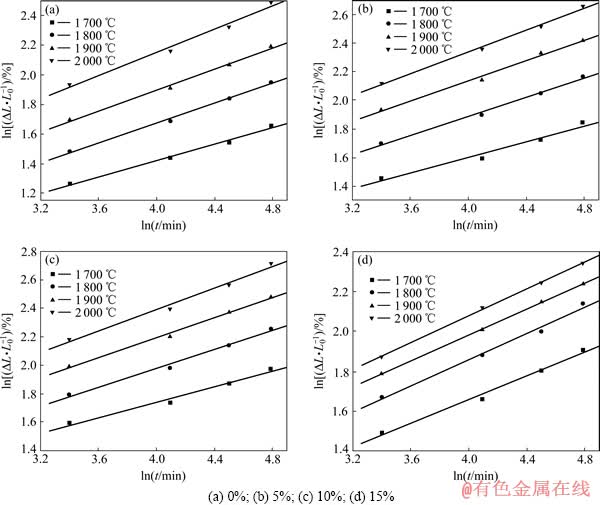

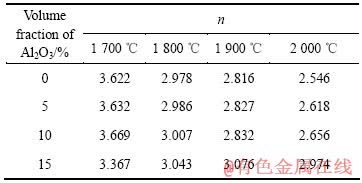

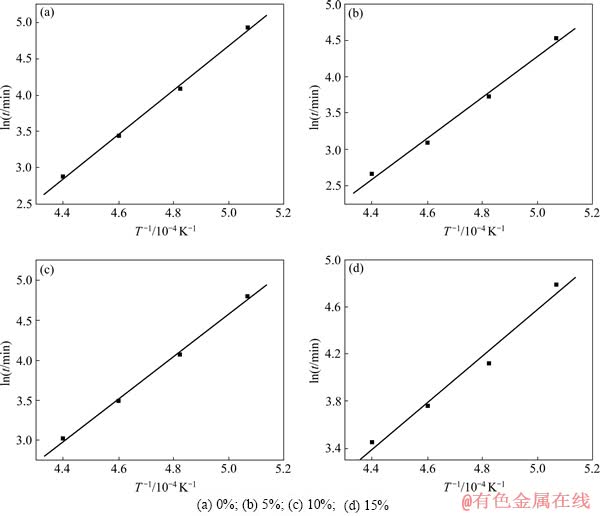

由压坯烧结动力学实验可得出试样线收缩率与Al2O3含量、烧结温度和保温时间的关系,结果如表3所列。由表3中的数据经线性拟合处理可得到烧结收缩动力学直线,见图1。根据图1中直线的斜率可求出烧结动力学特征指数n,如表4所列。

表3 线收缩率与Al2O3体积分数、烧结温度和保温时间的 关系

Table 3 Relationships among shrinkage rate and volume fraction of Al2O3, sintering temperature and sintering time

从表4可以看出,在高温阶段随着Al2O3含量的增加,复合材料烧结动力学特征指数n逐渐增大,当Al2O3体积分数为15%时n趋近于3;同一种成分的复合材料,动力学特征指数随烧结温度的升高有所降低。从n的平均值更容易看出这种变化趋势:纯Mo的动力学特征指数n的平均值为2.78,Al2O3体积分数为5%的复合材料的n值为2.81,Al2O3体积分数为10%的复合材料的n值为2.83,体积分数为15%的复合材料n的平均值为3.03。动力学特征指数反映了烧结过程中物质的主要迁移机制,当n=2.5时,体积扩散为主要迁移机制;当n=3时,晶界扩散为主要迁移机制[12];介于两种特征指数之间的数值,说明烧结过程中两种机制共同起作用。因此,纯Mo的高温烧结机制为体积扩散和晶界扩散。随着Al2O3体积分数的增加,复合材料烧结动力学特征指数由2.81增加到3.03,说明复合材料高温烧结过程中,晶界扩散趋势明显,物质迁移机制由体积扩散和晶界扩散共同作用逐步转变到以晶界扩散为主。

图1 不同Al2O3体积分数复合材料的烧结动力学直线

Fig. 1 Sintering kinetics lines of composite materials with different volume fractions of Al2O3

表4 复合材料烧结动力学方程(1)的指数n值

Table 4 Values of exponent n in Eq.(1) of composite materials

2.4 烧结激活能

通过研究激活能可判断烧结过程中的物质输送机制,为制定合理的烧结工艺提供理论依据。多种动力学模型公式都可以用来计算烧结激活能,主要通过等温烧结或恒速烧结实验来实现[13-14]。利用阿累尼乌斯公式线性回归拟合法来确定烧结激活能是一种有效的方法,该方法已在一些陶瓷材料的激活能计算方面得到成功的运用,如纯Al2O3或掺杂Al2O3[15-16]、硫化铈[17]、氧化锆[18]和铌酸锶钡[19]。阿累尼乌斯公式揭示反应速率系数K与烧结温度T的关系,即:

(3)

(3)

式中:Q为烧结激活能;T为热力学温度;R为摩尔气体常数,取值8.314 J/(mol·K);B为实验常数。

对式(3)两边取对数,可得:

(4)

(4)

式中:ln t与1/T呈线性关系。Q/R为直线的斜率,根据直线斜率就可以求得烧结激活能Q。在图1所示的动力学直线中,以纵坐标ln(ΔL/L0)为定值,可分别得到4种材料ln t与T的值。根据实验数据,以ln t为纵坐标,1/T为横坐标绘图,可得到纯Mo和Al2O3体积分数为5%、10%和15%复合材料ln t与1/T的关系,如图2所示。

从图2中可以看出,在1 700~2 000 ℃温度范围内,实验点近似呈线性关系,经一元线性回归处理可得到拟合直线方程分别如下:

对于纯Mo,

(5)

(5)

对于5% Al2O3/Mo,

(6)

(6)

对于10% Al2O3/Mo,

(7)

(7)

对于15% Al2O3/Mo,

(8)

(8)

应用阿累尼乌斯公式可计算出纯Mo及Al2O3体积分数为5%、10%和15%的复合材料的烧结激活能分别为254.24、234.04、221.40和164.37 kJ/mol。可以看出,随着Al2O3含量的增加,材料的烧结激活能有降低的趋势。在实验所用的混合粉末中,Mo和Al2O3两种颗粒尺寸相差较大,随着较小尺寸的Al2O3含量的增加,压坯中颗粒接触面上能形成更多的边界,在复合材料烧结过程中容易形成稳定的晶界,有利于晶界扩散的进行。纯Mo的烧结激活能较高是因为其高温烧结机制以体积扩散为主;随着Al2O3体积分数的增加和烧结温度的升高,粉体颗粒之间的距离不断减小,试样逐渐致密化,边界面积增加,烧结主导机制转变为以晶界扩散为主,因此烧结激活能有所降低。实验结果也验证了多数学者认为体积扩散激活能高于晶界扩散激活能的观点[10]。由于激活能较低,从图1中可以明显看出15%Al2O3/Mo复合材料具有较强的致密化动力。

图2 不同Al2O3体积分数的复合材料ln t与1/T的关系

Fig. 2 Relationship between ln t and 1/T of composite materials with different volume fractions of Al2O3

2.5 复合材料的相分析

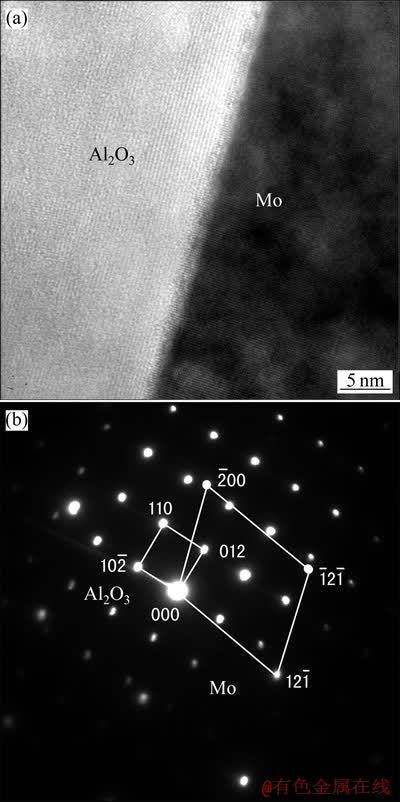

图3所示为Al2O3体积分数为10%的复合材料中Mo与Al2O3界面的高分辨TEM像及电子衍射斑点图。

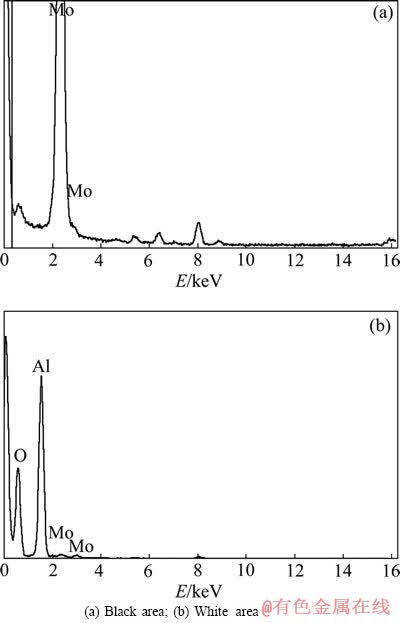

图4所示为Al2O3体积分数为10%的复合材料透射电镜(TEM)下的区域能谱图。由图4看出,图3(a)中黑色区域为Mo基体,白色区域为Al2O3,由图3(a)高分辨像可以看出,Al2O3和钼界面结合状态良好,界面干净无污染,平滑并且呈直线状。为进一步验证相结构,对复合材料的界面层进行透射电镜电子衍射分析,得到如图3(b)所示的衍射斑点。界面结构中共有两套衍射斑点,采用尝试-校核法标定衍射花样,其中,基体Mo(000,  ,

,  ,

,  )为体心立方结构,增强相α-Al2O3(000,

)为体心立方结构,增强相α-Al2O3(000,  , 110, 012)为六方晶系。

, 110, 012)为六方晶系。

图3 复合材料中Mo与Al2O3界面TEM像及衍射斑点图

Fig. 3 TEM image of Mo/Al2O3 interface and diffraction pattern in composite

图4 复合材料的EDS谱

Fig. 4 EDS patterns of composite

2.6 Al2O3在烧结过程中的作用

Al2O3的加入使得复合材料的烧结激活能降低,高温烧结时复合材料烧结体的致密度较纯Mo的高,同时可提高烧结活性,一定程度上起到促进烧结的作用。增强相Al2O3与基体相Mo之间的作用较弱,压坯中尺寸较小的Al2O3颗粒偏聚在Mo颗粒之间,形成一个“活化层”,为基体Mo的物质迁移提供通道,从而加速原子扩散,促进烧结进行。在本实验中加入少量Al2O3即可起到促进烧结的作用,但超过一定体积分 数后,高温烧结时,Al2O3的加入量对烧结的促进作用差别不大。

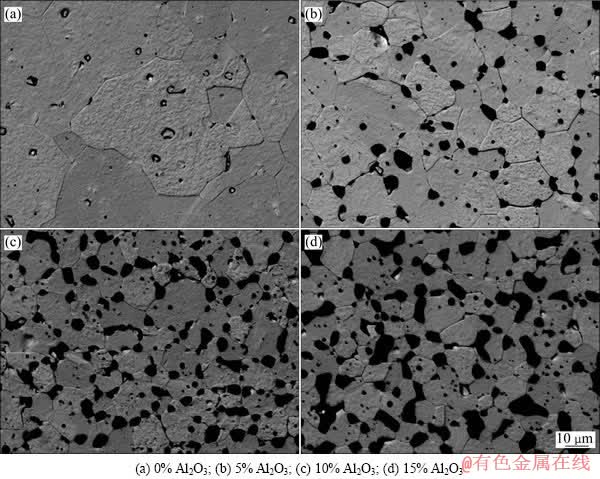

图5所示为纯Mo和Al2O3/Mo复合材料的显微组织。从图5中可看出,烧结体中Mo和Al2O3晶粒尺寸相对于粉体颗粒有明显的增大;纯Mo烧结体中有较多的气孔,复合材料烧结体中气孔很少;Al2O3作为增强相主要分布于基体相Mo的晶界处,少部分Al2O3存在于晶内,其尺寸比晶界处的Al2O3小;纯Mo烧结体晶粒粗大,随着Al2O3体积分数增加,复合材料晶粒逐渐细化。这是由于烧结时均匀分布的Al2O3颗粒对Mo晶界有钉扎作用,阻碍了晶粒的长大,有助于得到具有细小均匀晶粒的复合材料,实验结果也证明了Al2O3的加入对细化Mo晶粒作用明显。

图5 纯Mo和含Al2O3不同体积分数Al2O3/Mo复合材料的显微组织

Fig. 5 Microstructures of pure Mo and Al2O3/Mo composite materials

3 结论

1) 压坯密度随着Al2O3含量的增加先降低后升高。对于烧结体,烧结温度较低时,Al2O3含量对致密度影响明显;烧结温度较高时,Al2O3/Mo复合材料的致密化速率较快,烧结成形时复合材料的致密度高于纯Mo的致密度;烧结温度对材料致密度的影响大于保温时间的影响。

2) Mo的常压烧结机制既有体积扩散也有晶界扩散。随着Al2O3含量的增加,在Al2O3/Mo复合材料高温烧结过程中,物质迁移机制由体积扩散和晶界扩散共同作用,逐步转变为以晶界扩散为主。

3) 通过1 700~2 000 ℃的等温烧结确定了纯Mo及5%Al2O3/Mo、10%Al2O3/Mo和15%Al2O3/Mo复合材料的烧结激活能分别为254.24、234.04、221.40和164.37 kJ/mol。

4) Al2O3的加入能降低复合材料的烧结激活能并提高材料的致密度,起到促进烧结的作用。同时,随着Al2O3体积分数的增加,复合材料晶粒逐渐细化和均匀化,烧结体中气孔数量大幅减少。

REFERENCES

[1] 王东辉, 袁晓波, 李中奎, 郑 欣, 张良军, 张 清, 白 润. 钼及钼合金研究与应用进展[J]. 稀有金属快报, 2006, 25(12): 1-7.

WANG Dong-hui, YUAN Xiao-bo, LI Zhong-kui, ZHENG Xin, ZHANG Liang-jun, ZHANG Qing, BAI Run. Research and application progress of Mo and Mo alloys[J]. Rare Metals, 2006, 25(12): 1-7.

[2] NAWA M, SEKINO T, NIIHARA K. Fabrication and mechanical behaviour of Al2O3/Mo nano-composites[J]. Journal of Materials Science, 1994, 29(12): 3185-3192.

[3] SBAIZERO O, PEZZOTTI G, NISHIDA T. Fracture energy and R-curve behavior of Mo /Al2O3 composites[J]. Acta Mater, 1998, 46(2): 681-687.

[4] 余大江, 常 春, 刘俊涛, 姜 江. Mo/Al2O3复合材料的耐磨性[J]. 摩擦学报, 2009, 29(5): 442-446.

YU Da-jiang, CHANG Chun, LIU Jun-tao, JIANG Jiang. Wear resistance of Mo/Al2O3 composites[J]. Tribology, 2009, 29(5): 442-446.

[5] 果世驹. 粉末烧结理论[M]. 北京: 冶金工业出版社, 1998: 1-10.

GUO Shi-ju. Powder sintering theory[M]. Beijing: Metallurgical Industry Press, 1998: 1-10.

[6] MAJUMDAR S, RAVEENDRA S, SAMAJDAR I, BHARGAVA P, SHARMA I G. Densification and grain growth during isothermal sintering of Mo and mechanically alloyed Mo-TZM[J]. Acta Materialia, 2009, 57: 4158-4168.

[7] GBT 3850—1983. 致密烧结金属材料与硬质合金密度测定方法[S].

GBT 3850—1983. Impermeable sintered metal materials and hardmetals determination of density[S].

[8] 王盘鑫. 粉末冶金学[M]. 北京: 冶金工业出版社, 1997: 188-214.

WANG Pan-xin. Powder metallurgy[M]. Beijing: Metallurgical Industry Press, 1997: 188-214.

[9] 赵 虎, 杨秦莉, 庄 飞, 刘仁智, 张常乐, 刘俊怀. 纯钼烧结规律研究[J]. 中国钼业, 2011, 35(6): 53-56.

ZHAO Hu, YANG Qin-li, ZHUANG Fei, LIU Ren-zhi, ZHANG Chang-le, LIU Jun-huai. Research on sintering process of pure molybdenum[J]. China Molybdenum Industry, 2011, 35(6): 53-56.

[10] 黄培云. 粉末冶金原理[M]. 北京: 冶金工业出版社, 2004: 265-338.

HUANG Pei-yun. The principle of powder metallurgy[M]. Beijing: Metallurgical Industry Press, 2004: 265-287.

[11] 王零森, 杨义斌, 张金生, 樊 毅, 吴 芳. 掺碳碳化硼活化烧结及其动力学[J]. 中国有色金属学报, 2000, 10(1): 37-42.

WANG Ling-sen, YANG Yi-bin, ZHANG Jin-sheng, FAN Yi, WU Fang. Activated sintering of carbon doped boron carbide and its kinetics[J]. Chinese Journal of nonferrous metals, 2000, 10(1): 37-42.

[12] LANGE R G, MUNIR Z A, HOLT J B. Sintering kinetics of pure and doped boron carbide[J]. Mater Sci Res, 1989, 13: 311-321.

[13] MATSUI K, MATSUMOTO A, UEHARA M, ENOMOTO N, HOJO J. Sintering kinetics at isothermal shrinkage: Effect of specific surface area on the initial sintering stage of fine zirconia powder[J]. J Am Ceram Soc, 2007, 90: 44-49.

[14] MAQUEDA P, LUIS P M, JOSE M C, CONCEPCION R. Kinetics of the initial stage of sintering from shrinkage data: Simultaneous determination of activation energy and kinetic model from a single nonisothermal experiment[J]. J Am Ceram Soc, 2002, 85: 763-768.

[15] SATO E, CARRY C. Effect of powder granulometry and pretreatment on sintering behavior of submicron-grained- alumina[J]. J Eur Ceram Soc, 1995, 15: 9-16.

[16] FANG T T, SHIUE J T, SHIAU F S. On the evaluation of the activation energy of sintering[J]. Mater Chem Phys, 2003, 80: 108-113.

[17] HIRAI S, SHIMAKAGE K, SAITOU Y. Synthesis and sintering of cerium sulfide powders[J]. J Am Ceram Soc, 1998, 81: 145-151.

[18] GUILLAUME B G, CHRISTIAN G. Apparent activation energy for the densification of a commercially available granulated zirconia powder[J]. J Am Ceram Soc, 2007, 90: 1246-1250.

[19] LEE W J, FANG T T. Effect of the strontium: Barium ratio and atmosphere on the sintering behavior of strontium barium niobate[J]. J Am Ceram Soc, 1998, 81: 300-304.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(50972039)

收稿日期:2012-12-06;修订日期:2013-08-09

通信作者:魏世忠,教授,博士;电话:0379-64279731;E-mail: wsz@mail.haust.edu.cn